Abstract

The effects of temperature (T) and moisture content (MC) on bark/wood shear strength (BWSS) were studied. Fifteen stems of black spruce (Picea mariana (Mill.) B.S.P.) and balsam fir (Abies balsamea (L.) Mill.) logs were selected and cross-cut into three 1.25 m log sections, corresponding to bottom (1.3 m), middle (3.8 m), and top (6.3 m) positions. BWSS was measured at five temperatures, ranging from 10 to − 30 °C, and at five levels of sapwood moisture contents (SMC), obtained by air-drying, from green state to near to the fiber saturation point (FSP). Bark and sapwood properties, MC and basic density (BD) were also determined. Temperature had a significant effect on BWSS for both species. This property was similar between 10 and 0 °C, and significantly increased as temperature decreased below 0 °C. However, the influence of temperature on BWSS depended on SMC and it varied between the two species. For black spruce, for each temperature between 0 and − 20 °C, BWSS showed similar values for SMC between 157 and 62%. At − 30 °C, BWSS showed a tendency to increase with SMC. For balsam fir, the BWSS increase due to the decrease in temperature was more important as the SMC increased. BWSS increased as SMC approached the FSP of wood for both species. Among the studied covariates, inner bark MC and inner and outer bark BDs significantly affected BWSS. Inner bark MC and SMC affected BWSS similarly. Multiple regressions were developed for prediction purposes, which explained 68 and 69% of BWSS variability for black spruce and balsam fir, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Debarking performance depends, among other factors, on bark-to-wood adhesion. Logs are easy to debark when the bark/wood bond strength is low (Baroth 2005). As the adherence of bark-to-wood increases, bark tends to remain attached to the log surface, which decreases debarking quality. Ideally, the amount of bark remaining on logs in sawmills should be reduced to a minimum to meet the requirements of the pulp and paper manufacturers. Bark tolerance limits in wood chips depend on the type of pulping process, equipment, and product (Hartler and Stade 1979). The anatomical structure and chemical composition of bark is different compared to the wood. In general, softwood bark is composed of periderm (phellogen, phellem, and phelloderm), sieve cells, albuminous cells, phloem parenchyma, and sclerenchyma (fibers and sclereids) (Martin and Crist 1970). Moreover, the main chemical component of wood is cellulose (about 50%), while the major constituent of bark is extractives, about 30–40%. Since bark has a 20–30% lignin content, the total content of phenolic materials amounts between 50 and 70% (Chow and Pickles 1971). Therefore, the presence of bark on wood chips decreases pulp yield and compromises the mechanical properties of pulp (Erickson 1979). Moreover, the contamination of chips with bark produces darker pulp and thus increases the consumption of chemicals during the pulping process (Hartler and Stade 1979).

The adhesion between bark and wood for debarking applications is commonly assessed by a shearing test in the cambial region, at the bark/wood interface. The knowledge of bark/wood shear strength (BWSS) and the factors affecting this property are thus of great interest for the debarking mechanism. There are several factors affecting BWSS, which include species, tree age, felling season, log temperature (T), moisture content (MC), and storage conditions before debarking (Wilcox et al. 1954; Perem 1958; Berlyn 1965; Calvert and Garlicki 1972; Einspahr and Harder 1983; Wingate-Hill et al. 1989; Duchesne and Nylinder 1996; Chow and Obermajer 2004; Laganière and Bédard 2009). Trees harvested during the growing season are easier to debark compared to those cut down during the dormant season (Perem 1958; Berlyn 1965; Einspahr and Harder 1983; Hatton 1987). According to Fiscus et al. (1983), the bark/wood adhesion failure zones are mainly located between immature initials xylem cells in the proximity of the cambium zone during the growing season, and between cells in the cambium zone located near to the fully mature xylem cells, during the dormant season. Therefore, seasonal variation within the cambium cell layers might affect bark/wood adhesion. The ultrastructure of cambium cells differs significantly between their active and dormant states, which can be seen in the different organization, distribution, number, and shape of the organelles (Prislan et al. 2013).

Several studies have reported that the adhesion between bark and wood increases as temperature drops over the freezing point (Berlyn 1965; Calvert and Garlicki 1974; Chow and Obermajer 2004; Laganière and Bédard 2009). Accordingly, bark/wood adhesion would be affected by the temperature variation throughout the year, being more critical during winter. The winter historical weather data in the Quebec province reported a mean temperature variation between 6 and − 30 °C from 1981 to 2010 (Service Info-Climat 2018). Thus, bark, cambium, and xylem in a tree can undergo a temperature variation of about 36 °C at variable freezing rates (depending on the local climate conditions of each year) from December through March. In general, boreal conifers have a high freezing resistance over winter periods (Sakai and Larcher 1987). In trees, bark cells adapt to subzero temperatures by extracellular freezing. As the temperature declines, the water outside the cell membrane is first frozen. As extracellular ice growth progresses, cells undergo a freezing-induced dehydration, resulting in cell shrinkage and deformation. Conversely, in xylem tissues of boreal trees, freezable water remains inside the cells in a supercooled state, in which the temperature of the cell solutions is lowered below its freezing point without it becoming a solid (Arakawa et al. 2018). This difference of overwintering mechanisms between bark and xylem cells might also influence the bark-to-wood adhesion during winter.

Moisture content (MC) is another important factor affecting BWSS of logs. Wingate-Hill et al. (1989) reported that BWSS increased as bark MC decreased below 40%. Duchesne and Nylinder (1996) indicated that the critical sapwood MC zone was between 20 and 40%, in which shear strengths strongly changed. Chow and Obermajer (2004) also reported that adhesion strength increased exponentially below 28% of sapwood MC. Therefore, the storage time before debarking would affect the bond between bark and wood, as they negatively affect bark and sapwood moisture contents. Moreover, high moisture content in a log could amplify the effect of freezing temperatures in the BWSS depending on the amount and type of ice formed. A few studies have reported green moisture content variation throughout the year in conifer trees. It is, however, known that sapwood moisture content varies among seasons. Coniferous trees have generally higher sapwood MC during winter, closely followed by fall. Trees harvested in spring and summer showed lower sapwood MC, which appears to be closely related to climatic conditions (Clark and Gibbs 1957; Markstrom and Hann 1972; Shottafer and Brackley 1982).

The wood species selected for the present study were balsam fir (Abies balsamea (L.) Mill.), which has been generally recognized as difficult to debark during the winter months (Laganière and Hernández 2005), and black spruce (Picea mariana (Mill.) B.S.P.), which is less difficult to debark. Both species belong to the spruce-pine-fir group, which are the main softwood species processed in eastern Canada sawmills. Overall, bark/wood adhesion depends on the raw material condition at the time of debarking. Moreover, it is an important property that could help to adjust the debarking process to the different seasonal and storage conditions. In this context, the aim of this study was to assess the effects of temperature and moisture content of logs on BWSS of these two wood species. The probable influences of inner and outer bark moisture contents and densities on bark/wood adhesion were also evaluated.

Materials and methods

Materials

Fifteen straight stems of black spruce and balsam fir, without external signs of decay, were harvested in early April 2017 from Montmorency forest in the province of Quebec, Canada (47.3° N, 71.1° W). Three logs of approximately 2.5 m in length were cut from each stem, at 1.3 m (bottom), 3.8 m (middle), and 6.3 m (top) of height, making a total of 45 logs per species. The logs were transported to Laval University in Quebec City a day later. All logs were then cross-cut into two halves (1.25 m in length); the first half (closer to the ground) was used for this study and the second half was used in a parallel debarking study (Fig. 1). A section of 125 mm in length was trimmed to remove eventual loss in MC from all 1.25 m log ends. Log characteristics are described in Table 1. The cambial age of black spruce and balsam fir trees, measured at 1.30 m above from the ground, were 63 and 56 years old, respectively.

Treatments

Each log was used to evaluate BWSS at five temperatures, each one at five moisture contents for each species. MC was determined by the oven-drying method (ASTM D4442-16, 2016). The first level of MC (AD1) corresponded to the time of felling (green state). The four other levels of MC were obtained by air-drying. Green MC was immediately measured a day after harvesting. A 200-mm-thick disc was cross-cut from each log to make the first BWSS tests (AD1). Initial sapwood MC was then measured. Afterward, logs were stored outside under a tent, for air-drying between April and September 2017. Air-drying steps (AD2–AD5) depended on the climatic conditions, and time was adjusted to reach four sapwood MCs distributed between the green state and the fiber saturation point (about 30% MC) for each species specifically. Log ends were coated with a water-based sealer to prevent rapid moisture exchange through the cross-section. Sapwood MC was monitored over air-drying time by extracting 25-mm-long cores from 15 of the 45 logs per species. Once the target MC was reached, a 200-mm-thick disc was cut from each log. Each obtained disc was immediately wrapped in polyethylene and kept in a freezer at − 20 °C to maintain its moisture content until the beginning of the BWSS sample preparation. The distribution of discs within a log is shown in Fig. 1.

In addition, five temperatures ranging from 10 to − 30 °C were selected to assess the effect of log temperature on bark/wood adhesion (Table 1). Thus, five adjacent cores of 12.7 mm in diameter and 25 mm in length were obtained from each frozen disc in the radial direction (Fig. 1) with a drill press (General International®, model GEN75-150 M1) at 680 r min−1. Cores were drilled where the bark was still intact. Therefore, a total of 1125 cores (15 stems × 3 logs × 5 AD × 5 temperatures) were obtained per species for all trials. Twenty-four hours before testing, 45 cores from each moisture content step and species were placed in a Cincinnati Sub-Zero environmental simulation chamber (CSZ 44 PLUS-1576), which was previously conditioned at each temperature treatment. Prior to temperature treatments, cores were wrapped with a polystyrene foam protection (Foamular® 600 Insulation, 50-mm thickness, 0.029 W mK−1 thermal conductivity) to maintain their temperature during the bark/wood adhesion tests (Fig. 1).

Shear strength tests

The adhesion strength between wood and bark was evaluated in the cambial region by shearing perpendicular to the grain. In a conventional ring debarker, knives remove bark in this direction. Measurements were taken in a MTS QT5 universal testing machine equipped with a 500 N load cell. Load was applied at a rate of 15 mm per min until complete failure. Shear strength (MPa) was calculated by dividing the load at failure (N) by the cross-sectional area of the wood/bark interface (mm2).

Bark and sapwood properties

Bark thickness (BT), including inner and outer bark, of all samples was measured prior to the shearing tests (Table 1). Inner bark and outer bark were separated using a razor blade after shearing. Green mass and volume of sapwood, inner, and outer bark (tissue type: TT) samples were also taken immediately after shearing tests. Volume was measured by the water displacement method according to ASTM D2395-17 (2017). Samples were then oven-dried at 103 °C for at least 24 h to obtain their oven-dry mass. All mass measurements were taken to the nearest 0.0001 g. Finally, MC at the time of shear tests, as well as basic density (BD: oven-dry mass divided by green volume for AD1) were calculated.

Statistical analysis

Statistical analyses were performed with SAS software, version 9.4 (SAS Institute Inc. 2013, Cary-NC). Data of all covariates were analyzed separately to assess their variation. MC were analyzed following a split-split-plot with log position (LP) in the main plot, AD in the sub-plot and TT in the sub-subplot. This design allowed to evaluate the differences between sapwood, inner bark, and outer bark as tissue types following a radial position. BD was evaluated only at the initial green moisture content following a split-plot design with LP in the main plot and TT in the sub-plot. BWSS data followed a split-split-plot design with the LP in the main plot, the sapwood MC (SMC) in the sub-plot, and the temperature in the sub-subplot. A mixed model analysis of covariance (ANCOVA) was used to evaluate the variation in the BWSS. Covariates were added to the model keeping only the ones that were significant. A summary of all the treatments and covariates used in the present study is shown in Table 2. Afterwards, for a practical purpose, a multiple linear regression was done to estimate BWSS as a function of temperature and SMC (at the 5% probability level). Finally, the normality was verified with Shapiro–Wilk test; the homogeneity of variance was verified with the graphical analysis of residuals in all the analyses.

Results and discussion

Bark and wood properties

The ANOVAs for moisture content and basic density for black spruce and balsam fir are shown in Table 3. In agreement with previous works (Zhang and Koubaa 2008), green MC of sapwood was higher for balsam fir (218%) than for black spruce (157%) (Table 4). In contrast, green MC in inner bark was higher for black spruce (113%) than for balsam fir (94%). Differences in green MC between sapwood and inner bark were thus lower for black spruce compared with balsam fir. This behavior is due to the fact that the differences in BD between the two types of tissues are low for black spruce and high for balsam fir. As expected, MC decreased during air-drying for all tissue types in both species. Air-drying rate was generally higher for sapwood than for inner and outer barks. As a result, differences in MC among the three tissue types (sapwood–inner bark–outer bark) decreased as air-drying advanced to the last step (Table 4). The moisture content variation among tissue types and air-drying steps should be related to the differences in the anatomical and chemical compositions between bark and wood (Martin and Crist 1970; Chow and Pickles 1971).

The basic density was significantly different among tissue types for both species (Table 3). Basic densities of black spruce and balsam fir increased significantly from sapwood (405 and 316 kg m−3) to inner bark (458 and 454 kg m−3) and then to outer bark (472 and 482 kg m−3) (Table 4). Several factors can contribute to the higher density of outer bark. First, the expanding periderm causes crushing of the outer bark cells and, second, the loss of moisture from the outermost bark tissue results in shrinkage and cell collapse (Martin and Crist 1970; Smith and Kozac 1971; Meyer et al. 1981). It is also important to notice that the inner bark BD was 138 kg m−3 higher than sapwood in balsam fir and 53 kg m−3 in black spruce, which is a result of the difference between the anatomical structures of these two tissues. Inner bark in softwood is composed of sieve cells, albuminous cells, phloem parenchyma, and sclerenchyma (fibers and sclereids), whereas their xylem is composed of tracheids, parenchyma, and rays (Martin and Crist 1970). Previous studies from trees grown in eastern Canada found that sapwood BD varied from 399 to 461 kg m−3 in black spruce and from 323 to 351 kg m−3 in balsam fir (Hernández and Quirion 1993, 1995; Hernández and Lessard 1997; Hernández and Boulanger 1997; Laganière and Bédard 2009; Hernández et al. 2014; Cáceres et al. 2015, 2016; Kuljich et al. 2017), which was consistent with the present results. On the other hand, the inner and outer barks BDs that were found for both species were higher than those reported in the literature (Table 4). According to the previous findings, inner bark BD varied between 259 and 330 kg m−3 in black spruce and it was on average 320 kg m−3 in balsam fir (Lamb and Marden 1968; Isenberg 1980). Outer bark BD of black spruce and balsam fir varied from 424 to 460 kg m−3 (Lamb and Marden 1968; Harder et al. 1975; Isenberg 1980). BD of wood and bark can be quite variable depending on many factors, including the geographic location of trees, which varies by species, diameter at breast height, age, and stem position (Miles and Smith 2009).

BT decreased from the bottom to the top of the stem for about 11 and 14% for black spruce and balsam fir, respectively (Table 1). Previous works have shown that BT is strongly associated with height level, age, and diameter of the stem (Hale 1955; Smith and Kozac 1971; Eberhardt 2013). Bark of the lower parts of old trees usually has lost its smoothness, becoming typically thick and fissured or scaly, while bark is relatively thin on the smaller younger logs toward the top of trees (Hale 1955).

Bark/wood shear strength

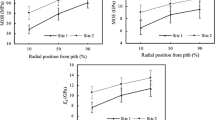

The BWSS of both species was significantly affected by temperature, sapwood moisture content, and the interaction between these two factors (Table 5). The effect of temperature on BWSS was the most important factor as shown by the F values. Its impact was much more important for black spruce (F value: 1029) than for balsam fir (F value: 429). Means of BWSS as a function of T and SMC for black spruce and balsam fir are presented in Table 6 (all log positions in the stem are pooled). BWSS was similar at 10 °C and 0 °C for all SMCs and species. Temperatures above 0 °C had no effect on BWSS, which is in agreement with the previous studies on the bark/wood strength bond (Laganière and Bédard 2009; Chow and Obermajer 2004) and with the mechanical behavior of wood (Hernández et al. 2014). In contrast, BWSS increased significantly as temperature decreased from 0 to − 30 °C for all SMCs above FSP (157–34% SMC for black spruce and 218–59% SMC for balsam fir, Fig. 2 and Table 6). Previous studies have reported that, above FSP, MC affects mechanical strength in frozen conditions as the portion of liquid water freezes, expands, and reinforces wood structure (Mishiro and Asano 1984; Mishiro 1990; Hernández et al. 2014). In the same manner, at higher SMCs, the temperatures below 0 °C seem to reinforce the bark/wood interface, increasing the adhesion between bark and wood. According to Voronitsyn and Vorobyev (1965), at freezing temperatures, the bond at the cambium and bark interface is governed by the strength of the resulting ice. Laganière and Bédard (2009) reported a similar behavior for both species at green condition, and thus, BWSS increased linearly as temperature decreased below 0 °C. Consequently, the increase in BWSS as log temperature decreases under frozen conditions would negatively influence the debarking efficiency (Berlyn 1965; Calvert and Garlicki 1972, 1974; Chow and Obermajer 2004; Laganière and Bédard 2009).

Furthermore, the effect of T on BWSS depended on the SMC level. This is confirmed by the significant interaction between these two sources of variation, as shown in Table 5. It is thus observed in Fig. 2 that slopes of curves vary for the five levels of SMC studied. For black spruce, Fig. 2a shows that the rate of change in BWSS due to temperature variation decreases slightly from 157 to 62% of SMC. This change in BWSS is only lower for 34% SMC. Figure 2a also shows the little effect that SMC between 62 and 157% has on BWSS for temperatures below freezing. For practical purposes, the effect of moisture content on black spruce debarking could be considered negligible and, thus, log assessment before debarking should focus mainly on temperature variation. On the contrary, the effect of T on BWSS for balsam fir depended more on SMC. This effect was, in fact, higher as SMC increased (Fig. 2b). The influence of SMC on BWSS could be related to the way the cooling mechanisms occur in black spruce and balsam fir. In general, bark cells adapt to subzero temperatures by extracellular freezing, while xylem tissues use supercooling (Arakawa et al. 2018). The amount and/or the variation of one respect to the other would affect bark-to-wood adhesion during winter. In addition, an increase in BWSS was found at AD5 for both species at unfrozen temperatures (0 °C and 10 °C), which could be explained by an increase in wood resistance at SMCs near and below FSP, which is in agreement with the previous studies. Duchesne and Nylinder (1996) found an important increase in the BWSS of Norway spruce and Scots pine as SMC decreases from 40 to 20%. Chow and Obermajer (2004) also found the same tendency for subalpine fir in samples exposed to inside storage (from 30 to 10% SMC).

The ANCOVA also showed a significant interaction between SMC and LP on BWSS for black spruce (Table 5). BWSS varied thus differently with the LP depending on the SMC. BWSS was similar for the three log positions in the stem for the two higher SMCs (AD1-2), but it decreased from the bottom log to the top log for the following SMCs (AD3-5) (Table 6, all temperatures are pooled). Thus, as the logs started to dry-out, a decrease in bark/wood adhesion with height in the stem occurred in black spruce. Accordingly, bottom logs would be harder to debark than other logs as they dry-out.

In addition, results showed that black spruce had higher BWSS than balsam fir. Mean BWSS at − 30 °C varied from 2.20 to 1.53 MPa for SMCs from 157% down to 34% in black spruce and between 1.99 and 0.79 MPa for SMCs from 218% down to 24% in balsam fir (Table 6). Therefore, higher moisture contents in balsam fir did not necessarily result in higher BWSS, not even at the lowest temperature tested. This indicates that there are other factors that affected BWSS. Among these factors, BD, MC, and thickness of inner and outer barks were studied as covariates. The ANCOVAs showed only the covariates that were found significant in each species (Table 5). For black spruce, inner bark MC showed a negative effect on BWSS. BWSS increased as inner bark MC decreased. For balsam fir, all covariates positively affected BWSS. The inner bark basic density appeared as the more important given its highest F value in the ANCOVA (Table 5). In fact, the higher values of inner and outer bark BDs (454 and 482 kg m−3, respectively) could increase the resistance of the bond with sapwood (316 kg m−3), which had 138 kg m−3 lower density than inner bark. This effect was not significant in black spruce, probably because the difference between its sapwood and inner bark BDs was not high enough (53 kg m−3). Moreover, the effect of inner bark MC on BWSS was positive for balsam fir and negative for black spruce, thus being dependent on the species. This could be linked to the different cooling mechanisms occurring in these two species as suggested above. According to F values, this effect was higher for balsam fir than black spruce. Another parameter that could affect the BWSS difference between the species is the seasonal changes. In the present study, trees were collected in early April. Thus, harvested trees could have been still in dormancy or at the beginning of a new growing season. According to Perem (1958), the period of dormancy, where the BWSS is stronger, could last until May and it depends on tree species, size, and vigor.

Prediction of BWSS

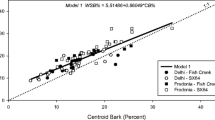

One of the goals of this study was to predict BWSS as a function of moisture content and temperature to use this relationship in debarking applications. Therefore, the MC of sapwood was favored given that potentially its assessment in sawmills should be easier to obtain. Multiple linear regressions were obtained for black spruce and balsam fir and are shown in Table 7. The global fit models explained 68% and 69% (R2) of BWSS for black spruce and balsam fir, respectively. These equations were obtained between − 30 and 0 °C. Higher T (up to 10 °C) gave statistically similar BWSS values to those measured at 0 °C. Temperature was the most important variable correlated to BWSS, with the greatest contribution to the R2 for both species. However, the effect of temperature was stronger for black spruce compared to balsam fir (R2 64.5% and 43.9%). Sapwood MC represented 0.6% of R2 for black spruce and 17.3% for balsam fir. SMC was negatively correlated with BWSS for black spruce, but it was positively correlated for balsam fir. The same behavior was found for inner bark MC as previously explained. The interaction term (T*SMC) was added to the equation to take into consideration that the effect of T on BWSS varied depending on the SMC. T*SMC contributed to 2.9% of R2 for black spruce and to 7.8% for balsam fir. Figure 2 also allows us to observe that BWSS showed the same overall behavior with the variation of temperature at each SMC in black spruce. These results are in agreement with the F values obtained in the ANCOVAs (Table 5). The regression showed the combined action of these variables to predict BWSS. Overall, there could be a potential benefit in measuring the temperature and SMC of the logs at the time of debarking to estimate a BWSS. This could allow the setup of the ring debarker parameters taking into account the adhesion between bark and wood.

Conclusion

Black spruce and balsam fir BWSS were significantly affected by temperature and moisture content of bark and sapwood. The bark/wood adhesion was similar at temperatures above 0 °C and it significantly increased as temperature decreased below 0 °C. Furthermore, BWSS behavior under frozen conditions varied with the moisture content. For black spruce, BWSS obtained between temperatures from 0 to − 20 °C were similar for SMCs from 157 to 62%. BWSS increased with SMC only at − 30 °C. For balsam fir, the increase in BWSS as temperature decreased below 0 °C was progressively more significant as SMC increased. Thus, the effect of SMC on BWSS was more important for balsam fir compared to black spruce. Moreover, at temperatures above 0 °C, BWSS increased at moisture contents near the fiber saturation point of wood for both species. Among the studied covariates, inner bark moisture content, and inner and outer bark basic densities significantly affect BWSS. Inner bark moisture content effect depended on the species, being positive for balsam fir and negative for black spruce. Moreover, the higher basic densities of balsam fir inner and outer barks compared to sapwood resulted in the bark/wood bond strengthening. The BWSS multiple regressions with T and SMC gave coefficients of determination of 68 and 69% for black spruce and balsam fir, respectively, and could be used for prediction purposes among the studied conditions.

Abbreviations

- AD1:

-

First level of moisture content

- AD2–AD5:

-

Air-drying steps

- BD:

-

Basic density

- BT:

-

Bark thickness

- BWSS:

-

Bark/wood shear strength

- FSP:

-

Fiber saturation point

- LP:

-

Log position in the stem

- MC:

-

Moisture content

- SMC:

-

Sapwood moisture content

- T:

-

Temperature

- TT:

-

Tissue type

References

Arakawa K, Kasuga J, Takata N (2018) Mechanism of overwintering in trees. In: Iwaya-Inoue M, Sakurai M, Uemura M (eds) Survival strategies in extreme cold and desiccation: adaptation mechanisms and their applications, 1st edn. Springer, Singapore, pp 129–147

ASTM D2395–17 (2017) Standard test methods for density and specific gravity (relative density) of wood and wood-based materials. ASTM International, West Conshohocken

ASTM D4442–16 (2016) Standard test methods for direct moisture content measurement of wood and wood-based materials. ASTM International, West Conshohocken

Baroth R (2005) Literature review of the latest development of wood debarking. University of Oulu, Finland

Berlyn RW (1965) The effect of variations in the strength of the bond between bark and wood on mechanical barking. Research note No. 54. Pulp and Paper Research Institute of Canada, Montréal

Cáceres CB, Hernández RE, Koubaa A (2015) Effects of the cutting pattern and log provenance on size distribution of black spruce chips produced by a chipper-canter. Eur J Wood Prod 73:357–368

Cáceres CB, Hernández RE, Koubaa A (2016) Effects of log position in the stem and cutting width on size distribution of black spruce chips produced by a chipper-canter. Wood and Fiber Sci 48:25–42

Calvert WW, Garlicki AM (1972) A study of bark removal at low temperatures by simulated cambium-shear methods. Forest Prod J 22:37–43

Calvert WW, Garlicki AM (1974) The use of ring barkers at low temperatures. Publication No. 1334. Canadian Forestry Service, Ottawa

Chow S, Obermajer A (2004) Wood-to-bark adhesion of subalpine fir (Abies lasiocarpa) in extreme temperatures. Wood Sci Technol 38:391–403

Chow SZ, Pickles KJ (1971) Thermal softening and degradation of wood and bark. Wood Fiber Sci 3:166–178

Clark J, Gibbs RD (1957) Studies in tree physiology: IV. Further investigations of seasonal changes in moisture content of certain Canadian forest trees. Can J Bot 35:219–253

Duchesne I, Nylinder M (1996) Measurement of the bark/wood shear strength: Practical methods to evaluate debarking resistance of Norway spruce and Scots pine pulpwood. Forest Prod J 46:57–62

Eberhardt TL (2013) Longleaf pine inner bark and outer bark thicknesses: measurement and relevance. South J Appl For 37:177–180

Einspahr DW, Harder ML (1983) Wood/bark adhesion measurements assist in drum debarker development. Forest Prod J 33:21

Erickson JR (1979) Separation of bark from wood. In: Hatton JV (ed) Chip quality monograph. Joint Textbook Committee of the Paper Industry, Vancouver, pp 145–170

Fiscus MH, Vaneperen RH, Einspahr DW (1983) Method for obtaining wood bark adhesion measurements on small samples. Wood Fiber Sci 15:219–222

Hale JD (1955) Thickness and density of bark; trends of variation for six pulpwood species. Pulp Pap-Canada 56:113–117

Harder ML, Einspahr DW, Hankey JD, Swanson JW (1975) Bark and wood properties of pulpwood species as related to separation and segregation of chip/bark mixtures. Institute of Paper Industry, Appleton

Hartler N, Stade Y (1979) Chip specifications for various pulping processes. In: Hatton JV (ed) Chip quality monograph. Joint Textbook Committee of the Paper industry, Vancouver, pp 273–301

Hatton JV (1987) Debarking of frozen wood. Tappi J 70:61–66

Hernández RE, Boulanger J (1997) Effect of the rotation speed on the size distribution of black spruce pulp chips produced by a chipper-canter. Forest Prod J 47:43–49

Hernández RE, Lessard J (1997) Effect of cutting width and cutting height on the size distribution of black spruce pulp chips produced by a chipper-canter. Forest Prod J 47:89–95

Hernández RE, Quirion B (1993) Effect of a chipper-canter knife clamp on the quality of chips produced from black spruce. Forest Prod J 43:8–14

Hernández RE, Quirion B (1995) Effect of knife clamp, log diameter, and species on the size distribution of pulp chips produced by a chipper-canter. Forest Prod J 45:83–90

Hernández RE, Passarini L, Koubaa A (2014) Effects of temperature and moisture content on selected wood mechanical properties involved in the chipping process. Wood Sci Technol 48:1281–1301

Isenberg IH (1980) Pulpwoods of the United States and Canada, vol I—Conifers. The Institute of Paper Chemistry, Appleton, Wisconsin

Kuljich S, Hernández RE, Blais C (2017) Effects of cutterhead diameter and log infeed position on size distribution of pulp chips produced by a chipper-canter. Eur J Wood Prod 75:747–760

Laganière B, Bédard N (2009) Debarking enhancement of frozen logs. Part I: Effect of temperature on bark/wood bond strength of balsam fir and black spruce logs. Forest Prod J 59:19–24

Laganière B, Hernández RE (2005) Effects of radial force and tip path overlap on the ring debarking efficiency of frozen balsam fir logs. Forest Prod J 55:44–49

Lamb FM, Marden RM (1968) Bark specific gravities of selected Minnesota tree species. Forest Prod J 18:76–83

Markstrom DC, Hann RA (1972) Seasonal variation in wood permeability and stem moisture content of three Rocky Mountain softwoods. Forest Service USDA, Fort Collins

Martin RE, Crist JB (1970) Elements of bark structure and terminology. Wood Fiber Sci 2:269–279

Meyer RW, Kellogg RM, Warren WG (1981) Relative density, equilibrium moisture-content, and dimensional stability of western hemlock bark. Wood Fiber Sci 13:86–96

Miles PD, Smith WB (2009) Specific gravity and other properties of wood and bark for 156 tree species found in North America. Research Note NRS-38, Forest Service, USDA, Philadelphia

Mishiro A (1990) Effect of freezing treatments on the bending properties of wood. Bull Tokyo Univ Forests 82:177–189

Mishiro A, Asano I (1984) Mechanical properties of wood at low temperatures. Effect of moisture content and temperature on the bending properties of wood. II. Moisture content beyond the fiber-saturation point. Mokuzai Gakkaishi 30:277–286

Perem E (1958) Bark adhesion and methods of facilitating bark removal. Pulp Pap Canada 59:109–114

Prislan P, Cufar K, Koch G, Schmitt U, Gricar J (2013) Review of cellular and subcellular changes in the cambium. IAWA J 34:391–407

Sakai A, Larcher W (1987) Frost survival of plants: responses and adaptation to freezing stress. Springer, Berlin

SAS Institute Inc. (2013) SAS/Stat user’s guide, release 9.3 ed. SAS Institute Inc, Cary, North Carolina

Service Info-Climat (2018) Le climat du Québec, Normales climatiques 1981–2010. https://www.mddelcc.gouv.qc.ca/climat/normales/index.asp. Accessed 19 Nov 2019

Shottafer JE, Brackley AM (1982) An analysis of moisture content variation in eastern spruce and balsam fir in Maine. Technical bulletin 104, Forest Products Laboratory, Orono

Smith JH, Kozak A (1971) Thickness, moisture content, and specific gravity of inner and outer bark of some Pacific Northwest trees. Forest Prod J 21:38–40

Voronitsyn KI, Vorobyev IV (1965) The effect of the season on barking. Symposium on Mechanical Barking of Timber, Helsinki

Wilcox H, Czabator F, Girolami G (1954) Seasonal variations in bark-peeling characteristics of some adirondack pulpwood species. J Forest 52:338–342

Wingate-Hill R, Cunningham RB, MacArthur IJ (1989) The relationship between bark/wood bond strength and other properties in logs of Eucalyptus regnans F. Muell during air drying. Appita J 42:115–119

Zhang YS, Koubaa A (2008) Softwoods of eastern Canada: their silvics, characteristics, manufacturing and end-uses. FPInnovations, Quebec

Acknowledgements

The authors wish to thank Paul Desaulniers, Luc Germain, and Daniel Bourgault for their valuable assistance. This research was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) and by DK-Spec Inc.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ugulino, B., Cáceres, C.B., Hernández, R.E. et al. Influence of temperature and moisture content on bark/wood shear strength of black spruce and balsam fir logs. Wood Sci Technol 54, 963–979 (2020). https://doi.org/10.1007/s00226-020-01198-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-020-01198-x