Abstract

Concern about the environmental fate and potential effects of synthetic organic chemicals used in soaps, lotions, toothpaste, and other personal care products continues to increase. This review describes procedures used for the analysis of five classes of these compounds–synthetic musk fragrances, antimicrobials, ultraviolet filters, insect repellents, and parabens–in water, sediment, sewage sludge, air, and aquatic biota. The primary focus is on sample extraction and preparation methods for these compounds. Instrumental methods commonly used for these compounds are also discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Several personal care product ingredients were among the most commonly detected compounds in the seminal report on organic contaminants in United States’ (US) streams published in 2002 by the United States Geological Survey (USGS) [1]. Concern about the environmental fate and potential effects of synthetic organic chemicals used in soaps, lotions, toothpaste, and other personal care products continues to increase [2–6]. Of particular concern are compounds that are used in large volumes, persist in the environment, bioaccumulate, or have a designed bioactivity. The primary objective of this review is to provide a thorough summary of sample preparation methods published over the last decade (ca. 1995 to 2005) for the routine measurement of five important groups of personal care chemicals in air, water, sediments, aquatic biota, and sewage sludge. These groups are synthetic musk fragrances, antimicrobials, sunscreen agents, insect repellents, and parabens (Tables 1, 2, 3, 4, 5 and 6). Common instrumental analysis techniques are also summarized.

Synthetic musk fragrances are compounds added to scent a variety of personal care products, including deodorant, shampoo, and detergents. There are two types of synthetic musk fragrances: nitro musk fragrances and polycyclic musk fragrances. The nitro musk fragrances were the first to be produced and include musk xylene, musk ketone, musk ambrette, musk moskene, and musk tibetene. In the environment, the nitro substituents can be reduced to form amino metabolites of these compounds. The structures, formula names, CAS registry numbers, and molecular masses of these compounds are listed in Table 1. The polycyclic musk fragrances include 1,3,4,6,7,8-hexahydro-4,6,6,7,8,8-hexamethylcyclopenta-γ-2-benzopyrane (HHCB), 7-acetyl-1,1,3,4,4,6-hexamethyl-1,2,3,4-tetrahydronaphthalene (AHTN), 4-acetyl-1,1-dimethyl-6-tert−butylindane (ADBI), 6-acetyl-1,1,2,3,3,5-hexamethylindane (AHMI), 5-acetyl-1,1,2,6-tetramethyl-3-iso-propylindane (ATII), and 6,7-dihydro-1,1,2,3,3-pentamethyl-4(5H)-indanone (DPMI) (structures shown in Table 2). The polycyclic musk fragrances are used in higher quantities than the nitro musk fragrances. HHCB and AHTN are used in the highest quantities and HHCB is on the US Environmental Protection Agency (EPA) High Production Volume (HPV) list [its use and production in the United States is greater than 450,000 kg per year (1 million pounds)]. Recent global usage statistics for these compounds are unavailable. Worldwide production estimates in 1996 for the nitro musk fragrances (mainly musk xylene and musk ketone) and polycylic musk fragrances (mainly HHCB and AHTN) were 2000 metric tons and 5600 metric tons [7, 8].

The first synthetic musk fragrances detected in the environment were the nitro musk fragrances musk xylene and musk ketone [9]. The concentrations of these compounds in freshwater fish collected from the Tama River in Tokyo, Japan in 1980 were ≈0.2 ng/g and ≈0.05 ng/g for musk xylene and musk ketone, respectively. In this first study, an extensive sample extraction and preparation procedure was used followed by analysis using gas chromatography with an electron capture detector (GC-ECD) and gas chromatography with electron impact mass spectrometry (GC/EI-MS). Using similar methods, these compounds were measured for the first time in surface water and wastewater treatment plant effluent, and marine shellfish around Tokyo [10]. Rimkus and coworkers have highlighted the published extraction, purification, and analysis methods for musk xylene and musk ketone in fish [11]. In response to reports of a rapid method for the analysis of musk xylene in fish without further purification [12, 13], they stressed the importance of lipid removal prior to analysis by gas chromatography–mass spectrometry (GC/MS). The occurrence and fate of nitro musk fragrances [8] and polycyclic musk fragrances [7, 14] in the aquatic environment has been reviewed recently.

Triclosan and triclocarban (structures shown in Table 3) are antimicrobial compounds used in soap, toothpaste, and other consumer products. The environmentally relevant metabolites of triclosan (methyl triclosan and three chlorinated derivatives) are also included in this review. Kanetoshi and coworkers first identified the potential for triclosan to form chlorinated products [15]. Triclosan has been measured in human milk samples in Sweden [16] and in environmental matrices in North America and Europe.

Sunscreen agents [ultraviolet (UV) filters] are increasingly added to cosmetics and lotions as protection against harmful UV radiation. These compounds are added to products in relative amounts of 0.1% to 10%. There are currently sixteen different compounds permitted for use as sunscreen agents in the US, fourteen of which are organic compounds [17]. In the European Union, twenty-six different organic compounds are permitted [17]. Several of these compounds show estrogenic activity [18–28]. Salvador and Chisvert recently reviewed methods for the analysis of these compounds in sunscreen cosmetics [29].

Relatively little is known about the occurrence and fate of UV filters in the environment. The hydrophobicity of many of these compounds (log K ow 5–8) indicates the potential for bioaccumulation. Analytical methods for the identification and quantification of ten UV filters and two metabolites shown in Table 4 are reviewed here. The lack of analytical methods for the other UV filters of economic importance is an important limitation on the understanding of the environmental fate of this class of compounds.

Analytical methods for the insect repellents N,N-diethyl-m-toluamide (DEET, from N,N-deethyl-m-toluamide) and Bayrepel, and an oxidation product of Bayrepel—Bayrepel-acid—are reviewed (structures shown in Table 5). Of these compounds, the majority of published works is on DEET, which is widely used. An estimated 1.8 million kg was used in the US in 1990 [30]. It is possible that the use of DEET has increased in the US over the last several years due to concern about the spread of West Nile Virus by mosquitoes. DEET is classified as an indoor, residential-use pesticide by the US EPA. As such, ecological risk assessments are not required. DEET has been detected widely in aquatic systems, but the processes controlling its environmental fate have not been well-studied. From limited toxicity data, DEET is slightly toxic to aquatic invertebrates, fish, and birds [30]. In some places (e.g., Germany) DEET has been phased out. One alternative chemical is Bayrepel.

P-hydroxybenzoic esters (parabens) are the most common preservatives used in personal care products. Parabens are also used as preservatives in pharmaceuticals and food products. This group of compounds includes methylparaben, propylparaben, ethylparaben, butylparaben, and benzylparaben (structures shown in Table 6). Methylparaben and propylparaben are the most widely used parabens and are normally used together due to synergistic preservative effects. Due to their high use and resistance to antimicrobial degradation, it is expected that parabens enter the environment; however, little work has been done to quantify the distribution and fate of these compounds in the environment. Routledge and coworkers first reported on the estrogenic behavior of parabens in 1998 [31]. The current knowledge about the endocrine activity of these compounds has been summarized recently in two reviews [32, 33]. Parabens have been measured in a variety of consumer products including cosmetics, pharmaceuticals, and food using high-pressure liquid chromatography (HPLC) with UV absorbance detection (HPLC-UV) [34, 35], ion mobility spectrometry [36], and chemiluminescence [37] detection.

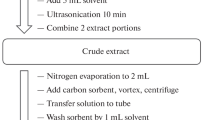

General comments on sample preparation methods

Extraction and preparation methods

Several of the sample preparation methods described in here have been reviewed in detail previously. Soxhlet extraction has been a common method for the extraction of environmental contaminants [38]. The use of pressurized fluid extraction (PFE) for contaminants in environmental and biological matrices has been reviewed recently [39–43]. PFE is also referred to as pressurized liquid extraction (PLE), and by the trade name Accelerated Solvent Extraction (ASE; Dionex; Sunnyvale, CA, USA). Microwave-assisted extraction (MAE) is becoming an important extraction method for environmental samples [44–46]. In addition, there are a variety of solid-phase extraction (SPE) sorbents available for the concentration of contaminants in water. The selection and use of these materials has been reviewed recently [47–49].

Precautions to avoid sample contamination

Due to the ubiquitous use of these compounds, care must be taken to avoid contamination of samples and the laboratory environment. Basic precautions include avoiding the use of products containing these target compounds and the use of gloves for sample handling. Careful cleaning of glassware is important. A typical cleaning procedure involves sonication with a detergent without these chemicals, baking for at least 4 h at 450 °C, and rinsing with acetone and hexane or similar solvents prior to use. High-purity solvents should be used. Also, method blanks should be used to monitor for contamination from the laboratory environment, contaminated solvents, or other sources. The potential for contamination of solvents by musk xylene [50] and UV filters [51, 52] has been discussed.

Synthetic musk fragrances

Sample extraction and preparation

Water

Liquid–liquid extraction (LLE) [1, 53–67], SPE [68–78], solid-phase microextraction (SPME) [79–82], and simultaneous steam-distillation/solvent extraction (SDE) [83] have been used for the analysis of synthetic musk fragrances in various water matrices. These methods are summarized in Table 7.

Filtered and unfiltered wastewater and surface water samples (0.5 L to 100 L) have been extracted using LLE with dichloromethane [1, 56–58], pentane [67], dichloromethane and pentane [61, 62], hexane [55, 59, 60, 63], toluene [65, 66], cyclohexane [82], and petroleum ether [64]. In many instances, particularly for surface water samples, additional extract purification was not performed. The most common purification procedure for these extracts was SPE using silica [64, 67, 82] and alumina [59, 60].

Several SPE sorbents have been used for the analysis of synthetic musk fragrance in water, including C18 [68, 75–78], Abselut NEXUS (Varian; Palo Atlo, CA, USA) [73, 74], Bio Beads SM-2 (Bio-Rad Laboratories; Hercules, CA, USA) [71], XAD-2 (Supelco; St. Louis, MO, USA) [72], and XAD-4/XAD-8 [70]. HHCB, AHTN, musk ketone, and musk xylene were among suites of compounds concentrated from water with C18 at ambient pH [75–78] and pH<3 [68]. Eluents included acetone, dichloromethane and acetone, and dichloromethane and methanol. Polystyrene-divinylbenzene (PS-DVB) copolymers, including XAD-2 [72], XAD-4/XAD-8 [70], and Bio Beads SM-2 [71] have also been used to concentrate synthetic musk fragrances from surface water and wastewater. Large-volume water samples (80–200 L) were used in two of these studies [71, 72]. Abselut NEXUS, a proprietary 1:1 mixture of modified PS-DVB and poly(methyl methacrylate), was also used for the concentration of synthetic musk fragrances and amino metabolites from large-volume (60 L) water samples [73, 74]. Elution from these materials was achieved with hexane/acetone (1:1 VR) [72], methanol and dichloromethane [71], hexane and ethyl acetate [73, 74], and acetone [70]. Some researchers purified extracts prior to analysis using SPE with silica [71–74] and size-exclusion chromatography (SEC) [73, 74].

HHCB, AHTN, ADBI, musk xylene, musk ketone, musk ambrette, musk moskene, and musk tibetene were analyzed in water by direct solid-phase microextraction (DI-SPME) with polydimethylsiloxane (PDMS) (100 μm) [80]. A sorption time of 40 min at room temperature (22 °C) with stirring (1000 rpm) was used. DI-SPME and headspace solid-phase microextraction (HS-SPME) using PDMS (100 μm), PDMS-DVB (65 μm), Carboxen-PDMS (75 μm), and Carbowax-DVB (65 μm; Supelco) provide adequate recoveries of HHCB, AHTN, ATII, AHMI, ADBI, and DPMI [81]. PDMS-DVB (65 μm) was more efficient than PDMS (30 μm), polyacrylate (PA) (85 μm), and Carboxen-PDMS (75 μm; Supelco) for DI-SPME of HHCB, AHTN, ADBI, and musk ketone [79]. Using the PDMS-DVB fiber, equilibrium was achieved after 90–120 min at 1250 rpm. Reproducible recoveries were obtained after 45 min with 45–50% recoveries compared to those obtained at equilibrium. Negligible depletion solid-phase microextraction (nd-SPME) [84] was used to measure the dissolved-phase concentration of HHCB and AHTN in wastewater [82].

Semipermeable membrane devices (SPMDs) have been used for passive sampling of synthetic musk fragrances in surface water [70]. The sampling devices were deployed for 3–4 weeks and semiquantitative concentrations were reported (mass/SPMD). HHCB has been sampled from wastewater effluents using another passive, in situ sampler [85] (the polar organic chemical integrative sampler or POCIS [86–88]). These devices were deployed for 54 days followed by recovery of target compounds with methanol and methanol/toluene/dichloromethane (1:1:8 VR).

Sludge

Extraction of synthetic musk fragrances from activated and digested sludge has been accomplished by PFE [63, 64, 76, 77, 89], supercritical fluid extraction (SFE) [64], sonication [89], Soxhlet extraction [65, 66, 90, 91], and LLE [92–94]. HS-SPME has also been used for the determination of synthetic musk fragrances in wet and dry sludge [95]. These methods are summarized in Table 8.

HHCB, AHTN, musk xylene, and musk ketone were among sixteen fragrance chemicals extracted from activated sludge by PFE with dichloromethane [77]. The extraction cells were packed with activated silica at the cell outlet for initial extract purification. The remaining cell volume was packed with a mixture of sludge solids and diatomaceous earth (30–40% mass fraction). The resulting extract was purified using silica columns with elution with dichloromethane. This method was used later for the determination of HHCB, AHTN, musk xylene, musk ketone, and eighteen other fragrance compounds in sludge and sludge-amended soil with minor alterations [76]. All synthetic musk fragrances were extracted from wastewater treatment plant solids by PFE with hexane/ethyl acetate (1:1 VR) [63]. The resulting extracts were purified by SEC with a Bio Beads S-X column (Bio-Rad Laboratories; Hercules, CA, USA) and hexane/ethyl acetate (1:1 VR) mobile phase. Following SEC, extracts were loaded onto activated silica columns and eluted with ethyl acetate and acetone. All synthetic musk fragrances were extracted by PFE from freeze-dried sludge mixed with sand using acetone/hexane (1:1 VR) [64]. These authors also extracted freeze-dried samples by supercritical fluid extraction using supercritical CO2. Extracts using both methods were purified using 5% deactivated silica columns. When necessary, sulfur was removed by shaking with activated copper or mercury. AHTN and HHCB were extracted by PFE from freeze-dried sludge samples mixed with quartz sand with methanol [89]. These authors also extracted freeze-dried sludge samples by sonication with methanol and acetone. Sample extracts resulting from both methods were dissolved in water and passed through C18 cartridges. AHTN and HHCB were eluted with methanol. The extracts were further purified using 1.5% deactivated silica columns with elution using hexane/acetone (17:3 VR). This method was also used for the determination of these compounds in 1 L water samples.

HHCB, AHTN, ATII, ADBI, and AHMI were extracted with a suite of polychlorinated biphenyls (PCBs), polychlorinated naphthalenes (PCNs), polychlorinated alkanes (PCAs), and polycyclic aromatic hydrocarbons (PAHs) by Soxhlet extraction with dichloromethane [91]. Sulfur was removed with activated copper added to the Soxhlet collection flask. Extracts were purified using columns packed with 1% deactivated alumina and 5% deactivated silica with elution with dichloromethane/pentane (1:1 VR). Similar methods have been used for the extraction of these compounds and DPMI [90]. Sludge from anaerobic digesters has been Soxhlet-extracted with ethyl acetate for the analysis of HHCB and AHTN [66]. Extracts were purified using silica cartridges and SEC with a Bio Beads SX-3 column.

Liquid sludge samples have been extracted with hexane for the analysis of nitro musk fragrances and their amino metabolites [93, 94] and the polycyclic musk fragrances and HHCB-lactone [92]. Purification for the nitro musk fragrances and amino musk metabolites consisted of SEC with a Bio Beads SC-3 column and cyclohexane/ethyl acetate mobile phase (1:1 VR) followed by a silica column with elution with dichloromethane [93, 94]. For analysis of the polycyclic musk fragrances the extracts were filtered prior to analysis [92]. These methods could be used for the analysis of these compounds in whole water samples with minimal alteration.

Headspace SPME with PA (85 μm), PDMS (100 μm), PDMS-DVB (75 μm), Carboxen-PDMS (75 μm), and Carbowax-PDMS (65 μm) was used for the determination of HHCB, AHTN, ATII, AHMI, ADBI, musk xylene, musk ketone, musk tibetene, and musk moskene from solid and liquid sludge samples [95]. Headspace sampling times of 15 min at 100 °C provided reproducible results with all fibers. The PDMS-DVB fiber provided the lowest detection limits for all compounds. The photodegradation kinetics of musk xylene, musk ketone, musk tibetene, and musk moskene were studied using SPME [96].

Surficial and suspended sediments

Synthetic musk fragrances have been Soxhlet-extracted from suspended sediments collected from surface water using dichloromethane [55, 75] and hexane/acetone [72]. HHCB, AHTN, AHMI, and ADBI were measured in surficial and suspended sediment collected from river water and banks as part of a screening study of organic contaminants in the German Bight [62, 97, 98]. These samples were dispersion-extracted sequentially with acetone, acetone/hexane (1:1 VR), and hexane. HHCB, AHTN, ADBI, musk xylene, and musk ketone were Soxhlet-extracted from surficial sediment with toluene [99]. HHCB, AHTN, ATII, AHMI, and ADBI were extracted from freeze-dried surficial sediment using SDE [83]. HHCB and AHTN and 59 other compounds were extracted from wet sediment by PFE with water/isopropanol (1:1 VR) followed by water/isopropanol (1:4 VR) [100].

Suspended and surficial sediment extracts have been purified by SPE using silica [55, 62, 72, 97–99], Oasis HLB (Waters; Milford, MA, USA) [100], and Florisil (US Silica Company; Berkeley Springs, WV, USA) [100]. Copper has been used to remove sulfur from sediment extracts [55, 83].

Aquatic biota

Synthetic musk fragrances have been extracted from aquatic biota by dispersion–extraction [101, 102], Soxhlet extraction [83, 99, 103–105], cold extraction [106, 107], PFE [73, 108, 109], and closed-loop stripping [73, 108]. These methods are summarized in Table 9.

HHCB, AHTN, ATII, musk xylene, musk ketone, and HHCB-lactone were extracted from fish tissue by dispersion–extraction. Fish tissue was mixed with sodium sulfate and sequentially homogenized with isopropanol and hexane [101]. All synthetic musk fragrances were similarly extracted from fish tissue using ethyl acetete/cyclohexane (1:1 VR) or acetone/pentane (1:3 VR) [102].

A variety of solvent systems have been used for the extraction of synthetic musk fragrances from homogenized biota with a Soxhlet apparatus. Tissue homogenate mixed with sodium sulfate have been extracted with hexane/acetone (9:1 VR) [105], dichloromethane/hexane (3:1 VR) [103], dichloromethane/hexane (8:1 VR) [104], and cyclohexane/ethyl acetate (98.5:100 VR) [83, 99] for 2.5–12 h. Musk xylene, musk ketone, musk ambrette, musk moskene, and musk tibetene were cold-extracted from homogenized fish, mussels, and shrimp with water/acetone/petroleum ether [106, 107].

Fish muscle tissue homogenate was mixed with diatomaceous earth and extracted using PFE with ethyl acetate/hexane (1:5 VR) for the analysis of the polycyclic musk fragrances [109]. Prior to extraction, the PFE cell was packed with the dried fish homegenate and deactivated alumina at the outlet to remove lipids. Additional lipid removal and extract purification was not necessary. This PFE method was later used for the extraction of all synthetic musk fragrances and 2-amino musk ketone, 2-amino musk xylene, and 4-amino musk xylene with ethyl acetate/hexane (5:1 VR) [73, 108]. The higher polarity solvent was likely necessary due to the higher polarity of the nitro musk fragrances and amino musk metabolites relative to the polycyclic musk fragrances. Due to this change in solvent, additional removal of lipids was necessary.

A closed-loop stripping system was developed for the analysis of all synthetic musk fragrances and 2-amino musk ketone, 2-amino musk xylene, and 4-amino musk xylene in fish tissue [73, 108]. A mixture of fish tissue homogenate, water, sodium sulfate, and sodium hydroxide was continually mixed at 50 °C in a closed system for 24 h. Nitrogen was pumped through the system and the target compounds were collected on Abselut NEXUS sorbent in the exhaust gas. The synthetic musk fragrances and amino musk metabolites were recovered from the sorbent with 25 mL ethyl acetate and 25 mL hexane. The recoveries using this system were low (2–32%) but reproducible.

Typically, lipids are removed from extracts by SEC. Lipids cannot be removed destructively with sulfuric acid for the determination of nitro musk fragrances due to the simultaneous destruction of the target compounds [11]. SEC phases and solvent systems used for lipid removal in the analysis of synthetic musk fragrances include Bio Beads SX-3 with hexane/dichloromethane (1:1 VR) [103, 104], Bio Beads SX-3 with cyclohexane/ethyl acetate (98.5:100 VR) [83, 99], Bio Beads SX-3 with cyclohexane/ethyl acetate (1:1 VR) [101, 102], and Envirogel and Phenogel guard column with dichloromethane [73, 108]. Final extract purification has been accomplished primarily with silica and a variety of eluents [83, 99, 101, 103–105, 107]. Florisil [102] and Strata-NH2/alumina (Strata-NH2; Phenomenex; Torrance, CA, USA) [73, 108] have also been used.

House dust

HHCB, AHTN, ATII, ADBI, AHMI, and musk xylene were extracted from house dust collected from vacuum cleaner bags with hexane/diethyl ether (19:1 VR) using PFE [110]. Additional purification steps were not performed.

Air

Synthetic musk fragrances have been collected from indoor [110, 111] and outdoor [72, 111, 112] air by active sampling through polyurethane foam (PUF) [110, 112] and XAD-2 resin [72] (Table 10). The outdoor air samples were passed through glass fiber filters prior to the PUF or XAD-2 to collect the particulate phase. The glass fiber filters and PUF or XAD-2 resin were Soxhlet-extracted with hexane/diethyl ether (9:1 VR) [112] or acetone/hexane (1:1 VR) [72]. A sample fractionation was developed using activated silica columns [112]. Extracts were loaded onto the columns in hexane, rinsed with hexane and hexane/ethyl acetate (99:1 VR), and HHCB, AHTN, ATII, musk xylene, and musk ketone eluted in hexane/ethyl acetate (9:1 VR). The PUF used for sampling indoor air was extracted with hexane/diethyl ether (19:1 VR) using PFE [110]. Additional purification steps were not performed.

Detection and quantification

The GC methods used for these compounds are summarized in Tables 7, 8, 9 and 10. Synthetic musk fragrances are most commonly analyzed by GC/EI-MS, but gas chromatography coupled to negative chemical ionization mass spectrometry (GC/NCI-MS) is more sensitive for the nitro musk fragrances. Nitro musk fragrances have also been analyzed by gas chromatography with a flame ionization detector (GC-FID) and GC-ECD. Common GC phases, including 5%-phenyl-methylpolysiloxane and dimethylpolysiloxane, can be used for the separation of these compounds. Separation of the enantiomers of HHCB and AHTN has been reported with a heptakis (6-O-tert-butyldimethylsilyl-2,3-di-O-methyl)-β-cyclodextrin in 20%–50% OV1701 GC columns [113, 114]. Typical ions monitored for the analysis of synthetic musk fragrances by GC/EI-MS, GC/NCI-MS, and gas chromatography with positive chemical ionization (GC/PCI-MS), as well as high-resolution and ion trap tandem mass spectrometry (MS/MS) methods are summarized in Table S1 of the Electronic Supplementary Material. There has been one report of a method for the analysis of HHCB in wastewater by HPLC-UV [115].

Synthetic musk fragrance standards are commercially available. The amino musk metabolites have been synthesized by the reduction of the parent nitro musk fragrance using a variety of methods [59, 74, 93, 94, 108]. HHCB-lactone has been synthesized from HHCB [114]. Deuterated musk xylene and AHTN standards are commercially available for use as recovery or injection standards. There have been reports of problems with the use of the deuterated AHTN (AHTN-d 3) due to the occurrence of proton exchange during sample processing [65, 71]. A variety of other recovery and injection standards have been used for the analysis of synthetic musk fragrances, including pentachloronitrobenzene, deuterated polycyclic aromatic hydrocarbons, and various labeled and unlabeled polychlorinated biphenyls. A summary of common recovery and injection standards used for these compounds is provided in Table S2 of the Electronic Supplementary Material.

Antimicrobials

Sample extraction and preparation

Water

Methods for the extraction of triclosan, triclocarban, and triclosan metabolites are summarized in Table 11. Triclosan has been extracted using LLE from unfiltered surface water and wastewater samples with dichloromethane at pH 2 [56] and toluene at ambient pH [116, 117]. Lipophilic interferences and methyl triclosan were removed from unfiltered river water samples with hexane at pH>13. Triclosan was then extracted with hexane at pH 2–3 [118]. Due to the formation of hydroxide precipitates with the addition of NaOH, the washing step was omitted for seawater samples. Continuous liquid–liquid extraction (CLLE) with dichloromethane at ambient pH and pH 2 has also been used for the extraction of triclosan from unfiltered surface water samples [1, 57, 58].

Triclosan has been extracted from water using various SPE sorbents including C18 [68, 69, 119, 120], Oasis MAX (Waters; Milford, MA, USA) [121], XAD-4/XAD-8 [70], SDB-XC [122, 123], Bio Beads SM-2 [124, 125], Isolute ENV+ (Biotage; Charlottesville, VA, USA) [120], and Oasis HLB [120, 126–137].

Triclosan and its metabolites methyl triclosan, tetra(II)closan, tetra(III)closan, and pentaclosan were extracted from unfiltered wastewater influent and effluent samples with C18 mixed with Florisil [119]. Prior to extraction, the samples were adjusted to pH<2 with phosphoric acid. Ethanol was also added to minimize clogging. After extraction, the sorbent was rinsed with ethanol/water (1:4 VR) and ethyl acetate. The closans were recovered with toluene and hexane. Triclosan and several acidic drugs were concentrated from wastewater samples using C18 sorbent [68, 69]. Prior to concentration samples were centrifuged, filtered, and adjusted to pH<3 with HCl or formic acid. Target compounds were eluted with acetone. Filtered, wastewater samples at pH 4 were processed with C18 cartidges with elution of triclosan with methanol and acetone [120].

Oasis MAX is a mixed-mode sorbent with reversed-phase and anion exchange functionality. Oasis MAX cartridges were used to extract triclosan and twenty other phenolic and acidic compounds from filtered, acidified (pH 3) wastewater samples [121]. Prior to elution the cartridges were washed with a methanol/sodium acetate solution. Triclosan was eluted with other phenols with methanol.

Several PS-DVB copolymers have been used to extract triclosan from water. One advantage of using PS-DVB is that large water volumes can be passed through it before clogging relative to other sorbents. Due to its relatively low selectivity, a second purification step is normally necessary prior to instrumental analysis. PS-DVB copolymers used for triclosan extraction include XAD [70], SDB-XC (3M; St. Paul, MN, USA) [122, 123], and Bio Beads SM-2 [124, 125]. A mixture of XAD-4 and XAD-8 was used to extract a large suite of compounds from 80 L surface water samples [70]. Triclosan and other compounds were eluted with acetone. SDB-XC Empore disks have been used to extract triclosan and ten other compounds associated with wastewater from surface water samples [122, 123]. Prior to extraction samples were filtered and acidified to pH<2. Compounds were eluted with methanol, dichloromethane, and methanol. Extracts were purified using silica columns using three bed volumes of dichloromethane and methanol for elution. Triclosan and methyl triclosan were extracted from surface water samples after acidification (pH 2) with Bio Beads SM-2 [124, 125]. Methanol/dichloromethane was used as the eluent. These extracts were purified using silica with elution using ethyl acetate/methanol (19:1 VR).

Isolute ENV+ is a chemically modified (hydroxylated) PS-DVB polymeric sorbent. Isolute ENV+ cartridges were used to extract triclosan from filtered wastewater samples at pH 4 [120]. Triclosan was eluted with methanol and acetone.

The most commonly used SPE sorbent for the analysis of triclosan has been the divinylbenzene/N-vinylpyrrolidone copolymer Oasis HLB. Triclosan has been efficiently extracted from filtered surface water and wastewater samples ranging in volume from 50 mL to 1 L using 60 mg [127–130, 132–134], 200 mg [120, 126, 131], and 500 mg [135–137] Oasis HLB cartridges. The breakthrough volume for triclosan with Oasis HLB has not been determined, but it is likely much larger than 1 L for 500 mg sorbents as 60 mg cartridges adequately retained triclosan in 1 L water samples [128–130, 132, 133]. Sample volumes are likely limited by sorbent clogging rather than contaminant breakthrough. Triclosan recovery using Oasis HLB appears to be independent of sample pH (for pH range 2–7). Several researchers have extracted at pH 7 to reduce clogging and interferences caused by retention of dissolved organic matter (DOM) [132, 133, 136, 137]. Retention of DOM by a variety of polymeric sorbents is reduced at pH 7 relative to lower pH values [138].

After extraction, potential interferences have been removed from Oasis HLB cartridges with rinses of water [135], methanol/water (1:9 VR) [128–130], methanol/water (1:3 VR) [126], hexane [132, 133]. Eluents for triclosan from Oasis HLB include ethyl acetate, [127, 132, 133], methanol [126, 134, 136, 137], ethyl acetate/acetone (1:1 VR) [128–130], methanol and acetone (sequential) [120, 131], methanol/methyl tert-butyl ether (MTBE) (1:9 VR) and methanol (sequential) [135].

SPMDs have been used for triclosan and methyl triclosan in surface water [70, 124, 125, 139]. The sampling devices were typically deployed for 3–6 weeks and semiquantitative concentrations were reported (mass/SPMD). Triclosan has also been sampled using POCIS [85].

Triclocarban has been extracted from water by LLE [140] and SPE using Oasis HLB [141, 142] and C18 cartridges [140]. Triclocarban was used as a recovery standard for the analysis of the mothproofing compounds sulcofuron and flucofuron in water [140]. These compounds were extracted by LLE with dichloromethane at pH 2 after the addition of NaCl. A separate extraction method involved concentration of these compounds on C18 cartridges at ambient pH with elution with methanol. Triclocarban was concentrated from centrifuged wastewater and surface water samples using Oasis HLB cartridges and eluted with methanol/acetone (1:1 VR) with 10 mmol/L acetic acid [141, 142]. The extracts were filtered prior to analyses. The centrifuged solids were extracted with methanol/acetone (1:1 VR) and filtered prior to analysis.

Sludge and sediments

Several extraction methods have been used for triclosan in sludge and surficial sediments, including dispersion–extraction [98], supercritical CO2 extraction [119, 143], Soxhlet extraction [117, 144, 145], PFE [100, 120, 129, 144], microwave-assisted extraction [146], and focused microwave-assisted Soxhlet extraction [145]. These methods are listed in Table 12.

Triclosan was among a suite of compounds quantified during a non-target screening of organic contaminants in sediments [98]. Sediment samples were dispersion-extracted with acetone and hexane (sequential). Sulfur was removed from extracts with activated copper and further purified on silica.

Triclosan and the metabolites methyl triclosan, tetra(II)closan, tetra(III)closan, and pentaclosan were extracted from lyophilized or air-dried sludge using supercritical CO2 extraction [119, 143].

Freeze-dried sludge samples were Soxhlet-extracted with ethyl acetate for the analysis of triclosan [117]. Extracts were purified using silica cartridges with elution with ethyl acetate and by SEC with a Bio Beads SX-3 column and cyclohexane/ethyl acetate (1:1 VR) mobile phase. Triclosan was among ten compounds extracted from freeze-dried sediment samples by sequential Soxhlet extraction with dichloromethane (12 h) and water (12 h) or water (12 h) and dichloromethane (12 h) [144, 145]. The extraction time using the same extraction solvents was reduced using focused microwave-assisted Soxhlet extraction (25 min dichloromethane and 50 min water extractions) [145]. The water extracts from both methods were extracted with hexane for GC analysis. Sediment and sludge samples were analyzed for triclosan and two chlorophenols by microwave-assisted extraction with acetone/methanol (1:1 VR) [146]. Extracts were centrifuged, dissolved in 0.2 mol/L NaOH, and washed with hexane. The resulting aqueous solution was adjusted to pH 2.5 and concentrated on an Oasis HLB cartridge.

Triclosan was extracted from sediments and sludge by PFE with dichloromethane [120, 129]. Extracts were purified by SPE using silica. Triclosan and 60 other compounds were extracted from wet sediment by PFE with water/isopropanol (1:1 VR) followed by water/isopropanol (1:4 VR) [100]. Extracts were collected in vials containing pentane. The extracts were purified using Oasis HLB and Florisil cartridges. Freeze-dried sediment samples mixed with sand were extracted by PFE with dichloromethane and water [144]. The water extract was extracted with hexane for GC analysis. This was the only study reviewed that did not use a commercial Dionex system (ASE) for PFE.

Suspended sediment collected on filters has been extracted by sonication with ethyl acetate for the analysis of triclosan [131].

Aquatic biota

Methyl triclosan was extracted from homogenized fish filets mixed with sodium sulfate by mixing with cyclohexane/dichloromethane (1:1 VR) or from homogenized fish filets mixed with diatomaceous earth by PFE with cyclohexane/dichloromethane (1:1 VR) [139]. Extracts from both methods were purified by SEC with an EnviroSep-ABC column (Phenomenex; Torrance, CA, USA) and dichloromethane/hexane (7:13 VR) mobile phase or Bio Beads SX-3 and dichloromethane/cyclohexane (7:13 VR) mobile phase. Extracts were then passed through 5% deactivated silica with hexane/ethyl acetate (10:1 VR).

Derivatization

Triclosan and its chlorinated metabolites have been transformed to a variety of ether derivatives for analysis by gas chromatography (Fig. 1). N,N-diethyltrimethylamine (TMS-DEA) [119, 147], N,O-bis(trimethylsilyl)trifluoroacetamide (BSTFA) [122, 123, 132, 133] and BSTFA with 1% trimethylchlorosilane (TMCS) [126] have been used to form triclosan and chlorinated triclosan trimethylsilylethers (Fig. 1a). Trislosan has been transformed to methyl triclosan using diazomethane (Fig. 1b) [56, 118, 128–130]. Because methyl triclosan is a natural derivative of triclosan, this method can overestimate the triclosan concentration. Triclosan concentrations can be determined by difference if the methyl triclosan concentration is determined prior to methylation. A similar alternative has been the use of diazoethane to form ethyl triclosan (Fig. 1c) [124, 125]. A methoxycarbonyl derivative (Fig. 1d) is formed by reaction with methyl chloroformate (MCF) [68, 69, 136, 137]. A pentafluorinated triclosan derivative (Fig. 1e) can be formed with pentafluoropropionic acid anhydride (PFPA) [121]. Reaction of triclosan with N-tert-butyldimethylsilyl-N-methyltrifluoroacetamide (MTBSTFA) [127, 146] and MTBSTFA with 1% tert-butyldimethylchlorosilane (TBDMSCl) [121] forms a tert-butyldimethylsilyl triclosan derivative (Fig. 1f).

Derivatization of triclosan (and chlorinated triclosan metabolites) with A TMS-DEA [119, 147], BSTFA [122, 123, 132, 133], or 1% TMCS in BSTFA [126]; B diazomethane [56, 118, 128–130]; C diazoethane [124, 125]; D MCF [68, 69, 136, 137]; E PFPA [121]; and F MTBSTFA [127, 146] or 1% TBDMSCl in MTBSTFA [121]

Detection and quantification

Triclosan has been analyzed by liquid chromatography-mass spectrometry (LC/MS), liquid chromatography–tandem mass spectrometry (LC/MS/MS), and GC/MS with and without derivatization. Lower detection limits are achieved with derivitization using GC/MS and LC/MS provides lower sensitivity than LC/MS/MS. Triclocarban is best analyzed by LC-based methods. Common ions and transitions monitored for these compounds are listed in Table S3 of the Electronic Supplementary Material. Liquid chromatography/time-of-flight mass spectrometry (LC/TOF-MS) has been used for the identification of photodegradation products of triclosan [148].

Labeled triclosan (13C12-triclosan) is currently available for use as a recovery standard. Other compounds used as recovery and injection standards for triclosan, triclocarban, and metabolites are listed in Table S4 of the Electronic Supplementary Material.

UV filters

Sample extraction and preparation

Water

Methods used for the analysis of UV filters (sunscreen agents) in environmental matrices are summarized in Table 13. Benzophenone-3,4-methylbenzylidene camphor, homosalate, octyldimethyl-p-aminobenzoic acid, and octyl methoxycinnamate were analyzed in water samples at pH 7 using LLE with cyclohexane [52]. A suite of PCBs and chlorinated pesticides was also analyzed using this method. Benzophenone-3,4-methylbenzylidene camphor, octyl methoxycinnamate, 2-phenylbenzimidazole-5-sulfonic acid, and avobenzone were extracted from water using micelle-mediated extraction with solvent back-extraction at pH 3 (adjusted with HCl) [149]. NaCl was added after pH adjustment to yield a 0.2 mol/L ionic strength. The surfactant Triton X-114 (A.G. Scientific; San Diego, CA, USA) was added at 0.1%. After mixing (1 min) and resting (15 min) at 60 °C the samples were centrifuged and cooled. The surfactant phase was then removed and extracted with methanol (for LC analysis) or back-extracted with hexane (for GC analysis).

UV filters have been concentrated from water using several different SPE sorbents, including C18 [150–152], Oasis HLB [135], and Bio Beads SM-2 [153, 154]. C18 cartridges [150, 152] or disks [151] have been used for the concentration of benzophenone-3 [151, 152], octyldimethyl-p-aminobenzoic acid [150, 152], avobenzone [151], octyl methoxycinnamate [151], and 4-methylbenzylidene camphor from water. Compounds were eluted with ethyl acetate/dichloromethane (1:1 VR) or dichloromethane after drying C18 under vacuum. Benzophenone-3 was among 27 compounds concentrated from surface water samples at pH 2 using Oasis HLB cartridges [135]. Compounds were eluted using sequential elution with methanol/MTBE (1:9 VR) and methanol. Octyl methyoxycinnamate, 4-methylbenzylidene camphor, benzophenone-3, octocrylene, and avobenzone were extracted from surface water and wastewater samples with Bio Beads SM-2 [153, 154]. Compounds were recovered with sequential rinses of methanol and dichloromethane. Extracts have been purified by SPE using silica [153, 154].

SPME has been used for octyldimethyl-p-aminobenzoic acid and benzophenone-3 [152, 155] and its metabolites 2,4-dihydroxybenzophenone [155] and 2,2′-dihydroxy-4-methoxybenzophenone [155]. Both DI-SPME and HS-SPME with PDMS (100 μm) and PA (85 μm) provided adequate recoveries for benzophenone-3 and octyldimethyl-p-aminobenzoic acid [152]. The recoveries were similar to those provided by SPE using C18 for these compounds. PA (85 μm) and Carbowax-DVB (65 μm) were both adequate for the retention of benzophenone-3, 2,4-dihydroxybenzophenone and 2,2′-dihydroxy-4-methoxybenzophenone for DI-SPME [155]. The retention of benzophenone-3 using PDMS (30 μm) was lower than these other materials, but PDMS is still adequate for benzophenone-3. The retention of 2,4-dihydroxybenzophenone and 2,2′-dihydroxy-4-methoxybenzophenone was much lower with PDMS (30 μm). PA (85 μm) and Carbowax-DVB (65 μm) are better sorbent choices for these compounds.

SPMDs have been used for 4-methylbenzylidene, benzophenone-3, octyl methoxycinnamate, octocrylene, and avobenzone in surface water and wastewater [153, 154]. The sampling devices were typically deployed for 3–6 weeks, and semiquantitative concentrations were reported (mass/SPMD).

Sewage sludge

Wet sewage sludge mixed with NaCl was sequentially extracted with pentane/acetone (1:1 VR), pentane/diethyl ether (1:1 VR), and diethyl ether/dichloromethane (4:1 VR) by shaking [156]. The resulting extract was purified by SPE using silica. It is likely that this method could also be used for water samples with little modification.

Fish tissue

Benzophenone-3, 4-methylbenzylidene camphor, homosalate, octyldimethyl-p-aminobenzoic acid, octyl methoxycinnamate, 4-isopropyldibenzoylmethane and avobenzone were Soxhlet-extracted from fish tissue with petroleum ether/ethyl acetate (2:1 VR) [52]. Prior to extraction the tissue was homogenized and dried with sodium sulfate. Lipids and other potential matrix interferences were removed by SEC (Bio Beads SX-3) with a mobile phase consisting of cyclohexane/acetone (3:1 VR). After SEC, CH3I/NaH was added to half of the extract to derivatize 4-isopropyldibenzoylmethane and avobenzone (Fig. 2). The other half of the extract was loaded onto a silica column and the UV filters were eluted with hexane/ethyl acetate (91:9 VR). The derivatized extract was also loaded onto a silica column. Petroleum ether was first used to remove liphophilic interferences. The dimethylated 4-isopropyldibenzoylmethane and avobenzone compounds were recovered from the silica column with hexane/ethyl acetate (7:3 VR).

Derivatization of A isopropyl-dibenzoylmethane (4-IDM) and B avobenzone (BMDBM) with CH3I/NaH [52]

A similar method was used for the determination of 4-methylbenzylidene camphor, benzophenone-3, octyl methoxycinnamate, and octocrylene in fish tissue [154].

Detection and quantification

While LC-based methods dominate the analysis of UV filters in cosmetics [29], most of these compounds detected in the environment are measured with GC-based techniques. All of the compounds reviewed here are amenable to GC except octyl traizone, avobenzone, 4-isopropyldibenzoylmethane, and 2-phenylbenzimidazole-5-sulfonic acid. Derivatives of avobenzone and 4-isopropyldibenzoylmethane were analyzed by GC/MS [52]. 4-Methylbenzylidene camphor, octyl methoxycinnamate, and octocrylene were analyzed by GC/EI-MS using a programmable temperature vaporizing (PTV) inlet, a DB-5 column (Agilent; Palo Alto, CA, USA), and selected ion monitoring (SIM) [156]. Octyl triazone is not amenable to gas chromatography and has been analyzed by HPLC/UV using a C18 column [250 mm×4.6 mm inner diameter (i.d.); 5 μm film thickness] and gradient elution using methanol and water [156]. Enantiomeric separation of 4-methylbenzylidene camphor was achieved with a laboratory-prepared 2,6-bis-(tert-butyldimethylsilyl)-γ-cyclodextrin in 70% PS086 GC column [157]. LC/MS/MS with positive electrospray ionization has been used for the confirmation of octyl triazone [156]. Benzophenone-3 has been analyzed by GC/EI-MS. It has also been quantified by LC/MS/MS with separation using a Synergi Max-RP C12 column (250 mm×4.6 mm i.d.; 4 μm particle size; Phenomenex; Torrance, CA, USA), a gradient solvent program consisting of 0.1% formic acid in water and methanol, and positive electrospray ionization [135].

Recovery standards were not used in the majority of reviewed studies. Benzyl cinnamate [153], 13C3-caffeine [154], 13C6-metolachlor [154], and 13C12-PCB 77 [154] have been used as recovery standards for various UV filters. Development of isotopically-labeled compounds for use as recovery standards is an important need for the analysis of UV filters. Common ions monitored for the analysis of UV filters and recovery and injection standards used for these compounds are listed in Tables S5 and S6, respectively, in the Electronic Supplementary Material.

Insect repellents

Sample extraction and preparation

Water

Methods for the analysis of DEET, Bayrepel, and metabolites in water and sediments are summarized in Table 14. DEET has been extracted from surface water LLE with dichloromethane [158] and CLLE with dichloromethane for 3 h at ambient pH and pH 2 [1, 57, 58, 85, 159]. Sequential liquid–liquid extraction (SLLE) with pentane, dichloromethane, and dichloromethane after acidification to pH 2 was used to extract DEET from landfill leachate [53, 160].

Insect repellents have been extracted from water using several SPE phases, including C18 [161], Oasis HLB [135–137], LiChrolute EN/C18 [162, 163], SDB-1 [164]. DEET was eluted from C18 membrane disks with acetonitrile [161]. Sequential elution was used with Oasis HLB cartridges. An initial rinse with hexane to remove lipophilic interferences was followed by elution of DEET with ethyl acetate, and acidic compounds with methanol [136, 137]. DEET was eluted with 26 other compounds from Oasis HLB cartridges using sequential elution with methanol/MTBE (1:9 VR) and methanol [135]. DEET [162], Bayrepel [162, 163], and the metabolite Bayrepel-acid [163] were extracted from wastewater and surface water using a combination of LiChrolute EN (Merck; Darmstadt, Germany) and C18. Bayrepel and DEET were eluted with acetone/ethyl acetate (1:1 VR). Bayrepel-acid was then eluted with methanol. Typical sample volumes in these studies were 0.5–1 L. DEET was concentrated from 10 L to 20 L seawater using the polymeric styrene-divinylbenzene sorbent SDB-1 (J.T. Baker; Phillipsburg, PA, USA) followed by elution with ethyl acetate and hexane/ethyl acetate (4:1 VR) [164]. DEET has also been sampled with POCIS [85].

DEET appears to be stable in water samples. DEET did not degrade in unpreserved surface water samples stored for 14 days at 4 °C [135]. It was also unaffected by the addition formaldehyde or sulfuric acid used for the preservation of other target analytes [135].

Sediments

PFE with water/isopropanol (1:1 VR) was used to extract DEET from surficial and suspended sediments [100]. The extracts were loaded onto modified PS-DVB, washed with water, and dried under vacuum. Compounds were eluted from the modified PS-DVB and through a sodium sulfate/Florisil cartridge with dichloromethane/diethyl ether (4:1 VR).

Derivatization

Bayrepel-acid was derivatized to its methyl ester with diazomethane (Fig. 3) for GC/MS analysis [163].

Derivatization of Bayrepel acid with diazomethane [163]

Detection and quantification

DEET is typically analyzed by GC/EI-MS using splitless injection, a 5% polyphenylmethylsilicone or similar capillary column, and SIM [1, 57, 58, 85, 100, 136, 137, 158–160, 162, 164]. It has also been quantified by LC/MS/MS with separation using a Synergi Max-RP C12 column (250 mm×4.6 mm i.d.; 4 μm particle size; Phenomenex; Torrance, CA, USA) a gradient solvent program consisting of 0.1% formic acid in water and methanol, and positive electrospray ionization [135]. There has been one report of an online SPE/LC/MS/MS method for DEET [165]. DEET was among 40 different analytes concentrated from 100 mL water samples using PLRP-S columns (10 mm×2 mm i.d.; Polymer Laboratories; Amherst, MA, USA) with online desporption with acetonitrile. Analytes were separated using a Supelcosil LC-18-DB column (250 mm×4.6 mm i.d.; 5 μm particle size; Supelco; St. Louis, MO, USA) and a solvent gradient consisting of methanol/water (5:95 VR) and methanol, each with a glacial acetic acid volume fraction of 3 mL/L followed by positive atmospheric pressure chemical ionization. DEET has also been quantified by field-amplified concentration with micellar electrokinetic chromatography (FAC/MEKC) [161]. Bayrepel was analyzed with DEET by GC/EI-MS [162, 163]. Bayrepel-acid has been analyzed by LC/ESI(-)MS and its methyl derivative by GC/EI-MS [163]. Typical ions monitored for each compound using each type of analysis are listed in Table S7 of the Electronic Supplementary Material.

Isotopically labeled standards for these compounds are not commercially available for use as recovery or injection standards. Compounds that have been used include atrazine-d 5 and 15N2-caffeine (Table S8 in the Electronic Supplementary Material). It is unclear whether these compounds are good surrogate compounds for insect repellents.

Parabens

Sample extraction, preparation, detection, and quantification

Water

There have been few methods published for parabens in environmental matrices (Table 15). Methylparaben, ethylparaben, propylparaben, and benzylparaben were extracted from filtered water samples with 31 other compounds using Oasis HLB cartridges [166]. LC/ESI(-)MS/MS (ion trap) was used for quantification. Separation was achieved with a C18 HPLC column (C18 Luna; 100 mm×2 mm, 3 μm; Phenomonex; Torrance, CA, USA). The transition from [M-1]− to [M-alkyl-1]− or [M-alkyl-2]− was used for quantification of each compound. These transitions were 151>136, 165>137, 179>137, and 227>136 for methylparaben, ethylparaben, propylparaben, and benzylparaben, respectively. The recovery standard was d 2-estradiol. Good recoveries (91.1–104.5%) and reproducibility [relative standard deviation (RSD)<20%] were found in experiments using river water fortified at 10 ng/L, 40 ng/L, and 400 ng/L.

Methylparaben, ethylparaben, propylparaben, and butylparaben were among 21 compounds extracted from WWTP influent and effluent using Oasis MAX cartridges. Prior to extraction, the samples were filtered and acidified to pH 3. After extraction, the Oasis MAX was washed with a methanol/sodium acetate solution, and the analytes were eluted with methanol. Acidic compounds were then eluted with 2% (VF) formic acid in methanol. After extraction, the parabens were derivatized with pentafluoropropionic acid anhydride (PFPA) for GC/EI-MS analysis (Fig. 4). The separation was performed with an Rtx-5Sil column (30 m×0.25 mm; 0.25 μm; Restek; Bellefonte, PA, USA). The derivatized parabens were quantified using SIM and their [M-alkyl]+ ions (m/z=267). The closest eluting recovery standard was Bisphenol A-d 16. Good recoveries (87–99%) and reproducibility (RSD <10%) were found in experiments using distilled water fortified at 0.1 μg/L and 1 μg/L.

Using the reported detection limits (10 ng/L and 0.2–0.5 ng/L) and correcting for differences in sample volumes (1 L and 0.5 L), final extract volumes (1 mL and 0.2 mL), and injection volumes (1 μL and 50 μL) between the two methods, the on-column detection limits of the GC/MS and LC/MS/MS methods are similar (10 pg and 10–50 pg, respectively).

Indoor air and house dust

Methylparaben, ethylparaben, and butylparaben were measured in indoor air and house dust using GC/MS after derivatization with N,O−bis(trimethylsilyl)trifluroacetamide (BSTFA) (Fig. 4) [167]. These compounds were concentrated from air with XAD-2 resin sandwiched between two PUF plugs. The XAD-2 and PUF sorbents were extracted by shaking with dichloromethane. House dust was extracted by sonication with dichloromethane after acidification. After derivatization, the analytes were quantified by GC/MS (SIM; 30 m×0.25 mm DB-5MS column) using 3,4,5-trichlorophenol as the recovery standard. Additional information about the analysis of parabens is listed in Tables S9 and S10 of the Electronic Supplementary Material.

References

Kolpin DW, Furlong ET, Meyer MT, Thurman EM, Zaugg SD, Barber LB, Buxton HT (2002) Environ Sci Technol 36:1202–1211

Ternes TA, Joss A, Siegrist H (2004) Environ Sci Technol 38:392A–399A

Daughton CG, Ternes TA (1999) Environ Health Perspect 107:907–938

Tanabe S (2005) Mar Pollut Bull 50:1025–1026

Richardson BJ, Larn PKS, Martin M (2005) Mar Pollut Bull 50:913–920

Ingerslev F, Vaclavik E, Halling-Sorensen B (2003) Pure Appl Chem 75:1881–1893

Rimkus GG (1999) Toxicol Lett 111:37–56

Rimkus GG, Gatermann R, Huhnerfuss H (1999) Toxicol Lett 111:5–15

Yamagishi T, Miyazaki T, Horii S, Kaneko S (1981) Bull Environ Contam Toxicol 26:656–662

Yamagishi T, Miyazaki T, Horii S, Akiyama K (1983) Arch Environ Con Tox 12:83–89

Rimkus GG, Butte W, Geyer HJ (1997) Chemosphere 35:1497–1507

Boleas S, Fernandez C, Tarazona JV (1996) Bull Environ Contam Toxicol 57:217–222

Fernandez C, Carballo M, Tarazona JV (1996) Chemosphere 32:1805–1811

Heberer T (2002) Acta Hydroch Hydrob 30:227–243

Kanetoshi A, Ogawa H, Katsura E, Kaneshima H (1987) J Chromatogr A 389:139–153

Adolfsson-Erici M, Pettersson M, Parkkonen J, Sturve J (2002) Chemosphere 46:1485–1489

Reisch MS (2005) Chem Eng News 83:18–22

Suzuki T, Kitamura S, Khota R, Sugihara K, Fujimoto N, Ohta S (2005) Toxicol Appl Pharm 203:9–17

Maerkel K, Lichtensteiger W, Durrer S, Conscience M, Schlumpf M (2005) Environ Toxicol Phar 19:761–765

Schlumpf M, Schmid P, Durrer S, Conscience M, Maerkel K, Henseler M, Gruetter M, Herzog I, Reolon S, Ceccatelli R (2004) Toxicology 205:113–122

Heneweer M, Muusse M, Berg Mvd, Sanderson JT (2005) Toxicol Appl Pharm 208:170–177

Schlumpf M, Jarry H, Wuttke W, Ma R (2004) Toxicology 199:109–120

Schlumpf M, Durrer S, Maerkel K, Ma R, Conscience M, Fleischmann I, Lichtensteiger W (2003) Toxicol Sci 72:133–134

Schlumpf M, Cotton B, Conscience M, Haller V, Steinmann B, Lichtensteiger W (2001) Environ Health Perspect 109:239–244

Markel K, Durrer S, Conscience M, Schlumpf M, Lichtensteiger W (2002) N-S Arch Pharmacol 365:R133–R133

Ma RS, Cotton B, Lichtensteiger W, Schlumpf M (2003) Toxicol Sci 74:43–50

Durrer S, Maerkel K, Schlumpf M, Lichtensteiger W (2005) Endocrinology 146:2130–2139

Schreurs RHMM, Sonneveld E, Jansen JHJ, Seinen W, van der Burg B (2005) Toxicol Sci 83:264–272

Salvador A, Chisvert A (2005) Anal Chim Acta 537:1–14

US EPA (1998) Reregistration Eligibility Decision (RED): DEET. US Environmental Protection Agency, Washington, DC

Routledge EJ, Parker J, Odum J, Ashby J, Sumpter JP (1998) Toxicol Appl Pharm 153:12–19

Golden R, Gandy J, Vollmer G (2005) Crit Rev Toxicol 35:435–458

Soni MG, Carabin IG, Burdock GA (2005) Food Chem Toxicol 43:985–1015

Borremans M, Van Loco J, Roos P, Goeyens L (2004) Chromatographia 59:47–53

Saad B, Bari MF, Saleh MI, Ahmad K, Talib MKM (2005) J Chromatogr A 1073:393–397

Lokhnauth JK, Snow NH (2005) Anal Chem 77:5938–5946

Zhang QL, Lian M, Liu LJ, Cui H (2005) Anal Chim Acta 537:31–39

de Castro MDL, Garcia-Ayuso LE (1998) Anal Chim Acta 369:1–10

Carabias-Martinez R, Rodriguez-Gonzalo E, Revilla-Ruiz P, Hernandez-Mendez J (2005) J Chromatogr A 1089:1–17

Dean JR, Xiong GH (2000) Trends Anal Chem 19:553–564

Fitzpatrick LJ, Zuloaga O, Etxebarria N, Dean JR (2000) Rev Anal Chem 19:75–122

Giergielewicz-Mozajska H, Dabrowski L, Namiesnik J (2001) Crit Rev Anal Chem 31:149–165

Ramos L, Kristenson EM, Brinkman UAT (2002) J Chromatogr A 975:3–29

Camel V (2000) Trends Anal Chem 19:229–248

Eskilsson CS, Bjorklund E (2000) J Chromatogr A 902:227–250

Letellier M, Budzinski H (1999) Analusis 27:259–271

Hennion MC (1999) J Chromatogr A 856:3–54

Pyrzynska K (2003) Chem Anal–Warsaw 48:781–795

Leon-Gonzalez ME, Perez-Arribas LV (2000) J Chromatogr A 902:3–16

Helbling KS, Schmid P, Schlatter C (1994) Chemosphere 29:477–484

Hany J, Nagel R (1995) Deut Lebensm-Rundsch 91:341–345

Nagtegaal M, Ternes TA, Baumann W, Nagel R (1997) Z Umweltchem Oekotox 9:79–86

Dsikowitzky L, Schwarzbauer J, Kronimus A, Littke R (2004) Chemosphere 57:1275–1288

Franke S, Hildebrandt S, Schwarzbauer J, Link M, Francke W (1995) Fresen J Anal Chem 353:39–49

Winkler M, Kopf G, Hauptvogel C, Neu T (1998) Chemosphere 37:1139–1156

Kanda R, Griffin P, James HA, Fothergill J (2003) J Environ Monitor 5:823–830

Stackelberg PE, Furlong ET, Meyer MT, Zaugg SD, Henderson AK, Reissman DB (2004) Sci Total Environ 329:99–113

Kolpin DW, Skopec M, Meyer MT, Furlong ET, Zaugg SD (2004) Sci Total Environ 328:119–130

Gatermann R, Huhnerfuss H, Rimkus G, Attar A, Kettrup A (1998) Chemosphere 36:2535–2547

Gatermann R, Huhnerfuss H, Rimkus G, Wolf M, Franke S (1995) Mar Pollut Bull 30:221–227

Ricking M, Schwarzbauer J, Hellou J, Svenson A, Zitko V (2003) Mar Pollut Bull 46:410–417

Dsikowitzky L, Schwarzbauer J, Littke R (2002) Org Geochem 33:1747–1758

Yang J-J, Metcalfe CD (2006) Sci Total Environ 363:25–37

Lee HB, Peart TE, Sarafin K (2003) Water Qual Res J Can 38:683–702

Bester K (2005) J Environ Monitor 7:43–51

Bester K (2004) Chemosphere 57:863–870

Bester K, Huhnerfuss H, Lange W, Rimkus GG, Theobald N (1998) Water Res 32:1857–1863

Bendz D, Paxeus NA, Ginn TR, Loge FJ (2005) J Hazard Mater 122:195–204

Paxeus N (2004) Water Sci Technol 50:253–260

van Stee LLP, Leonards PEG, van Loon WMGM, Hendriks AJ, Maas JL, Struijs J, Brinkman UAT (2002) Water Res 36:4455–4470

Buerge IJ, Buser H-R, Muller MD, Poiger T (2003) Environ Sci Technol 37:5636–5644

Peck AM, Hornbuckle KC (2004) Environ Sci Technol 38:367–372

Osemwengie LI, Gerstenberger SL (2004) J Environ Monitor 6:533–539

Osemwengie LI, Steinberg S (2001) J Chromatogr A 932:107–118

Standley LJ, Kaplan LA, Smith D (2000) Environ Sci Technol 34:3124–3130

Difrancesco AM, Chiu PC, Standley LJ, Allen HE, Salvito DT (2004) Environ Sci Technol 38:194–201

Simonich SL, Begley WM, Debaere G, Eckhoff WS (2000) Environ Sci Technol 34:959–965

Simonich SL, Federle TW, Eckhoff WS, Rottiers A, Webb S, Sabaliunas D, de Wolf W (2002) Environ Sci Technol 36:2839–2847

Winkler M, Headley JV, Peru KM (2000) J Chromatogr A 903:203–210

Heberer T, Gramer S, Stan H-J (1999) Acta Hydroch Hydrob 27:150–156

Garcia-Jares C, Llompart M, Polo M, Salgado C, Macias S, Cela R (2002) J Chromatogr A 963:277–285

Artola-Garicano E, Borkent I, Hermens JLM, Vaes WHJ (2003) Environ Sci Technol 37:3111–3116

Fromme H, Otto T, Pilz K (2001) Water Res 35:121–128

Vaes WHJ, Ramos EU, Verhaar HJM, Seinen W, Hermens JLM (1996) Anal Chem 68:4463–4467

Alvarez DA, Stackelberg PE, Petty JD, Huckins JN, Furlong ET, Zaugg SD, Meyer MT (2005) Chemosphere 61:610–622

Alvarez DA, Petty JD, Huckins JN, Jones-Lepp TL, Getting DT, Goddard JP, Manahan SE (2004) Environ Toxicol Chem 23:1640–1648

Petty JD, Huckins JN, Alvarez DA (2002) US Patent 6,478,961 [Nov 12, 2002]

Petty JD, Huckins JN, Alvarez DA, Brumbaugh WG, Cranor WL, Gale RW, Rastall AC, Jones-Lepp TL, Leiker TJ, Rostad CE, Furlong ET (2004) Chemosphere 54:695–705

Ternes TA, Bonerz M, Herrmann N, Loffler D, Keller E, Lacida BB, Alder AC (2005) J Chromatogr A 1067:213–223

Zeng XY, Sheng GY, Xiong Y, Fu JM (2005) Chemosphere 60:817–823

Stevens JL, Northcott GL, Stern GA, Tomy GT, Jones KC (2003) Environ Sci Technol 37:462–467

Kupper T, Berset JD, Etter-Holzer R, Furrer R, Tarradellas J (2004) Chemosphere 54:1111–1120

Berset JD, Bigler P, Herren D (2000) Anal Chem 72:2124–2131

Herren D, Berset JD (2000) Chemosphere 40:565–574

Llompart M, Garcia-Jares C, Salgado C, Polo M, Cela R (2003) J Chromatogr A 999:185–193

Sanchez-Prado L, Lores M, Llompart M, Garcia-Jares C, Lourido M, Cela R (2004) J Chromatogr A 1048:73–80

Schwarzbauer J, Littke R, Weigelt V (2000) Org Geochem 31:1713–1731

Kronimus A, Schwarzbauer J, Dsikowitzky L, Heim S, Littke R (2004) Water Res 38:3473–3484

Fromme H, Otto T, Pilz K, Neugebauer F (1999) Chemosphere 39:1723–1735

Burkhardt MR, ReVello RC, Smith SG, Zaugg SD (2005) Anal Chim Acta 534:89–100

Kallenborn R, Gatermann R, Nygard T, Knutzen J, Schlabach M (2001) Fresen Environ Bull 10:832–842

Duedahl-Olesen L, Cederberg T, Pedersen KH, Hojgard A (2005) Chemosphere 61:422–431

Kannan K, Reiner JL, Yun SH, Perrotta EE, Tao L, Johnson-Restrepo B, Rodan BD (2005) Chemosphere 61:693–700

Nakata H (2005) Environ Sci Technol 39:3430–3434

Gatermann R, Hellou J, Huhnerfuss H, Rimkus G, Zitko V (1999) Chemosphere 38:3431–3441

Rimkus G, Wolf M (1993) Deut Lebensm-Rundsch 89:171–175

Rimkus GG, Wolf M (1995) Chemosphere 30:641–651

Osemwengie LI, Steinberg S (2003) J Chromatogr A 993:1–15

Draisci R, Marchiafava C, Ferretti E, Palleschi L, Catellani G, Anastasio A (1998) J Chromatogr A 814:187–197

Fromme H, Lahrz T, Piloty M, Gebhart H, Oddoy A, Ruden H (2004) Indoor Air 14:188–195

Kallenborn R, Gatermann R (2004) Synthetic musks in ambient and indoor air. In: Rimkus GG (ed) Synthetic musk fragrances in the environment. Springer, Berlin Heidelberg New York

Kallenborn R, Gatermann R, Planting S, Rimkus GG, Lund M, Schlabach M, Burkow IC (1999) J Chromatogr A 846:295–306

Bester K (2003) Anal Bioanal Chem 376:302–304

Franke S, Meyer C, Heinzel N, Gatermann R, Huhnerfuss H, Rimkus G, Konig WA, Francke W (1999) Chirality 11:795–801

Schussler W, Nitschke L (1998) Fresen J Anal Chem 361:220–221

Bester K (2005) Arch Environ Con Tox 49:9–17

Bester K (2003) Water Res 37:3891–3896

Okumura T, Nishikawa Y (1996) Anal Chim Acta 325:175–184

McAvoy DC, Schatowitz B, Jacob M, Hauk A, Eckhoff WS (2002) Environ Toxicol Chem 21:1323–1329

Aguera A, Fernandez-Alba AR, Piedra L, Mezcua M, Gomez MJ (2003) Anal Chim Acta 480:193–205

Lee HB, Peart TE, Svoboda ML (2005) J Chromatogr A 1094:122–129

Boyd GR, Palmeri JM, Zhang SY, Grimm DA (2004) Sci Total Environ 333:137–148

Boyd GR, Reemtsma H, Grimm DA, Mitra S (2003) Sci Total Environ 311:135–149

Lindstrom A, Buerge IJ, Poiger T, Bergqvist PA, Muller MD, Buser HR (2002) Environ Sci Technol 36:2322–2329

Poiger T, Lindstrom A, Buerge IJ, Buser HR, Bergqvist PA, Muller MD (2003) Chimia 57:26–29

Lee RB, Sarafin K, Peart TE, Svoboda ML (2003) Water Qual Res J Can 38:667–682

Canosa P, Morales S, Rodriguez I, Rubi E, Cela R, Gomez M (2005) Anal Bioanal Chem 383:1119

Ollers S, Singer HP, Fassler P, Muller SR (2001) J Chromatogr A 911:225–234

Singer H, Muller S, Tixier C, Pillonel L (2002) Environ Sci Technol 36:4998–5004

Tixier C, Singer HP, Canonica S, Muller SR (2002) Environ Sci Technol 36:3482–3489

Mezcua M, Gomez MJ, Ferrer I, Aguera A, Hernando MD, Fernandez-Alba AR (2004) Anal Chim Acta 524:241–247

Thomas PM, Foster GD (2004) J Environ Sci Heal A 39:1969–1978

Thomas PM, Foster GD (2005) Environ Toxicol Chem 24:25–30

Quintana JB, Reemtsma T (2004) Rapid Commun Mass Sp 18:765–774

Vanderford BJ, Pearson RA, Rexing DJ, Snyder SA (2003) Anal Chem 75:6265–6274

Weigel S, Berger U, Jensen E, Kallenborn R, Thoresen H, Huhnerfuss H (2004) Chemosphere 56:583–592

Weigel S, Kallenborn R, Huhnerfuss H (2004) J Chromatogr A 1023:183–195

Pichon V, Coumes CCD, Chen L, Guenu S, Hennion MC (1996) J Chromatogr A 737:25–33

Balmer ME, Poiger T, Droz C, Romanin K, Bergqvist PA, Muller MD, Buser HR (2004) Environ Sci Technol 38:390–395

Hancock PM, Walsh M, White SJG, Catlow DA, Baugh PJ (1998) Analyst 123:1669–1674

Halden RU, Paull DH (2005) Environ Sci Technol 39:1420–1426

Halden RU, Paull DH (2004) Environ Sci Technol 38:4849–4855

Lee HB, Peart TE (2002) Water Qual Res J Can 37:681–696

Morales-Munoz S, Luque-Garcia JL, Ramos MJ, Fernandez-Alba A, de Castro MDL (2005) Anal Chim Acta 552:50–59

Morales-Munoz S, Luque-Garcia JL, Ramos MJ, Martinez-Bueno MJ, de Castro MDL (2005) Chromatographia 62:69–74

Morales S, Canosa P, Rodriguez I, Rubi E, Cela R (2005) J Chromatogr A 1082:128–135

Sabaliunas D, Webb SF, Hauk A, Jacob M, Eckhoff WS (2003) Water Res 37:3145–3154

Ferrer I, Mezcua M, Gomez MJ, Thurman EM, Aguera A, Hernando MD, Fernandez-Alba AR (2004) Rapid Commun Mass Sp 18:443–450

Giokas DL, Sakkas VA, Albanis TA, Lampropoulou DA (2005) J Chromatogr A 1077:19–27

Sakkas VA, Giokas DL, Lambropoulou DA, Albanis TA (2003) J Chromatogr A 1016:211–222

Giokas DL, Sakkas VA, Albanis TA (2004) J Chromatogr A 1026:289–293

Lambropoulou DA, Giokas DL, Sakkas VA, Albanis TA, Karayannis MI (2002) J Chromatogr A 967:243–253

Poiger T, Buser HR, Balmer ME, Bergqvist PA, Muller MD (2004) Chemosphere 55:951–963

Balmer ME, Buser HR, Muller MD, Poiger T (2005) Environ Sci Technol 39:953–962

Felix T, Hall BJ, Brodbelt JS (1998) Anal Chim Acta 371:195–203

Plagellat C, Kupper T, Furrer R, de Alencastro LF, Grandjean D, Tarradellas J (2006) Chemosphere 62:915–925

Buser HR, Muller MD, Balmer ME, Poiger T, Buerge IJ (2005) Environ Sci Technol 39:3013–3019

Pereira WE, Hostettler FD (1993) Environ Sci Technol 27:1542–1552

Sandstrom MW, Kolpin DW, Thurman EM, Zaugg SD (2005) Environ Toxicol Chem 24:1029–1034

Schwarzbauer J, Heim S, Brinker S, Littke R (2002) Water Res 36:2275–2287

He Y, Lee HK (1997) Electrophoresis 18:2036–2041

Knepper TP (2004) Water Sci Technol 50:301–308

Knepper TP (2004) J Chromatogr A 1046:159–166

Weigel S, Kuhlmann J, Huhnerfuss H (2002) Sci Total Environ 295:131–141

Geerdink RB, Kooistra-Sijpersma A, Tiesnitsch J, Kienhuis PGM, Brinkman UAT (1999) J Chromatogr A 863:147–155

Benijts T, Lambert W, De Leenheer A (2004) Anal Chem 76:704–711

Rudel RA, Camann DE, Spengler JD, Korn LR, Brody JG (2003) Environ Sci Technol 37:4543–4553

Acknowledgements

I would like to thank Keri Hornbuckle at the University of Iowa and Barb Jones, John Kucklick, and Michele Schantz at the National Institute of Standards and Technology for helpful comments on the manuscript.

Disclaimer

Certain commercial equipment, instruments, or materials are identified in this paper to specify adequately the experimental procedure. Such identification does not imply recommendation or endorsement by the National Institute of Standards and Technology, nor does it imply that the materials or equipment identified are necessarily the best for the purpose.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Peck, A.M. Analytical methods for the determination of persistent ingredients of personal care products in environmental matrices. Anal Bioanal Chem 386, 907–939 (2006). https://doi.org/10.1007/s00216-006-0728-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-006-0728-3