Abstract

Aptamers are nucleic acid binding species capable of recognizing a wide variety of targets ranging from small organic molecules to supramolecular structures, including organisms. They are isolated from combinatorial libraries of synthetic nucleic acid by an iterative process referred to as SELEX (Systematic Evolution of Ligands by Exponential Enrichment). Here we describe an automated microfluidic, microline-based assembly that uses LabView-controlled actuatable valves and a PCR machine, and which is capable of the selection and synthesis of an anti-lysozyme aptamer as verified by sequence analysis. The microfluidic prototype described is 1) a simple apparatus that is relatively inexpensive to assemble, making automated aptamer selection accessible to many investigators, and 2) useful for the continued “morphing” of macro→meso→microfabricated structures until a convergence to a few functional systems evolves and emerges, partly or completely achieving simpler, smaller and more rapid SELEX applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

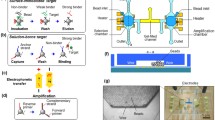

Nucleic acid-binding species (aptamers) are proving increasingly useful in therapeutic and diagnostic applications [1–3]. They are isolated from combinatorial libraries of synthetic nucleic acid by an iterative process referred to as SELEX (Systematic Evolution of Ligands by Exponential Enrichment), summarized in Fig. 1. Aptamers can be discovered for any target protein using SELEX regardless of the protein’s function [4, 5]. Recently, the SELEX process used to isolate specific RNA aptamers was automated, significantly reducing the time required for isolation and amplification of oligonucleotide sequences capable of high-affinity binding to specific target molecules of interest from months/weeks to less than two days (∼42 hours for 12 rounds) [6, 7]. However, if moved to a chip-based, microfluidic environment, SELEX (as well as a variety of SELEX-related chemistries) could potentially be standardized, giving significant advantages in terms of increased speed and reduced costs. Furthermore, such automated devices would pave the way for a variety of high-throughput applications. Such advantages have been documented in connection with chip-based enzymatic assays [8, 9], immunoassays [10, 11], and nucleic acid detection [12, 13]. At the heart of the microfabrication process is the generation of precisely defined wells, channels, valves and pumps onto silicon-based, glass or polymeric substrates using a variety of techniques. There are elegant examples of self-contained, fully integrated, miniaturized devices [14, 15]. However, to date there have been no such devices that are capable of carrying out SELEX, primarily because of the required automated synergy of SELEX system components (three different molecular biological methodologies), which significantly increases the complexity of the structures to be fabricated.

The aim of the work detailed in this report was to develop a microfluidic, microline-based assembly, capable of carrying out automated SELEX which could also provide a way to design and integrate microfabricated chip components. Thus, key microchip issues that can affect the chemistries of the respective SELEX processes could be logically addressed prior to microfabrication. Key questions to consider are:

-

Can this process be miniaturized; can one design a workable, self-contained, microfabricated chip-based SELEX platform?

-

What are the acceptable dimensions, volumes, and flows?

-

Which components are needed (such as valves, chambers, channels, mixers)?

-

How are the process logistics to be accommodated by chip real estate?

-

Are the respective materials comprising the chip friendly to the required bioanalytical processes?

-

If they are unfriendly, how do they influence the biochemical reactions and their outcomes?

-

How can the generation of product be optimized?

Using externally, microprocessor-controlled actuatable valves connected “in line” to reagent-loaded microlines and a microline reaction chamber, we report here on the automated conversion of (1) a specific, anti-lysozyme encoding DNA construct to its corresponding transcript, (2) selection (capture) using a Streptavidin-derivatized silicon microline, and (3) reverse transcription of thermally eluted target-specific RNA back to DNA and amplification. The automated microline assembly described constitutes a considerably simpler, easily accessible, stand-alone apparatus occupying a much reduced total footprint area than that of the currently used robotic-based workstations. Equally important, this microfluidic prototype can aid in the movement of SELEX component processes to integrated, self-contained, microfabricated platforms.

Experimental

Chemicals/components

An EZ-Link Sulfo-NHS-Biotinylation Kit was obtained from Pierce Biotechnology (Rockford, IL, USA). Streptavidin was obtained from Roche (Indianapolis, IN, USA). An anti-lysozyme aptamer was obtained from Dr. Andrew Ellington (University of Texas, Austin, TX, USA). Primers used for amplification were GATAATACGACTCACTATAGGGAAT-GGATCCACATCTACGA (T7 RNA polymerase promoter underlined) and AAGCTTCGTCAAGTCTGCAGTGAA. MEGAscript T7 Kits and SuperScript One-Step RT-PCR System with Platinum Taq DNA Polymerase Kits were obtained from Ambion (Austin, TX, USA). DNase and RNase treatment of SELEX products was carried out using MasterPure Kit reagents (Epicentre, Madison, WI, USA) per the manufacturer’s instructions. E-gels and RNase Out were obtained from Invitrogen (Carisbad, CA, USA). Blue dextran 2000 dye was obtained from Sigma Chemical Co. (St. Louis, MO, USA). LabView software was purchased from National Software (Austin, TX, USA). Nitrogen gas (5.0 grade) was obtained from Praxair (San Antonio, TX, USA). Microlines and actuatable valves were obtained from Upchurch Scientific (Oak Harbor, WA, USA).

Target immobilization

Lysozyme was biotinylated using a Sulfo-NHS-Biotin (spacer arm 13.5 Å) biotinylation reagent kit procured from Pierce Chemical Company (Rockford, IL, USA) per the manufacturer’s instructions. Biotinylated protein (∼10 μgm dissolved in 0.02 M Tris buffer, pH 7.5 containing 0.10 M NaCl and 0.005 M MgCl2) was incubated in a 150 μm fused-silica microline previously coated with streptavidin. Immobilization of FITC-labeled streptavidin to silicon microlines was carried out according to the procedure of Soper and coworkers [16]. Fluorescence microscopy indicated the presence of surface immobilized streptavidin (data not shown).

Operational configuration of the microfluidic SELEX prototype

Shown in Fig. 2 is an operational schematic of the microfluidic SELEX prototype, comprising reagent-loaded microlines, pressurized reagent reservoir manifold, thermocycler, and actuatable valves. Reference to valves, ports and reagent/connecting microlines in the subsequent text is made as follows: notation preceding brackets (for example “10P[ ]”) indicates where in the system (the ten-port valve), the function is occurring. Numbers within brackets (for example [4→5]) indicate the respective valve ports through which fluid is being moved as indicated by the arrows. The notation “><” indicates the holding of fluid in a particular loop as designated by the number (for example >2< indicates loop 2).

Operational diagram of the microfluidic SELEX prototype device. Upper left: Selection and routing schematic showing integration of the three-, four-, six- and ten-port valves with microlines (as designated 10P is in position 1). Upper right: Pressurized reagent reservoir manifold: A, In vitro transcription master mix+dye; B, RT/PCR master mix+dye; C, high-salt solution; D, low-salt solution; E, nuclease free water+dye (selection release carrier fluid); F, N2 (purge nitrogen); G, nuclease-free water used as pressure head. Bottom center: System photo: 1, Pressurized reagent reservoir manifold; 2, modified PCR top plate; 3, Ruler (12”); 4, PCR machine; 5, Actuatable valve

The microfluidic SELEX prototype device employs two types of valves: selection and routing. Selection valves have a common port that can be directed to the “peripheral” ports. For example, the six-port selection valve consists of a center port that is common to the six peripheral ports, allowing any one of the peripheral ports to be common (“in line”) with the center port. Two such valves are employed for reagent selection. The three-port valve allows redirection from the “0” position to that of positions 1 and 2 similar to the six-port selection valve. The functioning of the routing valve is not as intuitive. The four (S1), six (P2), and ten (10P)-port valves have only two functionally actuable positions, so only ports adjacent to one another may be connected; for example, the ten-port valve in position 1 connects 1→2, 3→4, 5→6, 7→8, and 9→10 configurations. Conversely, position 2 connects 2→3, 4→5, 6→7, 8→9, and 10→1 configurations. The two six-port routing valve positions are denoted “inject” and “load” by the manufacturer, a convention retained in this paper.

The microlines used in the microfluidic SELEX prototype are all 360 μm (outer diameter), but they have variable inner diameters of 75, 100, and 150 μm which correspond to miniscule volumes per unit length; a 10 cm length of tubing with the previously mentioned inner diameters corresponds to 0.44, 0.79, and 1.76 μL, respectively. Reagent microlines were cut to accommodate prescribed volumes. Preloading of reagents into respective microlines was accomplished using a pressurized loading injection chamber.

DNA pool sample loading

Initial loading of the DNA-containing pool (round 0) was achieved via the “sample injection port” in the starting position (see Fig. 2, S1 [1] and S2 [position: load]). The path of the DNA pool from the pressurized (∼40 psi) injection loading chamber to its final loading “hold” destination in the sample loop (S2[>1→4<]) is as follows: sample (injection chamber) → S1[3→4] → S2[6→1→ >sample loop<4→5] → discard (atmosphere). Movement of injection fluid was monitored visually by addition of prefiltered dye. Isolation of the loaded sample was accomplished by actuating S2 to “inject” contingent upon the pressure being “off” at S2 [2].

Reagent loading and storage

Reagents are stored and/or held in microlines between the two six-port selection valves (A1 and A2, see Fig. 2). These reagents are readily accessed by actuating the selection valve to positions 1 through 6. Line number 6 serves as a bypass loop allowing for flushing as well as continuity of pressure if needed. The two 6-port selection valves are operated in concert in order to place a respective reagent loop in line with the active pressurized line.

The ten-port NanoPeak valve (10P) is also a crucial reagent-loading component. As previously indicated, it can be actuated to two positions (1 and 2). Position 1 allows for the utilization of reagents stored in microlines between the two six-port reagent selection valves (A1/A2). Position 2 allows for loading of reagents into the microlines residing between A1 and A2. The ten-port valve has an internal dead volume of approximately 20 nL between ports, thus making the microlines and their respective fluids contained within virtually continuous.

Loading of reagents into the respective microlines is accomplished using a pressurized reagent delivery module (see Fig. 2, upper right). This module consists of a pressurized box (approximately 40 psi) with eight feed-through lines connected to a six-port selection valve (designated RL). The common central port of the six-port valve is connected to the reagent injection port (10P [6]), so any one of the six peripheral valve ports can access the central port and consequently the reagent delivery port on the ten-port valve. This configuration allows for bulk storage of reagents used in the SELEX process and the delivery of reagents to the respective microline reagent loops of prescribed volumes. Reagents—in vitro transcription (IVT) and reverse transcriptase (RT) polymerase chain reaction (PCR) master mixes–as well as water for the selection release step are all spiked with dye (Blue Dextran 2000) which is detectable via sensors specifically positioned in the system. Port number 5 (RL) is used to flush the reagent delivery line with nuclease-free water, while port number 6 (RL) is left unconnected, resulting in reagent delivery being shut off due to removal of the pressure head in the line. As configured, ports number 4 and 6 (RL) are currently unused. The path of the reagent(s) to the reagent loop(s) is summarized as follows: RL [1–6]→10P[position 2:6→7]→A1/A2[C→1–6/1–6→C]. The path continues beyond the reagent/bypass loop arrangement to 10P[position 2:4→5→10→1] to the discard. Sensor 2 monitors the common exiting of reagent lines and is instrumental in automated reagent loading.

In vitro transcription (IVT)

All lines are purged with diluted ELIMINase (Decon Laboratories) to remove residual DNA and other potential contaminates. After purging with ELIMINASE, lines are flushed with nuclease-free water. A master mix comprised of MEGAscript (Ambion) reagents was prepared and loaded into reagent loop 1 via an “IVT load” LabView subroutine. In summary, the path utilized was (Bulk Reagent A→RL[1→C]→S0[1→C]→10P position 2: A1/A2[C→1/1→C]), and it contained the following reagents: UTP (2 μL), ATP (2 μL), GTP (2 μL), CTP (2 μL), 10X Reaction Buffer (2 μL), T7 Enzyme Mix (2 μL), RNase Out (2 μL) and 2 μL filtered dye dissolved in nuclease-free water. DNA template was loaded into the sample loop (S2[1→4]) as previously described. The sample loop was custom-cut to accommodate 2 μL when isolated by actuation of the required valves. The volume of fluid (nuclease-free H2O) in the connecting lines from the pressure head to the reaction chamber (P1[0]→P2[3→2]→S2[2→3]→10P[8→7]→A1[C]→A2[C]→10P[4→3]→R1[C]) was sized to contain 4 μL. This volume plus that of the respective reagents moved to the reaction chamber brings the reaction volume up to the desired 20 μL.

The in vitro transcription LabView subroutine is engaged once the reagents are loaded. Reagent loop 1 (loaded with master mix as detailed above) is opened (10P position 1 as diagrammed, Fig. 2, A1/A2 [C→1/1→C]), placing reagents “in line” with the sample loop. The resulting microline path (A1/A2 [C→1/1→C]) allows for delivery of the reagents, nuclease-free water, and lastly the template into the reaction chamber. Sensor number 2 is triggered, with the LabView programmed response resulting in a switch from reaction chamber 1 to the bypass loop R1[6],R2[6]. This configuration isolates IVT reactants within the microline. The reaction microline (R1[1]→R2[1]) was incubated for two hours at 37 °C utilizing a Techne Touchgene Thermocycler with customized heating block. Pressurized water continues to flow via the bypass line during in vitro transcription, flushing the lines and therefore eliminating all trace of dyes and reagents in the system, with the exception of the reaction vessel containing the IVT reaction mix. Dye flushing is vital to clear signaling for subsequent movement of the reaction mix. Following transcription, transcripts were transferred automatically from the reaction chamber to the sample loop (holding loop) via the following pathway: R2[1→0] → S1[1→4] → S2[6→1→4→5] → discard (open to atmosphere). Following the appearance of dye at sensor 3 near the discard (Fig. 2), pressure is diverted by actuation of S1 to position 1, thus isolating the transcripts in S2[1→4]. Pressurized water was allowed to flow for an additional minute in order to flush the remaining dye-colored solution out of the system before switching P1 to port 1, cutting off pressure to the system.

Selection

Bulk quantities of high salt binding solution (HSS, 20 mM Tris HCl, pH 7.5 containing 1 M LiCl and 2 mM EDTA) reside in the pressurized reagent loading module. The large quantity of HSS in this vessel is substantially larger than that required for multiple rounds of SELEX. The reagent line is connected to A2 [4], so when engaged, it flushes the reaction chamber via the following pathway (see Fig. 2): pressurized bulk HSS vessel A2 [5→C]→10P[position 1, 4→3] → R1[0→2] → reaction chamber. The contents (∼2 μl transcripts) of the storage loop S2[1→4] are moved into the reaction chamber containing the HSS and immobilized lysozyme via the following pathway: S2[2→1→4→3] → 10P[position 1, 8→7] → A1/A2[C → bypass/bypass → C] → 10P[position 1, 4→3]→R1[0→2] → reaction chamber. Sensor number 2 detects the presence of dye in transcript carrier fluid, triggering isolation of the IVT products by switching to the reaction chamber 1 loop. The contents isolated in reaction chamber 2 are allowed to sit for ten minutes at room temperature in order to bind lysozyme-specific aptamers.

Following binding of lysozyme-specific aptamers to microline-immobilized lysozyme, the bound aptamers were washed with low-salt solution (LSS, 10 mM Tris HCl, pH 7.5 containing 0.15 M LiCl and 2 mM EDTA) stored as a bulk reagent in almost identical fashion to that described for HSS, the only exception being the bulk line attachment to port A2 [5] instead of A2 [4]. To prepare the system, the HSS residing within lines leading up to the reaction chamber is flushed out of the system with LSS. The pathway is as follows (see Fig. 2): pressurized bulk LSS vessel A2 [4→C]→10P[position 1, 4→3] → R1[0→1] → reaction chamber → R2[1→0] → to discard at S2. After ten minutes, R1 and R2 were actuated to position 2, opening the reaction chamber 1 to the LSS flush. LSS flushing is allowed to proceed for one minute.

Bound aptamers were released from immobilized lysozyme target as follows: the HSS and LSS flushes completely remove any trace of dye, so the carrier fluid for the aptamers (the nuclease-free water), must be spiked with dye in order to be sensed. This carrier fluid is stored in reservoir E. Water containing dye is pumped to the reaction vessel following a one-minute LSS flushing. The dye is detected at sensor R2, triggering isolation of the selection chamber (microline 2) by actuating R1 and R2 to position 1. The thermal block is remotely cued to heat the microline (65 °C for three minutes), releasing bound aptamers into the dye-containing water. Valves R2 and R1 are actuated to position 2, placing the released aptamers and solution back in line with the system’s pressurized line. Dye-labeled solution moves to the sample storage loop and is detected at sensor number 1, signaling S2 to divert pressure to P2, resulting in the storage of the selected aptamers for future steps. The fluidic diversion occurs for an additional minute in order to ensure that the working lines are cleared of any residual reaction mix.

RT/PCR

Loading and delivery of the RT/PCR reaction mix is accomplished in a similar fashion to that described for in vitro transcription. Master mix (2 μL) residing in the reagent delivery module is delivered to reagent Loop 2 (A1[2]→A2[2]) and isolated. The master mix stock contains the following components: 2X Reaction Mix (11 μL), forward primer 10 μM (0.5 μL), reverse primer 10 μM (0.5 μL), and RT/Platinum Taq Mix (0.2 μL). The master mix and transcripts are delivered and isolated in the reaction microline in similar fashion to that described for the in vitro transcription step. The amplification parameters are as follows: 50 °C (15 min); 94 °C (2 min); 40 cycles (94 °C for 15 s and 61 °C for 45 s). As with the in vitro transcription step, the product is automatically transferred to the holding loop. Once sensor number 1 detects the presence of the dye, S1 diverts pressure and the system is ready to begin SELEX round n+1.

Agarose gel electrophoresis

Electrophoretic examination of SELEX products (DNA→in vitro transcripts→selection→RT-PCR DNA product) was carried out using 4% (w/v) agarose E-gels (Invitrogen). Reaction products (2 μL) were brought to 20 μL with the addition of nuclease-free water and 2 μL aliquots of in machina-generated reaction products were incubated with/without DNAse/RNAse per the manufacturer’s instructions, loaded onto gels, and electrophoresis was carried out for 30 minutes at 70 volts using an E-Gel (BioRad) electrophoresis apparatus. Bands were visualized by ethidium bromide staining.

Cloning and sequencing

PCR products (on bench and in machina) were cloned into a pCR2.1 vector using a TA Cloning kit (InVitrogen) according to the manufacturer’s instructions. Briefly, transformation of INVαF’ competent E. coli cells was accomplished using 2 μL of pCR2.1 vector insert construct and 50 μL of E. coli cells in a one-shot transformation protocol. Cells were plated on LB agar plates containing X-gal and 50 μg/ml Kanamycin and incubated overnight at 37 °C. Transformed INVαF’ cells (20 white colonies) were randomly picked and grown in LB broth containing 50 μg/ml Kanamycin overnight in a shaker incubator at 37 °C.

Plasmid DNA was extracted using a Plasmid Miniprep kit (Qiagen, Valencia, CA, USA) according to the manufacturer’s instructions. Linearization was achieved by restriction enzyme digestion. Bst restriction enzyme digestion reaction mixtures contained the following components in a final volume of 50 μL: plasmid DNA (17 μL), 10X Buffer (5 μL), Bst X 1 (2.5 μL, 25 Units) and nuclease-free water (25.5 μL). These were incubated at 55 °C for two hours followed by 20 minutes at 65 °C for enzyme inactivation. Kpn 1 restriction enzyme digestion was carried out in similar fashion to that described above except that incubation was carried out at 27 °C for one hour followed by 20 minutes at 65 °C.

Sequencing reactions consisted of 4 ul Big Dye Terminator v3.1 Cycle Sequencing RR-100 (Applied Biosystems Foster City, CA, USA), 3.5 μl nuclease-free water, 500 nM primer and 2 μl template. Cycle conditions were 96 °C for one minute followed by 25 cycles at 96 °C for ten seconds, 50 °C for five seconds and 60 °C for four minutes. Excess dye terminator was removed using a DyeEx 2.0 Spin Kit (Qiagen Valencia, CA, USA) per the manufacturer’s instructions. All centrifugation steps were carried out using an Eppendorf centrifuge at a speed of 2,700 rpm. Respective spin column eluates were dehydrated using a vacuum centrifuge followed by resuspension in 10 μl formamide. All samples were sequenced using an ABI-Systems 3100 automated sequenator (Applied Biosystems, Foster City, CA, USA).

Results

The microfluidic SELEX prototype carries out automated SELEX. Shown in Fig. 3 is a gel analysis of automated SELEX [DNA→RNA (in vitro transcripts)→target selected (lysozyme)→reverse transcribed-PCR-amplified DNA] product (99 bp) generated on bench (lane 3) and in machina (lane 6) using the microfluidic SELEX prototype, starting with a DNA construct coding for a well-characterized anti-lysozyme aptamer. DNase 1 treatment of the 99 bp product generated on bench and in machina resulted in complete digestion of the 99 bp SELEX product, as evidenced by the absence of an ethidium bromide staining band (lanes 4 and 7, respectively). DNase 1 treatment of in vitro transcripts generated both on bench and in machina and subsequently selected and thermally eluted prior to RT-PCR exhibited the expected 99 bp band, indicating that the SELEX product produced occurred via reverse transcription of on bench- and in machina-generated RNA and not simple amplification of starting DNA template (lanes 5 and 8, respectively). Sequence analyses of aptamers made on bench and in machina were identical (5′-ATCAGGGCTAAAG-AGTGCAGAGTTACTTAG-3′).

Agarose gel electrophoresis. Electrophoresis was carried out using a 4 % (w/v) agarose gel as described under Experimental/Components: Agarose gel electrophoresis. Lane 2, 20 bp ladder; lane 3, SELEX product generated on bench; lane 4, SELEX product generated on bench plus DNAse 1; lane 5, on bench-generated in vitro transcripts+DNase 1 treatment prior to RT-PCR; lane 6, SELEX product generated in machina; lane 7, SELEX product generated in machina +DNase 1; lane 8, in machina-generated in vitro transcripts+DNase 1 treatment prior to RT-PCR; lane 9, 20 base pair ladder. Sequence analysis of aptamers derived on bench and in machina was carried out as described in Experimental/Components: Cloning and sequencing

Discussion

Due to the fact that aptamers can be generated against any protein target using SELEX, they are extremely versatile reagents and appear to be alternative candidates to the antibodies and antibody fragments used universally. In many cases, aptamers offer considerable advantages when used in analytical devices, proteomic microarrays and as therapeutic agents [1, 17–19]. The SELEX process has been recently automated with the development of macro-robotic systems consisting of a PCR machine and a robotic manipulator to move reagents to multiple workstations on the worksurface where the individual steps of the SELEX process are performed [6, 7].

In contrast to these complex systems, the microfluidic prototype described here comprises reagent-loaded microlines in lieu of a robotic manipulator, multiple cassettes and microliter plates. A major aspect of microfluidics involves the manipulation of fluid flows on various platforms by differential pressure [20, 21]. The microfluidic SELEX prototype described in this report utilizes a simple fluidic pressure gradient for the loading and movement of reagents through the microlines. Reagents are moved from a small, pressurized reservoir manifold and moved into specific microlines by actuation of valves via dye sensing sensors. Thus the automated microfluidic SELEX prototype described here is considerably smaller and simpler than current robotic workstations.

With the exception of initial sample loading, the apparatus is capable of automated “start to finish” SELEX (DNA pool→in vitro transcription→selection→RT-PCR→DNA amplicon) aptamer synthesis. Furthermore, the aptamer generated using the established automated robot and that generated using the microfluidic prototype are identical in sequence, validating the fidelity of the integrated process carried out by the prototype apparatus.

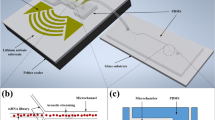

The microfluidic prototype can be used in a “snap-on” modular fashion to evaluate individual processes and/or run in sequences, affording an empirical basis for design changes from which external functions, such as PCR and valving/pumping, can be easily modified. The microlines allow simple, low-volume interconnections that can provide robust, leakage-free connections with low-to-negligible dead volumes between grafted chip components, as shown in Fig. 4. For example, the PCR component of the SELEX process is a mature technique. However, adaptation of PCR to a microchip platform is an evolving technology [22]. Many of the analytical challenges associated with performing efficient, fast, low volume PCR in microfabricated structures are yet to be completely addressed, much less solved. The evolution of such structures involves optimizing both “off line” as a stand-alone process and “in line” as a system component of multiple parameters; for example PCR chamber design, means of temperature cycling, fluid flow and temperature sensing, to mention a few.

If decreased thermocycling time is sought in order to further reduce the time required per round of SELEX, smaller PCR reaction volumes are required (at least one, possibly two orders of magnitude). The microline (254 mm in length, 0.1 mm or 100 micron inside diameter) accommodates 2 μl RT-PCR reaction mixture with a surface area-to-volume ratio (SA/V) of 40 mm2/mm3. Increased thermal management efficiency resulting from increased surface area could be achieved by increasing the SA/V ratio, for example to 80 mm2/mm3 using a 0.05 mm (50 micron) line (100 mm in length) accommodating 200 nl RT-PCR reaction mix; thus enhancing the PCR speed, or decreasing the time per PCR cycle via reduction of reaction mixture volume (one order of magnitude) and microline inside diameter (two-fold). This can be empirically determined prior to microfabrication by repeating 50 micron channels of required length in various substrates and chip surface real estate can be assigned accordingly. Adsorption of products as well as reactants using different SA/V ratios could also be evaluated prior to microfabrication using a variety of commercially available microlines made of different materials.

Currently, the microfluidic prototype is operated at 40 psi (∼3 bar), resulting in a flow rate of ∼100 nl/sec. However, reducing the microline diameter will result in a corresponding pressure increase that is required to move the contents of the microline at a similar rate. Importantly, the microlines and chip substrate surface ferrules shown in Fig. 4 (negligible dead volume) all have pressure tolerances far in excess (137.9 bars, 2000 psi) of the 50–100 bars required for laminar flow in microfabricated structures if desired.

In addition to platform development, a very attractive feature of the microfluidic SELEX prototype as configured here is the possible grafting of existing miniaturized platforms; for example, integration of high-throughput “on-chip” generation of temperature gradients [23]. On-chip generation of temperature gradients could be very useful in gradient elution (selection of weak vs. high affinity binding aptamers), significantly reducing the time and number of SELEX rounds required for picking out aptamers of interest. Thus far, very few chemical functions have been integrated because of the difficulties imposed by current fabrication methods of the on-chip valve. Valving is one of the most important microfluidic functions, because flow control in microfluidic structures becomes much more complicated with the system integration that a process such as automated SELEX demands. Recently, Koh and coworkers have reported PCR valving in a plastic device utilizing gel valves that can withstand hydrostatic pressures up to 100 psi, which is considerably higher than the pressures encountered with the prototype [24]. These kinds of grafted, miniaturized platforms and functionalities will decrease both the analysis time and the size of the apparatus.

Conclusion

The prototype described in this report is smaller, simpler and relatively inexpensive compared to current robotic workstations, making automated SELEX and generation of aptamers more accessible. It can be argued that the advantage derived from instrumentation miniaturization has in some instances been overstated due to a variety of technical and economic restrictions. However, the microfluidic prototype apparatus may be useful in the continued “morphing” of macro→meso→microfabricated structures until the convergence to a few functional systems evolves and emerges, achieving simpler, smaller and more rapid SELEX applications.

References

Jayasena SD (1999) Clin Chem 45:1628–1650

Rajendran M, Ellington AD (2002) Comb Chem High T Scr 5:263–270

Wilson DS, Szostak JW (1999) Annu Rev Biochem 68:611–647

Tuerk C, Gold L (1990) Science 1249:505–510

Ellington AD, Szostak JW (1990) Nature 346:818–822

Cox JC, Ellington AD (2001) Bioorgan Med Chem 9:2525–2531

Gold L, Zichi DA, Smith JD, Schneider DJ (2003) United States Patent Application Publication: US 2003/0054360 A1

Wang J (2002) Electrophoresis 23:713–718

Hadd AG, Raymond DE, Halliwell JW, Jacobson SC, Ramsey JM (1997) Anal Chem 69:3407–3412

Sato K, Tokeshi M, Kimura H, Kitamori T (2001) Anal Chem 73:1213–1218

Wang J, Ibanez A, Chatrathi MP, Escarpa A (2001) Anal Chem 73:5323–5327

Righetti PG, Gelfi C, Acunto MR (2002) Electrophoresis 23:1361–1374

Fan ZH, Mangru S, Granzow R, Heaney P, Ho W, Dong Q, Kumar R (1999) Anal Chem 71:4851–4859

Anderson RC, Su X, Bogdan GJ, Fenton J (2000) Nucleic Acids Res 28:e60

Liu RH, Yang J, Lenigk R, Bonanno J, Grodzinski P (2004) Anal Chem 76:1824–1831

Soper SA, Williams DC, Xu Y, Lassiter SJ, Zhang Y, Ford SM, Bruch RC (1998) Anal Chem 70:4038–4045

Hesselberth J, Robertson MP, Jhaveri S, Ellington AD (2000) Rev Mol Biotechnol 74:15–25

Brody EN, Gold L (2000) J Mol Biotechnol 74:5–13

Osbourne SE, Matsumura I, Ellington AD (1997) Curr Opin Chem Biol 1:5–9

McEnery M, Tan A, Alderman J, Patterson J, O’Mathuna SC, Glennon JD (2000) Analyst 125:25–27

Liu H, Felten C, Xue Q, Zhang B, Jedrzjewski P, Karger BL, Foret F (2000) Anal Chem 72:3303–3310

Roper MG, Easley CJ, Landers JP (2005) Anal Chem 77:3887–3894

Mao H, Holdin MA, You M, Cremer PS (2002) Anal Chem 74:5071–5075

Koh CG, Tan W, Zhao M, Ricco AJ, Fan ZH (2003) Anal Chem 75:4591–4598

Acknowledgements

The research reported in this document/presentation was supported in part by Contract number DAAD17-01-D-0001 (U.S. Army Research Laboratory) and NIH Grant 3S06GM008194-25S1. The views and conclusions contained in this document/presentation are those of the authors and should not be interpreted as presenting the official policies or position, either expressed or implied, of the U.S. Army Research Laboratory or the U.S. Government unless so designated by other authorized documents. Citation of manufacturer’s or trade names does not constitute an official endorsement or approval of the use thereof. The U.S. Government is authorized to reproduce and distribute reprints for Government purposes notwithstanding any copyright notation hereon.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hybarger, G., Bynum, J., Williams, R.F. et al. A microfluidic SELEX prototype. Anal Bioanal Chem 384, 191–198 (2006). https://doi.org/10.1007/s00216-005-0089-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-005-0089-3