Abstract

This research studied the influence of formulations of wood-plastic composites on dynamic mechanical properties—storage modulus (E′), loss modulus (E′′) and mechanical loss factor (tan δ)—according to dynamic mechanical analysis spectra. The specimens were made with wood flour, high-density polyethylene (HDPE) and maleic anhydride polypropylene as a coupling agent. Generally, the presence of fillers and a coupling agent in polymer affect the relaxation processes and produce a more complex morphology, thereby influencing the mechanical and viscoelastic properties of the composites. In this work, the addition of a higher content of wood flour resulted in higher values of E′, indicating a better stiffness, but tan δ decreased. The bonding agent significantly improved E′, which can be attributed to an enhanced interface between the wood and the HDPE. Coupled products had better E′ retention at elevated temperatures than uncoupled samples. The addition of wood flour and a coupling agent increased the value of E′, but did not significantly change the range of relaxation transition.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Currently, wood-plastic composites (WPCs) are widely used for outdoor applications due to their excellent durability, which has been demonstrated in previous research studies (Hwang and Hsiung 2000; Verhey and Laks 2002; Clemons and Ibach 2004; Stark et al. 2004; Tajvidi et al. 2010; Benthien and Ohlmeyer 2013). However, their viscoelastic nature and the effect of temperature limit the application of WPCs. Understanding the viscoelastic properties and associated influential factors can improve material selection and optimize the balance between cost and performance in new and existing products.

Dynamic mechanical analysis (DMA) is an effective technique for studying viscoelastic properties of materials. The most common graphical presentation of a DMA experiment involves plotting the storage modulus (E′), the loss modulus (E′′) and the mechanical loss factor (tan δ) as functions of temperature. DMA plots provide comparisons of the elastic modulus at different temperatures and pictures of temperature regions where material properties are very stable or where rapid change may occur. The glass transition temperature (Tg) can be measured by the onset point of E′, or by the E′′ peak, or tan δ peak. The determined Tg may vary according to different above-mentioned indices.

DMA has been applied extensively in the study of viscoelastic properties of WPC materials. Most of the studies obtained similar trends with the addition of wood flours, particles, fibers and/or coupling agents in polymeric matrices (Son et al. 2003; Tajvidi et al. 2003, 2010). A general summary is provided in the following points:

-

1.

With the addition of flours/fibers, composites have higher values for E′ and E′′, but lower tan δ values than in pure polymer.

-

2.

When flours/fibers are present, the glass transition shifts toward higher temperatures, the intensity of which is greater at higher fiber contents.

-

3.

Coupled composites have a higher E′ than uncoupled composites, which can be attributed to the improved interface quality. However, the Tg is not significantly influenced by coupling agents.

Tajvidi et al. (2010) studied hemp-polypropylene (PP) composites with DMA and found that the composite material containing higher fiber content had higher E′ values; furthermore, the composite material with higher fiber content showed better E′ retention at given temperatures above Tg, indicating that composites with higher fiber content have better mechanical performances at elevated temperatures. Moreover, the formulation did not affect the onset of glass transition. In addition, Son et al. (2003) used DMA to analyze the effect of additives on the viscoelastic properties of various extruded wood/PP composites. The results showed that composites with a coupling agent resulted in higher values for E′, but lower values for tan δ.

Samal et al. (2009) mentioned that the mobility of macromolecular chains located in the fiber surface interface is reduced with an increase in the fiber/matrix interaction, resulting in a shift in the α-transition temperature, referring to the relaxation of rigid amorphous polymer chains in the crystalline phase, towards a higher temperature range. Mortezaei et al. (2011) also reported that the addition of particles to a polymeric matrix increases the glass-transition temperature of polymer.

Santos et al. (2009) suggested that the E′′ value increases in filled polymer, indicating that the fibers easily dissipate energy, which is probably related to the increased internal friction between the molecules of polymer and the filler particles. Furthermore, Chartoff et al. (1994) indicated that particulate fillers broaden the tan δ peak and that the peak position shifts to a higher temperature. However, the strong adhesion created by a coupling agent can cause the tan δ peak to narrow and the peak temperature to decrease.

Swaminathan and Shivakumar (2009) reported discrepancies in measuring E′ using DMA, particularly for materials with high moduli. Factors that may impact DMA testing include specimen preparation, geometry, aspect ratio and magnitude of acting load.

Some effects of composite material formulations were discussed in previous studies, mostly based on visual observations of DMA plots, but there was no clear association with the content of those composites. In this study, the DMA spectra were assessed in terms of the formulations, in order to describe the dynamic mechanical behaviors of materials under various temperatures, analyze and discuss the effects of the formulation on the viscoelastic properties and transition behaviors based on not only the DMA spectra, but also with the multiple regression method.

2 Materials and methods

Both the raw materials and processing methods of all WPC samples used in this study are discussed in Chang et al. (2010). The processing method of WPC specimen is extrusion. Mountain pine beetle (MPB) attacked Lodgepole pine (Pinus contorta var. latifolia Engelm) lumber was refined into flours, passing 60-mesh screen. The wood flours were dried to a moisture content of approximately 2 % before extrusion. Virgin high-density polyethylene (HDPE, Equistar Petrothene® LB0100-00 with a density of 950 kg/m3 and a melt index of 0.5 g 10 min−1) was selected as the plastic matrix. As well, additives, maleated anhydride polypropylene (MAPP, Honeywell A-C® 950P) and a lubricant (Honeywell OptiPak™ 100) were added to the formulations. Specimens were produced with the formulations shown in Table 1. The extruded products were machined as rectangular samples, measuring approximately 60 mm in length, 12 mm in width and 3 mm in thickness. The same HDPE and MPB attacked lodgepole pine as raw materials were processed as similar specimens to be used as references for further comparison. Before the tests were conducted, the products were conditioned for at least 4 weeks in a constant climate room at 20 ± 1 °C and 65 ± 5 % RH.

All DMA experiments were conducted on a TA Instrument Q 800 Dynamic Mechanical Analyzer, using a three-point bending clamp and a span of 50 mm. This experimental arrangement was used to study the viscoelastic response of specimens under free resonant oscillatory loads in temperature ramp tests.

The E′, E′′ and tan δ values were measured and calculated at a fixed frequency of 1 Hz. The temperature scan ranged from −50 to +120 °C at a heating rate of 1 °C/min. A controlled sinusoidal strain of 0.05 % was selected for this work. The specimens were equilibrated at −50 °C for 5 min before starting the ramp. Five specimens were tested for each formulation, the average of which was used to evaluate the properties.

To discuss the effect of the formulations on the properties of the products, multiple comparison and multiple regression analyses for various properties were conducted. Comparisons of the different formulations were examined with an analysis of variance (ANOVA, α = 0.05) to test for significant effects; and, the Tukey test (confidence level of 95 %) was conducted to test for significant differences between groups.

Three main explanatory variables were examined: wood content (WC), HDPE content (PC) and coupling agent (CA). CA was deemed a qualitative variable, since there were only two options in this study—with or without the coupling agent. Interactions between the variables were also investigated and were removed if no significant effect existed.

Since the true regression function is unknown, this study adopted the multiple regression method, which is approximated by a second-order regression model. The second-order function with three variables was set up as:

where Y is the property of interest; x 1 is the WC; x 2 is the PC; x 3 is CA, where 1 is with the coupling agent or 0 without the coupling agent; β 0 is the interception; β 1, β 2, and β 3 are the coefficients for WC, PC and CA, respectively; β 12, β 13 and β 23 are the interaction effect coefficients for the interaction between pairs of variables; and ε i is the error.

3 Results and discussion

The representative results of the DMA of WPCs are shown in Figs. 1 and 2. Only one phase transition was observed within the scanned temperature interval for different formulations. According to these figures, the E′ values decreased with the elevating temperature, while the value of E′′ increased up to a certain level and then decreased. The tan δ value increased with elevating temperature, indicating an increase in the viscoelastic response of the polymer at high temperatures.

The WPC formulations, specifically wood flour (WF) content and the presence of a coupling agent (maleic anhydride polypropylene, MAPP), influenced the dynamic mechanical properties. The anhydride groups of MAPP reacted chemically with the hydroxyl groups of the wood flours to form ester bonds, and the tail of the MAPP entangled with HDPE, improving the interfacial adhesion between hydrophilic wood and hydrophobic HDPE (Lu et al. 2000; Son et al. 2003; Chowdhury and Wolcott 2007).

Figure 1 is a comparison of E′ as a function of temperature for the various WPC formulations and neat HDPE, which showed a considerably lower E′ in all temperature domains. The value of E′ of the WPCs increased with higher WF content (WF content of F3 > F2 > F1), indicating enhanced stiffness (E′ of F3 > F2 > F1); however, the formulation F4’s E′ was significantly lower than the other formulations, indicating that the presence of MAPP improved the stiffness and enhanced the interaction between the HDPE and the wood flours.

This result can be attributed to the reinforcing effect imparted by the combination of the wood component and MAPP entanglement with HDPE. This allows for a greater degree of stress transfer from the HDPE to the wood. In this case, no well-developed rubbery plateau appeared above the onset point of the relaxation transition in the plot of E′ versus temperature. The decline of E′ values associated with temperature showed different degrees of drop for different formulations.

One peak can be observed within the scanned temperature range in Fig. 1. The temperature at the peak value of E′′ is commonly regarded as the α-transition and is associated with the molecular motions of rigid amorphous polymer chains in the crystalline phase (Samal et al. 2009). This peak shifts towards a higher temperature with the coupling agent and additional WF content. In addition, for a highly crystalline polymer, the α-transition is the major relaxation below the melting point (Tajvidi et al. 2003), whereas the glass transition in a highly crystalline polymer is difficult to identify. Sirotkin and Brooks (2001) mentioned that β-relaxation, due to the relaxation of unrestricted amorphous part, is usually absent for HDPE, and only observed in branched polyethylene. However, the γ-relaxation can be detected and accepted as glass transition in linear polyethylene (Sirotkin and Brooks 2001; Balasuriya et al. 2003).

Since the general phase transition is related to the relaxation of amorphous HDPE chains, this shift indicates that the mobility of HDPE chains decreased with the addition of MAPP and higher WF content. This may be attributed to the restricted motions of the amorphous HDPE molecule chains at the WF/MAPP/HDPE interface, which is caused by the covalent interaction between the MAPP and the wood and the entanglement between the tail of the MAPP and the HDPE. The similar shifting trend was also found in Balasuriya et al. (2003) for wood-MAPE (maleic anhydride modified polyethylene)-HDPE compound, indicating the interaction between wood and coupling agent, in both crystalline and amorphous phase.

In a composite system, tan δ is affected by the incorporation of fibers, due to the elastic nature of fibers, the shear stress concentrations at the fiber ends, and the additional viscoelastic energy dissipation in the matrix material (Samal et al. 2009). According to Fig. 2, there were no apparent peaks of tan δ for each formulation, indicating that the β transition is not the major relaxation process in neat HDPE or its composites, as previously reported by Tajvidi et al. (2003).

Tan δ changed slowly at temperatures below approximately 15 °C; however, it increased rapidly above 15 °C. Moreover, the curves shown in Fig. 2 started to deviate into two groups: one containing formulations F1–F3 and the other consisting of formulation F4 and neat HDPE, which represent coupled and uncoupled systems, respectively.

Higher tan δ values indicate a greater degree of molecular mobility and correspond to higher impact strength, toughness and energy dissipation (Sepe 1998). The difference became even more pronounced at higher temperatures. Moreover, based on the lower value of tan δ, better interface adhesion was observed in the formulations that contained MAPP.

HDPE is a type of semi-crystalline polymer with high degree of crystallinity. Nevertheless, the movement of the amorphous part, which is associated with the movement of small groups and chains of molecules in the polymer structure, all of which are initially frozen, still causes a reduction of stiffness. The onset of a declining E′ implied that the amorphous parts started to move with elevated temperature; whereas a rise of E′′ indicated an increase in the structural mobility of the polymer. These circumstances may be explained by Table 2, where the temperature at which the peak value of E′′ appeared was close to the temperature at which the end point of the relaxation for E′ occurred.

The DMA spectrum of MPB lodgepole pine solid wood was also investigated, as shown in Fig. 3. No major transition was detected with E′; however, clear peak values of E′′ and tan δ appeared at around 50 °C. This may explain why the peak of E′′ for the wood/HDPE composites was located at a higher temperature (approximately 50 °C) than that of neat HDPE (42 °C), and also indicate the effect of the formulation on final properties of composite, when adding fiber reinforcement and the coupling agent to the polymeric matrix.

Due to improved bonding between wood flour and HDPE with the addition of the coupling agent (Lu et al. 2000; Selke and Wichman 2004; Chowdhury and Wolcott 2007), indicating better efficiency of stress transfer from matrix to fiber, peak values of E′′ of coupled WPC products appeared at approximately the same temperature as that of wood; whereas this effect was not so significant for the uncoupled products. These results suggest that the behavior was that of a composite rather than of two individual components. This point can be confirmed with the result of formulation F4: without a coupling agent, the temperature at which the peak of E′′ appeared was not significantly different from that of neat HDPE.

From the viewpoint of mechanical properties and product applications, the change of E′ with temperature is very important, because E′ directly refers to the stiffness of the material. Chen and Gardner (2008) also suggest that Tg should be determined from E′ for the same reason.

E′ should be very close to the complex modulus (E*), which is equal to the square root of [(E′)2 + (E′′)2], when material is still in its solid state and when tan δ < 0.1 (Sepe 1998). The modulus of elasticity (MOE) was obtained from the flexural test conducted at the ambient temperature of approximately 25 °C; the results of which are summarized in Table 3, as well as those of DMA E* and E′, at various temperatures. Within the ambient temperature range of 20–40 °C, DMA E* and E′ were almost the same, since tan δ was still below 0.1, except for formulation F4, where tan δ was 0.1 at approximately 28 °C. However, the flexural MOE values obtained at around 25 °C were lower than the dynamic testing results obtained by DMA at the same temperatures, falling between 30 and 35 °C for formulations F1 and F3, 35 and 40 °C for formulation F2, and 25 and 30 °C for formulation F4.

These results may imply that the DMA method may overestimate the modulus compared to the conventional method. This difference should be taken into consideration when applying DMA modulus values, as the difference between dynamic loading and static loading may also contribute to this discrepancy. Furthermore, the temperature homogeneity may also case the discrepancy. Since samples used in DMA tests were relatively small, comparing with samples for conventional static flexural tests, the temperature difference between inner and outer parts may be relatively small, resulting in actual responses of materials under the testing temperature, whereas temperature gradient may be observed in samples of larger size.

The specimen was isothermally controlled in a furnace for the DMA test; whereas the specimen in the traditional method was conditioned and tested in an ambient environment. The results of the conventional flexural MOE may not reflect the real performance of the material at specific temperatures.

The effect of the formulation on the relaxation transition of WPCs can be discussed according to several transition points, including temperatures at the onset, middle and end points of the transition zone of the E′ curve and the temperature at the peak of the E′′ curve. According to the results, the related relaxation transition was affected by the different formulations, but not considerably, as indicated in Table 2.

The predictions of pointers associated with formulations were studied with the multiple regression method, and the results are presented in Table 4. As to the midpoint of the transition, there were no significant differences among the formulations; whereas the peak value of E′′ was highly associated with the individual formulations. Moreover, the end point of the E′ transition was not very well accounted for by the formulations.

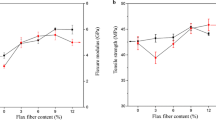

The E′ as a function of wood content at various temperatures was plotted as shown in Fig. 4. In order to eliminate the effect of the coupling agent, the uncoupled formulation (F4) was not considered in this comparison. Mahieux and Reifsnider (2002) suggested that filler could be expected to act as crystallites, which impede molecular motion and broaden the distribution of secondary bond strengths. Therefore, the mechanical properties can be enhanced through the addition of fillers.

According to the results, a higher wood content resulted in a higher E′ value at all temperatures; however, this effect decreased with increasing temperatures. Furthermore, a higher wood content also resulted in a higher E′′ value (Fig. 5), and this consequence was considerable at the temperature around which the α-transition took place.

In this study, the E′ versus temperature spectra did not appear as a clear plateau after transition, which caused difficulty in determining the end point. However, the end point was close to the peak of E′′. Information about the transition of the product could be inferred with the prediction of the onset point and the peak of E′′ with the formulation.

Assuming the transition of E′ was considered as a straight line from onset to the end, the influence of the formulation can be observed in Table 5. The greater the slope in absolute values implies a more abrupt transition. Formulation F3 resulted in the most abrupt transition, yet retained the highest E′ after transition. Furthermore, compared to neat HDPE, the addition of MAPP and higher WF content simply increased the modulus value, but did not significantly change the range of transition.

4 Conclusion

To understand the performance of WPC products at various temperatures, dynamic mechanical analysis was applied to obtain the spectra of the storage modulus (E′), loss modulus (E′′) and mechanical loss factor (tan δ) within a temperature range from −50 to 120 °C.

A higher content of wood flour resulted in a higher value of E′, indicating better stiffness, but resulted in a lower tan δ. The inclusion of a coupling agent (MAPP) also significantly increased the E′ value, which can be attributed to the enhancement of the interface property between wood and HDPE, coupled by MAPP.

The addition of wood and MAPP reduced the mobility of the macromolecular chains at the fiber surface interface, the fiber/matrix interaction was increased. This resulted in a shift of the α-transition temperature towards a higher temperature range. This may also imply that the WPC is less susceptible to temperature effects, comparing with pure HDPE. Moreover, the coupled products retained their moduli more than uncoupled products.

A higher wood content resulted in a higher E′ value at all temperatures, although it decreased with elevated temperatures. A higher wood content also resulted in a higher E′′ value; however, this consequence was more considerable at the temperature around which the α-transition took place. Also, the addition of MAPP and a higher content of wood flour simply increased the value of modulus, but did not significantly change the range of transition.

References

Balasuriya PW, Ye L, Mai YW (2003) Morphology and mechanical properties of reconstituted wood board waste-polyethylene composites. Compos Interface 10(2–3):319–341

Benthien JT, Ohlmeyer M (2013) Thickness swelling and water absorption of WPC after immersion in cold and boiling water. Eur J Wood Prod 71(4):437–442

Chang F-C, Lam F, Englund KR (2010) Feasibility of using mountain pine beetle attacked wood to produce wood-plastic composites. Wood Fiber Sci 42(3):388–397

Chartoff RP, Weissman PT, Sircar A (1994) The application of dynamic mechanical methods to Tg determination in polymers: an overview. In: Seyler RJ (ed) Assignment of the Glass Transition. American Society for Testing and Materials, Philadelphia, pp 88–107

Chen J, Gardner DJ (2008) Dynamic mechanical properties of extruded nylon-wood composites. Polym Compos 29(4):372–379

Chowdhury MA, Wolcott MP (2007) Compatibilizer selection to improve mechanical and moisture properties of extruded wood-HDPE composites. For Prod J 57(9):46–53

Clemons CM, Ibach RE (2004) Effects of processing method and moisture history on laboratory fungal resistance of wood-HDPE composites. For Prod J 54(4):50–57

Hwang GS, Hsiung JC (2000) Durability of plastics/wood composite boards manufactured with waste wood particles. Taiwan J For Sci 15(2):201–208

Lu JZ, Wu Q, McNabb HS Jr (2000) Chemical coupling in wood fiber and polymer composites: a review of coupling agent and treatments. Wood Fiber Sci 32(1):88–104

Mahieux CA, Reifsnider KL (2002) Property modeling across transition temperature in polymers: application to filled and unfilled polybutadiene. J Elastom Plast 34:79–89

Mortezaei M, Famili MHN, Kokabi (2011) The role of interfacial interactions on the glass-transition and viscoelastic properties of silica/polystyrene nanocomposite. Compos Sci Technol 71(8):1039–1045

Samal SK, Mohanty S, Nayak SK (2009) Polypropylene–bamboo/glass fiber hybrid composites: fabrication and analysis of mechanical, morphological, thermal, and dynamic mechanical behavior. J Reinf Plast Comp 28(22):2729–2747

Santos EF, Mauler RS, Nachtigall SMB (2009) Effectiveness of maleated- and silanized-PP for coir fiber-filled composites. J Reinf Plast Comp 28(17):2119–2129

Selke SE, Wichman I (2004) Wood fiber/polyolefin composites. Compos Part A Appl S 35(3):321–326

Sepe MP (1998) Dynamic mechanical analysis for plastic engineering. Plastic Design Library, Norwich, NY

Sirotkin RO, Brooks NW (2001) The dynamic mechanical relaxation behavior of polyethylene copolymers cast from solution. Polymer 42:9801–9808

Son J, Gardner DJ, O’Neill S, Metaxas C (2003) Understanding the viscoelastic properties of extruded polypropylene wood plastic composites. J Appl Polym Sci 89:1638–1644

Stark NM, Matuana LM, Clemons CM (2004) Effect of processing method on surface and weathering characteristics of wood-flour/HDPE composites. J Appl Polym Sci 93:1021–1030

Swaminathan G, Shivakumar K (2009) A re-examination of DMA testing of polymer matrix composites. J Reinf Plast Comp 28(8):979–994

Tajvidi M, Falk RH, Hermanson, JC, Felton C (2003) Influence of natural fibers on the phase transitions in high-density polyethylene composites using dynamic mechanical analysis. In: Seventh International Conference on Woodfiber-Plastic Composites. Forest Product Society, Madison, WI, 19–20 May 2007, pp 187–195

Tajvidi M, Motie N, Rassam G, Falk RH, Felton C (2010) Mechanical performance of hemp fiber polypropylene composites at different operating temperatures. J Reinf Plast Comp 29(5):664–674

Verhey SA, Laks PE (2002) Wood particle size affects the decay resistance of woodfiber/thermoplastic composites. For Prod J 52(11/12):78–81

Acknowledgments

The authors acknowledge Forestry Innovation Investment Ltd., British Columbia, Canada, for providing financial support to this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, FC., Kadla, J.F. & Lam, F. The effects of wood flour content and coupling agent on the dynamic mechanical and relaxation properties of wood-plastic composites. Eur. J. Wood Prod. 74, 23–30 (2016). https://doi.org/10.1007/s00107-015-0962-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-015-0962-5