Abstract

Non-destructive measurement techniques were used to study the characteristics of thermally modified timber (TMT), especially checking. Two non-destructive measurement techniques were evaluated: air-coupled ultrasound (ACU) and electrical impedance spectroscopy (EIS). In the studied TMT (N = 38), density and pith location in the cross-section were positively correlated with the number of checks in the cross-section. Several ultrasound signal features correlated with TMT characteristics, most strongly with number of checks. Severely checked samples and other samples were considered as two different classes of checking, and the potential of ultrasound for differentiating between the two classes was tested by using Bayesian classification method. The correct classification rate was 97 %. EIS parameters correlated with density and latewood content of TMT more strongly than the ACU parameters. Thus, for determination of checking and density or earlywood/latewood content, both EIS and ACU measurements are recommended.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In thermal modification, wood is kept at 170–230 °C for several hours in an atmosphere that prevents it from burning. Thermal modification affects both the physical and chemical properties of wood. For example, it improves the dimensional stability and increases decay resistance and the thermal insulating capacity of wood. On the other hand, the bending, tensile and compression strength of wood tend to decrease. The extent of the changes is affected by treatment temperature and the wood species. Internal checking in TMT is mainly caused by drying, although to some extent it can be caused by the stress attributable to thermal degradation (Johansson 2008). Checking of wood during drying or thermal modification is an undesirable phenomenon. Surface checks can be detected from wood visually, but in practice, internal checks are usually detected in a destructive manner by cutting a test set of samples and imaging them visually. Thus, there is a need for a non-destructive testing (NDT) technique to detect the internal checks of TMT.

Ultrasound has been conventionally used as a non-destructive measurement technique for detecting internal defects (e.g. Pellerin Roy and Ross 2002; Bucur 2003). Different types of defects exert various effects on the ultrasound propagation. Honeycombs, i.e. internal checking and surface checks increase the ultrasound transmission time in a perpendicular direction to the grain (Fuller et al. 1994). In addition, bacterially infected sections of wetwood increase the stress wave travel time (Verkasalo et al. 1993). Presumably the honeycombs in wood cause scattering of the ultrasound, whereas wetwood increases viscoelastic damping, both resulting in attenuated sound signals (Schafer 1999, 2000). The recent development of ACU techniques (Bhardwaj 2004a, b) makes the method more feasible for online industrial applications. For example, the use of an online meter for wood moisture content (MC) based on ACU has been proposed (Vun et al. 2008), and density and defects in wood samples have been studied by ACU (Marchetti et al. 2004). In addition, through transmission, ACU has been utilised in the detection of checks in timber (Gan et al. 2005), delamination in wood (Bucur 2010, 2011) and in glulam beams up to 500 mm thickness (Sanabria 2012; Sanabria et al. 2013). In wood-based panels, both density and particle type affect the ACU response (Hilbers et al. 2012a). In addition, the interference of the through transmitted ultrasound signals has an effect, although blister detection in panels is not affected by the interference (Hilbers et al. 2012b).

Moisture content (MC) and the mechanical properties of wood such as strength and density can influence the propagation of the ultrasound signal. The effect of wood density on ultrasound velocity is ambiguous; it has been concluded in earlier studies that it has no influence (Ilic 2003; Baar et al. 2012), or it has a positive correlation (de Oliveira and Sales 2006) or a negative correlation (Bucur and Chivers 1991). Ilic (2003) attributed the variance to microfibril angle and other anatomical characteristics of wood. The results of de Oliveira and Sales (2006) are in accordance with the hypothesis; there were clearer relationships between ultrasound velocity and the density of wood when each species was analysed separately rather than trying to analyse all species together. On the other hand, the dielectric properties of wood are mostly affected by the MC of wood, although also density has an impact (Lin 1967; Hasted 1973; James 1975; Torgovnikov 1993). Promising results have been obtained by combining different NDT techniques, for example, in strength grading (Hanhijärvi and Ranta-Maunus 2008; Brännström 2009), monitoring the wood drying process (Tiitta et al. 2010) or to determine the MC and density of timber (Tiuri et al. 1980) or the MC of TMT (van der Beek et al. 2011).

In addition to ultrasound and other acoustic techniques, rather few methods are suitable for detection of internal checks. These include computed tomography (e.g. Bhandarkar et al. 2005) and microwave imaging (e.g. Pastorino et al. 2007). However, the X-rays or microwaves are related to the density of the sample, whereas acoustic methods evaluate its mechanical and structural properties, and in most applications, this is a real advantage. Furthermore, the imaging techniques tend to be costly and time-consuming.

In the current study, the TMT was studied under laboratory conditions. The macroscopic characteristics of thermally modified pine were surveyed with respect to the severity of the checking. The main goal was to determine whether air-coupled ultrasound could potentially detect internal checks in thermally modified pine and whether electrical impedance spectroscopy could be used to improve the possible check or density prediction capability of ultrasound.

Materials and methods

Thermowood D timber planks of Scots pine (Pinus sylvestris, 50 × 150 × 1,500 mm3, treatment temperature 212 ± 3 °C, N = 38) were measured in laboratory with ACU and EIS from the middle of the plank. The samples were collected from a sawmill warehouse and measured after at least 2 weeks of storage under normal laboratory conditions. Oven dry density (ρ), moisture content (MC), average width of a year ring (wYR), latewood content (LW) and pith content (pith %), distance of pith from the surface of the plank (d p ) and checking of the samples were determined with destructive techniques from cross-cuts sawn from the planks. Latewood and pith % were determined from a straight line drawn on the cross-section radially normal to the flat side surface. Pith % was the length of the line including pith in relation to total length. Checks were detected with the naked eye, which is the standard procedure in TMT quality control. The numbers of checks in four categories were determined: length <5 mm, 5–10 mm, 10–20 mm and >20 mm. In addition, the total number of checks (NC) in a cross-section was determined.

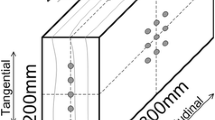

ACU measurements were made with two through transmission setups across the grain. The measurements with 100 kHz (nominal) transducers were taken from three points close to each other and with 380 kHz transducers from three locations, from the middle and from the edges of the plank (Fig. 1). The measurement system consisted of Olympus 5058PR high-voltage pulser-receiver (Olympus Corporation, Tokyo, Japan) and a PC with Compuscope 8380 digitiser (Gage Applied Technologies Inc. Lachine, Quebec, Canada). GMP transducers (Gas Matrix Piezoelectric) were used for the measurements: NCG100-D50-P150 (transmitter, focused), NCG100-S25 (receiver) and NCG500-D13 (The Ultran Group, State College, PA, USA). Several parameters describing the shape and the amplitude of the signal were determined: centroid time (Ct), centroid frequency (Cf), time to maximum amplitude (T_max), maximum amplitude in time domain (Maxamp), frequency of the maximum peak in frequency domain (Fmax), maximum amplitude in the frequency domain (Fmaxamp) and area of the signal in frequency domain (AF). The signals in frequency domain had two peaks, which were also analysed separately. Thus, the frequency of the maximum peak at lower/higher frequencies was determined (Fmax1/Fmax2) with the maximum amplitudes in frequency domain at lower/higher frequencies (Fmaxamp1/Fmaxamp2).

Electrical impedance measurements were taken in the longitudinal direction with plate electrodes at 2 kHz–1 MHz using Hioki 3531 Z HiTester (Hioki E. E. Corporation, Ueda, Japan), and 23 frequencies were measured in total. Open and closed loop calibrations were conducted before the measurements. The impedance measurements were conducted after the ultrasound measurements in the same conditions from the location indicated in Fig. 1. The measurement electrodes were put on the top of the plank, and a weight was placed on top of the electrodes in order to enhance the contact. The complex impedance response is \( Z = R\left( \omega \right) + jX\left( \omega \right) \), where j is the imaginary unit, ω is the angular frequency and R the resistance and X the reactance (Barsoukov and Macdonald 2005). The impedance modulus \( \left| Z \right| = \sqrt {R^{2} + X^{2} } \) and phase angle \( \phi = \tan^{ - 1} \left( \frac{X}{R} \right) \) were determined from the complex impedance response. The electrodes (40 × 50 mm2, 3 mm gap between) were coated with an approximately one micron thick amorphous diamond coating using the pulsed plasma arc discharge method (Lappalainen et al. 2003).

The statistical analyses were carried out with MATLAB R2010a (Mathworks, Natick, MA, USA). For the classification analyses, the samples were divided into two groups according to checking: checks <10 mm (N = 24) and checks >10 mm (N = 14). The characteristics and NDT response of the groups were compared with Mann–Whitney U test. In addition, a Bayesian classification model was constructed to evaluate the classification ability of the ACU measurement. The probability density functions were estimated by using kernel smoothing density estimate (John and Langley 1995), and the prior probabilities were estimated from the relative frequencies of the classes for checking. The model was validated using full cross-validation, because the sample number was limited. The partial least square (PLS) method was employed to analyse the ACU and EIS data with respect to the density of the TMT.

Results and discussion

The average values and range of the determined characteristics of the samples are presented in Table 1. The moisture content of the samples was very low, on average 2.5 %. Most of the samples included pith, but there were 14 samples without pith in the cross-sectional cut of the measured section. The correlations between the determined characteristics are shown in Table 2. For example, the following correlations were significant: NC/density, NC/pith and density/MC. Examples of plank cross-cuts are presented in Fig. 2. Most of the checks visible in the tested TMT were radial, but also tangential or mixed checks were present.

The slightly checked samples were compared to the severely checked counterparts. According to Mann–Whitney U test, there were significant differences between the groups in terms of density and wYR (Table 3). A nearly statistically significant difference was observed for the dp. In fact, if the cutoff of the two groups was changed towards lower checking, i.e. group with checks <5 mm was compared to others (N = 17/21), the difference between percentage of pith in the groups (Pith = 1.5/4.0 %, p = 0.007) and pith location (d p = 1.4/6.1 mm, p = 0.004) became highly significant. Pith in the cross-section of a timber has been previously identified as a factor for increased checking with both normal drying (Sandberg 2005) and thermal modification (Johansson 2006). The relation between density and checking can be explained by MC; MC of high-density timber is usually higher at the beginning of drying (e.g. Chafe 1985; Ilic 1999, 2001), which creates strong moisture gradients and stresses during drying and thus more checking.

Examples of ACU signals from clear and checked sample are presented in Fig. 3. The density correlated significantly with the centroid frequency (cf, r = 0.53, p < 0.001) and amplitude-related parameters of the 100 kHz ACU signal (Table 4). The same parameters also correlated significantly with the NC (e.g. r = 0.53, p < 0.001 for cf). There were also significant correlations between amplitude parameters and MC as well as with latewood content. Year ring and pith characteristics wYR, pith and d p did not correlate with the 100 kHz ACU parameters. Partial correlations were calculated to analyse the relationships in more detail as the density correlated with MC, earlywood, latewood and NC. When density was controlled, the NC was the only characteristic correlating with the 100 kHz ACU parameters. Similarly, the strength of the correlations between ACU 100 kHz parameters and density decreased when NC was controlled.

Samples without checking or with slight checking (<10 mm) were compared to those with more severe checking by Mann–Whitney U test (Table 5). In each ACU measurement, there were parameters that were significantly different for the compared groups. In the 100 kHz ACU measurement, Cf and the amplitude-related parameters Maxamp, Fmaxamp and AF were significantly different between the groups with p < 0.05 or p < 0.01.

Bayesian classification algorithm was used to distinguish the severely checked samples from the others by ACU measurement (Table 6). Full cross-validation was used for evaluating the quality of the model. With both ACU measurements, the correct classification rate (CCR) for the model was 97 and 84 % for the cross-validated model. Several ACU parameters were needed for efficient classification of the samples. ACU measurements at one frequency and from one direction also revealed clear potential for the classification of the samples. The cross-validated CCRs were very close to each other (76 % for 100 kHz and 74 % for 380 kHz). However, ultrasound in general cannot be used to detect defects oriented in the direction of ultrasound propagation, and therefore, measurements in several directions, such as the two perpendicular directions used in this study, are beneficial.

TMT characteristics were also correlated with EIS measurements (Table 7). Z correlated significantly with density and earlywood/latewood content, and the same properties correlated significantly with the ϕ at high frequencies. At certain frequencies, the phase angle correlated significantly with the numbers of checks.

Three PLS models for density were constructed: one using parameters from the ACU measurement at 100 kHz, one using EIS responses and one using both. The results are shown in Table 8 and Fig. 4. In the current study, the correlation between density and ultrasound amplitude was negative, which was probably affected by the positive correlation between NC and density. The investigation by examining partial correlation coefficients indicates that the relationship between density and ultrasound amplitude might not actually exist or it is weak. Due to the small MC variation in the sample set, there was no correlation between the MC and Z or phase angle, but the correlation between density and Z was significant throughout the frequency range. The r 2 (0.38) of the PLS model constructed with only EIS was higher than that of ACU PLS model. Wood properties have different effects on EIS and ACU, and thus, the methods were combined in the third PLS model. This approach increased the r 2 slightly to 0.43 with RMSEP 23 kg/m3. This result demonstrates the supplementary characteristics of EIS and ACU. It should be emphasised that in the current study, the original goal was not to determine the density, but to study the density as a cofactor in the ACU determination of checking. Measurement in the longitudinal rather than in the transverse direction would be advisable in the density determination. The classification result between severely checked samples and the others was not improved with the combination of ACU and EIS parameters as predictors compared with the ACU.

Both ACU measurements are non-contacting, and they could be developed into industrial online measurement applications. In the industrial measurement, 100 kHz would be a frequency that is more suitable because the attenuation at that frequency is lower, although the resolution is also lower. On the other hand, measurement at higher frequencies could be used for scanning the plank in the longitudinal direction and information about the start and end of an internal check could be used for example for making cutting decisions.

Conclusion

An effective detection method for internal checks in TMT was developed based on the ACU technique. The method requires measurements in two directions, and several parameters are determined from the ultrasound signals which are then subjected to statistical analyses. The method also holds potential for determination of internal checking in normally dried timber, and since it is a non-contacting technique, it is a feasible method for the use in quality control.

The ACU was primarily studied for classifying TMT according to the severity of checks. The checks included both surface and internal checks. The correct classification rates of 87 % and above were very promising, and the current study represents the basis for a large-scale study. Furthermore, it seems that EIS is not needed if the goal is to classify severely checked samples from the others. However, for the determination of checking and the density or earlywood/latewood content, a combination of EIS and ACU measurements is recommended.

References

Baar J, Tippner J, Gryc V (2012) The influence of wood density on longitudinal wave velocity determined by the ultrasound method in comparison to the resonance longitudinal method. Eur J Wood Prod 70:767–769

Barsoukov E, Macdonald JR (2005) Impedance spectroscopy—theory, experiment, and applications. Wiley, Hoboken

Bhandarkar SM, Luo X, Daniels R, Tollner EW (2005) Detection of cracks in computer tomography images of logs. Pattern Recognit Lett 26:2282–2294

Bhardwaj MC (2004a) High efficiency non-contact transducers and a very high coupling piezoelectric composite, 16th world conference on nondestructive testing, Aug 30th–Sept 3rd, Montreal, Canada

Bhardwaj MC (2004b) Evolution of piezoelectric transducers to full scale non-contact ultrasonic analysis mode, 16th world conference on nondestructive testing, Aug 30th–Sept 3rd, Montreal, Canada

Brännström M (2009) Integrated strength grading. Dissertation, Luleå University of Technology, LTU Skellefteå, Division of Wood Physics

Bucur V (2003) Nondestructive characterization and imaging of wood. Springer Verlag, Berlin

Bucur V (2010) Delamination detection in wood–based composites, a methodological review. Proceedings of 20th international congress on acoustics, ICA, Aug 23–27, Sydney, Australia, pp 1–8

Bucur V (2011) Delamination in wood, wood products and wood-based composites. Springer, Dordrecht

Bucur V, Chivers RC (1991) Acoustic properties and anisotropy of some Australian wood species. Acta Acustica 75:69–74

Chafe S (1985) The distribution and interrelationship of collapse, volumetric shrinkage, moisture content and density in trees of Eucalyptus regnans F Muell. Wood Sci Technol 19:329–345

de Oliveira FGR, Sales A (2006) Relationship between density and ultrasonic velocity in Brazilian tropical woods. Bioresour Technol 97:2443–2446

Fuller JJ, Ross RJ, Dramm JR (1994) Honeycomb and surface check detection using ultrasonic nondestructive evaluation FPL-RN–0261. Forest Products Laboratory, Madison

Gan TH, Hutchins DA, Green RJ, Andrews MK, Harris PD (2005) Noncontact, high-resolution ultrasonic imaging of wood samples using coded chirp waveforms. IEEE Int Ultrason Ferr 52:280–288

Hanhijärvi A, Ranta-Maunus A (2008) Development of strength grading of timber using combined measurement techniques. Report of the Combigrade project-phase 686, Espoo

Hasted JB (1973) Aqueous dielectrics. Chapman and Hall, London

Hilbers U, Neuenschwander J, Hasener J, Sanabria S, Niemz P, Thoemen H (2012a) Observation of interference effects in air-coupled ultrasonic inspection of wood-based panels. Wood Sci Technol 46:979–990

Hilbers U, Thoemen H, Hasener J, Fruehwald A (2012b) Effects of panel density and particle type on the ultrasonic transmission through wood-based panels. Wood Sci Technol 46:685–698

Ilic J (1999) Shrinkage-related degrade and its association with some physical properties in Eucalyptus regnans F Muell. Wood Sci Technol 33:425–437

Ilic J (2001) Variation of the dynamic elastic modulus and wave velocity in the fibre direction with other properties during the drying of Eucalyptus regnans F Muell. Wood Sci Technol 35:157–166

Ilic J (2003) Dynamic MOE of 55 species using small wood beams. Eur J Wood Prod 61:167–172

James WL (1975) Dielectric properties of wood and hardboard: variation with temperature, frequency, moisture content, and grain orientation. USDA For Serv Res Pap FPl USDA FPL-245. Forest products laboratory, Madison

Johansson D (2006) Influences of drying on internal checking of spruce (Picea abies L.) heat-treated at 212 °C. Holzforschung 60:558–560

Johansson D (2008) Heat treatment of solid wood - effects of absorption, strength and colour. Dissertation, Luleå University of Technology, LTU Skellefteå, Division of Wood Physics

John GH, Langley P (1995) Estimating continuous distributions in Bayesian classifiers, UAI’95 Proceedings of the eleventh conference on uncertainty in artificial intelligence, 338–345. Morgan Kaufmann Publishers Inc., San Francisco

Lappalainen R, Selenius M, Anttila A, Konttinen YT, Santavirta SS (2003) Reduction of wear in total hip replacement prostheses by amorphous diamond coatings. J Biomed Mater Res B Appl Biomater 66:410–413

Lin RT (1967) Review of the electrical properties of wood and cellulose. For Prod J 17:54–61

Marchetti B, Munaretto R, Revel G, Tomasini EP, Bianche VB (2004) Non-contact ultrasonic sensor for density measurement and defect detection on wood, 16th world conference on nondestructive testing, Aug 30–Sept 3, Montreal, Canada

Pastorino M, Salvade A, Monleone R, Bartesaghi T, Bozza G, Randazzo A (2007) Detection of defects in wood slabs by using a microwave imaging technique, instrumentation and measurement technology conference proceedings, 2007, IMTC 2007. IEEE, May 1–3, Warsaw, Poland, pp 1–6

Pellerin Roy F, Ross RJ (eds) (2002) Nondestructive evaluation of wood. Forest Products Society, Madison

Sanabria S (2012) Air-coupled ultrasound propagation and novel non-destructive bonding quality assessment of timber composites. Dissertation, Swiss Federal Institute of Technology Zürich, Institute for Building Materials

Sanabria SJ, Furrer R, Neuenschwander J, Niemz P, Sennhauser U (2013) Novel slanted incidence air-coupled ultrasound method for delamination assessment in individual bonding planes of structural multi-layered glued timber laminates. Ultrasonics 53:1309–1324

Sandberg D (2005) Distortion and visible crack formation in green and seasoned timber: influence of annual ring orientation in the cross section. Holz Roh Werkst 63:11–18

Schafer ME (1999) Development of ultrasound-based scanning for wetwood and honeycomb detection in hardwood lumber. In: Szymani R (ed) Scanning technology and process optimization—advances in wood industry, 1st edn. Miller Freeman Books, San Francisco, pp 160–167

Schafer ME (2000) Ultrasound for defect detection and grading in wood and lumber, ultrasonics symposium, 2000 IEEE, October 22–25. San Juan, Puerto Rico, pp 771–778

Tiitta M, Tomppo L, Lappalainen R (2010) Combined acoustic and electric method for monitoring wood drying process: a review. Wood Mater Sci Eng 5:78–83

Tiuri M, Jokela K, Heikkilä S (1980) Microwave instrument for accurate moisture and density measurement of timber. J Microw Power Electromagn Energy 15:251–254

Torgovnikov GI (1993) Dielectric properties of wood and wood-based materials. Springer-Verlag, Berlin

van der Beek J, Tiitta M, Tomppo L, Lappalainen R (2011) Moisture content determination of thermally modified timber by electrical and ultrasound methods. Int Wood Prod J 2:60–66

Verkasalo E, Ross RJ, TenWolde A, Youngs RL (1993) Properties related to drying defects in red oak wetwood Res. Pap. FPL-RP-516. Forest products laboratory, Madison

Vun RY, Hoover K, Janowiak J, Bhardwaj M (2008) Calibration of non-contact ultrasound as an online sensor for wood characterization: effects of temperature, moisture, and scanning direction. Appl Phys A 90:191–196

Acknowledgments

We would like to thank Mr. Jelle van der Beek and Mr. Sauli Vesamo for their help in the experimental part of the study. We also thank Mr. Mauno Multamäki for preparing the samples for destructive analysis. The study was funded by the European Regional Development Fund (ERDF) and the Finnish Funding Agency for Technology and Innovation (TEKES).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tomppo, L., Tiitta, M. & Lappalainen, R. Non-destructive evaluation of checking in thermally modified timber. Wood Sci Technol 48, 227–238 (2014). https://doi.org/10.1007/s00226-013-0603-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-013-0603-2