Abstract

Wood samples of nine tropical hardwoods from Peru and sugar maple wood from Quebec were selected to perform moisture sorption tests associated with parallel-to-grain and tangential compression tests using a multiple step procedure at 25°C. Cold-water and hot-water extractives, sequential cyclohexane (CYC), acetone (ACE) and methanol (MET) extracts, ash content (ASH), wood density and interlocked grain (IG) were evaluated on matched samples too. Wood density corrected for the accessory substances was by far the major factor positively affecting the compressive properties of tropical hardwoods. The total amount of accessory substances is required in order to establish better relationships between physico–mechanical properties and density of tropical hardwoods. For a given wood density, the ultimate stress in parallel-to-grain compression was higher in tropical hardwoods than in temperate hardwoods. However, the compliance coefficients for both types of woods were quite similar. Sequential extraction with organic solvents was the most suitable method for evaluating the effect of extractives on compressive properties of tropical hardwoods. The CYC and ACE fractions did not contribute to variation in these mechanical properties. The substances dissolved in MET affected positively the compliance coefficient s 11 in parallel-to-grain compression and negatively the compliance coefficient s 33 in tangential compression. The IG decreased the compliance coefficient s 11 but also decreased the ultimate stress in parallel-to-grain compression. Finally, variations in compressive properties that were due to changes in equilibrium moisture content (EMC) were clearly influenced by wood density; denser woods were more sensitive to changes in EMC than lighter woods.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Accessory substances in wood can influence its mechanical behaviour in two ways: by acting as an inert mass in relation to the cell wall matrix structure, or by affecting its hygroscopicity and swelling. Petterson and Bodig (1983) noted the potential importance of these substances when studying the parameters of rupture in wood.

Some controversy has existed in the literature concerning the influence that accessory substances exert on the mechanical behaviour of wood. During his pioneering studies on unextracted and extracted woods, Luxford (1931) showed that extractives helped to reinforce wood structure. The parallel-to-grain compression strength and the modulus of rupture (MOR) in static bending increased more than did the shock resistance in the presence of extractives. Conversely, Arganbright (1971) found that extractives did not affect MOR of redwood (Sequoia sempervirens), while the modulus of elasticity (MOE) decreased as the amount of extractives increased. Narayanamurti and Verma (1964) also observed that the dynamic MOE of two tropical hardwoods decreased after an extraction treatment. Similar results were found for Japanese larch (Larix leptolepis), where Kubo and Kaburagi (1973) reported a 20% decrease in MOE after cold-water (CW) extraction.

Badran and El-Osta (1977) found no effect of extractives on parallel-to-grain compression strength of wood, but they attributed this finding to the strong variability among their results. El-Osta et al. (1981) evaluated the influence of wood density, extractives and lignin contents on the same property in three tropical woods. Extractives and density explained up to 44% of the total variation in the ultimate crushing stress of African mahogany (Khaya grandifoliola); increases in both components had a positive effect on crushing stress. However, compressive properties of teak (Tectona grandis) and vuba (Isoberlinia doka) woods were apparently unaffected by the presence or absence of extractives.

Mineral nutrients that are distributed throughout wood may influence its compressive properties. For example, the ASH of six African hardwoods was evaluated by Ahonkhai and Nwokoro (1987), but these compounds appeared to be randomly distributed in the wood tissue and cannot directly affect wood strength. However, because a positive relationship was observed between calcium content and wood density, the authors suggested an indirect effect of ash on mechanical properties.

The importance that extractives and their distribution could have on the mechanical behaviour of wood was outlined by Kellogg and Ifju (1962). They claimed, but could not conclusively state that the effect of extractives would be positive or negative, depending on the mechanical property under consideration, and depending on the location of extractives in the wood structure. Wood extractives in situ behave as a complex material; thus, an approach that characterizes wood extractives from material matched to unextracted mechanical samples should be considered. A study that includes several wood species and focuses on the location and distribution of these substances within wood would be useful. This would contribute to a better understanding of the effect of these substances on mechanical properties of wood.

Interlocked grain (IG) is another feature peculiar to many tropical trees. This grain pattern is formed by the cells of successive growth layers alternately aligned in clockwise and anticlockwise spirals (Weddell 1961). These changes both in direction and angle of spirals occur between growth increments as well as within a single growth increment. IG is responsible for many problems during wood manufacturing, but this grain pattern also shows up as a ribbon figure in quarter-sawn lumber and quarter-sliced veneer, which is particularly attractive for several end-uses of wood.

The influence of the IG on wood strength has long been recognized, but with the increasing use of tropical hardwoods more information is needed. The effect that this feature exerts on the physical and mechanical properties of wood is not well understood. Weddell (1961) reported that the MOR and MOE in bending were negatively affected by the presence of IG in utile (Entandrophragma utile) and greenheart (Ocotea rodiaei) woods. This grain pattern also decreases the impact bending strength of white meranti (Shorea spp.) wood (Marsoem and Kikata 1987) and the shear strength of ishpingo (Amburana cearensis), pumaquiro (Aspidosperma macrocarpon) and tulpay (Clarisia racemosa) woods (Hernández and Almeida 2003). For this global study, it was judged important to assess the effect of IG on the compressive properties of tropical hardwoods.

The objective of this study was to evaluate the effects of accessory substances, wood density and IG on the compressive properties of nine tropical hardwoods in addition to sugar maple wood. Compressive properties were evaluated with unextracted samples under five moisture conditions, which were obtained during the first full sorption cycle at 25°C. Matched material was used for IG measurements and chemical analyses. Several extraction procedures were performed to ascertain the location and distribution of extractives within wood.

Materials and methods

This paper is part of an extensive study concerning the effects of accessory substances, wood density and IG on physical and mechanical properties of hardwoods. The experiment reported here consisted of moisture sorption tests associated with mechanical tests. Unextracted wood samples were mechanically tested as soon as the desired equilibrium moisture content (EMC) was reached. Matched material coming from the same board was used to determine the IG and the proportion of accessory substances. Results of the IG and of the individual chemical analyses obtained for each board were assigned to each one of the physico–mechanical specimens prepared from the same board. Chemical analyses included CW and hot-water (HW) extractions, sequential extractions with cyclohexane (CYC), acetone (ACE) and methanol (MET), as well as determination of ash content (ASH). According to Morgan and Orsler (1969), the first solvent must remove cell cavity material and the latter two, mainly cell wall constituents. Detailed descriptions of the experiments are given in Hernández (2006a).

The experiments were carried out with nine Peruvian tropical hardwoods: caoba or mahogany (Swietenia sp.), cedro (Cedrela sp.), ishpingo negro (Amburana cearensis A.C. Smith), pumaquiro (Aspidosperma macrocarpon Mart.), copaiba (Copaifera sp.), palisangre negro (Pterocarpus sp.), estoraque (Myroxylon sp.), tahuarí (Tabebuia serratifolia Nichols) and palosangre (Brosimum sp.), as well as with sugar maple wood (Acer saccharum Marsh.).

Ten flatsawn boards were selected per species and stored at 20°C and 60% RH until EMC was reached. After conditioning, the boards were cut according to a pattern that yielded at least five parallel samples and three tangential samples. These matched samples were used to determine the EMC, the parallel-to-grain and perpendicular-to-grain tangential compression strength, swelling and oven-dry density. Five moisture sorption conditions were studied with the parallel samples. Three of these were repeated with the tangential samples (Table 1). The longitudinal matching yielded eight comparable groups of 100 samples each, with every species represented by ten samples. The test material was all heartwood, except for sugar maple, which was sapwood.

Dimensions of samples for mechanical tests differed from those recommended by the ASTM D143-94. Matching techniques used and moisture sorption tests were limiting factors in determining these dimensions. For the parallel-to-grain compression test, a length-to-width ratio of four was used to preclude buckling during the test (Bodig and Jayne 1982). For the pure perpendicular-to-grain tangential compression test, a ratio of three was used to limit the curvature of growth rings. Both types of samples had cross sections of 20 × 20 mm2.

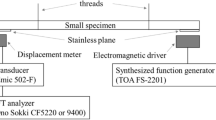

Wood samples were mechanically tested as soon as the desired EMC was reached. As soon as each point of sorption was completed, mechanical tests were carried out on an Olsen machine (parallel-to-grain compression) or a Riehle machine (perpendicular-to-grain tangential compression). For the parallel-to-grain compression test, strain was measured over a span of 50 mm in the central section of the specimen, using a two-side clip gauge provided with a Sangamo DG 1.0 linear displacement sensor. This same clip gauge was used to measure the strain for the tangential compression test, but the span was adjusted to 40 mm. In all cases, hygrothermal changes during the mechanical test were controlled by wrapping the specimen in cotton, which had been previously conditioned above a corresponding saturated salt solution. As per Sliker (1978), the cross-head speed was adjusted in order to ensure a similar strain rate for all species. In the elastic range, these strain rates were of 0.15 mm mm−1 min−1 for the parallel specimen and of 0.40 mm mm−1 min−1 for the tangential sample.

The test results were used to calculate the compliance coefficient in the longitudinal direction s 11 of the wood. Young’s modulus in the same direction is the reciprocal of this parameter. The maximum load at failure and cross-sectional area of the sample yielded the ultimate crushing stress in the longitudinal direction (σ Lu). Lastly, the transverse compression test yielded the compliance coefficient in the tangential direction, s 33.

Exploratory analysis

Multiple regression models were developed for compressive properties after first identifying sources of collinearity in the data sets. As one precautionary measure, a new wood density corrected for the accessory substances (D oc) was used instead of the oven-dry wood density (D o), and was defined as follows:

where M oc denotes the oven-dry mass without accessory substances, V o is the oven-dry volume, M o is the overall oven-dry mass and e is ASH plus extractives soluble in organic solvents (TOT) (i.e. ASH + TOT). Five different multiple regression models were applied using a stepwise technique, as described by Hernández (2006a). Four common independent variables were included in each regression: corrected oven-dry density (D oc), ASH, the maximum angular deviation of the IG and EMC. The other independent variables were:

-

model 1: substances soluble in CW,

-

model 2: extractives soluble in CW, and substances soluble in HW minus those soluble in CW (HW-CW),

-

model 3: substances soluble in HW,

-

model 4: extractives soluble in a sequence of CYC, ACE and MET,

-

model 5: extractives soluble in the organic solvents when taken together (TOT).

Results and discussion

Accessory substances and IG properties were quite variable within- and among species and are presented elsewhere (Hernández 2006a). CW extractives ranged from 1.6% in both sugar maple and cedro to 13.2% in copaiba. Concentrations of HW extractives were 1.3–2.5 times higher than those of CW extractives, and ranged from 2.8% in sugar maple to 17.9% in ishpingo negro. Organic solvent-soluble extractives (TOT) were even higher and ranged from 2.2 (sugar maple) to 23.6% (ishpingo negro). The inorganic fraction (ASH) was a minor constituent in all samples, ranging from 0.01% in pumaquiro to 0.97% in copaiba. IG was absent in sugar maple, but ranged from 3° in caoba to 20° in pumaquiro.

Means and coefficients of variation of compressive properties for all hardwoods and moisture sorption conditions are shown in Table 1. Means were calculated from ten replicate samples. For a given RH, EMC varied among the different hardwoods due to the presence of variable amounts of extractives in the wood (Hernández 2006a). For this reason, direct comparisons between compressive property values are not possible, except for those obtained in the saturated state. In this case, the compliance coefficient s 11 ranged from 37.8 TPa−1 for tahuarí to 115.6 TPa−1 for caoba, and the ultimate crushing stress in the longitudinal direction (σ Lu) ranged from 23.6 MPa for sugar maple to 70.6 MPa for estoraque. The compliance coefficient in the tangential direction, s 33, ranged from 0.72 GPa−1 for palosangre to 3.14 GPa−1 for caoba. This confirms the wide variation in compressive properties currently observed in tropical hardwoods. As discussed later, this variation is principally due to the wide range of wood densities covered in this study. In fact, the oven-dry density ranged from 0.46 t m−3 for caoba to 0.91 t m−3 for palosangre.

Wood species played an important role in the precision obtained during measurements. Greater variability in compressive properties was generally associated with copaiba, ishpingo negro and palosangre. These species exhibited the highest concentrations of extractives (Hernández 2006a). Species as sugar maple and tahuarí, which contained lower amounts of wood extractives, exhibited the lowest variation in their compressive properties.

The compressive properties of caoba in the tangential direction (Table 1) were highly variable, even though the extractives content of this species was not very high (Hernández 2006a). However, anatomical analysis showed that caoba wood presented two groups of samples having different structure. Five samples presented storied rays, which were 3–4 cells wide, and had a mean oven-dry density of 0.49 t m−3. Five other samples exhibited unstoried but larger and more abundant rays and, as a result, had a mean oven-dry density of 0.44 t m−3. The presence of these two groups significantly affected the means of tangential compliance coefficient s 33.

The ultimate stress in parallel-to-grain compression σ Lu was evaluated with greater precision than the corresponding compliance coefficient s 11. The better stability of rupture values compared to the stiffness values is similar to results reported in tangential tension by Goulet and Hernández (1991) for sugar maple. Lastly, the compliance coefficients s 33 and s 11 were evaluated with a similar precision.

Exploratory analysis

The results of the exploratory analysis in terms of coefficients of determination (R 2) and CV for the five models studied are summarized in Table 2. The CV is useful for evaluating a regression for predictive purposes; a value lower than 15% is normally acceptable. All models used to explain variation in compressive properties were statistically significant at the 0.01 probability level. It was previously reported that EMC was very sensitive to the different models of regression (Hernández 2006a). Model 4, which included the substances soluble in organic solvents taken separately, explained best the variation in compressive properties of tropical hardwoods studied. Model 5, which takes the same extractives together, gave generally similar results. The mechanical properties studied here are less sensitive than EMC to the different models but show the same trends. The tangential compliance coefficient s 11 was the most sensitive to model choice while the ultimate stress in parallel-to-grain compression was the least sensitive (Table 2).

Therefore, only model 4 will be considered in the following discussion. It is clear that a study of this kind for tropical hardwoods based on extractions using either CW or HW as solvents would not give such good results. The results show that mechanical properties are affected by the presence of wood extractives.

Compressive properties of wood

Compliance coefficient s 11

Results of the multiple regression analysis for the compliance coefficient s 11 in parallel compression are given in Table 3. Only statistically significant variables at the 0.10 probability level were included in the summary. The relative importance of each independent variable in explaining variation in s 11 was evaluated by converting the regression coefficients to standardized beta values. These coefficients were calculated for each individual regression, and therefore, they are not comparable from one moisture sorption condition to another. On the other hand, the order of importance of each variable was verified by systematic elimination of the more influential points of measurement, which were chosen from Cook’s distances, as proposed by Draper and Smith (1981).

The regression models explained 80–85% of the variation in s 11. The four most important independent variables of the models were the corrected oven-dry density, ASH, IG and the MET fraction (Table 2).

Corrected oven-dry wood density was by far the major factor controlling s 11 variation. The beta coefficients show that the effect of wood density accounted for about 60% of the s 11 variation explained by regression (all equations pooled). The greater the content of cell wall substance for a given volume, the greater was the stiffness of the wood. Simple linear regressions between s 11 and corrected oven-dry wood density showed that this latter factor alone explained 75–82% of the variation in s 11 (not shown). The effect of corrected oven-dry density on s 11 for adsorption conditions over 76% RH is shown in Fig. 1.

Ash content explained very little of the in the compliance coefficient s 11. The location of these mineral substances in wood tissue, particularly in parenchyma cells, would contribute to increased wood strength parallel to the grain. IG plays a similar role to that of ASH in relation to dampening parallel stresses. The alternating orientation of different layers would produce, by compensation, a decrease in the strain under stress, as occurs in plywood. For this same reason, longitudinal swelling was also observed to decrease as IG increases (not shown).

In contrast, substances soluble in MET had a significant negative effect on stiffness under parallel compression conditions. Such substances also decrease the tangential swelling of the hardwoods studied (Hernández 2006b). It is possible that the blockage in tangential direction resists poorly to a parallel compression stress, which would increase the strain rate for this type of stress. However, this hypothesis must be confirmed by means of an analysis of the Poisson coefficients.

Ultimate stress in parallel-to-grain compression σ Lu

Ultimate stress in parallel-to-grain compression σ Lu was the mechanical property evaluated with greater precision in this study (Table 1). This allowed to note that the behaviour of this mechanical property differed greatly between sugar maple and the tropical hardwoods. A comparison extended to include other temperate zone species (Fig. 2) demonstrated that tropical hardwoods offer greater parallel-to-grain compression strength for the same wood density. Similar basic conclusions were previously reached by Clarke (1937), but the present study showed that σ Lu was 20–50% lower in sugar maple than in tropical hardwoods having the same density. The greater difference was found at the saturated state, given that the fibre saturation points (FSP) of tropical hardwoods were lower than those of sugar maple wood (Hernández 2006a). Because the compliance coefficients for these two groups of species are similar, the ratio between the MOE and ultimate stress would be lower for tropical woods compared to temperate woods. Therefore, the determination of this ratio specifically for tropical hardwoods is required when rupture behaviour of wood is inferred from compliance coefficients, which is frequently the case in wood engineering (Keenan and Tejada 1987).

Relationship between the ultimate stress in parallel-to-grain compression at the saturated state and oven-dry density. Comparison among values of temperate zone woods (Jessome 1977) and those obtained in the present study

As a result, values of sugar maple wood were not included in the analysis exploring σ Lu variation through multiple regressions. Regression coefficients summarized in Table 4 are an improvement compared with those initially presented in Table 2, which included all wood species. They also were better than those obtained for the compliance coefficient s 11, which was estimated in the same mechanical test (Table 3). It should be noted that the estimates tended to be better at lower moisture contents than close to the fibre saturation state.

As for s 11, this analysis shows that cell wall substance estimated from the corrected oven-dry wood density (D oc) was by far the most important parameter for controlling variation in ultimate stress in the parallel direction. Simple linear regressions showed that wood density alone explains 93–96% of the variation in σ Lu (not shown). As an example, the relationship between corrected oven-dry density and σ Lu for desorption over 33% RH is depicted in Fig. 3. Sugar maple values were excluded from the analysis, but they are shown in the graph in order to show its atypical behaviour.

The remaining variation in σ Lu that was explained by the multiple regression equations was ascribed to EMC and IG. Both variables have a negative effect on variation in σ Lu. The direct influence of wood extractives on this property is negligible, but it is necessary to account for the indirect effects of these substances on σ Lu given their negative effect on EMC. Hence, analysis of variation in EMC showed that contributions of the independent variables were a function of RH (Hernández 2006a). As with EMC variation, the influence of wood density on σ Lu decreases as RH increases, at the expense of EMC and IG (Table 4). The behaviour of σ Lu is shown in Fig. 4, which compares corrected oven-dry density versus σ Lu using simple linear regressions for each of the five moisture sorption conditions. It is apparent that the fitted straight lines diverged as wood density increases, which meant that denser woods are more sensitive to changes in EMC than lighter woods. Analogous results are presented in Table 3 for the parallel compliance coefficient s 11. Similar behaviours have been reported by Kretschmann and Green (1996) for southern pine and by Matan and Kyokong (2003) for rubber wood with respect to parallel-to-grain compression.

Unextracted or raw wood density has been used as the sole criterion for grouping woods for structural and engineering purposes. For example, 104 Amazonian woods were classified under the Andean Pact using this criterion (Keenan and Tejada 1987). This approach for classification appears inadequate since tropical hardwoods frequently contain variable and substantial amounts of accessory substances. Given that these substances can have small, but important effects on mechanical strength parallel to the grain, correction of raw wood density for accessory substances is therefore required. The results of this study have shown that evaluation of accessory substances content is just as important as wood density measurements for engineering applications.

Compliance coefficient in the tangential direction s 33

The compliance coefficient s 33 that was obtained in tangential compression was studied under three moisture sorptions (Table 1). The second group of caoba samples, which had an unstoried tissue structure, was excluded from the analysis because their values deviated from the other results for a variety of unknown reasons. The results of the multiple regression analyses are given in Table 5. The regressions were more precise than those obtained in the exploratory analysis (Table 2).

Corrected oven-dry wood density was principally responsible for variation in s 33. The beta coefficients show that density accounted for about 52% of the variation explained by multiple regressions (all regressions pooled). This contribution is slightly lower than that of 60% established for parallel-to-grain stiffness (Table 3), and likely due to the contrasting effects that the MET fraction and the ASH exert on both compliance coefficients. The effect of ash on the tangential compliance coefficient is probably related to its influence on swelling behaviour (Hernández 2006b). However, additional work is needed to better understand the influence of ash on these properties.

Simple linear regressions were also calculated between s 33 and corrected oven-dry density. This latter factor alone explained 64–73% of the variation in s 33 (not shown). The relationship between the median compliance coefficient s 33 and corrected oven-dry density for desorption over 58% RH is depicted in Fig. 5. For comparative purposes, results from caoba specimens that have unstoried tissue structure, and which were excluded from the regression analysis, were plotted in the figure. The effect of wood density on compliance coefficient appears to be a function of MC, as shown from analysis of the simple and multiple regression coefficients associated with wood density. Simple and multiple regression coefficients for corrected oven-dry density were similar for 58% RH (desorption) and 76% RH (adsorption), but lower under the saturated state (≈100% RH). Analogous results have been reported by Siimes (1967) for three Finnish species with respect to perpendicular-to-grain compression strength, and by Goulet and Hernández (1991) for sugar maple wood in its stiffness and strength under tangential tension. It is therefore confirmed that changes in compressive properties due to changes in EMC increase with wood density; and this occurs in tangential direction and in parallel direction.

Conclusions and recommendations

-

1.

There was high variation in compressive properties within and among wood species.

-

2.

Compressive properties were principally related to the ligno-cellulosic structure of wood; wood density corrected for accessory substances was by far the major factor positively affecting the compressive properties of tropical hardwoods. Evaluation of the total amount of accessory substances is required in order to establish better relationships between physico–mechanical properties and density of tropical hardwoods.

-

3.

For a given wood density, ultimate stress in parallel-to-grain compression σ Lu was higher in tropical hardwoods than in temperate hardwoods. The greater difference was found at the saturated state. Given that compliance coefficients for both types of woods were quite similar, the MOE/Ultimate stress ratio used for wood engineering purposes needs to be specifically established for tropical hardwoods.

-

4.

The sequential extraction with organic solvents was the most suitable method for evaluating the effect of extractives on compressive properties of tropical hardwoods.

-

5.

The CYC and ACE fractions of wood extractives did not contribute to variation in compressive properties of tropical hardwoods.

-

6.

The substances dissolved in MET positively affected the compliance coefficient s 11 under parallel-to-grain compression and negatively affected the compliance coefficient s 33 under tangential compression.

-

7.

Interlocked grain decreased the compliance coefficient s 11, but also decreased the ultimate stress in parallel-to-grain compression.

-

8.

Variation in compressive properties that were due to changes in EMC was clearly influenced by wood density. Denser woods were more sensitive to changes in EMC than lighter woods. The corrected wood density must be considered in models used to adjust the mechanical properties of wood as a function of its EMC.

References

Ahonkhai SI, Nwokoro WI (1987) Chemical characterization of the ashes of some African hardwoods. Wood Sci Technol 21(3):257–260

ASTM Standard (2000) D143-94, Standard test methods for small clear specimens of timber

Arganbright DG (1971) Influence of extractives on bending strength of redwood (Sequoia sempervirens). Wood Fiber 2(4):367–372

Badran OA, El-Osta MLM (1977) Influence of specific gravity and extractive content on maximum crushing strength of wood. Alexandria J Agric Res 25(3):541–548

Bodig J, Jayne BA (1982) Mechanics of wood and wood composites. Van Nostrand Reinhold, New York

Clarke SH (1937) Comparison of certain properties of temperate and tropical timbers. Trop Woods 52:1–11

Draper NR, Smith H (1981) Applied regression analysis. Wiley, New York

El-Osta MLM, Badran OA, Ajoung E-MA (1981) Crushing strength of three Sudanese tropical hardwoods in relation to specific gravity, extractive and lignin contents. Wood Sci 13(4):225–232

Goulet M, Hernández RE (1991) Influence of moisture sorption on the strength of sugar maple wood in tangential tension. Wood Fiber Sci 23(2):197–206

Hernández RE (2006a) Moisture sorption properties of hardwoods as affected by their extraneous substances, wood density and interlocked grain. Wood Fiber Sci (in press)

Hernández RE (2006b) Swelling properties of hardwoods as affected by their extraneous substances, wood density and interlocked grain. Wood Fiber Sci (in press)

Hernández RE, Almeida G (2003) Effects of wood density and interlocked grain on the shear strength of three Amazonian tropical hardwoods. Wood Fiber Sci 35(2):154–166

Jessome AP (1977) Résistance et propriétés connexes des bois indigènes au Canada. Laboratoire des Produits Forestiers de l’Est, OT, Rapport Technique de Foresterie 21, 37pp

Keenan FJ, Tejada M (1987) Maderas tropicales como material de construcción en los países del Grupo Andino de América del Sur. Centre de recherche pour le développement international, publication IDRC-TS 49s, OT, Canada

Kellogg RM, Ifju G (1962) Influence of specific gravity and certain other factors on the tensile properties of wood. Forest Prod J 12(10):463–470

Kretschmann DE, Green DW (1996) Modeling moisture content-mechanical property relationships for clear southern pine. Wood Fiber Sci 28(3):320–337

Kubo T, Kaburagi J (1973) Basic studies on wood properties in Japanese larch (Larix leptolepis Gordan). I. The distribution of water-soluble extractives and the relationship between extractives and wood properties in Japanese larch. Bull Exp Forest Tokyo Univ Agric Technol 10:108–115

Luxford RF (1931) Effect of extractives on the strength of wood. J Agric Res 42(12):801–826

Marsoem N, Kikata Y (1987) The effect of interlocked grain on the mechanical properties of white meranti. Bull Nagoya Univ For 9:51–77

Matan N, Kyokong B (2003) Effect of moisture content on some physical and mechanical properties of juvenile rubberwood (Hevea brasiliensis Muell. Arg.). Songklanakarin J Sci Technol 25(3):327–340

Morgan JWW, Orsler RJ (1969) The interaction of wood with organic solvents. Part II. Its significance for extractive location. Holzforschung 23(2):48–51

Narayanamurti D, Verma GM (1964) Role of wood extractives on the rheological properties of wood. Holzforsch Holzverwert 16(3):51–55

Petterson RW, Bodig J (1983) Prediction of fracture toughness of conifers. Wood Fiber Sci 15(4):302–316

Siimes FE (1967) The effect of specific gravity, moisture content, temperature and heating time on the tension and compression strength and elasticity properties perpendicular to the grain of finnish pine, spruce and birch wood and the significance of these factors on the checking of timber at kiln drying. State Inst Tech Res, Publ 84, Helsinki, Finland

Sliker A (1978) Strain as a function of stress, stress rate, and time at 90° to the grain in sugar pine. Wood Sci 10(4):208–219

Weddell E (1961) Influence of interlocked grain on the bending strength of timber, with particular reference to utile and greenheart. J Inst Wood Sci 7:56–72

Acknowledgment

This research was supported by the Natural Sciences and Engineering Research Council of Canada.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hernández, R.E. Influence of accessory substances, wood density and interlocked grain on the compressive properties of hardwoods. Wood Sci Technol 41, 249–265 (2007). https://doi.org/10.1007/s00226-006-0114-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-006-0114-5