Abstract

Molecularly imprinted microspheres (MIMs, >3 μm) and nanospheres (MINs, ≈450 nm) for the environmental endocrine disruptor di(2-ethylhexyl)phthalate (DEHP) were prepared by a precipitation polymerization (PP) procedure. The effect of the dispersive solvents acetonitrile (ACN) and cyclohexane (CH), the cross-linkers ethylene glycol dimethacrylate (EDMA) and trimethylpropane trimethacrylate (TRIM), and the template on particle size and morphology of polymers was investigated in detail by scanning electron microscopy (SEM) and BET adsorption isotherm determination. When used as HPLC stationary phase, the microspheres exhibited strong affinity for the template DEHP with an imprint factor (IF) higher than 8.0 in ACN/water (60:40, v/v) as mobile phase. Furthermore, baseline separation of DEHP from benzyl butyl phthalate (BBP) and dibutyl phthalate (DBP) could be achieved. In contrast, no or only poor separation could be observed with non-imprinted polymeric polymers (NIPs) or imprinted bulk polymers (MIB), respectively. Similarly, the obtained MINs exhibited an imprinting effect in pure ACN, i.e. the bond amount of DEHP was significantly higher compared to NIPs, as was shown in rebinding experiments. Besides their use as an HPLC stationary phase, MIMs might further be applicable for SPE sample cleanup, while MINs could be used as a recognition layer on sensor surfaces.

Molecularly imprinting of di(2-ethylhexyl)phthalate (DEHP)

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

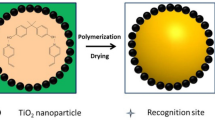

Molecularly imprinted polymers (MIPs) are tailor-made materials with high selectivity for the target molecule (template). MIPs have been exploited in several applications, such as chemical sensors [1, 2], capillary electrophoresis and electrochromatography [3], enantiomeric separations [4], catalysis [5], HPLC stationary phases [6–11], and solid-phase extraction (SPE) [12, 13]. Up to now, various strategies have been developed for the preparation of MIPs. The most widely used method is bulk polymerization. However, the obtained monolith needs to be crushed, ground and sieved, which is a rather time-consuming and labour-intensive procedure. Generally, less than 50% of the ground particles are recovered as useable items. Furthermore, the particles possess heterogeneous binding site distribution with poor site accessibility and low mass transfer kinetic properties for the target analyte. As a result, the irregular particles generally exhibit low separation efficiency for target molecules [10]. Thus, to avoid some of these drawbacks, several synthetic strategies have been proposed for the production of spherical MIP particles (spherical beads), such as suspension polymerization in water [8, 9], liquid perfluorocarbon [14] or mineral oil [15], two-step swelling polymerization [16], miniemulsion polymerization [2] and core-shell emulsion polymerization [17]. However, water or highly polar organic solvents, which possibly decrease the non-covalent interactions between functional monomers and templates during the polymerization procedures, were frequently used as dispersive solvents in the abovementioned methods. An attractive and reliable method for the routine production of monodisperse spheres is by means of precipitation polymerization (PP) which is performed under diluted conditions (<5% w/v) in a suitable dispersive solvent [18]. Particulate growth predominantly occurs by entropic precipitation of nanogel (seed) particulates followed by continuous capture of oligomers from solution [18]. The polymeric spheres formed in this way are protected from aggregation during polymerization by their cross-linker and are completely surfactant free [10]. Most of the spherical particulates obtained display diameters below 1 μm [19, 20]. Such small particles were only used for capillary electrophoresis [20], radioligand binding assays [21] and chemical sensors [22]. They are less suitable for HPLC and SPE applications due to the high backpressure of the column packed with such small particulates. A few attempts have been made to obtain particle sizes of approximately 3–10 μm (molecularly imprinted microspheres, MIMs) [1, 10, 11].

Di(2-ethylhexyl)phthalate (DEHP) is a common plasticizer used to improve the flexibility of poly(vinyl chloride) (PVC). DEHP easily leaches from the PVC products into the environment and may be transferred into water, air and food. Human beings may be readily exposed to phthalates in medical products, some food packaging materials or by exposure to contaminated workplaces and indoor air. Some animal experiments indicated that DEHP is a toxicant to the reproductive system [23, 24]. Hazard evaluation associated with phthalates such as DEHP revealed reproductive toxicity and teratogenicity and malformed offspring in mice [25]. A further report described the relationship between testicular cancer and occupational exposure to PVC containing phthalate plasticizer [26]. In addition, DEHP is a peroxisome proliferator that induced tumours in rodent livers [27]. To our knowledge, there exists no report on the synthesis, characterization and applications of MIPs for DEHP. In the present study, we prepared DEHP-imprinted microspheres using PP. The effect of synthesis conditions such as type of dispersive solvent, cross-linker and template on the morphology and particulate size distribution were investigated in detail. The particles were further characterized by HPLC, scanning electron microscopy and/or BET physisorption investigation and rebinding experiments.

Experimental

Chemicals and materials

DEHP, benzyl butyl phthalate (BBP), dibutyl phthalate (DBP), 2,2′-azobis (2-isobutyronitrile) (AIBN), methanol (MeOH, HPLC grade), dichloromethane (DCM, HPLC grade), acetonitrile (ACN, HPLC grade) and cyclohexane (CH) were obtained from Merck (Darmstadt, Germany). Methacrylic acid (MAA) and trimethylolpropane trimethacrylate (TRIM) were purchased from Sigma–Aldrich (Taufkirchen, Germany). Ethylene glycol dimethacrylate (EDMA) and hexadecane were obtained from Fluka (Steinheim, Germany). All solutions were prepared using ultrapure water, obtained by reversed osmosis including UV treatment (Milli-RO 5 Plus, Milli-Q185 Plus, Millipore, Eschborn, Germany).

Preparation of bulk polymers

DEHP (1 mmol) and MAA (4 mmol) were dissolved in 10 mL of ACN in a glass tube. EDMA (20 mmol) and AIBN (30 mg) were then added to the solution. After purging with nitrogen for 10 min, the glass tube was sealed under nitrogen and then placed in a temperature-controlled water bath at 60 °C for 24 h. The resultant monolith was crushed, ground and sieved. The particulates with size between 32 and 63 μm were collected and sedimented with acetone (three times) to remove fine particulates. The template was removed by washing with 50 mL of acetic acid/MeOH (1:9, v/v) using sonication for 15 min. After centrifugation at 4,000 g for 10 min the supernatant was discarded. This procedure was repeated up to five times until the DEHP in the supernatant could not be detected by HPLC. Finally, the particulates were washed with 50 mL of pure MeOH and dried under vacuum.

Preparation of microspheres and nanospheres by precipitation polymerization

The template (1 mmol) and monomer (4 mmol) (Table 1) were successively dissolved in 25 mL of ACN or CH and transferred into a 250-mL round-bottom or conical flask, respectively. The mixture was placed into a refrigerator at 0 °C and maintained for 30 min. Then, 20 mmol of EDMA or 16 mmol of TRIM, 30 mg AIBN and another 50 mL of ACN or CH were added and the mixture was sonicated in a water bath. The total mixture was sparged with nitrogen for 5 min to remove traces of oxygen. Finally, the flask was sealed and placed into a thermostatted water bath (MT, MGW Lauda, Königshofen, Germany). The polymerization was performed at 60 °C for 24 h. The microspheres obtained were filtered with a porous glass fibre filter (porosity 0.45 μm; Sartorius AG, Göttingen, Germany) and washed with MeOH, DCM, MeOH and MeOH/water (1:1, v/v) successively. The washing procedure with DCM was repeated until the template could not be detected by UV in the extraction solvent. Non-imprinted polymeric particulates (NIPs) were prepared in the same way without the addition of the template molecule. With the nanoparticles, the extraction of the template was slightly different. Approximately, 1.0 g of particles was weighed into a conical flask and 50 mL MeOH/acetic acid (9:1, v/v) was added. After sonicating for 15 min, the solution was centrifuged at 5,000 g for 10 min. The supernatant was collected and determined for the presence of DEHP by HPLC. The procedure was repeated until the template could not be detected. Finally, pure MeOH was used to remove remaining acetic acid. The obtained MIMs and MINs were used for HPLC and rebinding experiments, respectively.

Characterization of MIMs and MINs

Scanning electron microscopy images were obtained on a Stereoscan S360 (Leica/Cambridge) equipped with a VHV Dewar Xflash detector system (Röntec, Berlin, Germany). The conductive layer was created by sputtering the sample with Au using the Bal-Tec, Balzers SCD 004 sputter coater. The parameters used were as following: magnification ×10,000, voltage 20 kV, current 200 pA and distance 25 mm. The average size and size distribution of the MINs were obtained by dynamic light scattering (DLS) using a Zetasizer Nano ZS instrument (Malvern Instruments GmbH, Herrenberg, Germany). The sample was diluted with water to adjust the intensity of the scattering light. Physisorption measurements to determine the surface area and mesopore size distribution (using nitrogen as inert gas) were performed with a Sorptomatic 1990 instrument (ThermoQuest GmbH, Bremen, Germany). Surface areas were determined according to the BET model; pore volumes and size distributions were determined according to the BJH model.

Rebinding experiments

A 10-mg sample of the MINs or NIPs was weighed into an 8-mL glass tube. Then 2.0 mL of DEHP solution (ACN solution) with known concentration was mixed with the polymers. The mixture was incubated on a horizontal shaker (Minishaker MS 1, IKA-Werke, Staufen, Germany) for 24 h and then filtered (ISOPORE Membrane filters, 0.1μm VCTP, Millipore). The concentration of DEHP in the filtrate was measured by using an HPLC system which consisted of a Crystal 200 liquid chromatograph, a Crystal 250 diode array detector, temperature control module (Unicam, Cambridge, UK) and degasser (DGU-3A, Shimadzu, Japan). The amount of DEHP bound to the polymers was calculated by subtracting the amount of free DEHP from the initial concentration.

HPLC characterization of MIMs

The MIMs (≈3 μm) obtained were packed by a slurry method into a stainless steel column (125 × 4.0-mm i.d.) (Phenomenex, Aschaffenburg, Germany) using a S2100 solvent delivery system (Sykam, Gilching, Germany) with MeOH/water (80:20, v/v) as pushing solvent. Column oven temperature was set at 25 °C and the detection wavelength at 275 nm. The column was rinsed on-line with ACN/DCM (80:20, v/v) and ACN/water (60:40, v/v) solution successively until a stable baseline was obtained. The total flow rate was maintained at 0.8 mL min−1. Injection volume was 20 μL. The retention factor (k′) was calculated according to standard chromatographic procedure as k′ = (t − t 0)/t 0, where t and t 0 are retention time of sample peak maximum and void time, respectively. The void time (t 0) was determined by the elution time of a negative peak produced by the solvent. To serve as a control, an additional column was packed with NIPs and conditioned using an identical procedure. To compare with the bulk polymers, another column packed with bulk polymers (≈32–63 μm) was also prepared. The imprinting factor (IF) was calculated as IF = k′MIMs/k′NIPs, where k′MIMs and k′NIPs were the retention factors of analytes on the imprinted and non-imprinted column, respectively.

Results and discussion

Effect of dispersive solvent on polymer morphology

As mentioned in the Introduction, PP is a rather popular method for the synthesis of spherical particulates. However, most of the early reports in this area described imprinted polymeric spherical particulates with diameters typically less than 1 μm. Later, micron-sized imprinted spheres (>3 μm) for HPLC and SPE applications were obtained through rational design and control of the polymerization conditions [10, 11]. To obtain larger microspheres, matching the solubility parameter of the developing polymer network to that of the porogenic solvent(s) is particularly important [11]. For example, larger microspheres could be obtained by addition of toluene into ACN as dispersive solvent when divinylbenzene (DVB) was used as cross-linker [10, 11]. This is because poly(DVB) and toluene possess similar solubility parameters (17–18 and 18.6 MPa0.5). The present investigation demonstrated that CH was not suitable as porogen for the preparation of larger microspheres when TRIM was used as cross-linker. However, the morphology and particulate size were evidently improved with the dispersive solvent ACN and cross-linker EDMA (Fig. 1).

Effect of cross-linker on polymer morphology

It is well known that the radical polymerization process used in PP is kinetically controlled [18]. Therefore, all factors that affect the kinetic equilibrium during the polymerization process, such as the amounts and varieties of cross-linker, monomer, template, initiator and solvent, as well as the temperature, affect the morphology and distribution of the emerging particulates. For example, lower concentration of monomers and cross-linkers (<5%, w/v) in dispersive solvent are favourable in forming larger microspheres [10, 11]. This is because, under dilute conditions, less oligomers and nuclei are formed at the beginning of the polymerization. As a result, more radical monomers and cross-linkers diffuse to the surface of nuclei and grow up into larger microspheres. Particulate size also increases with increasing polymerization temperature, which is the result of faster diffusion [1].

In the present study, two cross-linkers were compared. It was found that with DEHP as template the average particle size of MAA-co-EDMA polymers (≈3–3.5 μm) was somewhat larger compared to that of MAA-co-TRIM polymers (≈2–2.5 μm). The solubility parameters of 18.2 and 18.5 MPa0.5 for EDMA and TRIM, respectively, are almost identical [28, 29]. The most obvious difference between these experiments was the amount of cross-linker used in the polymerization mixture. While the concentration of TRIM was about 7.2% (w/v), it was only 5.3% (w/v) in the case of EDMA. By analogy to earlier reports [10, 11] discussed above, this difference in concentration should have led to the observed discrepancy in particle size.

Effect of template on polymer morphology

A recent study suggested that the presence of template molecules (e.g. theophylline) in the polymerization process did not influence significantly the morphology of MAA-co-DVB polymers [11]. However, our results demonstrate that the presence of the template molecule (DEHP) apparently influenced the morphology and the particulate distribution of MAA-co-EDMA polymers. This is in accordance with previous findings [30, 31]. It can be observed from Fig. 1 that there is a clear difference between MIMs (Fig. 1, P3-MIMs) and NIPs (Fig. 1, P3-NIPs). This is likely attributed to the fact that DEHP is a rather hydrophobic compound which significantly changes the polarity of the polymerization mixture. This assumption could be further proved by the influences of BBP and DBP. It can be concluded from Fig. 3 (P3, P4, P5) that the different templates only slightly influenced the morphology and distribution of the microspheres. We speculate that this is caused by matching solubility parameters of the templates and the developing polymer network. To our knowledge, this is the first report which described the PP synthesis of MAA-co-EDMA microspheres with diameters >3 μm for possible use as HPLC stationary phases and SPE applications.

HPLC characterization of microspheres

To characterize the molecular recognition and chromatographic retention behaviour of the microspheric particles and a molecularly imprinted bulk polymer (MIB) they were packed into different HPLC columns and analysed as described in the Experimental section. It can be observed from Fig. 2a that a baseline separation of DEHP, BBP and DBP could be achieved on the P3-MIMs column. In contrast, no separation at all could be obtained with the NIP-column (Fig. 2b). The elution profiles showed that the retention time of template (DEHP) on the P3-MIMs column is much longer (Rt = 24.15 min) than that on the P3-NIPs column (Rt = 4.04 min). Moreover, the broad and long-tailing peak of DEHP on the P3-MIMs column is characteristic for an imprinted HPLC stationary phase.

Only a poor separation of DEHP, BBP and DBP was observed with the MIB (Fig. 2c). The retention time of DEHP was significantly shorter (5.04 min) compared to the MIMs column. This is supposed to be mainly caused by the differences in surface area, particulate shape and size between both polymers. The poor separation of the MIB column is ascribed to the larger size and irregular shape of the particulates, mainly. However, the calculated IFs of DEHP on both MIMs and MIB columns were quite similar (8.02 vs. 9.80) despite of the polymerization method. This implies that the IFs of DEHP are hardly influenced by the two polymerization procedures although the k′ values are distinctly different (15.88 and 8.0, respectively).

In addition, the recognition and retention behaviour of BBP and DBP on MIMs columns was also investigated. The k′ value and IF of the three phthalates are depicted in Fig. 3. Several conclusions can be drawn. Firstly, the DEHP-MIMs column has both the highest k′ value (Fig. 3a, column 1) and IF (Fig. 3b, column 1) for its template DEHP, which implies that the hydrophobic interaction between the long alkyl chains of DEHP and the MIMs binding sites was significant. Secondly, the NIPs showed the lowest retention (non-specific interaction) for all phthalates investigated (Fig. 3a, white columns). Finally, the highest IF values of the three phthalates were observed on their respective imprinted polymers (Fig. 3b, columns 1–3), which suggested the real existence of the imprinting effect. The much higher IF value of DEHP on its MIMs column compared with those on the other polymers indicated that there was a very strong specific interaction between the template and the binding sites.

Comparison of a the retention factors (k′) and b the imprinting factors (IFs) of DEHP, BBP and DBP on DEHP-MIMs, BBP-MIMPs, DBP-MIMs and NIPs column (HPLC conditions as described in the Experimental section)

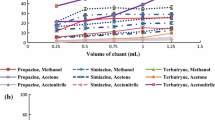

Owing to the good separation behaviour of the DEHP MIMs column, the effects of the composition of the mobile phase and flow rate on the retention behaviour were further investigated. The retention time of DEHP on the MIMs column increased with increasing water content in the mobile phase (Fig. 4a). This indicated that the hydrophobic interaction between the long alkyl chain of DEHP and the binding sites became the key factor in the retention and recognition process. On the other hand, Fig. 4b showed that the retention time decreased with increasing flow rate. Generally, a short retention time should be applied to reduce the analysis time. However, increasing the flow rate will cause high column backpressure (Fig. 4c) which will lead to column damage. Thus, as a compromise aimed at achieving good separation of phthalates in a rather short time with acceptable column pressure, ACN/water (60:40, v/v) and a flow rate of 0.8 mL min−1 were selected as the optimal mobile phase and flow rate, respectively.

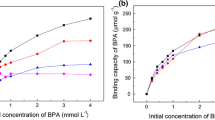

Characterisation of nanospheres

Interestingly, polymers of significantly different diameter (i.e. micrometre- and nanometre-sized particles) were obtained in this study, by apparently using the same synthesis conditions. The only obvious difference in conditions was discovered to be the shape of the reactor vessel. Our investigations demonstrated that microspheres were obtained with a round-bottom flask, whereas nanospheres (≈450 nm, Fig. 5a) were produced using a conical flask. Although highly speculative, kinetic parameters of the polymerization reaction such as radial diffusion and local concentration of reactants could be related to the shape of reactor; however, this has to be proved in the future. Results from rebinding experiments in pure ACN revealed a much higher binding of imprinted nanospheres (MINs, Fig. 5b, solid square) compared to the blank particles (NIPs, Fig. 5b, solid triangle). Based on data from nitrogen gas adsorption/desorption isotherms it became clear that this difference was not caused by differences in the surface area of both polymers, since these were very similar (32.77 and 36.18 m2 g−1 for NIP and MIN, respectively). Furthermore, a comparison of pore size distribution revealed that with both polymers the pore dimensions predominantly cluster in the 0- to 6-nm range based on pore surface area, respectively (Table 2).

Conclusions

For the first time, molecularly imprinted polymeric microspheres and nanospheres for di(2-ethylhexyl)phthalate were synthesized using precipitation polymerization. The type of dispersive solvent and cross-linker evidently influenced the particulate size and morphology of resulting polymers. MAA-co-EDMA microspheres of diameters >3 μm were successfully applied to HPLC. They exhibit a stronger affinity for DEHP (IF > 8.0) compared to the non-imprinted polymer (NIPs). In comparison with the irregularly shaped and larger-sized bulk polymeric material, the DEHP-MIMs column possessed good chromatographic behaviour such as baseline separation of DEHP from BBP and DBP. In accordance with the MIMs, prepared MINs (≈450 nm) exhibited a significant imprinting effect, as was observed from rebinding experiments in pure ACN. While MIMs might be further applicable as support material for SPE sample preparation, MINs might be used as a recognition layer on sensor surfaces.

References

Wei ST, Molinelli A, Mizaikoff B (2006) Biosens Bioelectron 21:1943–1951

Vaihinger D, Landfester K, Krauter I, Brunner H, Tovar GEM (2002) Macromol Chem Phys 203:1965–1973

Spiegel P, Schweitz L, Nilsson S (2003) Electrophoresis 24:3892–3899

Andersson LI, Mosbach K (1990) J Chromatogr 516:313–322

Ramstrom O, Mosbach K (1999) Curr Opin Chem Biol 3:759–764

Yano K, Karube I (1999) Trends Anal Chem 18:199–204

Caro E, Marce RM, Borrull F, Cormack PAG, Sherrington DC (2006) Trends Anal Chem 25:143–154

Lai JP, Lu XY, Lu CY, Ju HF, He XW (2001) Anal Chim Acta 442:105–111

Lai JP, Cao XF, Wang XL, He XW (2002) Anal Bioanal Chem 372:391–396

Turiel E, Tadeo JL, Cormack PAG, Martin-Esteban A (2005) Analyst 130:1601–1607

Wang JF, Cormack PAG, Sherrington DC, Khoshdel E (2003) Angew Chem Int Ed Engl 42:5336–5338

Lai JP, He XW, Jiang Y, Chen F (2003) Anal Bioanal Chem 375:264–269

Hu SG, Wang SW, He XW (2003) Analyst 128:1485–1489

Mayes AG, Mosbach K (1996) Anal Chem 68:3769–3774

Kempe H, Kempe M (2004) Macromol Rapid Commun 25:315–320

Haginaka J, Takekira H, Hosoya K, Tanaka N (1999) J Chromatogr A 849:331–339

Perez N, Whitcombe MJ, Vulfson EN (2000) J Appl Polym Sci 77:1851–1859

Li WH, Stover HDH (1998) J Appl Polym Sci Part A 36:1543–1551

Tamayo FG, Casillas JL, Martin-Esteban A (2005) J Chromatogr A 1069:173–181

de Boer T, Mol R, de Zeeuw RA, de Jong GJ, Sherrington DC, Cormack PAG, Ensing K (2002) Electrophoresis 23:1296–1300

Ye L, Surugiu I, Haupt K (2002) Anal Chem 75:959–964

Zhang ZH, Long YM, Liu YJ, Yao SZ (2003) Chin J Chem 21:550–555

Sjoberg P, Bondesson U, Gray TJB, Ploen L (1986) Acta Pharmacol Toxicol 58:225–233

Davis BJ, Weaver R, Gaines LJ, Heindel JJ (1994) Toxicol Appl Pharmacol 128:224–228

Peters JM, Taubeneck MW, Keen CL, Gonzalez FJ (1997) Teratology 56:311–316

Hardell L, Ohlson CG, Fredrikson M (1997) Int J Cancer 73:828–830

International Agency for Research on Cancer (1995) Peroxisome proliferation and its role in carcinogenesis. In: IARC Technical Report No 24. World Health Organization, Lyon

Horak D, Chaykivskyy (2002) J Polym Sci Pol Chem 40:1625–1632

Qi T, Sonoda A, Makita Y, Kanoh H, Ooi K, Hirotsu T (2002) J Appl Polym Sci 83:2374–2381

Cacho C, Turiel E, Martin-Esteban C, Pérez-Conde C, Cámara C (2004) J Chromatogr B 802:347–353

Perez-Moral N, Mayes AG (2004) Anal Chim Acta 504:15–21

Acknowledgements

We gratefully acknowledge the financial support by the European Commission (contract number QLK4-CT2002-02323). Further, we thank Dr. Rolf Nitzsche (Malvern Instruments GmbH, Herrenberg, Germany) for performing dynamic light scattering measurements with the Zetasizer Nano ZS instrument. Xaver Hecht (Department of Chemistry, Technische Universität München) is thanked for performing physisorption measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lai, JP., Yang, ML., Niessner, R. et al. Molecularly imprinted microspheres and nanospheres for di(2-ethylhexyl)phthalate prepared by precipitation polymerization. Anal Bioanal Chem 389, 405–412 (2007). https://doi.org/10.1007/s00216-007-1321-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-007-1321-0