Abstract

Our study focuses on predicting the ultimate short-term load carrying capacity of timber-to-timber connections with dowel-type fasteners. The wide range of possible configurations in practice makes the resolution of these values by tests unrealistic. Moreover, different current regulations do not consider some specific failure mechanisms. In many countries, the reduction of resistance involved by this phenomenon is taken into account by considering an effective number of dowels (nef) smaller than the actual number of dowels (n) in the connection. However, these different regulations disagree on the values of nef and on other points (spacing, partial coefficient of security, formulas). These discrepancies in design rules invite the fundamental research on this topic and, therefore, new methods are sought in order to estimate the load carrying capacities of the connections. In the light of these, our approach consists of predicting the load carrying capacity with the neural network numerical tool. The results obtained by this analysis tool are satisfactory, although the model remains complex. Subsequently, we focus on the simplification of this numerical model with classical regression techniques in order to implement it in a design code.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Connections in timber structures often determine the load carrying capacity of the whole structure. As a result of the complexity of designing connections, the thesis prepared in conjunction with LRBB and CTBA only deals with the short-term load carrying capacity, in double shear, under static loading, of single- and multiple-doweled-type timber-to-timber connections. Our approach consists of modeling the load carrying capacity with the neural network numerical tool. The first step when using the neural networks consists of creating a database related to our study as an input for the network.

2 Creation of a database

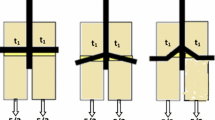

We reviewed several test results and gathered the common parameters (cf. Fig. 1) which were available from the literature (Jorissen 1998; Vermeyden 1980; Vincent 1988; Wilkinson 1986) in a database.

Studied configurations. The main parameters of the database are: the mean density of wood (kg/m3): ρ; the angle between the loading direction and the grain direction (rad): α; the dowel diameter (mm): d; the thickness of connected elements (mm): t1, t2; the number of dowel rows: m; the number of bolts in a row: n; the different spacings in the connections (mm): a1, a2, a3, a4; the characteristic tensile strength of the metallic dowel (MPa): f u

The spacings a1 and a2 in Fig. 1 are taken to be equal to zero when the number of rows and/or the number of bolts in a row are equal to one, respectively. The wood species are mainly spruce and pine. Using this approach, we listed 1368 configurations of connections with the corresponding ultimate values of the load carrying capacity (Cointe and Rouger 2001; Cointe 2003). Figure 2 shows a summary of the parametric variability of connections.

It can be seen that there are many gaps in this database. We thus appeal to authors who work on this topic to fill in these gaps and help improve the homogeneity of the database and the strength of the model given by the neural network.

3 Design approach

Many approaches have been developed since Johansen proposed the Yield Theory in 1949. The past fifty years have seen elastic analyses (Wilkinson 1986), a coupling between the Yield Theory and Fracture Mechanics (Jorissen 1998) and elasto-plastic analyses being developed. Nevertheless, there is no actual convergence between these approaches. Moreover, if the design codes are considered (CSA 086.1-94 1994; LRFD 1991; prEN 1995-1-1 2002), more discrepancies can be found. These design rules agree with the Yield Theory formulation for only one dowel in the connection, but disagree when the number of dowels increases. The load carrying capacity of a connection with several dowels is smaller than the same connection with only one dowel multiplied by the number of dowels (group effect). It is, therefore, a widespread practice to take into account an effective number (nef) smaller than the actual number (n) of dowels in the connection. In his thesis, Jorissen illustrated the differences on nef between the three design codes (CSA, LRFD, Eurocode 5). The comparison of Jorissen was modified with new values of nef for Eurocode 5, as can be seen in Fig. 3.

Moreover, the differences between the standards on the minimum spacing in a connection to abide by, in order to avoid brittle failures on the determination of the embedment strength of the wood fh, on the formulation of the unitary strength and on the coefficients considering the number of dowel rows (m) can also be found. Because of the lack of equations rendering specific mechanisms, the design rules do not explain well the cases when brittle failures occur in the connection, even if the design measures are satisfied. These differences using the whole database are shown in Fig. 4.

It is important to note that the values shown in Fig. 4 take into account the geometric data, but it does not represent the final design values. The modification factors for the duration of loading, the environmental conditions (temperature, humidity) and the partial coefficients of security on materials properties are disregarded to compare the mean values. The considerations for minimum spacing are not necessarily respected in order to make the comparison as large as possible. Finally, the Canadian design code appears to be too conservative because the load carrying capacities shown are the characteristic values and not the average ones.

4 Modelling by neural networks

4.1 Justification

In order to predict more accurately the load carrying capacity of connections, the neural network approach implemented by a commercially available software package (Matlab) was used. The justification for this approach is that the determination of the load carrying capacity from tests is quite impossible, the regulations in use are not uniform, and neural networks present interesting properties. Neural networks are defined as universal approximators: if an approximation with a given precision is needed, the neural networks will use less adjustable parameters than the other common approximators like polynomials, or developments in Fourier series. Neural networks represent a quick way to approximate non-linear functions, and are less noise sensitive to input data than the other methods. Moreover, the direct switch from input data to predictors does not necessitate formulation of any hypothesis on the model.

4.2 Principle of functioning

There are different types of neural networks and their area of application varies according to their topology. Among these, the networks with layers of neurons that are mainly used to solve problems relating to modelling, classification, or function approximation are common. This kind of structure was implemented in this study. The principle of functioning is quite simple, knowing that a neural network is an automaton made up of elementary cells: the neurons. The neurons perform a mathematical function of input data: a formal neuron performs a weighted sum of action potentials that reached it and then bustles about according to this weighted sum. Each neuron is associated with coefficients (weight, bias) weighting input data. The neuron realizes a function (called transfer function) of this weighted input and produces a scalar output. Neurons can be associated in a network linked by connexions weighted by coefficients. It has to be noted that both weight and bias are adjustable scalar parameters of the neuron. The central idea of neural networks is that such parameters can be adjusted so that the network would exhibit a desired or interesting behaviour. Thus, the network can be trained to do a particular job by adjusting the weight or bias parameters. This is the learning principle (generally done on two-thirds of the database). The input data are presented to the network, which is asked to modify the weights and biases so that it finds the desired output by successive iterations. The network compares the calculated output with the desired one and modifies its weights so that the error is minimal. Once the learning is done, the weights and the biases of the network are fixed and we can submit a new set of examples to verify the ability of the network to answer correctly to new data that are not in the learning sample (generally done on one-third of the database).

4.3 Choice of the neural network topology

To determine the optimum topology of the network, several parameters were adjusted: the number of neuron layers, the number of neurons in each layer, the transfer functions, the learning rule, and the initialization of the weights and the biases. The chosen network is a feed forward one with two layers of neurons. The learning rule is based on the scaled-conjugate gradient algorithm. An overview of this network is shown in Fig. 5.

Overview of the neural network used. The 12 input parameters in the database are connected to the first layer whose transfer function is tan sigmoid. This layer contains 18 neurons connected to the linear output layer that is made up of one neuron (because only one output is needed, namely the load carrying capacity of the connection)

5 Results

The results showed that neural networks could be a useful tool to estimate the load carrying capacity of connections. A comparison of predicted values using the neural network and the Eurocode 5 on the generalization sample has been carried out and is shown in the Fig. 6.

Filling in the gaps in the database could improve the results of the model. Unlike the standards, neural networks allow an estimation of the load carrying capacity without any restrictions on the geometric dimensions of the connections. Any possible configuration in the range of data can be generated with the corresponding strength without resorting to experimentation that is usually very tedious and expensive. However, the model provided by the neural network remains too complex to be incorporated into a design code.

6 Simplification of the neural network model

6.1 Eurocode 5-type model

In order to simplify the neural network model, it was assumed that the load carrying capacity of a multiple-dowel-type connection can be expressed as a Eurocode 5-type model:

For each multiple-dowel-type connection, the same configuration with only one dowel was generated and the corresponding strength was simulated by way of the neural network. The above ratio nef for each connection was then calculated and a correlation between this ratio and the input parameters was sought. However, there were no correlations between nef and the input data. Indeed, the maximum correlation coefficient is equal to 0.03.

The original hypothesis was thus rejected. This particular point challenges the relevance of using an effective number of dowels to calculate the multiple-dowel-type connection strength from the one of a connection with a unique dowel. In the light of this conclusion, it was decided to divide the database into three parts: connections with only one dowel, connections with one row of dowels, and connections with multiple rows of dowels.

6.2 Experimental design

In order to study the sensitivity of the neural network output to the input parameters, it was resorted to the experimental design. These designs were based on multifactor experiments and on a statistical processing of results with the help of multiple regressions and analyses of variance. In order to achieve this, a full design of experiments and fractional Plackett-Burman designs that are more accessible were used. For each split database, full experimental design with three levels per parameter (low, mid and high levels) were carried out and a variance analysis was undertaken to obtain the most influential parameters according to the Fisher-Snedecor test. An illustration of the results is shown in Figs. 7 and 8.

Pareto charts of the standardized effects (multiple-dowel-type connections) We notice that the influence of material properties (ρ, fu: black shading) is giving way to geometric properties (grey shading) when the number of dowels in the connection increases (in comparison with Fig. 7)

From the variance analysis, the most influential parameters and their interactions were determined. A multiple regression model for each database was created in this manner. The models showed quite good predictions for parameter levels that are taken into account in the design of experiments, but as soon as these level values become different, the models become not robust enough and the prediction results are poor when a random database is considered. The provided models thus present a poor ability to generalization. Moreover, with this analysis, the quadratic influences of input data remain unclear.

6.3 Stepwise regression

A stepwise regression tool that allows consideration of these quadratic effects was thus used. To reach this goal, three random sets of 5,000 configurations were generated. Three full quadratic generalized models (44, 65 and 90 terms, respectively) were formed from the input data (8 for the connections with only 1 dowel, 10 for the connections with only 1 row of dowels and 12 for connections with more than 1 row of dowels), its interactions and its quadratic effects. Starting with a full quadratic model and eliminating one by one, the terms that have a negligible influence on the load carrying capacity, a reasonable number of terms in the simplified models was reached. The coefficients associated to these terms were determined afterwards by constrained optimization. For each random database, simplified models that are less and less complex (models with 20, 18, 16, 12 and 8 terms plus a constant) were obtained. A simplified multiple-dowel-type connection model is formulated as:

This model shows satisfactory results, particularly for multiple-dowel-type connections (cf. Fig. 9).

The regression quality here is less reliable than the neural network one, but the models are simpler to interpret and the predictions improve the Eurocode 5 ones. The results for connections with only one dowel are a little less convincing are to of the lack of data, but a collection of other experimental values should improve these results.

7 Conclusions

Database development presented a long and tedious task, but can now be used by other authors who work on this topic. The initial idea that consisted in predicting the load carrying capacity of multiple-dowel- type connections with neural networks was demonstrated. Nevertheless, it should be noted that neural networks are good interpolators but their ability to extrapolate remains doubtful. Conclusions obtained from a simplified Eurocode 5-type model challenge the relevance of using an effective number of dowels we have to consider, in order to estimate the load carrying capacity of a multiple-dowel-type connection from one of the same connection with only one dowel. Moreover, it was shown that the influence of material properties (ρ, fu) is giving way to geometric properties when the number of dowels in the connection increases. Even if the simplified quadratic models are less accurate than the neural network ones, they remain closer to experimental values than the Eurocode 5. Finally, expanding the method with other types of connections, for example., steel to timber connections, screws and nails could be considered. A further possibility would be using probabilistic neural networks to include some notions of reliability.

References

Canadian Standards Association (1994) Engineering design in wood (limit states design). A national standard of Canada. CSA 086:1–94

Cointe A (2003) Prévision de résistances d’assemblages bois par organes multiples à l’aide des réseaux de neurones. PhD Thesis, Division of Mechanics, Bordeaux I University

Cointe A, Rouger F (2001) Predicting the load carrying capacity of dowel-type connections by using the neural network approach. International Rilem Symposium on Joints in Timber Structures PRO 22 Stuttgart, Germany, pp 51–61

Jorissen A (1998) Double shear timber connections with dowel type fasteners. Delft University Press Mekelweg 4 2628 CD Delft, The Netherlands

Load and Resistance Factor Design (1991) Specification for engineered wood construction. Guidelines for developing reference resistance, LRFD

prEN 1995-1-1, Eurocode 5 (2002) Design of timber structures, part 1-1, general rules and rules for buildings, final draft. Document CEN/TC 250/SC 5:N 195

Vermeyden P (1980) Test on bolted joints. CIB W18 (13-7-7) meeting 13 Otaniemi

Vincent B (1988) Analyse et modélisation du comportement mécanique des assemblages bois boulonnés ou cloués. PhD Thesis, Division of Civil Engineering, CUST, Clermont II University, Clermont-Ferrand

Wilkinson TL (1986) Load distribution among bolts parallel to load. J Struct Eng ASCE 112(4):835–852

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

1.1 Notation

The following symbols are used in this paper

- a 1 :

-

Spacing between dowels in a row

- a 2 :

-

Spacing between dowel rows

- a 3 :

-

End distance spacing

- a 4 :

-

Edge distance spacing

- d :

-

Dowel diameter

- f h :

-

Embedment strength of the wood

- f u :

-

Characteristic tensile strength of the metallic dowel

- m :

-

Number of rows

- n :

-

Number of dowels in a row

- n ef :

-

Effective number of dowels

- t 1 :

-

Lateral thickness of wood members

- t 2 :

-

Median thickness of wood member

- α:

-

Angle between the loading and the grain directions

- ρ:

-

Mean density of wood

Rights and permissions

About this article

Cite this article

Cointe, A., Rouger, F. Improving the evaluation of multiple-dowel-type connection strength. Wood Sci Technol 39, 259–268 (2005). https://doi.org/10.1007/s00226-005-0293-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-005-0293-5