Abstract

A simple and new reagentless phenolic compound biosensor was constructed with tyrosinase immobilized in the gelatine matrix cross-linked with formaldehyde. The morphologies of gelatine and gelatine/tryosinase were characterized by SEM. The tyrosinase retains its bioactivity when being immobilized by the gelatine film. Phenolic compounds were determined by the direct reduction of biocatalytically liberated quinone at -0.1 V vs SCE. The process parameters for the fabrication of the enzyme electrode were studied. Optimization of the experimental parameters has been performed with regard to pH, operating potential, temperature and storage stability. This biosensor exhibits a fast amperometric response to phenolic compounds. The linear range for catechol, phenol, and p-Cresol determination was from 5×10−8 to 1.4×10−4 M, 5×10−8 to 7.1×10−5 M, and 1×10−7 to 3.6×10−5 M, with a detection limit of 2.1×10−8 M, 1.5×10−8 M, and 7.1×10−8 M, respectively. The enzyme electrode retained ca.77% of its activity after 7 days of storage at 4°C in a dry state. The proposed sensor presented good repeatability, evaluated in terms of relative standard deviation (R.S.D.=8.6%) for eight different biosensors and was applied for determination in water sample. The recovery for the sample was from 99.0% to 99.8%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Phenolic compounds are widely used industrial chemicals in the manufacture of products. Most of them are generated artificially and found in wastewaters of chemical plants, exhaust gases of incinerators, sidestream smoke of cigarettes, etc [1]. They are easily adsorbed in humans, regardless of the type of existence. High levels of phenol have been shown to have detrimental effects on animal health, and some phenolic compounds are reportedly carcinogenic [2, 3]. There is considerable interest in the determination of phenolic compounds in industrial, environmental or food samples. And many methods of instrumental analysis have been used, such as colorimetry, gas chromatography, liquid chromatography, capillary electrophoresis and spectrophotometric analysis [4–8].

One promising and relatively simple approach to the quantification of phenolic compounds both in vitro and in vivo is based on electrochemical methods due to their advantages such as good selectivity in the presence of phenol oxidases, relatively low cost of realization and storage, the potential for miniaturization and automation [9, 10]. Tyrosinase (Tyr) is a copper protein that contains a coupled binuclear copper-active site, and catalyzes the hydroxylation of monophenols to form o-diphenols and the oxidation of o-diphenols to o-quinones, using molecular oxygen [11, 12]:

o-Quinones can be electrochemically reduced to o-diphenols with a low over-potential by the following equation without any electron transfer mediator:

Therefore, the detection of phenols relies on monitoring the liberation of the quinone products or the consumption of the oxygen cofactor [13].

Tyrosinase-based biosensors for the determination of phenolic compounds have been reported extensively, for example, the entrapment of tyrosinase in carbon paste [14, 15], Eastman-AQ [16], polyhydroxyl cellulose ‘cryohydrogel’ [17], clay [18] and electrogenerated polypyrrole derivatives [19, 20]. Due to the difficulties of producing these materials or the complexity of fabricating process, to develop a simple and reliable method to stabilize the enzyme is still interested.

Herein, we demonstrate a reagentless biosensor for phenolic compounds by entrapping tyrosinase in gelatine cross-linked matrix. Gelatine (Gel), as a natural biopolymer, is a linear polypeptide that consists of different amounts of 18 amino acids and offers an unique set of characteristics gel forming properties and hydrophilicity, biocompatibility, biodegradability to harmless products, nontoxicity, and remarkable affinity to proteins [21]. Additionally, its abundant source and low price is suitable for commercial application. These features are important for preparing biosensors and functional devices. To our best knowledge, there are few reports about the gelatine as matrix.

In our work, the prepared biosensor exhibits high sensitivity and wide linear range of voltammetric and amperometric measurements of phenolic compounds. Such behavior is attributed to the affinity of gelatine matrix that provides a friendly environment to enzyme. This method gives a general, inexpensive, simple and effective route for the immobilization of tyrosinase. Factors such as buffer pH, operational potential and enzyme loading were studied and optimized. In addition, the analytical performances of the biosensor with respect to response time, sensitivity, repeatability and stability were evaluated.

Experimental

Reagents

Mushroom tyrosinase (from mushroom. EC.1.14.18.1), noted activity of 2590 units mg−1 solid (Catalog No. T-7755), was obtained from Sigma Chemical Co (USA). and used as received. Phenol, catechol and p-cresol were purchased from Shanghai Chemical Reagent Company (Shanghai, China). All other reagents were of analytical grade and used without further purification. 0.1 M phosphate buffer solutions (PBS) with various pH values were prepared by mixing stock standard solutions of Na2HPO4 and NaH2PO4 and adjusting the pH with 0.1 M H3PO4 or NaOH. All the solutions were prepared with doubly distilled water.

Apparatus and measurements

All electrochemical experiments were carried out in a three-electrode cell controlled by CHI 660 Electrochemical workstation (CH Instruments, USA). A Tyr biosensor was used as the working electrode. Reference and counter electrodes were SCE and platinum wire, respectively.

The standard solutions of phenols were prepared with doubly distilled water. Aliquots of phenol standard solution were successively added to the solution. Current-time data were recorded after a steady-state current had been achieved.Scanning electron micrographs (SEM) of gelatine and gelatine/tyrosinase film were taken on a SEM (JSM-5610LV) instrument.

Preparation of enzyme electrodes

Glassy carbon electrodes were polished before each experiment with 1, 0.3 and 0.05 μm alumina powders, respectively, rinsed thoroughly with doubly distilled water between each polishing step, ultrasonicated in 1:1 nitric acid, acetone and doubly distilled water successively and then allowed to dry at room temperature.

Gelatine solution (1%) was prepared by dissolving gelatine flake in tepid doubly distilled water.

For preparation of a tyrosinase enzyme electrode, a suitable amount of tyrosinase was added into 0.2 ml of gelatine solution, and then 10 μl of formaldehyde solution was added into the enzyme solution. The mixture was hand-mixed thoroughly. Finally 10 μl of the new mixture was dropped on the surface of a glassy carbon electrode and allowed to dry at 4°C for 24 h. All the enzyme electrodes were washed thoroughly with doubly distilled water before use and stored at 4°C in a dry state.

Results and discussion

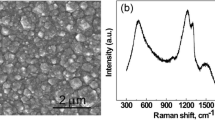

Morphologies of gelatine and gelatine/tyr films

SEM images as shown in Fig. 1 characterized the micrographs of the gelatine and gelatine/tyrosinase films. Obviously, the membrane of gelatine is in homogeneous structure (Fig. 1a) and the surface is symmetrically flat. Compared to the gelatine film, the blend membrane of gelatine/tyrosinase is a bump structure (Fig. 1b). The sizes and shapes of the bumps are regular and uniform, which was considered enzyme to be immobilized in the gelatine network film, successfully.

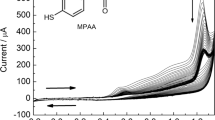

Cyclic voltammetric behavior of the tyr/gelatine modified electrode

Typical cyclic voltammograms of different electrodes in 0.1 M PBS (pH 7.0) at 50 mV/s are shown in Fig. 2. In absence of catechol, the bare GCE (Fig. 2a curve a), the gelatine modified electrode (Fig. 2b curve a) and the enzyme electrode (Fig. 2c curve a) showed a low background without detectable signal. Upon addition of catechol to the PBS, at the potential of 0 V, a little reduction peak current was observed at the gelatine modified electrode (Fig. 2b curve b) as well as the bare electrode (Fig. 2a curve b). In contrast, a substantially larger response was observed at the gelatine modified enzyme electrode. This modified electrode resulted in a large reduction peak (around -100 mV, Fig. 2c curve b), which was attributed to the reduction of the enzyme catalyzing catechol to form o-quinone at the ambience of oxygen, other than the effect of gelatine. Furthermore, the current-time experiments were carried out (curves are not shown). The results indicated that there is no response current for the bare electrode and gelatine modified electrode when the catechol stock solution (10−4M) was added to the buffer. For gelatine/enzyme electrode, in contrast, the response current increased rapidly as the same concentration catechol was added. Therefore, we can confirm that the increasing of current is due to the catalyzing reaction of enzyme.

Optimization of enzyme electrode preparation

In the construction of biosensor, the performance of the enzyme electrode mainly depended on the amount of enzyme and gelatine entrapped on the electrode surface.

Figure 3 shows the amperometric response of the enzyme electrode depends on the enzyme amount entrapped on the electrode surface. The response current increases with the enhancing of enzyme concentration in the solution dropped onto the surface of electrode. A plateau at an enzyme concentration of 1 mg mL−1 can be obtained. This indicates the enzyme loading capacity of gelatine thin film has been saturated.

Some factors, such as response time, linear range, and stability would be affected by the amount of gelatine. When the concentration of gelatine is too high, the response rate would be slow and the detected linear range would be narrow; and when it is too low, the stability of the biosensor would decrease. Through experiments, the concentration of gelatine was achieved, that is 2 mg mL−1.

Constructing eight sensors and determining the peak current obtained for each one, the repeatability in the construction of sensor was evaluated. The repeatability expressed as the relative standard deviation (R.S.D.) was 8.6% for n=8.

Optimization of the experimental parameters

Various factors influenced on the performance of the sensor. In order to obtain a high sensitivity and fast response, applied potential, buffer pH and temperature were investigated.

Figure 4 shows the effect of the applied potential on the amperometric response of the biosensor to catechol. The reduction current of o-quinone was already observed at around 100 mV, and it increased rapidly as the applied potential moved negatively from 100 mV to −100 mV, which was due to the increased driving force for the fast reduction of o-quinone at low potential. The current approached a plateau at −100 mV. In comparison with the results reported [22], working potential for phenol reduction was at a more positive value. −100 mV was selected as the operating potential for the low working potential made the sensor more capable of minimizing possible interferences [23].

At this potential, the effect of pH on the enzyme electrode response was studied in the pH range 5.0∼8.0 in the presence of 2 μM catechol (Fig. 5). It can be observed that the current response of the electrode reached the maximum value at pH 6.0. Therefore, pH 6.0 phosphate buffer solution was chosen throughout this study.

The effect of the temperature on the response of the sensor was also studied. After immersing the enzyme electrode in buffer solution at different temperatures for ten minutes, the steady-state current was recorded. As can be seen in Fig. 6, the almost peak-shaped profile was obtained. An increase of temperature enhanced the sensitivity of the electrode to catechol, but the noise also enhanced. It reaches a maximum value at 35°C according to S/N, and then decreases rapidly to a low value, because of the partial denaturation of the enzyme and the possible dissolution of the gelatine film. However, considering the requirement of real samples detection, room temperature was selected throughout the study.

Amperometric Response of the Biosensor

Figure 7 displays a typical current-time plot for the biosensor under the room temperature with successive additions of catechol to the 0.1 M PBS (pH 6.0) at −100 mV. When an aliquot of catechol is added into the supporting solution, the reduction current rises steeply to reach a stable value. The enzyme electrode achieves 95% of steady-state-current in less than 10 seconds.

Figure 8 illustrates the calibration plots of the enzyme electrode for catechol, phenol and p-cresol in 0.1 M pH 6.0 PBS under the optimal experimental conditions. The analytical performance including sensitivity, linear range and detection limit of the enzyme electrode to different substrates is listed in Table 1. The results illustrate that the gelatine matrix is suitable for enzyme loading.

According to the IUPAC definition [24] the detection limit (DL) can be related to the smallest response that can be detected with reasonable certainty. In a given analytical method, the detection limit is given as follow:

Where \(S_{B}\) is the standard deviation of the blank measurement, b is the sensitivity of the method (determined as the slope of the calibration curve), and k is a statistical constant (a value of k=3 is strongly recommended by IUPAC, based on the confidence interval). Using a least-squares regression program (linear fit and not forcing zero), the slope for the data from catechol, phenol, and p-cresol voltammetric analysis (Fig. 7) were determined as 0.06844, 0.01532, and 0.03545. Thus, the detection limit calculated for them is listed in Table 1.

The sensitivity trend is catechol >phenol >p-cresol. This is different from that of the tyrosinase/silica sol-gel electrode in aqueous solution [25]. The sensitivity sequence for a biosensor is dependent on the hydrophobic characteristics of the immobilization matrix [26]. At high concentration, platform responses are observed, showing the characteristic of the Michaelis-Menten kinetic mechanism. The apparent Michaelis-Menten constant (\(K^{{+AFw-alpha pp}}_{M}\)), generally used to evaluate the enzymatic affinity, were calculated according to the Lineweaver-Burk equation [27] and also listed in Table 1. Comparing the results for phenol determination with those reported previously [28, 29], the linear range, sensitivity and detection limit are better than those in aqueous solution. Thus, the immobilized tyrosinase shows slightly better affinity to phenol.

Stability of the enzyme electrode

The main objective of enzyme immobilization on a transducer, for analytical purpose, is to stabilize the enzyme for the biosensor to be used repeatedly over a long period time. The operational stability of the biosensor was investigated by measuring its resposnse to 2.0 μM catechol solution everyday. When not in use, the enzyme electrode was stored in the refrigerator at 4°C, it retained ca. 77% of the initial current response after 7 days and ca. 55% after 15 days.

Effect of the interferent

The possible effect of the presence of foreign ions and compounds in the solution was analyzed. When the concentration of catechol was 2 μM, the interferent effects were investigated by testing the response of the enzyme electrode when the interference to catechol molar ratio was 100. Table 2 shows the results obtained and the proposed sensor shows no significant interference in the presence of the tested ions and compounds, except SCN-, SO3 2- and Ac-. These anions could react with catechol, and make the responds decreased.

This method was applied for phenolic compounds determination in waste water sample. The percentage of the recovery values were calculated by applying the standard additions method. The recoveries range for the water sample is from 99.0% to 99.8%.

Conclusions

This work develops a simple biosensor for phenols by entrapping tyrosinase in gelatine cross-linked matrix. It provides a very simple process for immobilization of tyrosinase. Because gelatine is also protein, the biosensor has a good loading, high catalytic activity of the enzyme, and a fast response rate. It can avoid the leaching of tyrosinase from the surface of electrode under the operation conditions. The resulting biosensor exhibits high sensitivity, good repeatability and wide linear range, implying that the matrix can provide a suitable microenvironment for enzyme. Gelatine-based materials, as yet underutilized, are predicted to be widely exploited in the near future especially in environmentally benign applications in systems working in biological environments, among others as enzyme immobilization supports.

References

Manahan SE (1991) Environmental Chemistry, Lewis Publishers, Chelsea, USA

Huang MT, Ho CT, Lee CYE (1992) Phenolic Compounds in Food and their Effects on Health II, Antioxidants and Cancer Prevention, American Chemical Society, Washington, DC

Hideo Notsu, Tetsu Tatsuma (2004) J. Electroanal. Chem. 566:379–384

Castillo M, Domingues R, Alpendurada MF, Barceló D (1997) Anal. Chim. Acta 353:133–142

Berger TA, Deye JF (1991) J. Chromatogr. Sci. 29:54–57

MacCrehan WA, Brown-Thomas JM (1987) Anal. Chem. 59:477–479

Brage C, Sjöström K (1991) J. Chromatogr. 538:303–310

Poerschmann J, Zhang ZY, Kopinke FD, Pawliszyn T (1997) Anal. Chem. 69:597–600

Nistor C, Emnéus J, Gorton L, Ciucu A (1999) Anal. Chim. Acta 387:309–326

Marko-Varga G, Emnéus J, Gorton L, Ruzgas T (1995) Trends Anal. Chem. 14:319–328

May SW (1999) Curr. Opin. Biotech. 10:370–375

Durán N, Esposito E (2000) Appl. Catal. B: Environ. 28:83–99

Liu S, Yu J, Ju H (2003) J. Electroanal. Chem. 540:61–67

Conner MP, Sanchez J, Wang J, Smyth MR, Mannino SM (1989) Analyst 114:1427–1433

Deng Q, Dong S (1995) Anal. Chem. 67:1357–1360

Wang J, Reviejo AJ (1993) Anal. Chem. 65:845–849

Dong S, Guo Y (1994) Anal. Chem. 66:3895–3899

Shan D, Cosnier S, Mousty C (2003) Anal. Chem. 75:3872–3879

Coche-Guérente L, Cosnier S, Innocent C (1995) Anal. Lett. 28:1005–1016

Cosnier S, Lepellec A, Guidetti B, Rico-Lattes I (1998) J. Electroanal. Chem. 449:165–171

Stryer (1988) L. Biochemistry, 3rd ed.; Freeman; New York

Wang B, Dong S (2000) J. Electroanal. Chem. 487:45–50

Andreescu S, Sadik OA (2004) Anal. Chem. 76:552–560

Long GL, Winefordner JD (1983) Anal. Chem. 55:721A–726A

Wang B, Zhang J, Dong S (2000) Biosens. Bioelectron. 15:397–402

Wang J, Lu F, David L (1994) Analyst 119:455–458

Kamin RA, Wilson GS (1980) Anal. Chem. 52:1198–1205

Rajesh, Takashima W, Kaneto K (2004) React. Funct. Polym. 59:163–169

Rajesh, Pandey SS, Takashima W, Kaneto K (2004) J Appl. Polym. Sci. 93(2):927–933

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant No. 20325516 and 20575026) and the Foundation of State Key state Laboratory of Electroanalytical Chemistry from Changchun Institute of Applied Chemistry.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, N., Xue, MH., Yao, H. et al. Reagentless biosensor for phenolic compounds based on tyrosinase entrapped within gelatine film. Anal Bioanal Chem 383, 1127–1132 (2005). https://doi.org/10.1007/s00216-005-0115-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-005-0115-5