Abstract

The swelling kinetics of native and thermally modified wood was studied. Norway spruce, Scots pine, European beech, and English oak specimens of dimensions 20 × 20 × 10 mm were modified at 180, 200, and 220 °C. The swelling kinetics of the specimens was monitored during 24 h of water immersion. The results are presented as relative swelling rate, and values for maximal radial and tangential swelling, and anti-swelling efficiency. A relatively high initial linear-phase swelling rate was found for spruce, pine, and beech wood, while oak wood exhibited more gradual swelling. Thermal modification improved dimensional stability, depending on the wood species, anatomical direction, and intensity of treatment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Wood has many advantages as a building material, which are widely exploited. At the same time, there is a general effort to eliminate the natural disadvantages of wood, most often resulting from its interaction with water. As wood absorbs water, the cell walls swell significantly more in the radial and tangential (transversal) directions than in the longitudinal direction. The lesser longitudinal swelling results from the orientation of stiff cellulose microfibrils, which lie more or less parallel to the longitudinal direction in the thick S2 cell-wall layer. Wood swelling tends to be greater tangentially than radially, since the wood rays have a restraining effect on swelling in the radial direction (Höhne and Tauer 2016). Hardwood and softwood species exhibit different levels of anisotropy and swell differently, depending on their chemical composition, structure, and density, and the anatomical direction. Thermal modification is used to improve the material properties of wood and considerably reduce the interaction between wood and water. Heating to 160–240 °C in different media (water vapor, nitrogen, vacuum, or oil) results in a degradation of some of the cell-wall constituents accompanied by chemical changes (Allegretti et al. 2012). The most important changes for decreasing wood swelling are the reduction in hydroxyl (OH−) groups in hemicelluloses (which undergo dehydration reactions), a proportional increase in cellulose crystallinity, and cross-linking in lignin (Altgen et al. 2018). The reduction in concentration and accessibility of OH− groups results in less interaction between wood and water molecules, and a reduction in the equilibrium moisture content (EMC), and consequently of dimensional stability (Altgen et al. 2018). Currently, several methods based on two basic underlying principles, i.e., contact with liquid water and contact with water vapor, are used to analyze the dimensional stability of wood. When measuring the swelling kinetics of liquid–water-loaded wood, the results should provide a record of the initially linear period of wood-water interaction and thus give an indication of how wood behaves during its service life (Mantanis et al. 1994). However, experimental data from monitoring the swelling kinetics of wood from its first contact with water have not yet been reported in the scientific literature for native or thermally modified wood species. The present study aims to (1) analyze the swelling kinetics of selected native and thermally modified wood species, and (2) determine and compare the relative rates of the first linear phase of wood swelling.

2 Material and methods

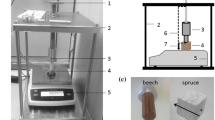

Softwood and hardwood species from Czech forest enterprise were analyzed in the present study. Norwegian spruce (Picea abies L. Karst., oven-dry density 520 kg/m3), Scots pine (Pinus sylvestris L., oven-dry density 570 kg/m3), European beech (Fagus sylvatica L., oven-dry density 690 kg/m3), and English oak (Quercus robur L., oven-dry density 670 kg/m3) sapwood specimens were each cut from a single quarter-sawn board. The specimens of dimensions 20 × 20 × 10 mm (R × T × L) were sorted into groups (thermally modified and reference), each group containing five specimens. The oven-dried specimens were thermally modified at 180, 200, and 220 °C for 2 h in a lab-scale chamber at atmospheric pressure and in a superheated-steam environment. The process intensity was determined by mass loss (ML), based on oven-dry mass before and after the thermal modification process. The oven-dried specimens were measured (accuracy of 0.01 mm), weighed (accuracy of 0.001 g) and immersed in water for 24 h at a temperature of 20 °C. The radial and tangential dimensions of the specimens were continuously measured by displacement transducers (WA/20 mm, HBM, Inc., accuracy of 0.02 mm) and data were transmitted by an acquisition system (QuantumX, MX440A, HBM, Inc.) and software (catman EASY, HBM, Inc.) to the computer every 5 s. Afterwards, the radial and tangential swelling and anti-swelling efficiency (ASE) were calculated. ASE represents the percentage difference between the swelling of the modified and reference wood. The radial and tangential swelling kinetics of the reference and thermally modified specimens was compared using the relative slopes of the linear part of the swelling curves calculated as a function of a tangent as follows: Δy/Δx. The beginning and end of the linear phase in the plots were determined at intervals of 10% and 50% of the maximum swelling after 24 h of immersion. The swelling kinetics is presented as relative swelling rate per time unit.

3 Results and discussion

With increasing modification temperature, a significantly greater loss of mass from the specimens was found (Table 1). Mass loss kinetics is strongly influenced by the nature of the wood species and their chemical composition. The greater sensitivity to thermal degradation of hardwoods can be explained by the hemicellulose composition and higher lignin content of softwoods compared to hardwoods (Čermák et al. 2021). Furthermore, the presence of natural resins, containing volatile substances, as well as other extractives, has an important effect on the mass-loss results and can consequently lead to a greater mass loss in softwoods (e.g., pine) than in hardwoods (e.g., beech) during thermal modification.

The radial and tangential swelling kinetics of the studied reference and thermally modified wood species during 24 h of water immersion is shown in Fig. 1. A relatively high initial linear-phase swelling rate (LSr) and quicker reaching of the fiber saturation point (FSP) were found for spruce, pine, and beech wood, while oak wood exhibited comparatively slow and gradual swelling, which was further reduced by thermal modification. The linear-phase swelling rates (LSr) give an overview of how the native and thermally modified wood behaved in the initial swelling period of wood–water interaction. The linear-phase swelling rate provides information about swelling per time unit, which depends on the size of the specimen (Nopens et al. 2019). To eliminate the influence of size, it is possible to relate the measured swelling kinetics of thermally modified wood to that of the reference to produce a linear-phase swelling ratio. When reference and thermally modified wood at 220 °C were compared, the linear-phase swelling ratio decreased from 10 to 2.9/3.4 (spruce), 10 to 1.7/1.9 (pine), 10 to 3.1/1.6 (beech), and 10 to 4.6/3.5 (oak) in the radial/tangential directions, respectively. These ratios may be used to predict the swelling of thermally modified wood species based on the knowledge of swelling kinetics of nontreated native wood.

The decrease in swelling kinetics reflects the reduced ability of wood to absorb water molecules (liquid water and water vapor) after thermal modification, due to degradation of the wood constituents—mainly hemicellulose and its OH- groups, which are mainly responsible for the wood’s hygroscopicity—and the presence of degradation products of the thermal modification, which may fill the wood micropores and therefore impede the penetration of water molecules. Even though hardwoods typically tend to swell more than softwoods, there may be wood species with very similar densities but very different swelling behavior. Therefore, the swelling kinetics depends not only on the density of wood species but also on other factors, such as chemical composition, wood anatomy, and microfibril angle (Mantanis et al. 1994). Swelling may also typically vary between earlywood (less dense) and latewood (denser) within the annual rings of softwoods. The lesser maximum swelling of oak and pine wood can also be attributed to more extractives (tannins and resins), which may be deposited in the capillary or cell-wall structure. Those extractives belonging to the capillary structure influence only the swelling–density relationship, while those belonging to the cell wall influence the swelling of the cell-wall structure as subsequently evidenced by the external dimensional change (Mantanis et al. 1994). Oak wood swelling can be greatly affected by the presence of tyloses that slow down the capillary uptake of water molecules during water immersion. Thermal modification significantly improves dimensional stability in both the radial and tangential directions, expressed as maximum swelling (Smax). As a consequence of swelling reduction by thermal modification, dimensional stability was considerably improved, ranging from 6 to 45% of ASE, depending on the species, anatomical direction, and the intensity of thermal modification.

4 Conclusion

The swelling kinetics of various thermally modified wood species was studied. According to the recorded data, swelling kinetics is strongly influenced by the density and anatomical direction of the wood. A higher swelling rate in the initial linear phase was found in spruce, pine, and beech wood; oak wood showed less increase and less linear behavior than the other studied species. Thermal modification significantly improved dimensional stability in both the radial and tangential directions. The swelling ratios may be used to predict the swelling kinetics of thermally modified wood species and their instant response to wood-water interaction. However, as much as the linear-phase swelling rate provides information about swelling per time unit, which is dependent on the size of the specimen, further studies should be undertaken to exclude the influence of specimen size, eventually to compare swelling kinetics when exposed to water vapor.

References

Allegretti O, Brunetti M, Cuccui I, Ferrari S, Nocetti M, Terziev N (2012) Thermo-vacuum modification of spruce (Picea abies Karst.) and fir (Abies alba Mill.) wood. BioResources 7(3):3656–3669

Altgen M, Willems W, Hosseinpourpia R, Rautkari L (2018) Hydroxyl accessibility and dimensional changes of Scots pine sapwood affected by alterations in the cell wall ultrastructure during heat-treatment. Polym Degrad Stab 152:244–252. https://doi.org/10.1016/j.polymdegradstab.2018.05.005

Čermák P, Hess D, Suchomelová P (2021) Mass loss kinetics of thermally modified wood species as a time-temperature function. Eur J Wood Prod. https://doi.org/10.1007/s00107-020-01634-6

Höhne P, Tauer K (2016) Studies on swelling of wood with water and ionic liquids. Wood Sci Technol 50:245–258. https://doi.org/10.1007/s00226-015-0779-8

Mantanis GI, Young RA, Rowell RM (1994) Swelling of wood. Part I Swelling in water. Wood Sci Technol 28(3):119–134. https://doi.org/10.1007/BF00192691

Nopens M, Riegler M, Hansmann C, Krause A (2019) Simultaneous change of wood mass and dimension caused by moisture dynamics. Sci Rep 9:10309. https://doi.org/10.1038/s41598-019-46381-8

Acknowledgements

This study was funded by the Czech Science Foundation (GAČR), project no. 19-25171Y “Multi-scale Hygro-thermo-mechanical Behavior of Modified Wood-based Materials”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Čermák, P., Suchomelová, P. & Hess, D. Swelling kinetics of thermally modified wood. Eur. J. Wood Prod. 79, 1337–1340 (2021). https://doi.org/10.1007/s00107-021-01690-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-021-01690-6