Abstract

Food authenticity and food safety are of high importance to organizations as well as to the food industry to ensure an accurate labeling of food products. Respective analytical methods should provide a fast screening and a reliable cost-efficient quantitation. HPTLC was pointed out as key analytical technique in this field. A new HPTLC method applying caffeine-impregnated silica gel plates was developed for eight most frequently found fat-soluble azo dyes unauthorizedly added to spices, spice mixtures, pastes, sauces, and palm oils. A simple post-chromatographic UV irradiation provided an effective sample cleanup, which took 4 min for up to 46 samples in parallel. The method was trimmed to enable 23 simultaneous separations within 20 min for quantitation or 46 separations within 5 min for screening. Linear (4–40 ng/band) or polynomial (10–200 ng/band) calibrations of the eight azo dyes revealed high correlation coefficients and low standard deviations. Limits of detection and quantification were determined to be 2–3 and 6–9 ng/zone, respectively. After an easy sample extraction, recoveries of 70–120% were obtained from chili, paprika, and curcuma powder as well as from chili sauce, curry paste, and palm oil spiked at low (mainly 25–50 mg/kg) and high levels (150–300 mg/kg). For unequivocal identification, the compound in a suspect zone was eluted via a column into the mass spectrometer. This resulted in the hyphenation HPTLC-vis-HPLC-DAD-ESI-MS.

Simplified clean-up by UV irradiation for Sudan dye analysis in food by HPTLC-vis-HPLC-DAD-ESI-MS.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Food authenticity and food safety are of high importance to organizations as well as to the food industry to ensure an accurate labeling of food products. The addition of unauthorized food colorants has to be detected. The so-called Sudan dyes are liphophilic azo compounds with more than ten yellow- to red-colored representatives mostly derived from ß-naphthol. There are also Sudan green, Sudan blue, and Sudan black, differing in chemistry from the red and orange ones. Sudan dyes generally are used as industrial solvent dyes to color fuels, oils, and waxes including shoe polish, but also for staining purposes in histology. As they are rather cheap, colorfast, and longer-term stable compared to natural dyes in food, they are attractive to stabilize respectively colored food and food preparations. In contrast, native food colorants, i.e., carotenoids, anthocyanes, betalaines, and chlorophylls, are susceptible to (photo-)oxidation, pH, or heating resulting in bleaching and browning. However, Sudan dyes, classified as category 3 carcinogens by the International Agency for Research on Cancer (IARC), are not authorized as food additives in most countries, including the USA, Canada, and the European Union (EU). As unauthorized food colorants, they attracted the attention of food authorities after the first EU-notified finding of Sudan I in hot chili peppers by the French food control in 2003, who posted an alert in the European Rapid Alert System for Food & Feed (RASFF) [1, 2]. This prompted the European Commision to decide that hot chili and hot chili products imported into the community should be accompanied by an analytical report demonstrating that the consignment does not contain Sudan red 1 [note: means Sudan I]. For the same reason, Member States shall carry out random sampling and analysis of hot chili and hot chili products at import or already on the market [3]. Consequently, food authorities, not only in the EU, increasingly started control programs resulting in increasing RASFF notifications reaching a maximum of 270 already in 2004 (see Electronic Supplementary Material (ESM) Fig. S1). The high number of findings including other Sudan dyes than Sudan I, not only in hot chili peppers but also in other spices like curry powder and in other food like sauces, pasta, and red palm oils, resulted in the decisions 2004/92 and 2005/402 of the European Commission, extending both the number of Sudan dyes and food products to be controlled [4, 5]. During the last 10 years, the number of RASFF notifications clearly dropped, when actually in 2017 eight entries were found. Food frauds obviously were alarmed or control intensities possibly also dropped. Nevertheless, it is important to have a rapid screening method to check suspect samples, especially to screen for unauthorized fat-soluble dyes actually not on a target list, and to be prepared for new activities of food fraud.

Simultaneously with the RASFF notification peak in 2004, the number of publications concerning the analysis of Sudan dyes in food rapidly increased and reached a maximum in 2007 [6]. Analytical methods of determination mainly used high-performance liquid chromatography (HPLC) on reversed-phase (RP) columns, coupled to spectrophotometric or increasingly mass selective detectors [6,7,8,9,10,11,12,13,14,15,16,17]. Alternatively, micellar electrokinetic chromatography [18] or supercritical fluid chromatography [19] were employed. Direct analysis in real-time mass spectrometry [20], electrochemical sensor techniques [21, 22], or immuno assays [23,24,25] are examples of methods different from chromatography. Co-extracted lipids, especially natural dyes and pigments, strongly interfered with spectrophotometric detections, why cleanup was essential, which also held true for most published methods of liquid chromatography-mass spectrometry (LC-MS) to prevent matrix effects. Cleanup methods included a simple freezing-out of lipids [26], gel permeation chromatography [17, 27], immunoaffinity chromatography [28], molecularly imprinted polymer solid-phase extraction [29, 30], matrix solid-phase dispersion [13, 31], and solid-phase extraction (SPE) on alumina [11, 12], normal phase silica [32], or C18 material [10]. Omitting any cleanup and applying tandem mass spectrometry (LC-MS/MS), authors also trusted in mass selective detections along with absence of ion suppression by food matrix [7, 16, 18, 26].

Targeted LC-MS(/MS) methods are highly selective and sensitive. A non-target screening, however, is the great chance for the matrix-robust and fast high-performance thin-layer chromatography, also being liquid chromatography. The whole sample (extract) is detectable at one look. This especially holds true, if the compounds of interest are colored and directly visible by the naked eye, when also so far unknown dyes will easily be detected. Besides recording of UV/vis spectra from the HPTLC plate, the meanwhile well-established coupling of HPTLC to (high-resolution) mass spectrometry (HPTLC-MS [33] or HPTLC-HRMS [34]) easily allows the unequivocal identification of unauthorized azo dyes. There are only few publications presenting the analysis of Sudan dyes by TLC or HPTLC [35,36,37,38]. The reports studied the purity of dyes [35], used a simple low-performance TLC equipment [37], or covered only two [36] or four [37] Sudan dyes. First, Kandeler et al. [38] separated 12 fat-soluble azo dyes among 13 illegal dyes on RP-18F254 HPTLC plates, but they grouped them in two standard mixtures to overcome co-elutions. To avoid interferences by natural dyes and pigments, extracts were submitted to an iron(III) oxidation followed by an SPE cleanup. The authors reported limits of detection of about 0.4 mg/kg and performed matrix-matched calibrations for quantitation. Time-consuming steps like iron(III) oxidation, SPE cleanup, and matrix-matched calibrations are not in favor of a simple screening of Sudan dyes in food.

As respective analytical methods should provide a fast screening and a cost-efficient quantitation, the potential of HPTLC as analytical key technique in this field was investigated. The aim of the present study was to develop a rapid, and at the same time, reliable HPTLC method for the identification and quantitation of eight relevant and most frequently found fat-soluble azo dyes to be tested on food, such as spices, spice mixtures, pastes, sauces, and palm oils.

Materials and methods

Chemicals and materials

Sudan I, Sudan II, Sudan III, Sudan IV, Sudan 7B, Sudan Orange G, Sudan Red B, and Para Red (analytical standards, > 96%) were obtained from Sigma-Aldrich (Steinheim, Germany). 4-(Dimethylamino)azobenzene (pure) was purchased from Carl Roth (Karlsruhe, Germany). Acetone, acetonitrile, n-hexane, and methyl ethyl ketone (all per analysis grade) were obtained from Th. Geyer (Renningen Germany). PTFE filter tips (0.45 μm) were from vwr (Bruchsal, Germany). Caffeine (> 99%), magnesium chloride hexahydrate, and potassium carbonate were from Fluka (Munich, Germany). Silver nitrate (ultrapure) was purchased from Acros Organics (Geel, Belgium). HPTLC plates Nano-SIL-PAH (20 cm × 10 cm) were delivered from Macherey-Nagel (Düren, Germany). HPTLC plates silica gel 60 and LiChrospher (both 20 cm × 10 cm) were obtained from Merck (Darmstadt, Germany). Caffeine impregnation [39] was performed by dipping the plate into a solution of caffeine in acetonitrile (1.7 g/100 mL) for 20 min, followed by drying the plate at 120 °C for 20 min. Food samples were purchased from local markets of Stuttgart (Germany).

Stock solutions and standard mixture

In 20-mL volumetric flasks, Sudan I, Sudan II, Sudan Red B, and Sudan Orange G were individually (10 mg) dissolved in 5 mL acetone, whereas Sudan III, Sudan IV, Sudan Red 7B, and Para Red were dissolved in 15 mL acetone. The solutions were filled up with methanol (0.5 mg/mL stock solutions). A standard mixture was obtained by pipetting 200 μL of each stock solution into a 10-mL volumetric flask to be filled up with methanol (10 ng/μL each). As internal standard, the stock solution (0.5 mg/mL) and standard solution of 4-dimethylaminoazobenzene (10 ng/μL) were prepared analogously.

Sample preparation

For dry spices, pastes, and oils, the homogenized sample (1 g) was weighed into a 20-mL screw-capped centrifuge tube. Internal standard solution (1 mL) and acetone (4 mL) were added, and the mixture was vortexed for 1 min. After the addition of 5 mL methanol, the tube was shaken for 1 min and centrifuged at 3200×g for 4 min at 20 °C (Biofuge primo R, Heraeus, Hanau, Germany). The supernatant was filtered (0.45 μm) and transferred into an autosampler vial.

For water-based sauces, the homogenized sample (10 g) was weighed into a 250-mL round-bottom flask and mixed with 100 mL acetonitrile. After the addition of internal standard solution (1 mL), the slurry was rotary evaporated to dryness (water bath 75 °C, vacuum 650 to 300 mbar). The residue was re-solubilized in acetone (4 mL), and the flask was shaken for 2 min. Thereafter, methanol (5 mL) was added, and the flask was shaken again for 1 min. The extract was centrifuged at 3200×g for 4 min at 20 °C, and the supernatant was transferred through a filter tip (0.45 μm) into an autosampler vial.

Silver nitrate application

For initial on-plate cleanup experiments with silver nitrate (omitted later), a 30 mm × 3 mm area of a silver nitrate solution (5% in methanol–water, 9:1, V/V) was sprayed with the Automatic TLC Sampler 4 (ATS 4, CAMAG, Muttenz, Switzerland) just above two application zones (15 mm from the lower edge), whereas the next two applications zones were used for comparison. The investigated amounts of silver nitrate were 115, 225, and 450 μg/cm. Chromatography followed immediately.

HPTLC-vis screening method

For simultaneous separation of 46 samples within 5 min, an antiparallel development was performed in the Horizontal Developing Chamber, 20 cm × 10 cm (CAMAG). Samples (4 μL/band) were applied as 6-mm bands at both sides of a 20 cm × 10 cm HPTLC plate with an 8-mm track distance, 1 or 2 mm from the lower edge and 15 mm from the left edge. The standard mixture was applied with 1–6 μL/band. The migration up to max. 50 mm took 5 min. The plate, mobile phase, and documentation were used as follows.

Quantitative HPTLC-vis-MS method

Sample application was performed by an Automatic TLC Sampler 4 (ATS 4, CAMAG), using the predefined application settings for methanolic solutions. Methanol was used as the rinsing solvent with one rinsing cycle and one filling cycle. Sample extracts and standards were applied on HPTLC plates Nano-SIL-PAH (if not stated otherwise) as 6-mm bands with an 8-mm track distance, 8 mm from the lower edge and 15 mm from the left edge. The application volumes were 4 μL/band for sample extracts and 1–20 μL/band for the standard mixture, resulting in 10–200 ng/zone. Samples were spiked at the very beginning of sample preparation; however for the calibration, the internal standard solution (1 μL/band) was simply applied by overspraying the start zones of the standard mixture. After chamber saturation for 10 min, chromatography was conducted in the Automatic Developing Chamber (ADC 2, CAMAG) with isohexane–ethyl methyl ketone (5:1, V/V) to a migration distance of 60 mm, followed by drying for 1 min. Plate activity was controlled by a saturated potassium carbonate solution (45% relative humidity) for 4 min. Post-chromatographic UV irradiations for 4 min were performed with 600 W/m2 in a Suntest CPS+ (Atlas Material Testing Technology, Linsengericht, Germany), equipped with a xenon lamp and a filter combination of coated quartz glass and UV special glass. Chromatograms were documented under white light illumination with the Digistore 2 Documentation System (CAMAG). The densitograms were recorded in the absorption mode at 390, 415, 500, 525, and 550 nm by the TLC Scanner 3 (CAMAG) using the deuterium and wolfram lamps, automatic detector mode optimized to resolution, scanning speed of 20 mm/s, data resolution of 50 μm/step, and slit dimension of 5.0 mm × 0.2 mm. UV/vis spectra were recorded from 300 to 600 nm, using automatic detector mode optimized to light, slit dimension of 6.0 mm × 0.4 mm, scanning speed of 20 nm/s, and data resolution of 1 nm/step. Recorded spectra from 20, 80, and 200 ng/band of each dye were stored in a library. HPTLC instruments were controlled by the winCATS software 1.4.6.2002 (CAMAG).

Zones of interest were eluted (15 s) with the oval elution head of the TLC-MS interface (CAMAG) using methanol–10 mM formic acid (9:1, V/V) at a flow rate of 0.5 mL/min, provided by an HP 1100 modular system (Agilent Technologies, Waldbronn, Germany) with diode array detector (DAD at 275, 400, 500, and 550 nm), coupled through a Chromolith SpeedROD RP-18 column (50 mm × 4.6 mm, Merck) to a single quadrupole mass spectrometer (G1956B MSD, Agilent Technologies) equipped with an electrospray ionization (ESI) interface, operated in the positive ionization mode. Para Red and Sudan Orange G can be detected in both the positive and negative ESI mode. The following parameters were used: capillary voltage 4.0 kV (− 4.0 kV for Para Red and Sudan Orange G), drying gas temperature 300 °C, drying gas flow rate 10 L/min, nebulizer gas pressure 308 kPa, and quadrupole temperature 100 °C. Full scan mass spectra were recorded in the range of m/z 200–500 with a fragmentor voltage of 100 V (− 100 V for Para Red and Sudan Orange G), gain of 1.0, step size of 0.05, and threshold of 1. Data were processed with the software ChemStation B.02.01 SR2 (Agilent Technologies). Exact masses were calculated with MassWorks software (Cerno Bioscience, Danbury, CT, USA).

Results and discussion

Method development

Eight most frequently found fat-soluble azo dyes were selected (Fig. 1). Thirteen food samples including spices, spice mixtures, pastes, sauces, and palm oils were chosen as typically concerned food (Table 1). First experiments were conducted on normal phase HPTLC plates silica gel 60, as they were lowest in price. Fifteen different solvent systems regarding the selectivity groups of Snyder [40] and the possible influence of the plate activity (relative humidity) were investigated to achieve the separation of the eight azo dyes under study. However, six Sudan dyes were only slightly separated, while Sudan Orange G and Para Red were well separated due to strong polar substituents (Fig. 2). As compared to the separation on RP-18F254 HPTLC plates [38], the obtained results on silica gel plates provided less co-elutions, but the separation was not sufficient for quantitation by densitometry. Applying amino phases and spheric silica gel phases (HPTLC plates LiChrospher) also did not improve the separation (data not shown). Therefore, with caffeine solution, self-impregnated HPTLC silica gel plates and ready-to-use caffeine-preimpregnated HPTLC plates Nano-SIL-PAH were tested, providing π-stacking interactions in terms of selectivity, as already demonstrated for the separation of polycyclic aromatic hydrocarbons [39]. After investigation of different mobile phases and their optimization, the best separation was obtained on HPTLC plates Nano-SIL-PAH using isohexane and ethyl methyl ketone (5:1, V/V) up to 60 mm (Fig. 2, Table 2). By doing so, 23 separations were simultaneously performed within 20 min (Fig. S2). There was no difference in the resolution whether the commercially available, conveniently ready-to-use Nano-SIL-PAH plates or self-impregnated silica gel plates were used.

Three different separation mechanisms for the eight Sudan dyes, i.e., Sudan I–IV, Sudan Red B (B), Sudan Red 7B (7B), Sudan Orange G (OR), and Para Red (PR) as well as the internal standard (IS) 4-(dimethylamino)azobenzene: chromatograms on HPTLC plate silica gel 60, HPTLC plate RP-18, and caffeine-impregnated HPTLC plate silica gel 60; for the latter, the densitogram at 500 nm is exemplarily shown

While the chromatographic separation of the regioisomers Sudan IV and Sudan Red B could not be achieved, the clear assignment, however, was obtained by the subsequent HPTLC-HPLC-MS coupling, in case of positive findings. The assignment of Sudan IV and Sudan Red B is also highly challenging for RP-HPLC, when only MS/MS experiments utilizing different fragmentations allow the differentiation of these two isobaric Sudan dyes [42]. Another type of selectivity was achieved by a multi-wavelength scan (Fig. S3) at the maxima of absorbance of the individual azo dyes.

Since for exact quantitations an internal standard is highly recommended, azobenzene, azophenol, and 4-dimethylaminoazobenzene were checked in terms of retardation. The latter turned out to be the best selection, providing a high retardation factor (hRF) and clearly separated from the target dyes (Fig. 2, Table 2).

Simplification of the sample preparation

For the extraction of Sudan dyes from food, different solvents like acetonitrile, acetone, methanol, or ethanol have been reported alone or in combinations, mostly followed by SPE cleanup and enrichment [6]. During the preparation of standard solutions, it was observed that the Sudan dyes are not sufficiently soluble in methanol, while acetone was the better solvent. For the preparation of stock solutions, the less soluble Sudan III, Sudan IV, Sudan Red 7B, and Para Red at least needed 1.5 mL acetone per milligram dye. That meant that the treatment of 1 g sample with 4 mL acetone roughly extracted ca.1.5 mg dye, corresponding to 1500 mg/kg. However, for acetone as extraction solvent for Sudan dyes in food, a wide range of recoveries was reported, while methanol like ethanol resulted in best recoveries, obviously due to better polar penetration of dry samples [6]. Therefore, a two-step extraction was performed, i.e., samples were treated with acetone first, followed by the addition of methanol. Water-containing sauces were first submitted to an azeotropic distillation with acetonitrile [43], followed by the two-step extraction of the dry residue.

As to be expected, sample lipids were co-extracted and interfered with Sudan dyes in the chromatogram, especially lipophilic natural dyes from the group of carotenoids. To omit a separate SPE cleanup, saving costs and time, experiments to overcome the interferences were performed directly on the HPTLC plate. In one experiment, the complexation with silver nitrate was investigated on the plate, and in the second one, a simple UV irradiation of the chromatogram. Silver nitrate is known to interact with unsaturated lipids and, for example, allows the separation of fatty acids depending upon the number and isomerism of double bonds on silver nitrate-impregnated silica gel [44]. Therefore, a 3-mm band of silver nitrate was sprayed just above the sample application zone. However, silver nitrate not only slightly reduced the interferences by natural dyes and pigments, especially for samples providing high amounts of carotenoids like chili or paprika, but also affected the separation toward lower hRF values (Fig. S4). As carotenoids are rather susceptible to photooxidation, post-chromatographic UV irradiation was investigated, also in combination with silver nitrate. The results clearly showed the success in terms of a reduced interfering carotenoid background, providing a smoothed baseline in the densitograms (Fig. S5). The additional application of the silver nitrate solution as area did not substantially reduce the background. Hence, the simple post-chromatographic UV irradiation became part of the method. Different sample matrices were investigated for interferences and the effect of UV-irradiation. As to be expected, samples rich in carotenoids like chili and paprika strongly benefitted from the UV irradiation (Fig. 3), while samples like curcuma, curry, and palm oil did not require an UV treatment (Fig. S6). During UV irradiation, the comparatively light-fast Sudan dyes were only slightly affected. This was compensated by the simultaneous irradiation of the calibration standards, applied along with sample extracts onto the HPTLC plate (Fig. S2). Thus, quantitation was successful despite the simple sample preparation.

Simplified clean-up through a simple 4-min UV irradiation: reduced interferences by natural pigments (a prior versus b post UV irradiation), shown for a chili extract (C; no. 3 in Table 1), also spiked with Sudan Red 7B (C*) and internal standard (IS) 4-dimethylaminoazobenzene; the dashed lines mark the hRF window of the azo dyes under study on HPTLC plates Nano-SIL-PAH using isohexane and ethyl methyl ketone (5:1, V/V). The multi-wavelength scans refer to the tracks C* before and after UV irradiation

Screening method

For a rapid screening, standards and sample extracts were applied onto a 20 cm × 10 cm caffeine-impregnated HPTLC plate from both sides, followed by antiparallel chromatography in a horizontal developing chamber (Fig. 4). This enabled the simultaneous chromatography of 46 samples (including standards) within 5 min. The migration distance, however, was reduced to 50 mm affecting the separation, which was not sufficient for a quantitative evaluation, but it is an attractive tool for a rapid high-throughput screening.

Sudan dye screening showing 46 simultaneous separations within 5 min: chromatogram of an antiparallel development of food samples 9–13 (Table 1; 4 μL/band, applied multi-fold) along with standard mixture (S1-S4: 10, 20, 40, and 60 ng/band); separation on HPTLC plates Nano-SIL-PAH using isohexane and ethyl methyl ketone (5:1, V/V) up to 50 mm and documentation after UV irradiation for 4 min

Confirmation of results by targeted recording of UV/vis and mass spectra

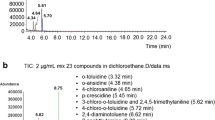

Positive results were easily confirmed by comparison of the recorded UV/vis spectrum with spectra stored in a library (Fig. S7). Additionally, the mass spectrum of a suspect zone was recorded to obtain a second proof of identification. The direct zone elution by the TLC-MS interface into the mass spectrometer, however, was not successful, because the high amount of co-eluting caffeine on the plate strongly superimposed the Sudan mass signals (Fig. 5b). Even the subtraction of a background mass spectrum did not reveal the mass signals of Sudan dyes. Therefore, a short RP-18 HPLC column was installed between the TLC-MS interface and the mass spectrometer, [45] allowing the separation of caffeine from the traces of Sudan dyes. Thus, clear mass signals of the respective Sudan dyes are obtained (Figs. 5c, d and S8) [46]. This orthogonal 2D procedure additionally had the great advantage to unequivocally differentiate the two co-eluting isobaric dyes Sudan IV and Sudan Red B, as they were clearly separated on the RP-18 column, which also held true for the adjacent pair Para Red and Sudan Orange G (Table S1). Using the software package MassWorks in combination with a single quadrupole MS [33, 47], mass signals were corrected by an algorithm and found to be a helpful tool to more reliably assign suspect zones, further strongly improving the identification (Fig. S9).

HPTLC-MS of a Sudan I zone (20 ng/band): a chromatogram of the separated azo dyes; b interfering caffeine from plate background only showed the mass signals of caffeine (m/z 195 [M + H]+; m/z 217 [M + Na]+; m/z 411 [2M + Na]+) versus c HPTLC-HPLC-MS resulting in the separation of caffeine and Sudan I, d clearly revealing the corresponding mass signal of Sudan I (m/z 249 [M + H]+)

Method validation

Sets of calibration were applied in a wide (10–200 ng/band) and a low (4–40 ng/band) range to cover samples of high and low spiking levels. For the wide and low calibration range, polynomial and linear calibration functions, respectively, with high correlation coefficients were obtained (Tables 2 and S2, Fig. S10). Limits of detection (LOD) and limits of quantification (LOQ) were calculated from signal-to-noise ratios and were about 2 and 7 ng/zone, respectively (Table 2). Regarding a sample weight of 1 g, the sample preparation procedure, and a sample extract application volume of 4 μL, the LOD and LOQ roughly correspond to 5 and 20 mg/kg, respectively, for all analytes under study, thus far below the amounts needed to successfully impact the color of spices or palm oils (100–1000 mg/kg [6]). The detectability, and thus, the LOD can be improved by the application of higher volumes of sample extracts, but is somewhat limited by interfering natural dyes and pigments, depending upon the sample under study. The UV irradiation, however, can also be increased up to 10 min without strongly affecting the targets.

All 13 studied samples of spices, pastes, sauces, and palm oil (Table 1) were found to be free (< LOD) of adulterations. Recovery studies exemplarily were performed with four Sudan dyes of different polarity at two levels, spiked to six different products representing dry powdered spicery, water-based sauces, oily pastes, and vegetable oils. The obtained recovery rates were between 73 and 120% (Table 3), which can be considered as highly satisfying at the trace level, considering the simple workflow and especially the rapid sample preparation without any cleanup of extracts.

Benchmarking

As compared to an LC-MS/MS analysis [42], the developed quantitative HPTLC method reduced the costs and time of analysis per sample by a factor of about 8 and 11, respectively, just regarding the chromatography (Table S3). For the total analysis including sample preparation and for the rapid qualitative screening method, these factors are even doubled and tripled, respectively. Especially to detect food fraud or adulteration, such an effective and reliable screening is highly desired for food control, as often several hundred samples need to be screened until getting a food fraud hit. This streamlined workflow was reached by the intrinsic key features of HPTLC that were robustness to sample matrix (plate is used only once), fast chromatography of many samples in parallel, UV irradiation of all samples at one go, detection as image and convenient evaluation of samples side by side, and for positive results, access to quantification and MS. The image-giving HPTLC screening additionally has the great chance to easily detect so far unknown fat-soluble dyes, rather than by accident [48].

Conclusions

The application of caffeine-impregnated silica gel plates allowed the separation of eight unauthorized fat-soluble azo dyes most frequently found in spices, spice mixtures, pastes, sauces, and palm oils. A simple sample extraction without SPE cleanup and enrichment afforded rapid analyses and a high sample throughput, while a post-chromatographic UV irradiation efficiently prevented interferences by natural dyes and pigments. This newly developed method enabled 23 simultaneous separations within 20 min for quantification or 46 separations within 5 min for screening. The analytical performance of detectabilities, calibrations, and recovery rates were highly suited to detect and quantitatively determine fat-soluble azo dyes unauthorizedly added to food. The combination of HPTLC with UV/vis spectroscopy and mass spectrometry performed as hyphenated HPTLC-vis-HPLC-DAD-ESI-MS guaranteed the unequivocal identification of positive results.

References

European Commission. RASFF - Food and Feed Safety Alerts. http://ec.europa.eu/food/safety/rasff_en.

The European Parliament and the Council of the European Union. Regulation (EC) no 178/2002 of 28 January 2002 laying down the general principles and requirements of food law, establishing the European food safety authority and laying down procedures in matters of food safety. Off J Eur Union. 2002;L 31:1–24.

The Comission of the European Communities. Comission decision of 20 June 2003 on emergency measures regarding hot chilli and hot chilli products (2003/460/EC). Off J Eur Union. 2003;L 154:114–5.

The Comission of the European Communities. Commission decision of 23 May 2005 on emergency measures regarding chilli, chilli products, curcuma and palm oil (2005/402/EC). Off J Eur Union. 2005;L 135:34–6.

The Comission of the European Communities. Commission decision of 21 January 2004 on emergency measures regarding chilli, chilli products, curcuma and palm oil (2004/92/EC). Off J Eur Union. 2004;L 27:52–4.

Rebane R, Leito I, Yurchenko S, Herodes K. A review of analytical techniques for determination of Sudan I-IV dyes in food matrixes. J Chromatogr A. 2010;1217:2747–57.

Ferrer Amate C, Unterluggauer H, Fischer RJ, Fernandez-Alba AR, Masselter S. Development and validation of a LC-MS/MS method for the simultaneous determination of aflatoxins, dyes and pesticides in spices. Anal Bioanal Chem. 2010;397:93–107.

Zheng M-M, Wu J-H, Feng Y-Q, Huang F-H. Rapid and sensitive determination of Sudan dyes in hot chilli products by solid-phase extraction directly combined with time-of-flight mass spectrometry. Anal Methods. 2011;3:1851–8.

Erdemir US, Izgi B, Gucer S. An alternative method for screening of Sudan dyes in red paprika paste by gas chromatography-mass spectrometry. Anal Methods. 2013;5:1790–8.

Siangproh W, Sonamit K, Chaiyo S, Chailapakul O. Fast determination of Sudan I-IV in chili products using automated on-line solid phase extraction coupled with liquid chromatography-mass spectrometry. Anal Lett. 2013;46:1705–17.

Genualdi S, MacMahon S, Robbins K, Farris S, Shyong N, DeJager L. Method development and survey of Sudan I-IV in palm oil and chilli spices in the Washington, DC, area. Food Addit Contam Part A. 2016;33:583–91.

Qi P, Zeng T, Wen Z, Liang X, Zhang X. Interference-free simultaneous determination of Sudan dyes in chili foods using solid phase extraction coupled with HPLC-DAD. Food Chem. 2011;125:1462–7.

Enriquez-Gabeiras L, Gallego A, Garcinuno RM, Fernandez-Hernando P, Durand JS. Interference-free determination of illegal dyes in sauces and condiments by matrix solid phase dispersion (MSPD) and liquid chromatography (HPLC-DAD). Food Chem. 2012;135:193–8.

Zhu Y, Wu Y, Zhou C, Zhao B, Yun W, Huang S, et al. A screening method of oil-soluble synthetic dyes in chilli products based on multi-wavelength chromatographic fingerprints comparison. Food Chem. 2016;192:441–51.

Schummer C, Sassel J, Bonenberger P, Moris G. Low-level detections of Sudan I, II, III and IV in spices and chili-containing foodstuffs using UPLC-ESI-MS/MS. J Agric Food Chem. 2013;61:2284–9.

Li J, Ding X-M, Liu D-D, Guo F, Chen Y, Zhang Y-B, et al. Simultaneous determination of eight illegal dyes in chili products by liquid chromatography-tandem mass spectrometry. J Chromatogr B Anal Technol Biomed Life Sci. 2013;942-943:46–52.

Tang B, Xi C, Zou Y, Wang G, Li X, Zhang L, et al. Simultaneous determination of 16 synthetic colorants in hotpot condiment by high performance liquid chromatography. J Chromatogr B Anal Technol Biomed Life Sci. 2014;960:87–91.

Fukuji TS, Castro-Puyana M, Tavares MFM, Cifuentes A. Sensitive and fast determination of Sudan dyes in chilli powder by partial-filling micellar electrokinetic chromatography-tandem mass spectrometry. Electrophoresis. 2012;33:705–12.

Khalikova MA, Satinsky D, Solich P, Novakova L. Development and validation of ultra-high performance supercritical fluid chromatography method for determination of illegal dyes and comparison to ultra-high performance liquid chromatography method. Anal Chim Acta. 2015;874:84–96.

Li Z, Zhang Y-W, Zhang Y-D, Bai Y, Liu H-W. Rapid analysis of four Sudan dyes using direct analysis in real time-mass spectrometry. Anal Methods. 2015;7:86–90.

Cao Y, Fang Z, Yang D, Gao Y, Li H. Voltammetric sensor for Sudan I based on glassy carbon electrode modified by SWCNT/β-Cyclodextrin conjugate. Nano. 2015;10:1550026.

Elyasi M, Khalilzadeh MA, Karimi-Maleh H. High sensitive voltammetric sensor based on Pt/CNTs nanocomposite modified ionic liquid carbon paste electrode for determination of Sudan I in food samples. Food Chem. 2013;141:4311–7.

Chang XC, Hu XZ, Li YQ, Shang YJ, Liu YZ, Feng G, et al. Multi-determination of Para red and Sudan dyes in egg by a broad specific antibody based enzyme linked immunosorbent assay. Food Control. 2011;22:1770–5.

Qi YH, Shan WC, Liu YZ, Zhang YJ, Wang JP. Production of the polyclonal antibody against Sudan 3 and immunoassay of Sudan dyes in food samples. J Agric Food Chem. 2012;60:2116–22.

Zvereva EA, Zaichik BT, Eremin SA, Zherdev AV, Dzantiev BB. Enzyme immunoassay for detection of Sudan I dye and its application to the control of foodstuffs. J Anal Chem. 2016;71:944–8.

Li C, Wu Y-L, Shen J-Z. UPLC-ESI-MS/MS analysis of Sudan dyes and Para red in food. Food Addit Contam Part A. 2010;27:1215–20.

Zhu Y, Zhao B, Xiao R, Yun W, Xiao Z, Tu D, et al. Simultaneous determination of 14 oil-soluble synthetic dyes in chilli products by high performance liquid chromatography with a gel permeation chromatography clean-up procedure. Food Chem. 2014;145:956–62.

Li Y, Wang Y, Yang H, Gao Y, Zhao H, Deng A. Establishment of an immunoaffinity chromatography for simultaneously selective extraction of Sudan I, II, III and IV from food samples. J Chromatogr A. 2010;1217:7840–7.

Piao C, Chen L. Separation of Sudan dyes from chilli powder by magnetic molecularly imprinted polymer. J Chromatogr A. 2012;1268:185–90.

Hu X, Cai Q, Fan Y, Ye T, Cao Y, Guo C. Molecularly imprinted polymer coated solid-phase microextraction fibers for determination of Sudan I-IV dyes in hot chili powder and poultry feed samples. J Chromatogr A. 2012;1219:39–46.

Rajabi M, Sabzalian S, Barfi B, Arghavani-Beydokhti S, Asghari A. In-line micro-matrix solid-phase dispersion extraction for simultaneous separation and extraction of Sudan dyes in different spices. J Chromatogr A. 2015;1425:42–50.

Xu Z, Wang S, Fang G, Song J, Yan Z. On-line SPE coupled with LC for analysis of traces of Sudan dyes in foods. Chromatographia. 2010;71:397–403.

Morlock GE, Brett N. Correct assignment of lipophilic dye mixtures? A case study for high-performance thin-layer chromatography–mass spectrometry and performance data for the TLC–MS Interface. J Chromatogr. 2015;1390:103–11.

Yüce I, Morlock GE. Streamlined structure elucidation of an unknown compound in a pigment formulation. J Chromatogr. 2016;1469:120–7.

Marshall PN. Thin-layer chromatography of Sudan dyes. J Chromatogr. 1977;136:353–7.

Dixit S, Khanna SK, Das M. A simple 2-directional high-performance thin-layer chromatographic method for the simultaneous determination of curcumin, metanil yellow, and sudan dyes in turmeric, chili, and curry powders. J AOAC Int. 2008;91:1387–96.

Guffog S, Brwon PA, Stangroom SG, Sutherland CA. The detection of sudan I, II, III and IV in palm oil by thin layer chromatography. Food Standards Agency Information Bulletin on Methods of Analysis and Sampling for Foodstuffs. 2004; (No. 52).

Kandler H, Bleisch M, Widmer V, Reich E. A validated HPTLC method for the determination of illegal dyes in spices and spice mixtures. J Liq Chromatogr Relat Technol. 2009;32:1273–88.

Morlock G, Kopacz S. Fast and precise SBSE-HPTLC/FLD method for quantification of six polycyclic aromatic hydrocarbons frequently found in water. J Liq Chromatogr Relat Technol. 2008;31:1925–42.

Snyder LR. Classification of the solvent properties of common liquids. J Chromatogr Sci. 1978;16:223–34.

Kowalska T, Kaczmarski K, Prus W. Theory and mechanism of thin-layer chromatography. In: Sherma J, Fried B, editors. Handbook of thin-layer chromatography, 3rd edition (chromatographic science series volume 89). New York: Marcel Dekker; 2003. p. 47–80.

Tsai C-F, Kuo C-H, Shih DY-C. Determination of 20 synthetic dyes in chili powders and syrup-preserved fruits by liquid chromatography/tandem mass spectrometry. J Food Drug Anal. 2015;23:453–62.

Pellissier E. HPTLC-Bestimmung von unerlaubt zugesetzten fettlöslichen Azofarbstoffen in Lebensmitteln: Diploma thesis, University of Applied Science, Western Switzerland/University of Hohenheim, Germany. 2009.

The American Oil Chemists‘ Society Lipid Library, http://lipidlibrary.aocs.org/Analysis/content.cfm?ItemNumber=40339&navItemNumber=19208. AOCS Lipid Library.

Morlock G, Schwack W. Hyphenations in planar chromatography. Journal of Chromatography A. 2010;1217:6600-6609

Oellig C, Schwack W. Strategies of coupling planar chromatography to HPLC–MS. In: Kowalska T, Sajewicz M, Sherma J, editors. Planar chromatography—mass spectrometry (chromatographic science series volume 110). Boca Raton, London, New York: CRC Press; 2016. p. 169–94.

Wang Y, Gu M. The concept of spectral accuracy for MS. Anal Chem. 2010;82:7055–62.

Ruf J, Walter P, Kandler H, Kaufmann A. Discovery and structural elucidation of the illegal azo dye Basic Red 46 in sumac spice. Food Additives & Contaminants: Part A 2012;29:897-907

Acknowledgements

Thank is owed to Merck (Darmstadt, Germany) and Macherey-Nagel (Düren, Germany) for providing HPTLC plates, and to CAMAG (Berlin, Germany) with regard to HPTLC instruments, and to Dr. Claudia Oellig (University of Hohenheim, Germany) for repeating a couple of MS experiments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Published in the topical collection Food Safety Analysis with guest editor Steven J. Lehotay.

Electronic supplementary material

ESM 1

(PDF 0.99 mb)

Rights and permissions

About this article

Cite this article

Schwack, W., Pellissier, E. & Morlock, G. Analysis of unauthorized Sudan dyes in food by high-performance thin-layer chromatography. Anal Bioanal Chem 410, 5641–5651 (2018). https://doi.org/10.1007/s00216-018-0945-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-018-0945-6