Abstract

Multi tubes in tube helically coiled heat exchanger is proposed as a compact heat exchanger. Effects of heat exchanger geometric parameters and fluid flow parameters; namely number of inner tubes, annulus hydraulic diameter, Reynolds numbers and input heat flux, on performance of the heat exchanger are experimentally investigated. Different coils with different numbers of inner tubes, namely 1, 3, 4 and 5 tubes, were tested. Results showed that coils with 3 inner tubes have higher values of heat transfer coefficient and compactness parameter (\(\bar{h}\,A_{h}\)). Pressure drop increases with increasing both of Reynolds number and number of inner tubes. Correlations of average Nusselt number were deduced from experimental data in terms of Reynolds number, Prandtl number, Number of inner coils tubes and coil hydraulic diameter. Correlations prediction was compared with experimental data and the comparison was fair enough.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

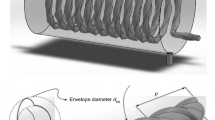

Helically coiled heat exchanger is very alluring for various engineering processes because its accommodation of large heat transfer area in a small space with high heat transfer coefficients. Helically coiled heat exchangers can be found in a wide range of engineering applications including food processing, nuclear reactors, compact heat exchangers, heat recovery systems, chemical processing, refrigeration and air conditioning systems and medical equipment. Tube curvature in helically coiled heat exchangers induces secondary flow patterns which enhance heat transfer between tube wall and flowing fluid. To enhance the main two advantages of helical coiled heat exchangers: high heat transfer surface area per occupied size and high heat transfer rate due to the induced secondary flow, a multi tubes in tube helical heat exchangers as shown in Fig. 1 is proposed. Multi tubes in tube helical heat exchangers, characterized as liquid to liquid compact heat exchangers, can accommodate large heat transfer surface area in a smaller size. While multi tubes in tube helically coiled heat exchangers are presented in market and used in a lot of engineering applications, fluid flow and heat transfer characteristics of such type of heat exchangers are not published yet. To the author’s knowledge, no data are available in the wide literature regarding the performance of such types of heat exchangers.

The present study aims to experimentally investigate fluid flow and heat transfer characteristics of multi tubes in tube helical heat exchanger. Parameters that can be used to measure performance of this type of heat exchanger are also presented, investigated and estimated. Effects of some geometric parameters of the heat exchangers, such as the number of inner tubes inside the helical outer tube and the effects of fluid flow parameters on the performance of the heat exchanger are also investigated.

Although no data are available in literature for multi tubes in tube helical heat exchangers, extensive work has been published on flow and heat transfer characteristics in helical/curved pipes and in annulus of double pipe helical heat exchangers.

Secondary flow profile in helical tube was firstly investigated and described by Dean [1]. He showed the occurrence of a swirling flow patterns separated by a horizontal centre line. Dean presented the Dean number (De), ratio of inertial to viscous forces, to characterize secondary flow profile. Dravid et al. [2] reported that the characteristics of outward directed flow originates at the centre point and depends on Dean number. Akiyama and Cheng [3] numerically studied the condition of a steady fully developed laminar forced convection in uniformly heated curved pipes for a range of Dean numbers up to about 200. Their solution employed a boundary vorticity method with a uniform wall heat flux and peripherally uniform wall temperature. Kalb and Seader [4] performed numerical studies for uniform wall heat flux with peripherally uniform wall temperature for Dean numbers in the range of 1–1,200, Prandtl numbers of 0.005–600, and curvature ratios (r/R) of 1/10–1/100 for fully developed velocity and temperature fields. They found that curvature ratio parameter has negligible effect on the average Nusselt number for any given Prandtl number. They reported that local Nusselt numbers on the outer wall of the helical tube continued to increase with increasing Dean number. They also noted that the fractional increase in heat-transfer coefficients is significantly greater than the fractional increase in friction losses, except for liquid metals. Laminar convective heat transfer in curved tubes was studied both experimentally and numerically by Janssen and Hoogendoorn [5] for both uniform heat flux and constant wall temperature boundary conditions. Thermal entry region was also studied. They showed that the effect of boundary conditions on laminar convection heat transfer was small. Effect of helical coil tube pitch on heat transfer and pressure drop was studied by Austin and Soliman [6] for the case of uniform wall heat flux. The results showed significant pitch effects on both of friction factor and Nusselt number at low Reynolds numbers; however these effects weakened as the Reynolds number increased. They suggested that these pitch effects are due to free convection, and the effect decreases as the forced convection becomes more dominant at higher Reynolds numbers. Liu and Masliyah [7] investigated the effect of pitch and torsion on secondary flow fields for fully developed laminar flow. Pressure drop and friction factors were also studied for fully developed laminar flow. Later, Liu and Masliyah [8] numerically studied laminar Newtonian flow and heat transfer development using fully parabolic equations in the axial direction. Their studies also took into consideration the pitch of helix. Yamamoto et al. [9] studied transition from laminar to turbulent flow for helical coils with large curvature and large torsion. They concluded that while curvature has a stabilizing effect on the flow, the torsion had a destabilizing effect. Yamamoto et al. [10] further investigated the effect of torsion on the stability of flow by first defining a torsion parameter and then proceeded to find the critical Dean number at different torsion parameter values. They showed that as the torsion parameter increases, critical Dean number decreases at first, reaching a minimum, then began to increase again. Effect of the pitch on the Nusselt number in laminar flow of helicoidal pipes was also determined by Yang et al. [11]. Effect of the Prandtl number on heat transfer rate and on both average and local Nusselt numbers for flow in helical pipes was studied by Xin and Ebadian [12]. In their studies, different torsions and curvature ratios were considered along with three different fluids, air, water and ethylene glycol. They concluded that the peripheral Nusselt numbers for laminar flow showed larger variation for higher Prandtl and Dean numbers.

Karahalois [13] studied heat transfer of a fluid flowing in a curved pipe with a solid core. The core and the curved pipe surface were at constant temperature gradient along the axial direction. Depending on Dean number, a reversal of the flow was detected in the inner portion of the bend for significantly large cores. Petrakis and Karahalios [14] studied steady annular flow of an incompressible viscous fluid in a curved pipe with a coaxial core. Their findings showed that presence of a core affects flow properties, especially at high Dean numbers. They also developed analytical expressions for axial velocity and for stream function for exponentially decaying flow in a curved annular pipe. In both works it was shown that in some instances two additional secondary flow patterns developed resulting in a total of four vortices. Xin et al. [15] experimentally studied both single-phase and two-phase flow in helicoidally annular pipes to determine pressure drop relationships. They developed a pressure drop correlation for single phase flow for laminar, transitional, and turbulent flow regimes. For the two-phase flow, they studied coils in both horizontal and vertical configurations and provided pressure drop correlations for each case. Petrakis and Karahalios [16] used a finite difference numerical method for flow of a viscous, incompressible fluid in a curved annular conduit with a circular cross section. The Dean range was from 96 to 8,000. Various core sizes were used. Influence of annular tube contact in a helical-wound tube-in-tube heat exchanger was studied by Louw [17]. Comparison of such heat exchangers to aligned (concentric) devices was done experimentally to quantify the influence of annular contact on heat exchange capabilities. Nusselt numbers were used to predict convection heat transfer coefficients, and by method of comparison it was found that annular contact decreased convection from an inner tube and improved it into an annular space. Rennie [18] and Rennie and Raghavan [19] experimentally reported the heat transfer in a tube-in-tube heat exchanger comprised of one loop. Two heat exchanger sizes and both parallel flow and counterflow configurations were tested. They reported a little differences between the overall heat transfer coefficients for the parallel flow and counterflow configurations. However, heat transfer rates were much higher in the counterflow configuration due to larger average temperature difference between the two fluids. They also reported that increasing tube Dean numbers or annulus Dean numbers resulted in an increase in the overall heat transfer coefficient. Pressure drop and heat transfer study for tube-in-tube helical heat exchanger was studied by Kumar et al. [20]. The experiments were carried out in counter current mode operation with hot fluid in the tube side and cold fluid in the annulus area. Overall heat transfer coefficients were calculated and heat transfer coefficients in the inner and outer tube were determined using Wilson plots.

The above literature show that although a significant amount of research has been performed on the flow patterns and heat transfer in curved pipes and helically coiled pipes, there is still much that needs to be investigated, in particular multi tubes in tube helical heat exchangers.

2 Experimental setup and procedure

The experimental setup and procedure were designed to study average heat transfer coefficients and pressure drop in the annulus of multi tubes in tube liquid to liquid helical heat exchanger. The annulus fluid used was water. To maintain and control a constant heat flux boundary conditions on inner annulus surfaces, electrical heaters rods are used to simulate the inner tubes of multi tubes in tube heat exchanger. To study effects of some of geometric parameters such as number of inner tubes and annulus hydraulic diameter on heat exchanger performance, different test sections with different number of inner tubes were designed, manufactured and tested. Namely, four multi tubes in tube heat exchangers with one, three, four and five inner tubes, denoted as coil 1, coil 2, coil 3 and coil 4 respectively, are tested. Figure 2 shows cross section views of the different arrangements of tested heat exchangers.

2.1 Experimental setup

A schematic diagram of the experimental setup is shown in Fig. 3. The experimental set up can be divided to two main sections; cooling water circuit and test section. Cooling water circuit is an open type circuit. It consists of a constant head tank, circulating pump with a bypass line, mixing cups, test section annulus, water flow meters and a graduated vessel used for flow rate measurements. Constant head tank is a thermally insulated polyethylene water storage tank. The tank is fitted with a water level controller to assure a constant water level inside the tank during the experiment. ¾ hp circulating pump with a bypass line is used to control cooling water flow rate passing through test section. Two water mixing cups are inserted just upstream and downstream test section to enable measuring average water temperatures at inlet and exit of test section. Two T-type thermocouples props were inserted in the mixing cups to measure water temperatures. Cooling water flow rates were measured by collecting certain water at test section exit in a graduated 1,000 ml vessel in a certain time period measured by a standard stop watch. Two acrylic variable area flow meters of different ranges are used to regulate and approach the required water flow rates. Flexible PVC tubing with standard fitting are used to connect sections of the water circuit together. Pressure drop of water flow in test section annulus was measured by an inverted U tube manometer.

Test section is a multi tubes in tube helical coil. The inner tube(s) was (were) simulated by a 6 mm diameter electrical heater rod(s). The heater rods were constructed from stainless steel-316 thin tubes with nickel Krum resistance wire impeded inside it and shield with a special powder. The outer tube of the helical coil was a copper tube of 23 and 25 mm inside and outside diameters, respectively. Four test sections of different numbers of heater rods; namely one, three, four and five were tested. The length of each heater rod and the outer tube was 3.5 m before coiling. Heater rod(s) was (were) inserted inside the outer tube and concentric in it by guidance from both ends. The outer tube with heater rods inside it were coiled to form a helical coil of five turns and 170 mm helical coil diameter with 25 mm pitch between each turn and other. Figure 4 and Table 1 give helical coils geometrical and physical parameters, respectively. Helical coils outer surfaces were thermally insulated from all sides by 5 cm-thick glass wall thermal insulation. Heater rods were connected together in parallel to an electrical power source via a Voltage transformer. The voltage transformer was used to regulate electrical power input to heater rods to achieve same required heat flux outlet from each one. Voltage drop and current carried in each electric heater rod were measured by digital ammeter and voltammeter. Two thermocouples (type T) were fixed on the surface of each heater rod at each two ends to measure the average heater rod surface temperature. The thermocouple wires were passed from the outer tube of the helical coils through holes and sleeves around the holes at the two ends of the coil as shown in Fig. 4. All thermocouples were calibrated in a constant temperature path and a measurement accuracy of ±0.2 °C was obtained. All the temperature signals were acquired using a data acquisition system and sent into a PC for data recording.

2.2 Data reduction

Reynolds number of water flow in the test section annulus was calculated based on annulus hydraulic diameter as given by:

where ρw and μw are density and dynamic viscosity of water calculated at (T wi + T wo )/2, \(\mathop V\limits^{.}\) is water volumetric flow rate, A c and D h are annulus cross sectional area and annulus hydraulic diameter given by:

where, D o , n and d o are annulus outer diameter, number of inner heater rods and outer diameter of inner heater rods, respectively.

Dean number for water flow in the helical annulus is defined by Eq. (4). The curvature ratio (R) used in Eq. 4 is taken as the ratio of the annulus gap to the radius of curvature of helical coil outer tube.

Heat transfer rate Q was calculated by making heat balance between cooling water conditions at inlet and exit of test section and electric heat input to heaters rods neglecting heat losses from test section due to well thermally insulated.

where \(\dot{m}_{w}\) is cooling water flow rate, T wi , T wo are cooling water temperatures at inlet and exit of test section. Cp is specific heat of cooling water calculated at average cooling water temperature (T wi + T wo )/2. V and I are voltage and current input to rod heaters, respectively.

Heat transfer rate q was determined from both Eqs. (5) and (6). The difference was usually smaller than ±5 %. A test run was repeated if the deviation was larger than ±5 %. In our calculations, the average of the two values was considered as the heat transfer rate.

The mean heat transfer coefficient was calculated from

where T s and T w are average surface temperature of heater rods and mean temperature of cooling water, respectively and L is heater rod length. T s and T w are calculated from

where T si and T so are heater rod average surface temperature at inlet and exit of test section.

The average Nusselt number is calculated based on annulus hydraulic diameter from:

where k w is water thermal conductivity calculated at T w .

2.3 Experimental conditions and procedure

Experiments were carried out at an electrical power supply to heater rods in the range 527–3,297 W. Reynolds number was varied in the range 350–6,500. Experiment data was recorded after maintaining steady state conditions. To be sure of steady state conditions temperature readings of all thermocouples are approximately constant with time (±0.2 °C was considered for a period of time 30 min). After achievement of steady state conditions, the following measurements were recorded in each experiment: water flow rates, pressure drop across test section, voltage and current applied on the heater rods and all thermocouple readings. The ranges of the measured variables during all experiments were 22.2–33.3 °C for T wi , 24.8–62.3 °C for T wo , 32.6–74 °C for T s , 0.006–0.228 kg/s for \({\dot{\text{m}}}_{\text{w}}\) and 527–3,297 W for electric power (VI). The uncertainty ranges of the measured variables during all experiments were: 0.9–0.6 % for T wi , 0.8–0.32 % for T wo , 0.61–0.27 % for T s , 0.507–0.7 % for \({\dot{\text{m}}}_{\text{w}}\), 0.44–2.2 % for electric power and 0.0001 m error of tube diameter measurements. Details of ranges of measured parameters and uncertainties are given in Al Shaer [21].

Using Eqs. 2–10, the average Nusselt number can be put on the form \(Nu = f(x_{1} ,x_{2} ,{ \ldots }x_{n} )\) where x 1 to x n are all the variables that affect the experimental determination of Nu. The uncertainty ΔNu in the value of Nu was estimated based on the procedure of Holman and Gajda [22] and is expressed as follows

where Δx i is the uncertainty in the x i variable. Following the above procedure, it was found that the uncertainty for all data of \(\overline{Nu}\) ranges from 5 to 7 %. For detailed calculation and uncertainty analysis kindly refer to Al Shaer [21].

3 Results and discussions

Experimental runs were performed to study the effects of number of the inner tubes, annulus hydraulic diameter, Reynolds numbers and input heat flux on pressure drop, \(\bar{h}A_{h}\) (the factor that measure performance and compactness of heat exchangers) and Nusselt number.

3.1 Variation of pressure drop

Figure 5 shows variation of cooling water pressure drop across heat exchanger against Reynolds number with coil number (number of inner tubes) as a parameter. The figure shows that the increase of pressure drop with increasing both of Reynolds numbers and number of inners tubes. The results agree with the scientific facts of increasing pressure drop with the increase of the fluid velocity and the increase of the wetted perimeter. Increasing the number of inner tubes increases the wetted perimeter which in turn increases pressure drop.

3.2 Heat transfer coefficients and compactness parameter

Figure 6 shows variation of average heat transfer coefficients versus Reynolds number with number of inner tubes as a parameter (coils 1, 2, 3 and 4). The figure shows that for all coils, heat transfer coefficient increases with increasing Reynolds number. Increase of heat transfer coefficient with Reynolds number agrees with scientific facts where heat transfer coefficient increases with increasing of Reynolds number due to the increase of mixing and turbulence level in the flow. Figure 6 shows that heat transfer coefficient for coil 2 (Number of inner tubes = 3) is significantly higher than those for other coils. Heat transfer coefficients of coils 1, 3 and 4 approaches each other. The trend is the same for all Reynolds number. Figure 6 reveals that there is an optimum number of inner tubes of the multi tubes in tube helical heat exchanger at which heat transfer coefficient is maximum. Since number of inner tubes has a direct impact on hydraulic diameter, as defined in Eq. 4, an optimum number of inner tubes means an optimum hydraulic diameter at which heat transfer coefficient is maximum.

To show the effect of hydraulic diameter on heat transfer coefficient and to indicate optimal hydraulic diameter, Fig. 7 is represented in Fig. 7, where heat transfer coefficient is plotted versus hydraulic diameter with Reynolds number as a parameter. Figure 7 shows that optimal hydraulic diameter is independent on Reynolds number and always occurs at D h = 0.012 m which is nearly equivalent to hydraulic diameter of coil 2. Figure 7, also shows that variation of heat transfer coefficient is parabolic with maximum value at D h = 0.012 m. The existence of optimum value for heat transfer coefficient at number of inner tubes equals three may be attributed to the optimization of the effects of flow mixing, turbulence and secondary flow on heat transfer coefficient that occurs at number of inner tubes equals three.

In addition to heat transfer coefficient, \(\bar{h}A_{h}\) is used to measure performance and compactness of heat exchangers. For same volume occupied by heat exchangers, increasing \(\bar{h}A_{h}\) means the increase of the capability of the heat exchanger to heat transfer. Figure 8 shows variation of \(\bar{h}A_{h}\) versus Reynolds number with coil number as a parameter. Figure 8 shows that coils 2 and 4 which have number of inner tubes equals 3 and 5, respectively have a higher \(\bar{h}A_{h}\) as compared to coil 1 and 3 which have number of inner tubes equals 1 and 4, respectively. The trend is the same at all Reynolds number. Figure 8 also shows that \(\bar{h}A_{h}\) are approximately the same for coil 2 and 4. Therefore, from heat transfer point of view in compact heat exchangers, coils number 2 and 4 have the same and best performance as compared to other coils. However, coil 2 is superior since it has smaller number of inner tubes (three inner tubes) as compared to coil 4 (five tubes). This means that cost and cooling water pressure drop of coil 2 is smaller than that of coil 4. The above discussion shows that for the studied multi tubes in tube helical heat exchanger, coil 2 which has three inner tubes has the best optimal performance; maximum heat transfer, maximum \(\bar{h}A_{h}\), minimum pressure drop and minimum cost.

3.3 Nusselt number and experimental correlations

Average Nusselt number, defined by Eq. 9, is mainly function of heat transfer coefficient and annulus hydraulic diameter. Annulus hydraulic diameter is not the same for all coils but it varies according to number of inner tubes as shown in Eq. 3 that reveals the decrease of hydraulic diameter with increasing number of inner tubes. Figure 9 shows variation of average Nusselt number versus Reynolds number with coil number (number of inner tubes) as a parameter. The figure shows that for all coils, Nusselt number increases with increasing Reynolds number. The figure also show that Nuseelt numbers of coils 1 and 2, which are approximately have the same values, are higher than those of coils No. 3 and 4. The figures also shows that coil 3 has higher Nusselt number than that of coil 4. This effect of coil Number on Nusselt number can be attributed to the effect of coil number on heat transfer coefficient as previously discussed and the decrease of hydraulic diameter with the increase of number of inner tubes.

The experiments were conducted at various input heat fluxes and various water cooling flow rates. Varying both of heat flux and water cooling flow rate varies heat transfer surface temperature and mean fluid temperature. These variations will lead to a variation in the average liquid temperature \(( {\text{T}}_{\text{wi}} + {\text{T}}_{\text{wo}} ) / 2\) at which the properties are calculated. This means that during the experiments program Prandtl number cannot be kept constant. It varies according to the variation of input heat flux and cooling water flow rate. The regression shows that for all coils, \(\overline{\text{Nu}}\) increases with increasing Re and Pr according to a power low as given by the following equation:

Table 2 gives the coefficients C and m for the different coils. As shown in Table 2, the exponent m is approximately constant and does not depend on the number of inner tubes. This indicates that trend of the variation (slop of the line) of \(\overline{\text{Nu}}\) with Re does not depend on number of inner tubes of the coil. The average values of the exponent m for all coils can be considered as 0.251. This value will be taken as an exponent of the power variation of \(\overline{\text{Nu}}\) with Re for all coils. Also, Table 2 shows that the value of the constant C is strongly depend on number of inner tubes of the coil. This means that Nusselt number is strongly depends on annulus hydraulic diameter of the multi tubes in tube helical coil.

Equation 12 and Table 2 are used to predict effect of annulus hydraulic diameters of multi tubes in tube helical coil on Nusselt number. Figure 10 shows variation of \(\overline{\text{Nu}} /\Pr^{0.474}\) versus hydraulic diameter for various Reynolds numbers. The figure indicates that there is a hydraulic diameter at which \(\overline{Nu} /\Pr^{0.474}\) is maximum. This hydraulic diameter can be considered as coil optimal hydraulic diameter. The Figure shows that this optimum hydraulic diameter always occurs at D h = 0.0142 m independent on Reynolds number. To correlate variation of Nusselt number with hydraulic diameter, \(\overline{\text{Nu}} / ( {\text{Pr}}^{ 0. 4 7 4} \;{\text{Re}}^{ 0. 2 5 1} )\) is plotted versus D h for all experimental data in Fig. 11. Figure 11 shows that variation of \(\overline{\text{Nu}} / ( {\text{Pr}}^{ 0. 4 7 4} \;{\text{Re}}^{ 0. 2 5 1} )\) with hydraulic diameters is parabolic and has its maximum value at D h = 0.0142 m with regression correlation:

The above equation is deduced from data of ranges 376 < Re < 6516 and 5.3 < Pr < 6.37. R2 value of this regression is 0.908 which means that scatter of experimental data around regression line is high. Careful examination of Fig. 11 reveals that data of coil 3 (No. of inner tubes = 4) are data with high scatter and the scatters of other coils data are small enough. Excluding data of coil 3, the only coil with even number of inner tubes, and make curve fitting of other coils data as shown in Fig. 12, R2 value will become 0.989. This means that trend of variation of \(\overline{\text{Nu}} /(\Pr^{0.474} \;\text{Re}^{0.251} )\) with D h for multi tubes in tube helical coil with odd number of inner tubes is differs than that of even number of inner tubes. This can be attributed to flow pattern and flow regime in coil annulus which strongly depend on distribution of inner tubes inside helical outer tube, where inner tubes distributions in case of odd number always assure presence of a tube inside the core of the helical shell. Figure 12 shows that for multi tubes in tube helical coils with odd number of inner tubes, the maximum Nusselt number always occurs at D h = 0.0138 m. Data of the Nusselt number for multi tubes in tube helical coil with odd number of inner tubes can be correlated by the following equation as shown in Fig. 12.

The above equation is deduced from data of ranges 376 < Re < 6516 and 5.3 < Pr < 6.37. Comparison of predictions of Eqs. 13 and 14 with experimental data are shown in Figs. 10, 11, 12 and 13 respectively. Figure 13 shows that Eqs. 13 and 14 can predict Nusselt number for all coils for coils with odd numbers of inner tubes within ±29.5 and ±8.5 %, respectively.

Deviation between experimental results and prediction of Eq. 14

4 Summary and conclusions

Experimental investigation of heat transfer and pressure drop characteristics of a multi tubes in tube helically coiled heat exchanger has been conducted to investigate effects of heat exchanger geometric parameters and fluid flow parameters on the performance of the heat exchanger. The results showed that: (a) the coil that had three inner tubes has higher heat transfer coefficient and bitter heat transfer characteristics as compared with other coils, (b) coils which have number of inner tubes equals 3 and 4, respectively, have higher values of \(\bar{h}\,A_{h}\), and (c) the pressure drop increases with increasing both of Reynolds number and number of inner tubes. Correlations of average Nusselt number were deduced from experimental data in terms of Reynolds number, Prandtl number and coil hydraulic diameter. The correlation prediction was compared with experimental data and the comparison was fair enough.

Abbreviations

- A c :

-

Annulus cross sectional area of test section (m2)

- Cp:

-

Specific heat of cooling water (J/kg K)

- De :

-

Dean number, dimensionless

- D h :

-

Annulus hydraulic diameter (m)

- D i :

-

Annulus inner diameter (m)

- D o :

-

Annulus outer diameter (m)

- d o :

-

Inner rod heater outside diameter (m)

- \(\bar{h}\) :

-

Average convection heat transfer coefficient (W/m2 K)

- \(\bar{h}\,A_{h}\) :

-

Compactness factor (W/K)

- I :

-

Applied current to rod heater (A)

- k w :

-

Water thermal conductivity (W/m K)

- L :

-

Heater rod length (m)

- \({\dot{\text{m}}}_{\text{w}}\) :

-

Cooling water mass flow rate (kg/s)

- \(\overline{\text{Nu}}\) :

-

Average Nusselt number, dimensionless

- n :

-

Number of inner rod heaters

- Pr :

-

Prandtl number, dimensionless

- Q :

-

Heat transfer rate (W)

- R :

-

Curvature ratio, dimensionless

- Re :

-

Reynolds number, dimensionless

- T s :

-

Average surface temperature of heater rods (°C)

- T si :

-

Average surface temperature of heater rod at inlet of test section (°C)

- T so :

-

Average surface temperature of heater rod at exit of test section (°C)

- T w :

-

Mean temperature of cooling water between inlet and outlet (°C)

- T wi :

-

Cooling water temperature at inlet of test section (°C)

- T wo :

-

Cooling water temperature at exit of test section (°C)

- V :

-

Applied voltage to rod heater (V) dry air

- \(\mathop V\limits^{.}\) :

-

Water volumetric flow rate (m3/s)

- ΔP:

-

Pressure drop (Pa)

- Ρ w :

-

Density of water (kg/m3)

- μ w :

-

Dynamic viscosity of water

References

Dean WR (1927) Note on the motion of fluid in a curved pipe. Philos Mag 20:208–223

Dravid AN, Smith KA, Merrill EW, Brian PLT (1971) Effect of secondary fluid motion on laminar flow heat transfer in helically coiled tubes. AIChE J 17(5):1114–1122

Akiyama M, Cheng KC (1972) Laminar forced convection heat transfer in curved pipes with uniform wall temperature. Int J Heat Mass Transf 15:1426–1431

Kalb CE, Seader JD (1983) Entrance region heat transfer in a uniform wall-temperature helical coil with transition from turbulent to laminar flow. Int J Heat Mass Transf 26(1):23–32

Janssen LAM, Hoogendoorn CJ (1978) Laminar convective heat transfer in helical coiled tubes. Int J Heat Mass Transf 21:1197–1206

Austen DS, Soliman HM (1988) Laminar flow and heat transfer in helically coiled tubes with substantial pitch. Exp Thermal Fluid Sci 1:183–194

Liu S, Masliyah JH (1993) Axially invariant laminar flow in helical pipes with a finite pitch. J Fluid Mech 251(1993):315–353

Liu S, Masliyah JH (1994) Developing convective heat transfer in helical pipes with finite pitch. Int J Heat Fluid Flow 15:66–74

Yamamoto K, Akita T, Ikeuchi H, Kita Y (1995) Experimental study of the flow in a helical circular tube. Fluid Dyn Res 16:237–249

Yamamoto K, Yanase S, Jiang R (1998) Stability of the flow in a helical tube. Fluid Dyn Res 22:153–170

Yang G, Dong F, Ebadian MA (1995) Laminar forced convection in a helicoidal pipe with finite pitch. Int J Heat Mass Transf 38(5):853–862

Xin RC, Ebadian MA (1997) The effects of Prandtl numbers on local and average convective heat transfer characteristic in helical pipes. J Heat Transf 119:467–473

Karahalios GT (1990) Mixed convection flow in a heated curved pipe with core. Phys Fluids A 2:2164–2175

Petrakis MA, Karahalios GT (1996) Technical note: steady flow in a curved pipe with a coaxial core. Int J Numer Methods Fluids 22(12):1231–1237

Xin RC, Awwad A, Dong ZF, Ebadian MA (1997) An experimental study of the single-phase and two-phase flow pressure drop in annular helicoidal pipes. Int J Heat Fluid Flow 18(1997):482–488

Petrakis MA, Karahalios GT (1999) Fluid flow behavior in a curved annular conduit. Int J Non Linear Mech 34(1):13–35

Louw WI (2002) The influence of annular tube contact in a helical-wound tube-in-tube heat exchanger, master in mechanical engineering in the Faculty of Engineering of the Rand Afrikaans University

Rennie TJ (2004) Numerical and experimental studies of a double-pipe helical heat exchanger, Ph.D. dissertation, McGill University, Montreal, Canda

Rennie TJ, Raghavan VGS (2005) Experimental studies of a double-pipe helical heat exchanger. Exp Thermal Fluid Sci 29:919–924

Kumar S, Sharma SM, Nigam KDP (2006) Pressure drop and heat transfer study in tube-in-tube helical heat exchanger. Chem Eng Sci 61:4403–4416

Al Shaer WG (2010) Heat transfer and pressure drop characteristics of multi tubes-in-tube helically coiled heat exchanger, M.SC. thesis, Benha University, Egypt

Holman JP, Gajda WJ (1989) Experimental method for engineering. McGraw Hill, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nada, S.A., El Shaer, W.G. & Huzayyin, A.S. Performance of multi tubes in tube helically coiled as a compact heat exchanger. Heat Mass Transfer 51, 973–982 (2015). https://doi.org/10.1007/s00231-014-1469-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-014-1469-z