Abstract

Engineered nanomaterials (ENMs) are commonly incorporated into food and consumer applications to enhance a specific product aspect (i.e., optical properties). Life cycle analyses revealed ENMs can be released from products during usage and reach wastewater treatment plants (WWTPs), with titanium dioxide (TiO2) accounting for a large fraction. As such, food grade (FG) TiO2, a more common form of TiO2 in wastewater, was used in this study. Nanomaterials in WWTPs have been well characterized, although the problematic septic system has been neglected. Elution and bioaccumulation of TiO2 ENMs from WTTPs in downriver sediments and microorganisms has been observed; however, little is known about mechanisms governing the elution of FG TiO2 from the septic drainage system. This study characterized the transport behavior and mechanisms of FG TiO2 particles in porous media conditions after septic waste treatment. FG and industrial grade (IG) TiO2 (more commonly studied) were introduced to septic tank effluent and low-ionic strength electrolyte solutions prior to column transport experiments. Results indicate that FG TiO2 aggregate size (200–400 nm) remained consistent across solutions. Additionally, elution of FG and IG TiO2 was greatest in septic effluent at the higher nanoparticle concentration (100 ppm). FG TiO2 was well retained at the low (2 ppm) concentration in septic effluent, suggesting that particles that escape the septic system may still be retained in drainage field before reaching the groundwater system, although eluted particles are highly stabilized. Findings provide valuable insight into the significance of the solution environment at mediating differences observed between uniquely engineered nanomaterials.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Engineered nanomaterials (ENMs) represent an expanding class of nanosized materials that are used in numerous applications for matrix stabilization and enhancement of optical properties [1], including consumer products such as foods [2,3,4] and cosmetics, coatings, pharmaceuticals, pigments, paints, and personal care products [4, 5]. Interestingly, multiple studies of the life cycle of consumer product-based ENMs have reported that nanomaterials can be released from products during the lifespan of their usage with many reaching full-scale wastewater treatment plants (WWTPs) [5, 6]. Titanium dioxide (TiO2) ENMs, for example, are estimated to account for a large fraction [40–50%] [5] of engineered nanomaterials reaching WWTPs, due to frequent usage and release from foods and consumer products [2, 3, 5, 7,8,9].

Full-scale WWTPs reduce the loading of organics, nutrients, and other potential environmental contaminants before wastewater is released into the environment [10]. Two to four primary treatment stages are typically incorporated at centralized facilities: preliminary treatment to remove large objects damaging to the plant, primary treatment using physical removal processes (i.e., sedimentation), secondary treatment using biological or chemical processes for nutrient removal, and tertiary treatment to further remove organics, pathogens, and parasites [11]. Nanomaterials tend to aggregate and associate with biosolids within full-scale WWTPs prior to sedimentation from treated effluent [12, 13]. However, in certain cases, though colloidal-sized TiO2 particles are well removed, up to 70% of nano-TiO2 was eluted from the full-scale WWTP [14]. Additionally, TiO2 nanoparticles released from WWTPs can remain bioavailable, which is evidenced by accumulation of small quantities (< 5 μg/L) in fish just downriver of the treatment facility [15]. Notably, TiO2 ENMs detected in receiving waters were determined to be engineered and non-naturally occurring [15]. These studies indicate that nanosized, engineered TiO2 can remain an environmental concern after leaving full-scale WWTPs.

Septic wastewater treatment systems, alternatively, are a simpler microbially driven, anaerobic digester utilizing only the sedimentation and filtration aspects of larger treatment operations [16]. Sedimentation of suspended solids and microbial degradation of organics occurs in the septic tank, and effluent slow trickle filtration occurs in the drainage field. Although septic systems are EPA regulated and effective when installed and maintained properly, they are often less rigorous than full-scale WWTPs [11] and shortcomings in design and maintenance lead to system failure [17]. Notably, TiO2 and other ENMs well studied and characterized in full-scale WWTPs have largely been neglected in the onsite, septic systems [18]. TiO2 ENMs in poorly maintained septic systems, as opposed to WWTPs, suggest the possibility of greater elution from the onsite system [19] and shifts the focus to nanoparticle behavior in the drainage field after septic treatment.

Nanoparticle fate and transport in porous media is dependent on both solution chemistry and inherent particle characteristics [20, 21]. TiO2 nanoparticles characterized under idealized conditions indicated that food grade (FG) TiO2, which is more commonly used in foods and consumer products [4], possessed a different isoelectric point (IEP) than a more commonly studied form of TiO2 (FG: pH 3.5; industrial grade: pH 6) [22]. Wastewater systems typically remain between pH 6 and 7, indicating that while industrial grade TiO2 particles should be destabilized, FG TiO2 should be stable with a negative charge based on IEP. Further, FG TiO2 nanoparticles exhibit interesting stability across multiple ideal and complex solution conditions [23], potentially increasing its chances of remaining suspended in effluent eluted from the drainage field into the groundwater system. Essentially, transport mechanisms governing FG TiO2 nanoparticle behavior in porous media after septic treatment are largely unknown and represent an important consideration regarding the environmental fate and transport of FG TiO2.

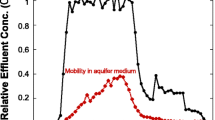

This study aimed to characterize the transport behavior and mechanisms of FG TiO2 particles in porous media indicative of conditions in post septic waste treatment. Two forms of TiO2 nanoparticles were utilized to assess the correlation between FG and a more commonly studied form of industrial grade (IG) TiO2. Characterization of nanoparticles included particle size and mobility within each solution condition. Nanoparticle transport experiments were conducted using a cylindrical glass column wet packed with quartz sand grains. Breakthrough curves were then created to elucidate the influence of solution chemistry and particle concentration in FG TiO2 porous media transport.

Experimental protocols

Nanoparticle selection and characterization

FG and IG TiO2 were used, independently, for all experimental conditions of this study. Nanomaterial selection was largely determined by FG being a commonly found particle in domestic sewage [4, 5], while the IG was used in this study as a control, as a most commonly studied TiO2 particle [22]. Interestingly, both grades have pathways to reach wastewater treatment facilities [4]. Food grade TiO2 are commercially available particles provided via Arizona State University and have a primary particle size of 122 ± 48 nm and mostly anatase crystal structure (> 95%); additionally, the particle carries an inorganic phosphate coating [22]. Industrial grade TiO2 are nanoparticles sourced from Sigma-Aldrich (Aeroxide TiO2 P25; Evonik Degussa Corporation, Essen, DE) and possess a primary particle size of 21 nm and a compound crystal structure of 75% anatase and 25% rutile [22, 23]. The isoelectric point of FG TiO2 is within the range of pH 3.5 to 4, while IG TiO2 is pH 6 in 10 mM monovalent electrolyte solutions [22, 23].

Nanoparticles were prepared following previously described methods [24]. Briefly, a 200 ppm stock solution of TiO2 nanoparticles was prepared and sonicated for 30 min prior to beginning experiments, then another 30 s just before each characterization experiment. Nanoparticle concentrations of 2 and 100 ppm were selected to approximate environmentally relevant levels and nanoparticle concentrations used in prior studies [21]. Although 0.2 ppm represents the high level of TiO2 in this environment [15, 25], 2 ppm was selected due to optical resolution limitations of the spectrophotometer.

Nanoparticle characterization included both hydrodynamic diameter and zeta-potential (ZP) measurements across each solution condition and TiO2 concentration. Hydrodynamic diameter was determined using dynamic light scattering (ZetaPALS, Holtsville, NY, USA) at a wavelength of 661 nm and a scattering angle of 90°. ZP was calculated using the Smoluchowski equation [20] converted using electrophoretic mobility measurements (ZetaPALS, Holtsville, NY, USA).

Solution chemistry and characterization

Treated wastewater released from septic treatment systems must first trickle through a drainage field of porous medium before entering the groundwater system [16]. Therefore, septic system wastewater effluent was the primary solution utilized in this study to replicate conditions present within the drainage field. Septic effluent was produced using a bench-scale model septic tank and human colon that provided human fecal matter [18, 23, 26]. The water quality of the septic effluent was evaluated via conductivity (570 μS/cm), pH (7.6), microbial concentration (5.01 × 108 ± 6 × 107 cells/mL), turbidity (9.9 ± 0.8 NTU), and chemical oxygen demand (315.9 ± 12.4 mg/L). Additionally, 4 mM KCl with pH adjusted to 7.6 and 10 mM KCl (no adjustment, pH 6) were two, separately tested, monovalent electrolyte suspensions used to indicate the significance of organic matter and increased ionic strength, respectively. Conductivity is the measure of charge transferring capacity of a solution and an estimate of IS. Calibration curves were created to determine the molar concentration of KCl equaling septic effluent conductivity with the result being 4 mM. The transport properties of six nanoparticle suspensions were tested independently in triplicate using sand columns. The six suspensions comprised two grades (food and industrial) of TiO2 nanoparticles independently suspended in three solutions (septic effluent, 4 mM KCl (pH 7.6), and 10 mM KCl (pH 6)). Solution chemistries provided a comparison of the role played by organic material remaining in the septic system (4 mM KCl, pH 7.6) and for the consideration of FG TiO2 filtration behavior in relation to commonly studied literature conditions (10 mM KCl).

Column transport experiments

Column transport experiments were conducted to elucidate the porous media behavior of FG TiO2. A borosilicate glass cylinder of dimensions 1.5 cm inner diameter and 5 cm length was wet packed with 275 μm ultrapure quartz sand, resulting in 0.46 porosity to simulate filtration through a septic drain field [16]. Column operation and setup are presented in greater detail elsewhere [21]. Flow rate was maintained at 2 mL/min which is commonly found in trickle flows and slow sand grain filtration [10]. Greater than 10 pore volumes (PV) of Millipore deionized water (18.2 MΩ at 25 °C) were flushed through the column after sand was wet packed. This initial flush was followed by greater than 10 PV of the electrolyte solution (4 mM KCl, 10 mM KCl, or septic effluent; without nanoparticles) to fully saturate the porous media in the respective background solution. Six PV of TiO2 nanoparticle suspensions (background electrolyte solutions spiked with TiO2) was then introduced followed by another 6 PV of the nanoparticle-free background electrolyte solution. Septic effluent was obtained from the column using 15-mL centrifuge tubes and fraction collector (CF 1 Fraction Collector, Spectrum Chromatography, Houston, TX, USA). The nanoparticle suspensions were constantly sonicated and stirred during TiO2 introduction.

DLVO calculations

Derwin-Landau-Verwey-Overbeek (DLVO) theory was applied to provide insight on deposition mechanisms of both FG and IG TiO2 in this porous media system. DLVO theory allowed for the determination of the significance of electrostatic repulsion and van der Waals interactions on the TiO2 nanoparticles and quartz sand collector comprising the transport column. Sphere plate geometry was assumed for this TiO2 quartz system due to the comparatively smaller diameters of nanoparticles compared with a quartz sand collector grain size of ~ 250–300 μm. DLVO theory was applied using the following equations for electrostatic repulsion (Vedl) (Eq. 1) and van der Waals forces (VVDW) (Eq. 2):

where the following assumed parameters were utilized from previously published and measurements from this study: permittivity constant of free space (ɛo) was 8.854 × 10−12 C/V/m, the dielectric constant of water (ɛ) was 78.5, and surface potentials (ψ) determined by EPM measurements were transformed to zeta-potentials using the Smoluchowski equation for the particle (p) and collector (c) [27]. Inverse Debye length and separation distance are denoted by ĸ and h, respectively [20]. The Hamaker constant (A102) selected for a quartz TiO2 system was 10−20 [28], and the particle radius (ap) was populated by hydrodynamic diameter values (Fig. 1). Lastly, characteristic wavelength (λ) was assumed to be 100 nm [27].

Statistical analysis

Student’s t test was used to determine the statistical significance for nanoparticle characterization and breakthrough curves. An alpha value of 0.05 (p value < 0.05) indicated statistically significant differences resulted in the FG or IG TiO2 nanoparticle suspensions.

Results

Nanoparticle characterization

The hydrodynamic diameter of each type of TiO2 particle is presented in Fig. 1. Notably, IG and FG TiO2 vary little in their respective mean diameters between both KCl suspensions. Industrial grade TiO2 developed a significantly larger (p < 0.05) hydrodynamic diameter than FG TiO2 in both 4 and 10 mM KCl, which is similar to previous research that found IG to form larger aggregates than FG [23]. Contrary size relationships by particle concentration were observed in KCl between FG and IG TiO2 hydrodynamic diameters with 100 ppm IG TiO2, developing significantly larger aggregates than 2 ppm (> 1200 to < 600 nm, respectively), while 100 ppm FG TiO2 formed significantly smaller aggregates than 2 ppm (< 282.5 ± 7.5 to > 358.3 ± 3.2 nm). Suspending the particles in septic effluent resulted in the development of very similar sizes between IG and FG TiO2. Septic effluent appears to stabilize IG TiO2 particle sizes compared to both KCl solutions, while the size FG TiO2 was determined to be independent of solution chemistry.

The electrophoretic mobility for both grades of TiO2 particles suspended in the three solution chemistries is presented in Fig. 2. The EPM of FG TiO2 was negative in all three solution conditions, and the value was independent of particle concentration. The greatest magnitude of EPM for FG was the 4 mM KCl solution, followed by the 10 mM suspension, while the FG suspended in the septic effluent had the lowest EPM. The IG particle EPM trends were similar across the two KCl suspensions. The low-concentration IG particles had negative EPM values, while those with higher concentrations had positive EPM values, yet irrespective of concentration, the IG particles developed equal, negative, and lower-magnitude EPM values when suspended in septic effluent (Fig. 2). Indeed, both grades of TiO2 at both concentrations exhibited no differences in EPM when suspended in septic effluent. Septic effluent may exhibit a capacity for EDL compression even at low IS (570 μS/cm, ~ 4 mM) as both TiO2 types and concentrations exhibit reduced EPM from either KCl solution [29].

Column transport experiments

Breakthrough curves for food and industrial grade TiO2 in each solution condition are provided in Fig. 3. Results indicate that FG TiO2 was eluted more than IG in 4 mM KCl although in 10 mM KCl, both nanoparticle types were well retained (Fig. 3a, b). Nanoparticle concentration had little effect on IG retention in 10 mM KCl except in the case of 100 ppm IG TiO2 where a small increase in particles eluted was observed (0.1 ± 0.0). Conversely, FG TiO2 was far more impacted by particle concentration where FG 100 ppm (max 0.4 ± 0.0) was much greater than FG 2 ppm (max 0.0 ± 0.0) when suspended in 4 mM KCl. In septic effluent, differences in nanoparticle behavior were observed for both FG and IG TiO2 when compared to the monovalent solutions (Fig. 3c). Septic effluent resulted in high elution values for all nanoparticles and concentrations except for FG 2 ppm. Notably, IG TiO2 displayed an increased tendency for elution than those observed in 4 and 10 mM KCl. TiO2 particle concentration played a major role under septic effluent conditions as both IG and FG TiO2 exhibited similar behavior at the 100 ppm TiO2 concentrations, and poor retention was observed at 100 ppm (max 0.8 ± 0.1) compared to 2 ppm (max 0.1 ± 0.0). Results indicate that septic effluent conditions facilitate increased elution of FG and IG TiO2 nanoparticles compared to the monovalent electrolyte suspensions, though high retention is observed at environmentally relevant concentrations (< 2 ppm).

Breakthrough curves for food grade (FG) and industrial grade (IG) TiO2 nanoparticles introduced to a 4 mM KCl at pH 7.6, b 10 mM KCl at pH 6, and c septic effluent. C0 and C represent the influent and effluent concentrations of TiO2, respectively. Error bars represent standard error of triplicate measurements

DLVO calculations

Total interaction energy profiles for food and industrial grade TiO2 developed for 4 and 10 mM KCl are presented in Fig. 4 as a function of nanoparticle concentration and separation distance. Unfavorable conditions (> 435 kT) for deposition were observed for both FG and IG TiO2 nanoparticles in 4 mM KCl apart from IG 100 ppm, where the deep primary minimum demonstrates those very favorable conditions developed (Fig. 4a, − 5292 kT). For the 10 mM KCl suspensions, TiO2 nanoparticle type was significant with FG TiO2 remaining in unfavorable deposition conditions, although reduced from observations in 4 mM, while IG 2 ppm became much closer to favorable deposition (Fig. 4b). Additionally, nanoparticle concentration affected total interaction energy with IG TiO2 more than FG TiO2. FG TiO2 remained unfavorable in 4 mM KCl at both particle concentrations and possessed similar interaction energy (FG 2 ppm, 225 kT; FG 100 ppm, 195 kT). Conversely, nanoparticle concentration was the difference between favorable and unfavorable deposition conditions for IG TiO2 in 4 and 10 mM KCl, with unfavorable conditions for IG 2 ppm, while IG 100 ppm was favorable. Results of interaction profiles suggest that more favorable conditions for FG and IG TiO2 nanoparticle deposition, at both 2 and 100 ppm concentrations, would exist in 10 mM KCl than 4 mM KCl.

Discussion

Nanoparticle characterization

Engineered nanomaterial interactions, and environmental behavior as a result, are very much dependent on nanoparticle stability and aggregation [30, 31]. High electrophoretic mobility (− 4.5 ± 0.2 × 10−8 m2/V/s) of FG TiO2 nanoparticles introduced to weak, monovalent electrolyte conditions is suggestive of a very stabilized nanoparticle (Fig. 2). Similar mobility displayed by FG TiO2 was also observed in concentrated colon medium comprising proteins, carbohydrates, and mono- and divalent salts, at even at high IS (~ 200 mM) [23]. Between 4 and 10 mM KCl, the hydrodynamic diameter of FG TiO2 remains in the range of 270 to 360 nm while IG TiO2 increases to well over 1000 nm in both solutions at IG 100 ppm, which also aligns with findings from previous work conducted in high-IS, multivalent electrolyte solutions [23]. FG TiO2 hydrodynamic diameters in 4 and 10 mM KCl support EPM observations of a stabilized aggregate showing that FG TiO2 maintains smaller aggregate sizes than IG TiO2 (Fig. 1). Di- and multivalent electrolyte suspensions are well understood to compress the electrical double layer surrounding a nanoparticle [32] and while this was observed previously with IG TiO2, FG TiO2 continues to respond differently in idealized and complex solutions highlighting the significance of inherent differences [23].

Suspension pH is an additional factor capable of influencing nanoparticle stability, where particles near the IEPs are destabilized and more readily aggregate [20, 21]. The IEPs of FG and IG TiO2 have been reported as pH 3.5 and 6, respectively [22]. Based on IEPs and nanoparticle concentration, the largest TiO2 aggregates would be expected to form in IG 100 ppm, although this was not the case (Fig. 1). Slightly larger IG 100 ppm aggregates observed in 4 mM KCl at pH 7.6 may potentially result from a positive and reduced stability compared to 10 mM, resulting in conditions that facilitate nanoparticle aggregation (Fig. 2) [29, 33].

In wastewater treatment, organic coatings are expected to develop on nanoparticle surfaces and can impart a stabilizing effect that minimizes further aggregation [29, 30, 34, 35]. Contrary to the monovalent solutions, septic effluent represented an environment that reduced the mobility of both TiO2 types; however, whereas the hydrodynamic diameter of IG TiO2 nanoparticles decreased, FG TiO2 aggregates became slightly larger at both 2 and 100 ppm nanoparticle concentrations (Figs. 1 and 2, respectively). Reductions in EPM and hydrodynamic diameter have been attributed to steric hindrance occurring from organic matter bound to the nanoparticle surface [31, 36] which can explain the observations for IG TiO2. These findings suggest that FG TiO2 would have low retention in porous media filtration increasing the possibility of reaching groundwater.

Column transport experiments

Findings from column breakthrough curves reveal an expectedly high rate of elution of FG TiO2 nanoparticles in septic system effluent at high concentrations (Fig. 3c) [12, 14, 37]. However, environmentally relevant concentrations of nanoparticles released from septic tank may not pose an immediate risk to groundwater as FG 2 ppm was well retained inside the column. IG TiO2 conversely exhibited a high degree of elution at both 2 and 100 ppm concentrations compared to the monovalent electrolyte solutions. Poor retention of IG TiO2 in septic effluent compared to 4 and 10 mM KCl may potentially result from steric hindrance minimizing aggregation and deposition, allowing particles to remain in suspension [29, 30, 35, 36]. Nanomaterials have the tendency to develop organic coatings in a number of environmental settings including wastewater treatment systems [13]. Steric hindrance represents a key colloidal phenomenon that occurs with particles in aquatic solutions containing natural organic matter as the organic coatings minimize further aggregation after a certain amount of surface coverage [20]. The nanoparticle aggregate becomes stabilized by the surface attached organic polymers hindering further aggregation and deposition. As such, steric hindrance caused by the nanoparticles interacting with the biomolecules contained in the septic effluent matrix may account for the increased elution compared to the simpler salt solutions. Interestingly, findings of the current study suggest that high stability of TiO2 ENMs may be a major factor in the frequency of their detection in WWTPs compared to other nanomaterials [13].

DLVO experiments

DLVO theory was used to provide insight on the influence of van der Waals and electrostatic repulsive forces on TiO2 nanoparticle interactions with quartz sand collectors during porous media transport (Fig. 4) [21, 38]. Total interaction energy profiles determine whether favorable conditions exist for TiO2 nanomaterials to deposit onto collector grains. Septic effluent exceeds the idealized solution assumption used for DLVO theory [27], so 4 mM KCl (pH 7.6) was used instead to consider effects of IS and nanoparticle concentration on interaction energy between FG TiO2 and the quartz collector as a function of distance.

FG TiO2 has unfavorable conditions for deposition at 2 and 100 ppm in both solutions with higher interaction energy in 4 mM KCl (max 537 kT, FG 2 ppm) (Fig. 4). Considering FG TiO2 has an IEP of 3.5, exposure to pH 7.6 would result in both negatively charged nanoparticles and the collector surface ultimately inhibiting deposition [20, 27]. Similarly, FG 2 ppm TiO2 also possesses the highest interaction energy (max 225 kT) although reduced from 4 mM KCl. Although FG 2 ppm developed the most unfavorable conditions for deposition in both solutions based on DLVO theory, it was observed to be the most retained nanoparticle filtration column when suspended in the septic effluent (Fig. 4). Additionally, IG 100 ppm would be expected to have highly favorable deposition in 10 and 4 mM KCl as shown in Fig. 4, yet high elution was recorded in septic effluent (Fig. 3). This suggests that organic material in water sources can potentially impart environmentally specific characteristics [30, 35] that may take precedent over inherent nanoparticle characteristics in governing nanoparticle behavior.

Engineered nanomaterials are an expanding class of emerging contaminants to environmental systems including water bodies and water treatment facilities. TiO2 nanoparticles commonly incorporated into food and consumer products and subsequently released during usage have been detected at wastewater treatment facilities. As such, the impact of TiO2 nanomaterials in wastewater treatment facilities was assessed using the environmentally relevant form of TiO2 (food grade) and concentration (< 2 ppm) to elucidate filtration behavior of food grade TiO2 nanoparticles after exiting the septic treatment system. Notably, septic effluent resulted in increased elution of both industrial and food grade TiO2 at higher nanoparticle concentrations. FG TiO2 was well retained at 2 ppm concentration in septic effluent, indicating that particles that escape the septic system may still be removed from the waste stream before reaching groundwater. However, particles that are eluted from the drainage field into the groundwater system are likely to be very stabilized in suspension likely resulting in greater transport. Findings of the current study provide essential insight into the significance of the solution conditions that nanoparticles are introduced to in that the potential exists for the environment to mediate differences observed between uniquely engineered nanomaterials. Future research into filtration of FG TiO2 will elucidate governing mechanisms that facilitate and suppress differing behaviors between nanomaterials to better understand mechanisms governing transport of nanoparticles in porous media.

References

Bishoge OK, Zhang L, Suntu SL, Jin H, Zewde AA, Qi Z. Remediation of water and wastewater by using engineered nanomaterials: a review. J Environ Sci Health A. 2018;53(6):537–54.

Abbas KA, Saleh AM, Mohamed A, MohdAzhan N. The recent advances in the nanotechnology and its applications in food processing: a review. J Food Agric Environ. 2009;7(3–4):14–7.

Bouwmeester H, Dekkers S, Noordam MY, Hagens WI, Bulder AS, de Heer C, et al. Review of health safety aspects of nanotechnologies in food production. Regul Toxicol Pharmacol. 2009;53(1):52–62.

Weir A, Westerhoff P, Fabricius L, Hristovski K, von Goetz N. Titanium dioxide nanoparticles in food and personal care products. Environ Sci Technol. 2012;46(4):2242–50.

Keller AA, McFerran S, Lazareva A, Suh S. Global life cycle releases of engineered nanomaterials. J Nanopart Res. 2013;15:1692.

Benn TM, Westerhoff P. Nanoparticle silver released into water from commercially available sock fabrics. Environ Sci Technol. 2008;42(11):4133–9.

Gottschalk F, Sonderer T, Scholz RW, Nowack B. Modeled environmental concentrations of engineered nanomaterials (TiO2, ZnO, Ag, CNT, fullerenes) for different regions. Environ Sci Technol. 2009;43(24):9216–22.

Brar SK, Verma M, Tyagi RD, Surampalli RY. Engineered nanoparticles in wastewater and wastewater sludge—evidence and impacts. Waste Manag. 2010;30(3):504–20.

Addo Ntim S, Norris S, Scott K, Thomas TA, Noonan GO. Consumer use effects on nanoparticle release from commercially available ceramic cookware. Food Control. 2018;87:31–9.

Crittenden JC, Trussell RR, Hand DW, Howe KJ, Tchobanoglous G. MWH’s water treatment: principles and design. Hoboken: Wiley; 2012.

Bitton G. Wastewater microbiology. 3rd ed. Hoboken: Wiley; 2005.

Westerhoff P, Song GX, Hristovski K, Kiser MA. Occurrence and removal of titanium at full scale wastewater treatment plants: implications for TiO2 nanomaterials. J Environ Monit. 2011;13(5):1195–203.

Westerhoff PK, Kiser A, Hristovski K. Nanomaterial removal and transformation during biological wastewater treatment. Environ Eng Sci. 2013;30(3):109–17.

Kiser MA, Westerhoff P, Benn T, Wang Y, Perez-Rivera J, Hristovski K. Titanium nanomaterial removal and release from wastewater treatment plants. Environ Sci Technol. 2009;43(17):6757–63.

Shi XM, Li ZX, Chen W, Qiang LW, Xia JC, Chen M, et al. Fate of TiO2 nanoparticles entering sewage treatment plants and bioaccumulation in fish in the receiving streams. Nano. 2016;3-4:96–103.

Canter LK, Knox RC. Septic tank system effects on ground water quality. Chelsea: Lewis Publishers, Inc; 1985.

EPA US. Decentralized systems technology fact sheet: septic tank—soil adsorption systems. EPA 932-F-99-075, U S EPA. 1999.

Taylor AA, Walker SL. Effects of copper particles ona model septic system’s function and microbial community. Water Res. 2015;91:350-60.

Waller T, Marcus IM, Walker SL. Influence of food and industrial grade TiO2 nanoparticles on microbial diversity and phenotypic response in model septic system. Environ Eng Sci. 2018; (accepted).

Gregory J. Particles in water: properties and processes. CRC Press, Boca Raton, Florida. 2006.

Chowdhury I, Hong Y, Honda RJ, Walker SL. Mechanisms of TiO2 nanoparticle transport in porous media: role of solution chemistry, nanoparticle concentration, and flowrate. J Colloid Interface Sci. 2011;360(2):548–55.

Yang Y, Doudrick K, Bi X, Hristovski K, Herckes P, Westerhoff P, et al. Characterization of food-grade titanium dioxide: the presence of nanosized particles. Environ Sci Technol. 2014;48(11):6391–400.

Waller T, Chen C, Walker SL. Food and industrial grade titanium dioxide impacts gut microbiota. Environ Eng Sci. 2017;34(8):537–50.

Chowdhury I, Hong Y, Walker SL. Container to characterization: impacts of metal oxide handling, preparation, and solution chemistry on particle stability. Colloids Surf A. 2010;368(1–3):91–5.

Qiu G, Au M-J, Ting Y-P. Impacts of nano-TiO2 on system performance and bacterial community and their removal during biological treatment of wastewater. Water Air Soil Pollut. 2016;227(10):386.

Marcus IM, Wilder HA, Quazi SJ, Walker SL. Linking microbial community structure to function in representative simulated systems. Appl Environ Microbiol. 2013;79(8):2552–9.

Elimelech M, Gregory G, Xia X, Williams R. Particle deposition and aggregation, paperback ed. Oxford: Butterworth-Heinemann; 1995.

Fatisson J, Domingos RF, Wilkinson KJ, Tufenkji N. Deposition of TiO2 nanoparticles onto silica measured using a quartz crystal microbalance with dissipation monitoring. Langmuir. 2009;25(11):6062–9.

Zhang Y, Chen YS, Westerhoff P, Hristovski K, Crittenden JC. Stability of commercial metal oxide nanoparticles in water. Water Res. 2008;42(8–9):2204–12.

Chen KL, Elimelech M. Influence of humic acid on the aggregation kinetics of fullerene (C60) nanoparticles in monovalent and divalent electrolyte solutions. J Colloid Interface Sci. 2007;309(1):126–34.

Chen KL, Mylon SE, Elimelech M. Enhanced aggregation of alginate-coated iron oxide (hematite) nanoparticles in the presence of calcium, strontium, and barium cations. Langmuir. 2007;23(11):5920–8.

French RA, Jacobson AR, Kim B, Isley SL, Penn RL, Baveye PC. Influence of ionic strength, pH, and cation valence on aggregation kinetics of titanium dioxide nanoparticles. Environ Sci Technol. 2009;43(5):1354–9.

Keller AA, Wang H, Zhou D, Lenihan HS, Cherr G, Cardinale BJ, et al. Stability and aggregation of metal oxide nanoparticles in natural aqueous matrices. Environ Sci Technol. 2010;44(6):1962–7.

Chowdhury I, Duch MC, Mansukhani ND, Hersam MC, Bouchard D. Colloidal properties and stability of graphene oxide nanomaterials in the aquatic environment. Environ Sci Technol. 2013;47(12):6288–96.

Chowdhury I, Walker SL, Mylon SE. Aggregate morphology of nano-TiO2: role of primary particle size, solution chemistry, and organic matter. Environ. Sci.: Processes Impacts. 2013;15(1):275–82.

Chowdhury I, Cwiertny DM, Walker SL. Combined factors influencing the aggregation and deposition of nano-TiO2 in the presence of humic acid and bacteria. Environ Sci Technol. 2012;46(13):6968–76.

Giese B, Klaessig F, Park B, Kaegi R, Steinfeldt M, Wigger H, et al. Risks, release and concentrations of engineered nanomaterial in the environment. Sci Rep. 1565;8(1):2018.

Bradford SA, Kim HN, Haznedaroglu BZ, Torkzaban S, Walker SL. Coupled factors influencing concentration-dependent colloid transport and retention in saturated porous media. Environ Sci Technol. 2009;43(18):6996–7002.

Acknowledgements

Thanks to P. Westerhoff (ASU) for providing the nanomaterials to conduct these experiments. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the NSF or the EPA. This work has not been subjected to EPA review, and no official endorsement should be inferred.

Funding

Funding from the National Science Foundation (NSF), Environmental Protection Agency (EPA), and Department of Education supported this study. T. Waller was supported by both the Department of Education (GAANN, Grant No. P200A130127) and the NSF IGERT: Water Social, Engineering, and Natural Sciences Engagement (WaterSENSE) Program (Grant No. 1144635). S. Walker’s participation and work was also funded through the University of California Center for Environmental Implications of Nanotechnology (UC-CEIN), which is supported by the NSF and the EPA under Cooperative Agreement Number DBI 0830117.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interests.

Additional information

Published in the topical collection Analytical Developments in Advancing Safety in Nanotechnology with guest editors Lisa Holland and Wenwan Zhong.

Rights and permissions

About this article

Cite this article

Waller, T., Marcus, I.M. & Walker, S.L. Influence of septic system wastewater treatment on titanium dioxide nanoparticle subsurface transport mechanisms. Anal Bioanal Chem 410, 6125–6132 (2018). https://doi.org/10.1007/s00216-018-1136-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-018-1136-1