Abstract

The reliable operation of transmission line depends on the condition of insulators. The condition of the insulator depends on the pollutants deposited on the surface of the insulator. Prediction of flashover voltage at different conditions is an important task in order to judge the health condition of insulators. Investigating the performance of insulator at every contamination level by experimental process is time consuming. So development of a precise simulation model is very important to predict various flashover performances. In this paper, a finite element method based approach has been proposed to develop a simulation model, which is mainly based on arc Obenaus model and Hapmton criteria. Finite element method analysis has been done by using COMSOL multiphysics software and MATLAB. To conduct the experimental and simulation study, two different types of insulator are used. Different temperature, pollution levels and hydrophobic classes are considered during flashover simulation technique. With the help of AR model leakage current, the residual resistance of the porcelain insulator has been determined. It has been found that arc constants are the most important factors for different types of insulator. Arc constants for the silicon rubber insulator are also determined in the present work to facilitate the simulation model. To validate the model simulation, results are compared with practical results obtained from laboratory experiment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In power system, for maintaining the reliability of the system outdoor insulator plays an important role. Under contaminated conditions, the flashover performance of different insulators is one of the significant aspects in designing of insulation in power system [1]. When an insulator is fresh and dry, very small capacitive current flows along the surface. But the presence of rain, fog or other pollutants introduces a flow of resistive current which has higher magnitude than capacitive one. On the other hand, incorporation of non-uniform heating and pollutants creates a ‘dry band’ on the insulator surface. These factors usually debase the surface condition of the insulator and lead the insulators toward flashover. The presence of water due to fog or rain on the insulator surface also degrades the insulator performance. The pollution flashover on high-voltage insulators usually happen after two consecutive phases: One is ignition and other phase is successive increase of discharges under polluted condition. Moreover, due to the growth of discharges across the dry band of the surface, enhancement in the flow of leakage current and finally flashover occurs.

In last one decade, some research has been conducted on flashover performance of different insulators at various contaminated condition [2,3,4,5,6,7,8,9,10,11,12,13,14]. But as we all know testing of any high-voltage insulator in a laboratory at different conditions is a huge and time consuming task. So a precise simulation method can decrease the burden of that test. Moreover, calculating the flashover phenomenon of different insulators in different conditions by simulation method is a critical task to conduct. Specially designing the insulator in a proper way and accurate calculation of electrostatic and voltage distribution at different conditions are the main concerning factors for developing a model.

Many researchers have proposed different static and dynamic models on insulator’s flashover performances. At the very beginning, Wilkins et al. [3] proposed a model to calculate the flashover voltage for uniform surface pollution films. After that a static model came into the account for determining the flashover performances [4]. Then it has been found that dynamic model gives better result than static model due to different arc phenomena [5]. A brief analysis of arcs on polluted surfaces was first made by Obenaus [6]. In another approach, form factors and leakage lengths of the insulators have been chosen for flashover voltage calculation [7]. By using dimensional analysis of insulator, Rizk [8] recommended a dynamic model. Another AC model based on experimental relationship between arc re-ignition voltages and the arc current has been proposed by Claverie [9]. The most convincing AR model was first introduced by Rumeli [10]. This method has been defined in terms of leakage path and radius of any given insulator. Another theoretical approach has been made by few authors, where for flashover voltage calculation they assumed uniform pollution film. But there is a strong relation between non-uniform pollution and flashover [11]. But dynamic arc model of the insulator has provided the most truthful information for both DC [12] and AC [13] voltages.

This paper presents a flashover model for both 11 kV porcelain and 11 kV silicon rubber insulator (SIR) at different polluted conditions. A comparison has been shown between simulated data and practical data to validate the proposed model. In recent times, many authors have shown some improved models to predict flashover voltages [13,14,15], where layer conductivity is chosen for modeling. In this work instead of layer conductivity, electrical conductance of pollution layers has been taken into account for modeling purpose. In a polluted insulator, relative permittivity of the protected creepage portion and surface portion cannot be same. After considering all those facts permittivity and electric conductance, calculation of polluted insulator during modeling gives better result which is shown in the result part.

As we know SIR insulator is more hydrophobic than other insulators, different fog conditions are also analyzed in this paper. Arc constants for the SIR insulator have been determined by the procedure described in [16]. For designing the insulators and different field calculations, finite element method (FEM)-based software COMSOL multiphysics incorporated with MATLAB has been used. This provides more accurate result with less computational burden.

2 Experimental tests

2.1 Experimental setup

An experimental setup is developed according to IEC 60507 [17]. The schematic diagram of experimental setup along with data acquisition system is shown in Fig. 1. A test voltage is applied across the sample insulator through a series resistance. Here C1 and C2 formed a potential divider.

A single-phase 50-Hz testing transformer having rating of 150 KVA, 500 V/250 kV is used for supplying the power to the conductor as shown in Fig. 1. The output voltage of the transformer was applied to insulator through series connected protective resistor of \(180\,\hbox {k}\Omega \). Waveforms related to surface leakage current were collected as information about voltage through a resistance of \(10\,\hbox {k}\Omega \) connected to output of the insulator. A protecting electronic system was utilized to prevent any damage that may occur in measurement devices due to any failure in the system. Waveforms were stored by a CRO.

2.2 Description of samples

Both 11 kV porcelain and silicon rubber insulators have been used for experimental purposes. Details of parameters of both insulators are tabulated in Table 1, and the photograph has been given in Fig. 2.

2.3 Preparation of samples

For artificial contamination test, here solid layer method has been chosen to contaminate the insulator surface [17]. It is possible to produce an approximately uniform contamination layer very quickly by using mentioned method. In this particular test, NaCl was used as conductive components with kaolin. For different levels of equivalent salt deposit density (ESDD), values of conductivity are tabulated in Table 2. ESDD is used to determine the severity of contamination on insulator surface which is standardized in terms of salt weight per unit area (\(\hbox {mg/cm}^{2})\). ESDD is measured by, \(\mathbf{ESDD}= \mathbf{SV} / \mathbf{A}\), where S is salinity (gm/ml), V is the volume of the solution (\(\hbox {cm}^{3})\), and A is the area (\(\hbox {cm}^{2})\) of the insulator surface. Generally, most of the power line insulators are affected by the sodium chloride (NaCl) salt from the wind near the coastal region. In this region, power lines insulators easily get damaged and frequent changes are needed. Kaolin (Al \(\hbox {SiO}_{2}\) \(\hbox {O}_{5}(\hbox {OH})_{4}\)), mainly abundant in tropical rainforest countries like China, Russia, India, Pakistan, Bangladesh, otherwise called as kaolinite or china clay is the white dirt. It easily absorbs the water content and evenly spreads the water content throughout the insulator surface. Because of insulator’s surface hydrophobicity, the insulator should be pre-contaminated at the beginning. An artificial fog condition has been created in laboratory to study the effect of fog on silicon rubber insulator. As we all know silicon rubber insulator is more hydrophobic than porcelain insulator, it is very important to know the flashover characteristic at different fog conditions. To create the hydrophobic condition, the conventional rain test method has been used, and the only difference is that the undersides of the sheds are covered by a continuous water film layer. 10–12 water droplets are assumed on each 10 degree segment of each weather shed for hydrophobic class (HC) one. Then, the sample was placed in an artificial pollution chamber and kept in a fixed humidity level (88%) and temperature (12–15 \({^{\circ }}\hbox {C}\)) for 1 h. For HC 2 and HC3, amount of water droplet varies from 17 to 20 and is kept in chamber for 2–3 h.

To execute that some droplets of distilled water were sprayed on the surface and then, kaolin powder is poured on it. After that the artificial pollution was prepared according to IEC 60507 by mixing of kaolin and NaCl. Initially the weight of the kaolin and NaCI were measured by the weight gauge apparatus. This mixture was coated on the insulator surface and allowed to dry for 24 h. The same procedure has been followed for silicon rubber insulators. Figure 3 shows artificially contaminated insulators including different hydrophobic levels.

3 Flashover model for polluted insulators

The model proposed here for flashover voltage prediction at various polluted and fog conditions of different insulators is mainly based on dynamic arc model analyses. As it is mentioned earlier, instead of calculating overall layer conductivity, electrical conductance of the pollution layer and dielectric constant of the pollution layer are employed here during flashover computation. In COMSOL-based simulation method, anyone has to choose the material properties and dielectric constant of that particular material. In practical cases, the conductivity of the polluted surface and conductivity of the protected creepage portion cannot be same. So here at different contaminated conditions, conductivity of the pollution layers and conductivity of the protected creepage portions have been measured in laboratory and those values are used in flashover modeling.

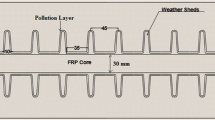

The variations of pollution resistance and the occurrence of partial discharge in the dry bands are the two important factors during flashover. In this study, a flashover is developed by using AR model [10] which considers those facts. AR model considers contaminated insulator a series resistance with the discharge phenomena, and it is depicted in Fig. 4. This model had been used by many authors for FEM analysis of disk-type insulators [2, 12, 15]. According to this model, if L is the total length of the insulator, then variable width a(l) is expressed as follows:

It has been found from different literature [2, 12, 18] the electric field can be easily calculated by Hampton condition. The criterion can be expressed as,

Here, \(E_\mathrm{avg}\) is the average electric field of the pollution layer, and \(E_\mathrm{arc}\) is the arc voltage gradient. This gradient in discharge column can be expressed as [3].

where A and n are the arc constants. To calculate, \(E_\mathrm{arc}\), the constants A and n are assumed 63 and 0.7 for porcelain-type insulator when the applied voltage is AC [3, 14, 18]. But for silicon rubber insulator to calculate the values of those constants another method [16] has been followed which has been shown in Fig. 5. Both, the presence of water droplets and uniform pollution are considered during the calculation.

3.1 Calculation of ARC constants for silicon rubber insulator

For calculating the arc constants of composite insulators, Farzaneh et al. [16] described a detailed method where ice surface with air gap on composite insulators had been considered for finding the values of arc constants. Same procedure has been followed here for calculating the arc constants of silicon rubber insulators at different contaminated and fog conditions. Initially in the laboratory, a constant air gap of 1 cm on the grounded side of insulator has been made. After adjusting the measuring electrode in the particular position, the voltage was applied. To change the arc length, new samples of both artificially polluted and different levels of hydrophobic insulators ware taken into account. Measuring electrode was again readjusted to the desired arc length. The arc length was adjusted from 15 to 100 mm. The water droplet was distributed on the sheds to make a continuous water film layer. Size of the water droplet was varied from 80 to 100 \(\upmu \mathrm{m}\). By fitting the curve for different values of \(\hbox {E}_{\mathrm{arc}}\), one Arc constant has been estimated in Fig. 6 to model the SIR-type insulator.

3.2 FEM model of the insulators

The finite element method (FEM) is widely used to investigate the electric field distribution on insulator surface. The surface of a zone-applied FEM is defined by triangular or quadrilateral elements. The FEM provides important advantages during calculation in terms of calculation speed and accuracy. A well explanation of using FEM to calculate the field distribution is provided in following references [14, 15]. The commercial finite element analysis programs, as in COMSOL multiphysics, have gained common acceptance among engineers in industry and researchers at universities and governments laboratories.

A mathematical model for calculating Dc flashover voltage of ceramic insulator was first proposed by Obenaus [6]. In this model, electric arc was considered as a series resistance. The model was expressed by the following expression:

where \(V_{n}=\) applied voltage (kV); I is the leakage current (mA); \(x=\hbox {arc length}\), \(R(x) =\) resistance of the pollution layer and water droplet on the insulator surface or the residual resistance. A and n = arc constant; \(V_{d}= \hbox {voltage}\) drop across the measuring electrode. This equation can be used for both AC and DC. \(V_{d}\) can be ignored when the applied voltage is AC [10]. Calculation of the value of R is the most complex part as it depends on the form factor and layer conductivity of the insulator. Form factor of the insulator usually changes with the size of the insulator. A FEM-based method has been proposed here to calculate the value of R. In this paper to perform the FEM analysis Eq. (4) can be rewritten as Eq. (5). From Fig. 7 it is quite obvious that distribution of current density is not uniform due to the non-uniformity of the pollution layer. Here leakage current (I) is determined by integrating the current density at ground electrode. On the other hand, for the calculation of \(E_\mathrm{avg}\), the entire conductive portion has been taken into account. So the value of R can be easily determined form Eq. (5). This has less computational burden if compared with other mathematical model [3, 10, 13, 15]

So for FEM analysis, COMSOL multiphysics is used and a simple MATLAB program incorporated with it gives a simple solution. COMSOL multiphysics is used here to perform FEM analysis by using Eq. (5) and to calculate the \(\hbox {E}_{\mathrm{avg}}\) on the entire conductive surface. Value of the leakage current is determined by integrating the current density. Figure 8 shows the FEM 2D model of both insulators. For FEM analysis of fresh and dry insulator, permittivity of the pollution layer is considered as air’s permittivity. In case of contamination, thickness of the dry band is varied from 4 to 7 mm, which has been measured in laboratory. In this paper, a MATLAB and COMSOL multiphysics-based model has been developed to compute flashover voltage. At first, potential distribution and electric field strength of the insulators along the leakage length have been determined. Variations of the potential distribution and electric field strength at different polluted conditions have been shown in Figs. 9 and 10. Variation of electric field strength with the increase of pollution layer is clearly visible from Fig. 10 for both the insulators (Fig. 11).

Dielectric constant at different salt concentrations [22]

A flowchart for the development of this particular model has been shown in Fig. 12. Different parameters like diameter, leakage length, relative permittivity of the materials have been given as input in COMSOL. It is discussed in earlier section that insulators are polluted at different amount of salt to get different polluted conditions. Dielectric constants of the salt solution are determined by using the method described in this paper [22].

In COMSOL 3, input has been given, electrical conductance of the solution which has been measured in the laboratory, relative permittivity and the temperature. For fog condition, the relative permittivity for the water droplets is 80 and their conductivity is \(250\,\upmu \hbox {s}/\hbox {cm}\). It is possible to vary the temperature in COMSOL, which makes the simulation process more appropriate. \(\hbox {E}_{\mathrm{avg}}\), \(\hbox {E}_{\mathrm{arc}}\) and the value of the leakage current value have been extracted for every input voltage. Value of \(\hbox {E}_{\mathrm{avg}}\) and \(\hbox {E}_{\mathrm{arc}}\) is compared by a simple program to fulfill the condition of Eq. (3). When the electric field of the pollution layer is greater than the electric field, flashover will occur. Calculated flashover voltage and their comparison with other methods have been discussed in Sect. 4.

4 Validation of AC flashover voltages

The proposed technique is validated by comparing the results with both experimental and theoretical data of other researchers.

It has been observed from Fig 13, that maximum relative error is very low. So it can be said that present model provides quite acceptable values with the experimental ones. The porcelain insulator used here is actually U40BL type [14, 15]. In lots of research paper, contamination severity is expressed in terms of surface conductivity (\(\upmu \hbox {S}\)). But ESDD(\(\hbox {mg/cm}^{2})\) and surface conductivity (\(\upmu \hbox {S}\)) in terms of contamination severity are actually correlated with each other which is mentioned by CIGRE working group 33 [20]. Figure 14 shows a comparison of proposed method with a recent flashover model of U40BL type insulators. It can be seen that the present model shows better result than the method proposed by Gencoglu et al. [15]. Authors have already published the experimental result in [21].

It is quite obvious that the values of conductivity of the pollution layer will change with different ESDD levels. On basis of ESDD level, pollution level can be classified into different categories [20]. For example, in case of average pollution the conductivity is varying in a certain range. In the present work, the condition of insulator has been predicted based on the different pollution layers. In Table 2, for pollution layers 4 and 5 ESDD values are very high, i.e., very heavy polluted condition. So any other value in-between these two, with different conductivity level, is possible to be determined by using this model and less error rate is expected. So it can be said that little error during those measurements will not affect the simulation result.

5 Conclusion

The flashover voltages of a polluted high-voltage insulator were computed using the developed new dynamic model in this study. An algorithm has been developed to predict the flash over voltage of different insulators, and it was implemented by using COMSOL multiphysics and Matlab® software. For porcelain-type insulator, AR model has been used to compute FEM analysis. A comparison of obtained result for porcelain-type insulators is shown here, and it is quite evident from the graph that simulation result has marginal error.

For SIR-type 11 kV insulator, arc constants are determined to compute flashover voltages at different polluted and hydrophobic conditions. Such a model can be used for ice-covered insulators by changing the values of contents which are actually dependent on nature of polluted surface. Variation of potential distribution and electric field strength of different insulators at various contaminated conditions has been also studied here.

References

Dhahbi-Mergriche N, Beroual A, Karhenbuhl L (1997) A new proposal model for flashover of polluted insulators. J Phys 30(3):889–894

Aydogmus Z, Cebeci M (2004) A new flashover dynamic model of polluted HV insulators. IEEE Trans Dielectr Electr Insulation 11(4):577–584

Wilkins R (1969) Flashover voltage of high voltage insulator with uniform surface pollution films. Proc IEE 116(3):457–465

Rizk FAM (1981) Mathematical models for pollution flashover. Electra 78:71–103

Cheng TC (1974) Mechanism mechanism of flashover of contaminated insulator. Ph.D. Thesis, MIT, Cambridge

Obenaus F (1958) Fremdschicht überschlag und Kriechweglange. Deutsche Electrotechnik 2(4): 135–136

Chatterje N (1978) Flashover characteristics of polluted insulators. IE (I) J EL 58:195

Rizk FA (1970) Application of dimensional analysis to flashover characteristics ofpolluted insulators. Proc IEE 117(12):2257–2260

Claverie P, Porcheron Y (1973) Howto choose insulators for polluted areas. IEEE Trans Power Appar Syst 92:1121–1131

Rumeli A, Hızal M, Demir Y (1981) Analytical estimation of flashover performances of polluted insulators. MADRAS 1(02):01–06

Streubel H (1983) The influence of nonuniform contamination on the flashover voltage of insulators. In: Proceedings of fourth international symposium on high voltage engineering, Athens, paper no. 46.10

Sundararajan R, Gorur RS (1994) Effect of insulator profiles on DC flashover voltage under polluted conditions. A study using a dynamic arc model. IEEE Trans Dielectr Electr Insulation 1(1):124–132

Dhabi N, Beroual A (2000) Flashover dynamic model of polluted insulators under AC voltage. IEEE Trans Dielectr Electr Insulation 7(2):283–289

Gencoglu MT, Cebeci M (2008) Computation of AC flashover voltage of polluted HV insulators using a dynamic arc model. Euro Trans Electr Power. doi:10.1002/etep.249

Gencoglu MT, Cebeci M (2008) The pollution flashover on HV insulators. J Electr Power Syst Res 78:1914–1921

Farzaneh M, Zangand J, Chen X (1997) Modeling of the AC ARC discharge on ICE surface. IEEE Trans Power Deliv 12(1):325

IEC 60507 (1991) Artificial pollution tests on high-voltage insulators to be used on a.c. systems, Edition 2

Hmaton BF (1964) Flashover mechanism of polluted insulation. Proc IEE 11(5):985–990

Karady G, Amrah F, Sundararajan R (1999) Dynamic modeling of AC insulator flashover characteristics. In: Proceedings of the 11th international symposium on ‘high voltage engineering’ 1999—London pp 1–4, paper no. 467

Working Group 33.04 (1979) Study committee no. 33, a critical comparison of artificial pollution test methods for HV insulators. Electra, no 64, pp 117–136

Banik A, Dalai S, Chatterjee B (2014) Condition monitoring of overhead line insulator by measuring surface leakage current. In: Proceedings of the 11th IEEE India conference INDICON, Yashudha Pune, pp 1–5

Gavish N, Promislow K (2016) Dependence of the dielectric constant of electrolyte solutions on ionic concentration. J Phys Rev E 94(1):1–14

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Banik, A., Mukherjee, A. & Dalai, S. Development of a pollution flashover model for 11 kV porcelain and silicon rubber insulator by using COMSOL multiphysics. Electr Eng 100, 533–541 (2018). https://doi.org/10.1007/s00202-017-0520-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00202-017-0520-8