Abstract

A series of bulk and Al2O3-supported perovskite oxides of the type LaMn1 − x − y Fe x Mo y O3 (x = 0.00−0.90 and y = 0.00–0.09) were synthesized by the citric acid complexation–gelation method followed by annealing in air at 800 °C. For all samples, the local environment and the chemical state and concentration of surface species were determined. Mössbauer spectra revealed the only presence of octahedral Fe3+ ions dispersed in the perovskite structure, however well-crystallized together with a poorly crystalline LaFeO3 phases were detected for larger substitutions (x = 0.90). A similar picture was obtained for Mo-loaded (y = 0.02 and 0.05) samples but a new phase most likely related to Fe3+ ions dispersed aside from the perovskite structure was found for larger substitutions (y = 0.09). Together with these structures, supported samples showed the presence of LaFeO3 nanoparticles. Finally, photoelectron spectroscopy indicated that the chemical state and composition of the samples in the surface region (2–3 nm) approaches that of the bulk. For the unsupported substituted samples, iron (and molybdenum) enters into the perovskite structure while manganese tends to be slightly segregated. Moreover, in supported perovskites, a fraction of Mo and La atoms interact with the alumina surface. All these oxides were active in methane combustion and best performance was recorded for the Fe-rich composition (x = 0.9) in which both Mn3+ and Mo3+ ions were in the same proportion (y = 0.05).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Perovskite-type oxides have attracted great interest in both applied and fundamental areas of solid-state chemistry, physics, advanced materials, and catalysis [see, e.g., 1, 2 and references therein]. Perovskite-type oxides have the general formula ABO3, where B is a cation, usually a transition metal, surrounded by six oxygens in octahedral coordination, and A is a cation, usually a rare-earth metal, 12-coordinated by oxygens, which occupies the cavities made by the BO6 octahedra. Many metallic elements are stable in the perovskite structure provided that the A and B cations have dimensions (r A > 0.90 Å and r B > 0.51 Å) in agreement with the limits of the so-called “tolerance factor” \( t\left( {0.{\text{8}}\kern1.5pt<\kern1.5ptt\kern1.5pt<\kern1.5pt{\text{1}}} \right) \) [1, 2]. As the tolerance factor decreases, the structure is distorted, becoming tetragonal, octahedral, or orthorhombic in structure. The properties of perovskites ABO3 can be easily modified by the substitution of the A site cation, usually La3+, by another cation of different oxidation state, and also by substitution of the B site cation. When the substituting cation has lower oxidation state, anionic vacancies or unusually high oxidation state of B cation are generated to maintain the structure electroneutrality. The high surface reactivity of such substituted systems is considered to be related to their defective structures and/or the unusual oxidation states of B cation [1, 2].

In general, perovskite-type oxides exhibit specific surface areas of a few square meters per gram, thus their potential as catalytic materials is limited. Most of the methods used for their preparation involve a calcination step at high temperature, i.e., above 700 °C, consequently large particle grain size and low specific surface area are usually obtained. In order to increase their specific surface area, many approaches have been undertaken along the last decade. Various methods of preparation were used for the synthesis of perovskite, among which reactive grinding [3–5], sol–gel and citrate methods [6–9], combustion synthesis [10], and spray drying [11] remain prominent. However, the literature data show that it is not easy to keep the high surface area and to avoid sintering processes simultaneously in those procedures.

Most perovskites have not been able to compete successfully in many catalytic applications, due to their low specific areas, weak mechanical strength, and poisoning by S compounds. To overcome these difficulties, developing a well-dispersed perovskite on a support having a high specific area has been an attractive strategy to optimize the number of exposed surface sites. By means of the impregnation methods, the first attempt was done by Johnson et al. [12], and then many other works were conducted with the aim to deposit perovskite particles on various substrates [13–16].

This paper deals with the effect of substitution of manganese by iron (and molybdenum) in LaMnO3 perovskite on the bulk and surface characteristics of the resulting unsupported and Al2O3-supported LaMn1 − x − y Fe x Mo y O3 (\( x = 0.00 - 0.90 \) and \( y = 0.00 - 0.09 \)) oxides. In addition, the reactivity of these systems for the catalytic combustion of methane is examined. The choice of this reaction was made with the aim to understand the effect of the oxygen mobility (surface or bulk) and transition metal reducibility on the catalytic activity. To achieve this objective, Mössbauer (MS) and photoelectron spectroscopy (XPS) techniques were employed.

Experimental

Samples preparation

The perovskite LaMn1 − x − y Fe x Mo y O3 oxides were prepared using the Pechini method [17, 18] by the reaction of 0.5 mol of citric acid (CA, Merck) dissolved in 2 mol of water at 60 °C, followed by the addition of 1 mmol of La(NO3)3·6H2O (Fluka), and different proportions of the other salts, such as Fe(NO3)3·9H2O (Aldrich), MnCl2 (Merck) and MoO2(acac)2 (Aldrich), in order to achieve the desired stoichiometry. The mixture was stirred for about 2 h, until a clear orange solution of the stable metals–CA complexes is obtained. After the complete dissolution, 400 mmol of ethylene glycol (EG) was added and the solution was continuously stirred while the temperature was slowly increased to 90 °C to remove the excess of water and allows the polyesterification reaction between CA and EG. The temperature was kept at 90 °C for 7 h after which a viscous dark-orange precursor was obtained. This resin was then treated at 400–450 °C in air for 2 h. The final dark brown powder was grinded into a fine powder and then calcined at 800 °C in air for 6 h.

The supported perovskites were prepared following the same procedures, just adding the Al2O3 nanoparticles (Aldrich) after the addition of EG to the salt solutions while keeping the suspension under stirring for 0.5 h. Drying and calcination of these perovskite-loaded Al2O3 particles was the same than above for the unsupported oxides. Substitution degree (x and y) in LaMn1 − x − y Fe x Mo y O3 samples and codes for both unsupported and alumina-supported oxides are given in Table 1.

Characterization techniques

The Mössbauer spectra at 298 K were taken in transmission geometry with a 512-channel constant acceleration spectrometer (CMTE spectrometer model MA250). A source of 57Co in an Rh matrix of nominally 50 mCi was used. Velocity calibration was performed against a 12-μm-thick α-Fe foil. All isomer shifts (δ) mentioned in this paper are referred to this standard at room temperature. The spectra were folded to minimize geometric effects and were evaluated using a commercial computer-fitting program coded Normos-90.

Surface analysis was carried out on a VG Escalab 200R electron spectrometer provided with AlKα1 X-ray (hv = 1,486.6 eV, \( {\text{1}}\,{\text{eV}} = {\text{1}}.{\text{63}}0{\text{2}} \times {\text{1}}{0^{ - {\text{19}}}}{\text{J}} \)) 120-W source and a hemispherical electron analyser. The powder samples were pressed into small Inox cylinders and then mounted on a sample rod, placed in a pretreatment chamber and degassed at 573 K and 10−5 mbar for 2 h prior to being transferred to the analysis chamber. Before the spectra were recorded, the samples were maintained in the analysis chamber under a residual pressure ca. 2 × 10−9 mbar for 2 h. The area under analysis was around 2.4 mm2 and the pass energy of the analyser was set at 50 eV, for which the resolution as measured by the full width at half maximum (FWHM) of the Au 4f 7/2 core level was 1.4 eV. The binding energies were referenced to the C 1s peak at 284.9 eV due to adventitious carbon. This reference gave BE values with an accuracy of ±0.2 eV. Data processing was performed with the XPS peak software, the spectra were decomposed with the least squares fitting routine provided with this software using Gauss/Lorentz (90/10) product function and after subtracting a Shirley background. Atomic fractions were calculated using peak areas normalized on the basis of sensitivity factors. Atomic ratios were computed from the intensity ratios normalized by atomic sensitivity factors [19].

Catalytic performance

All the samples were tested in the methane combustion reaction. The methane combustion reaction was carried out at atmospheric pressure in a tubular (8 mm i.d.) fixed-bed Pyrex glass reactor. Mass flow controllers (Bronkhorst) monitored and controlled the flow of gases used to obtain the feed mixture and pretreat the catalyst. The catalyst (0.05 g) was diluted with 0.30 g of silicon carbide. A thermocouple placed inside the reactor, in the center of the catalyst bed, monitored the reaction temperature. Prior to each experiment, the catalyst was treated under 100 cm3 min−1 (STP) of air (Praxair 99.999%) for 1 h at 200 °C. The total feed flow rate was 170 cm3·min−1 (STP) of a mix with 3% methane, 20% oxygen, and 77% nitrogen, resulting in a weight hourly space velocity (WHSV) referred to the amount of supported catalyst in the reactor and total feed mass flow rate of 200 L h−1 g −1cat . The ignition curves were obtained after pretreatment in the decreasing temperature mode starting from 50 °C and increasing temperature at a rate of 2 °C min−1 up to 900 °C. Online analysis of the product stream was performed on a Varian 3400 gas chromatograph provided with thermal conductivity detector and columns packed with Porapak N and 13X molecular sieves. Estimated error of gas-phase composition was within 5%.

Results

Local environment

As the Mössbauer spectroscopy is a versatile technique that can be used to provide very precise information about the chemical, structural, magnetic and time-dependent properties of the 57Fe nuclei placed in a solid matrix, we have used this technique to analyze both unsupported and Al2O3-supported Fe-containing perovskite oxides. These results are summarized below.

Unsupported perovskites

The Mössbauer spectra of the LaMn1 − x − y Fe x Mo y O3 perovskites series are shown in Fig. 1) and the analysis of the hyperfine parameters are collected in Table 2). The LaMn0.73Fe0.27O3 and LaMn0.46Fe0.54O3 perovskites show only a doublet located, respectively, at δ = 0.33 mm/s, Δ = 0.52 mm/s, and δ = 0.33 mm/s, Δ = 0.62 mm/s, which is related to octahedral Fe3+ ions dispersed in the perovskite structure (see subspectrum 1, Fig. 1). It can be seen in Fig. 1 that this structure splits into a sextet for higher concentration of iron. The LaMn0.10Fe0.90O3 sample displays a signal with hyperfine parameters at δ = 0.37 mm/s, ε = −0.05 mm/s and B Hf = 51.3 T (see subspectrum 2, Fig. 1) with a relative area of 47%, which is assigned to the well-crystallized LaFeO3 structure. A second sextet at δ = 0.37 mm/s, ε = 0.05 mm/s and B Hf = 49.2 T (see sub spectrum 3, Fig. 1) with area 53% is also observed. This is identified to a poorly crystallized LaFeO3 type structure, probably due to the presence of small particle size or to the presence of Mn [20, 21].

The results for the Mo-loaded LaMn0.08Fe0.90Mo0.02O3 sample are very similar (Fig. 1), but the relative intensity of the more crystalline phase is lowered down to 36% (δ = 0.36 mm/s, ε = −0.05 mm/s and B Hf = 50.9 T) with a slight increase to 64% of the poorly crystallized phase (δ = 0.37 mm/s, ε = 0.09 mm/s and B Hf = 48.4 T). Thus, the proximity of the molybdenum onto the octahedral Fe3+ centers induces an important change in the perovskite structure. Finally, the Mössbauer spectra for the perovskites having higher Mo concentration show an additional doublet (subspectrum 4, Fig. 1) at δ = 0.23 mm/s, Δ = 0.62 mm/s with a small relative spectral area of 7%. This signal is most likely related to Fe3+ ions dispersed outside of the perovskite structure. The values of the quadrupole shift/splitting near to zero in almost all spectra confirms the pseudo-cubic structure proposed on the basis of the respective X-ray diffraction patterns (data not shown here).

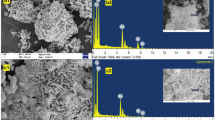

Supported perovskites

The Mössbauer spectra of the supported perovskites are shown in (Fig. 2) and the hyperfine parameters are compiled in Table 2. For each perovskite, three sub spectra are obtained: one sextet similar to that observed in the non-supported perovskite, and two doublets. For instance, for the Fe090(25%)/A sample subspectrum 1 is a sextet at δ = 0.36 mm/s, ε = −0.05 mm/s and B Hf = 47.1 T whose spectral area is 65%, whereas subspectra 2 and 3 are doublets whose Mössbauer parameters are δ = 0.29 mm/s, Δ = 0.96 mm/s with spectra area of 31%, and δ = 0.35 mm/s, Δ = 0.38 mm/s, with a spectral area of 4%, respectively. The sextet hyperfine field is smaller than that observed for the non-supported Fe090, indicating a low-crystalline and disperse perovskite phase. These results are in good agreement with the decrease of the crystallite size observed by XRD data not shown here). The two doublets (sub spectra 2 and 3) can be likely associated to two superparamagnetic Fe3+ phases in octahedral coordination, which could be related with perovskite nanoparticles. The hyperfine field distribution (Fig. 2, details) suggests a non-uniform particle size distribution.

The same explanation holds for the supported Mo002 sample. It can be observed otherwise a higher proportion of superparamagnetic phase, suggesting that the Mo promotes the formation of small particles. Furthermore, the proportion of these phases increases with decreasing the perovskite/alumina ratio (39, 32 and 20% for Mo002(25%)/A, Mo002(33%)/A and Mo002(50%)/A, respectively), indicating that the perovskite dispersion is higher upon decreasing the perovskite amount in the composite.

Surface analysis

The chemical state of the atoms and their relative abundance in the topmost few atomic layers of the solids were evaluated by photoelectron spectroscopy. It is emphasized that preliminary XPS experiments using MgKα1 radiation showed that the O 1s peak overlaps with the LaM3N3N3 Auger peak. Since the position of the Auger peaks is independent on the energy of the photon of the exciting source, the separation of the energy regions of O 1s core level and LaM3N3N3 Auger contribution was possible by using AlKα1 instead MgKα1 source. Accordingly, all XP spectra were recorded using AlKα1 radiation and the corresponding binding energies of core electrons are summarized in Table 3.

Figure 3a and b show the spectra of the most intense La 3d 5/2 core level of unsupported and Al2O3-supported LaMn1 − x − y Fe x Mo y O3 samples, respectively. As illustrated by each spectrum the 3d 5/2 line profile displays two maxima separated by nearly 4.1 eV. The appearance of this doublet indicates hybridization of the 3d–4f levels of lanthanum in all these compounds and correspond to 3d 94f 1 (binding energy in the region 834.3–835.1 eV) final state. Two final states in lanthanum are produced by empty (poorly screened) and filled (well screened) 4f states near Fermi level [22]. The binding energy values of the La 3d 5/2 (3d 94f 1) line are compiled in Table 3. While no significant differences are observed in the binding energy values (834.3–834.7 eV), both the resolution of the doublet and splitting of 3d 94f 1 and 3d 104f 0 differ among the samples suggesting that not only La–O–M (M = Fe, Mn, Mo) bonds, belonging to the perovskite structure, but also other La species such as La(OH)3 or/and La2O2(CO3) species are present on the topmost layer(s) of the solid. Another interesting finding derived from binding energy measurements of La 3d 5/2 core level is the slight shift by ca. 0.5 eV of the 3d 94f 1 component toward higher values in Al2O3-supported samples. Due to the relative ease with which La2O3 reacts with Al2O3 [23], this observation may reflect the interaction of lanthanum on the alumina surface.

The chemical state of manganese in the two series of unsupported and Al2O3-supported samples was also studied by the XPS technique. The binding energies of Mn 2p 3/2 core level (Table 3) for all LaMn1 − x Fe x O3 samples fall within the range 642.0–642.3 eV and are quite similar for the Al2O3-supported samples. On the contrary, the BEs values for the Mn 2p 3/2 level in Mo002 and Mo005 are ca 1 eV lower than that measured on the Mo-free and -supported samples. Unfortunately, no Mn 2p 3/2 signal was obtained for Mo009 due to the very low surface concentration of manganese in this sample. The Mn 2p 3/2 binding energy around 641.1 eV has often been assigned to Mn2+ [24, 25] whereas that close to 642 eV is characteristic of Mn3+ ions in oxide systems [26, 27]. Consistent with the formation of Mn2+ ions in the unsupported Mo-loaded samples is the decrease in the BE of Mo 3d 5/2 level (vide infra).

The Fe 2p line profiles were quite similar for all samples and the respective binding energies were very close to the values expected for LaFeO3 [28]. All the Fe 2p spectra (not shown) displayed the characteristic spin-orbit splitting of Fe3+ ions together with a weak satellite structure above the 2p 3/2 and 2p 1/2 peaks at about 8.3 eV which is the fingerprint of Fe3+ ions in an oxide environment. Only in the Al2O3-supported samples (Table 3) the binding energy of Fe 2p 3/2 level increases slightly (ca. 0.3 eV) which can be due to the interaction of a fraction of Fe3+ with the alumina substrate.

The binding energy of Mo 3d 5/2 level of LaMn1 − x − y Fe x Mo y O3 samples appears at ca. 231.8 eV and remains almost constant for all the samples. The molybdenum species responsible for this binding energies, which are some partially reduced molybdenum oxide species, presumably Mo4+ ions, and the parallel formation of Mn2+ in these samples can be taken as conclusive that Mo ions incorporate into the perovskite lattice. On the contrary, binding energies of this Mo 3d 5/2 level for the three Mo-loaded supported samples appear somewhere at 0.4 eV higher binding energies (Table 3) and approach the value expected for Mo6+ species [29]. This later finding suggests that the chemical environment of molybdenum changes to a significant extent when the perovskite phase is deposited on the alumina substrate.

The O 1s spectra were fitted to two components, the most intense one located at low binding energy (529.3–529-5 eV) assigned to surface O2− species [1] and the second one around 531.5 eV due to hydroxyl/carbonate groups [30]. The O 1s spectra of unsupported LaMn1 − x − y Fe x Mo y O3 samples are displayed in Fig. 4a. No other O 1s component at binding energies above 533.5 eV coming from molecular water was observed. This means that the degassing procedure prior to analysis was satisfactory. The Al2O3-supported samples exhibited a complete different line profile (Fig. 4b). While the O 1s peak can be fitted again to two components placed at almost the same binding energies, the intensity of the peak around 531.5 eV is higher than that of the peak of lower binding energy. This is because the binding energy of the oxygen atoms coming from the Al2O3 substrate, typically 531.5 eV [31], overlaps with the second high-binding-energy component of the perovskite oxides.

The C 1s energy region was also examined for all the samples. A common characteristic of lanthanum compounds is that they become quickly carbonated by moisture. This phenomenon has been already observed on the O 1s and La 3d 5/2 profiles but is clearer in the C 1s energy region. These C 1s profiles display two components, one at a binding energy of 284.9 eV due to adventitious carbon (contamination) and the second one at 288.8–289.0 eV for the unsupported samples and at 289.2–289.4 eV for the supported counterparts is characteristic of carbonate structures [1, 2, 32]. For the sake of simplicity, only the binding energy value of the high-energy component has been included in Table 3.

In addition to binding energy measurements of the elements, quantitative evaluation was also determined. The surface composition was calculated from peak intensities normalized by atomic sensitivity factors according to Wagner et al. [19]. The surface atomic ratios Fe/La, Mn/La, Mo/La, Al/La, and C/La are summarized in Table 4. It can be seen that the values of Mn/La ratios are a little higher than the nominal ones whereas that of Mo/La and Fe/La are closer (Fig. 5). It can also be noted that the extent of carbonation is somewhat higher for the supported samples than for the bulk ones, but in no case was a carbonate monolayer reached.

Performance for methane combustion

The light off curves for methane combustion over the perovskite oxide systems indicated differences in their catalytic activity. In order to compare catalytic performance, all systems were ranked according to the reaction temperature required to achieve 50% of methane combustion (T 50). The values of T 50 parameter are included in Table 4 (last column). From the values of T 50 it is clear that Fe090 sample is the most active (T 50 = 574 °C) among the LaMn1 − x Fe x O3 series whereas the parent Fe054 sample exhibits somewhat poorer performance (T 50 = 609 °C). It is also observed that partial substitution of Mo by Mn in Fe-rich LaMn0.1 − x Fe0.9Mo x O3 influences on catalysts performance. While the performance remains almost unchanged for a low substitution x = 0.02 (Mo002), an improvement is observed for the parent sample x = 0.05 (Mo005), whose T 50 is lowered (T 50 = 563 °C). For the sample with a higher substitution degree (Mo009) in which the Mn content is very low, its T 50 is increased indicating a poorer performance. In addition, the T 50 values collected in Table 4 around 50 °C higher than for the unsupported counterparts indicate poorer performance for all Al2O3-supported perovskites.

Discussion

The local environment around the Fe3+ ions was revealed by Mössbauer spectroscopy. The Mössbauer parameters of LaMn1 − x Fe x O3 (x = 0.27 and 0.54) samples indicated the presence of a well-crystallized perovskite phase in which octahedral Fe3+ ions appear well-dispersed. However, for the Fe-richer x = 0.9 sample a poorly crystalline LaFeO3 phase was detected together with the well-crystallized one. As this later sample exhibited smaller crystal sizes than the other Mn-rich counterparts (Rosmaninho et al. in preparation), it would be inferred that crystal size and crystalline order run in parallel. Moreover, Mössbauer spectra of Mo-loaded samples revealed some relevant structural details. Although the samples Mo002 and Mo005 still showed a highly crystalline LaFeO3 phase and another ill-defined structure, a slightly higher substitution (sample Mo009) gave rise to the formation of a minor fraction of Fe3+ ions dispersed outside the perovskite phase. According to this data, it appears that only a fraction of Mo3+/Mo4+ ions (most likely Mo4+ ions judging from their binding energies) up to y = 0.05 can be accommodated within the crystal. In the alumina-supported samples, the support has a dramatic effect on the structure of supported perovskite phase because not only the ill-crystalline and highly dispersed phases were developed but also two superparamagnetic Fe3+-containing nanoparticles appeared at the alumina interface. Moreover, as it would be expected, a higher alumina:perovskite ratio resulted in a higher perovskite dispersion.

While the Mössbauer technique appeared very useful to characterize the bulk structures of the unsupported and alumina-supported samples, new details on the type of species and their relative abundance at the surface region of the solids were derived from photoelectron spectroscopy. Surface region means a region of the solid including only the few topmost atomic layers. It is emphasized that the inelastic mean free path of the photoelectrons ejected from atomic orbitals is in the order of about 3 nm, and hence chemical information is confined to a very thin layer of the solid close to the surface.

An examination of the binding energies of La 3d 5/2 level for the supported perovskites (Table 3) indicates an increase of ca. 0.5 eV in supported samples with respect to the unsupported ones. This shift can be interpreted in terms of the formation of a small fraction of the LaAlO3 compound [23], also displaying a perovskite structure. In fact, such a structure would not be determined by XRD because its thickness is too low as to get coherent diffraction and hence, observable diffraction lines. Moreover, as the LaAlO3 structure does not have Fe nuclei, Al and La nuclei cannot be probed by Mössbauer spectroscopy. Another interesting finding was the observation of carbonate structures in all the samples. Because lanthanum oxides become easily carbonated when exposed to the ambient, all samples displayed a component in the C 1s core levels located at binding energies in the range 288.8–289.0 eV for the unsupported samples and at somewhat higher ca. +0.4 eV for the supported counterparts which is due to strongly held surface carbonate [1, 2, 32]. The slightly higher binding energy of C 1s peak of carbonates on supported samples with respect to the unsupported counterparts (see Table 3) points to a different carbonate structure present in these two systems. Indeed, we demonstrated that these carbonates adopt structures of the monodentate and bidentate type [1] and the respective binding energy depends on the type they adopt. We assume that structures of the bidentate type are likely located on the alumina interface and/or on the perovskite nanoparticles, revealed by Mössbauer spectroscopy, in close contact with the alumina surface.

Quantitative surface analysis (Table 4) indicated a relatively good agreement between the surface atomic ratios and that expected from nominal composition. Notwithstanding, careful examination of the Mn/La (and Mo/La) ratios in Fig. 5 indicate that XPS Mn/La ratios are slightly higher than that expected from the formula, however the Mo/La ratios are quite similar. This fact appears of great importance if we want to exploit a property of the material which is strongly linked with the transition element (B) in the LaBO3 structures, i.e., catalytic activity in combustion reactions in our case.

Finally, the enhancement in catalytic activity for methane combustion of LaMn1 − x − y Fe x Mo y O3 (x = 0.00–0.90 and y = 0.00–0.09) systems observed in the Fe-rich region (x = 0.9) and in the presence of a certain proportion of Mo (y = 0.05; Table 4, last column) appears to be related to some structural changes in the LaFeO3 phase. The observation of a well-dispersed and poorly crystalline LaFeO3 perovskite in which Mo3+ ions are substituted to a certain extent by Fe3+ can explain the observed improvement in catalytic performance. Moreover, the drop in catalytic activity observed for the Mo009 sample with respect to the most active Mo005 one suggests that coexistence of a minor proportion of Mn3+ ions in the La(Fe,Mo)O3 phases are essential to reach optimal reactivity of surface oxygen species of the perovskite system.

Summary and conclusions

The local environment of iron ions and identification and quantification of surface species on both unsupported and Al2O3-supported perovskite oxides of the type LaMn1 − x − y Fe x Mo y O3 (x = 0.00–0.90 and y = 0.00–0.09 have been investigated. It was found that annealing at 800 °C causes the formation of pseudo-cubic crystalline structures in which Mn3+ are isomorphically substituted by Fe3+ ions. For large Fe substitutions (x = 0.90), Mössbauer spectra revealed the presence not only of a well-crystallized LaFeO3 structure but also another less-crystalline perovskite phase. It was also demonstrated that Mo enters into the perovskite structure for Mo-loaded samples with low substitution degree (y = 0.02 and 0.05). In the Mo005 system, the enhancement of catalytic performance for methane combustion is associated to appearance of the less-crystalline LaFeO3 phase and incorporation of molybdenum into this perovskite structure.

Finally, XPS appeared as an extremely useful technique to determine both the chemical state of the elements and surface concentration. Although good agreement was found, the surface atomic ratios and that expected from nominal composition, slight surface manganese enrichment was observed (cf. Fig. 5) and this was clearer in the Mn-rich composition region.

References

Tejuca LG, Fierro JLG, Tascón JMD (1989) Adv Catal 36:237–328

Peña MA, Fierro JLG (2001) Chem Rev 101:1981–2017

Kaliaguine S, Van Neste A, Szabo V, Galot JE, Bassir M, Muzychyuk R (2001) Appl Catal A: Gen 209:345–358

Szabo V, Bassir M, Van Neste A, Kaliaguine S (2003) Appl Catal B: Environ 43:81–92

Petrovic S, Kirilov-Stefaniv P, Karanovic L, Zdujic M, Terlecki-Baricevic A (2005) Appl Catal B: Environ 58:133–141

Ponce S, Peña MA, Fierro JLG (2000) Appl Catal B: Environ 24:193–205

Porta P, Cimino S, De Rossi S, Faticanti M, Minelli G, Pettiti I (2001) Mater Chem Phys 71:165–173

Forni L, Rossetti I (2002) Appl Catal B: Environ 38:29–37

Ciambelli P, Cimino S, Lasorella G, Lisi L, De Rossi S, Faticanti M, Minelli G, Porta P (2002) Appl Catal B: Environ 37:231–241

Civera A, Negro G, Specchia S, Saracco G (2005) Specchia Catal Today 100:275–281

Sauvinet AL, Fouletier J, Gaillard F, Primet M (2002) J Catal 209:25–34

Johnson DW, Gallagher PK, Schnettler PK, Vogel EM (1977) Am Ceram Soc Bull 56:785–792

Skoglundh M, Lowendahl L, Jansson K, Dahl L, Nygren M (1994) Appl Catal B: Environ 3:259–274

Marti PE, Maciejewski M, Baiker A (1994) Appl Catal B: Environ 4:225–235

Klvana D, Kirchnerova J, Gauthier P, Delval J, Chaouki J (1997) Can J Chem Eng 75:509–519

Nguyen SV, Szabo V, Trong On D, Kaliaguine S (2002) Microp Mesop Mat 54:51–61

Moura FCC, Tristão JC, Lago RM, Martel R (2008) Catal Today 133–135:846–854

Popa M, Frantti J (2002) Solid State Ion 154–155:437–445

Wagner CD, Davis LE, Zeller MV, Taylor JA, Raymond RH, Gale LH (1981) Surf Interface Anal 3:211–224

Berry FJ, Ren X, Marco JF (2005) Czech J Phys 55:771–780

Zhong Z, Chen K, Ji Y, Yan Q (1997) App Catal A: Gen 156:29–41

Hufner S (1995) In: Cardona M, Fulde P, von Klitzing K, Queisser H-J (eds) Photoelectron spectroscopy. Springer, Berlin

Kuo CL, Wang CL, Chen TY, Chen GJ, Hung IM, Shih CJ, Fung KZ (2007) J Alloys Compd 440:367–374 and references therein

Hueso JL, Caballero A, Ocana M, Gonzalez-Elipe AR (2007) J Catal 257:334–344

Colmenares C, Deutsch S, Evans C, Nelson AJ, Terminello LJ, Reynolds JG, Roos JW, Smith IL (1999) Appl Surf Sci 151:189–202

Bukhtiyarova MV, Ivanova AS, Plyasova LM, Litvak GS, Rogov VA, Kaichev VV, Slavinskaya EM, Kuznetsov PA, Polukhina IA (2009) Appl Catal A: Gen 357:193–205

Arzamendi G, de la Peña VA, Alvarez-Galvan MC, Fierro JLG, Gandia LM (2009) J Catal 261:50–59

Pecchi G, Reyes P, Zamora R, Cadús LE, Fierro JLG (2008) J Solid State Chem 181:905–912

Moulder JF, Strickle WF, Sobol PE, Bomben (eds) (1992) Handbook of X-ray Photoelectron Spectroscopy. Perkin Elmer Co, Eden Prairie, MN, USA

Lee YN, Lago RM, Fierro JLG, Cortes V, Sapina F, Martinez E (2001) Appl Catal A: Gen 207:177–124

Kloprogge JT, Duong LV, Wood BJ, Frost RL (2006) J Colloid Interface Sci 296:572–576

Taguchi N, Sugita A, Nagao M (1995) J Solid State Chem 119:164–168

Acknowledgments

The authors would like to thank M.C. Pereira, J.D. Fabris, and J.D. Ardison for the Mössbauer analysis and the Brazilian CNPq and CAPES for the grants. The financial support provided for this work by the Spanish Ministry of Science and Innovation (ENE2007-07345-C03-01/ALT) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rosmaninho, M.G., Tristão, J.C., Moura, F.C.C. et al. Structural and surface analysis of unsupported and alumina-supported La(Mn,Fe,Mo)O3 perovskite oxides. Anal Bioanal Chem 396, 2785–2795 (2010). https://doi.org/10.1007/s00216-009-3308-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-009-3308-5