Abstract

Durability of non-durable sesenduk and jelutong wood treated using low molecular weight phenol formaldehyde (LmwPF) resin against white rot fungus was investigated. Phenolic resin treatment improved the resistance of treated wood against Pycnoporus sanguineus as much as 96.65–99.39 % compared to untreated wood, where jelutong and impregnated wood showed better durability compared to sesenduk and compregnated wood, respectively. Incorporation of 30 % urea in LmwPF further improved the resistance of treated wood against white rot fungus.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Most recently, lesser known wood species started to catch manufacturer’s attention due to their abundance in secondary forest. These underutilized timbers such as sesenduk (Endospermum diadenum) and jelutong (Dyera costulata) have potential to replace high density wood that now risks depletion. Both sesenduk and jelutong are light hardwoods with an air dry density ranging from 305 to 655 kg/m3 and 420–500 kg/m3, respectively. Both sesenduk and jelutong are classified as non-durable or class VI (service life less than 2 years) under exposed conditions. According to Jackson (1965), the average service life of sesenduk and jelutong wood are 1 year and 1.4 years, respectively. Therefore, sesenduk and jelutong are highly susceptible to biological degradation such as termites and fungi. On that account, treatment is needed to improve durability of the materials. Phenol formaldehyde (PF) resin has long been known as an effective way to improve the strength and dimensional stability of wood. Impregnation and compregnation using phenolic resin has been proven to enhance the properties and durability of the wood (Zaidon 2009). To the authors’ knowledge, information about durability enhancement of sesenduk and jelutong wood by phenolic resin is scarce. Therefore, this study evaluates the effectiveness of low molecular weight phenol formaldehyde (LmwPF) resin in protecting sesenduk and jelutong wood against white rot fungi.

2 Materials and methods

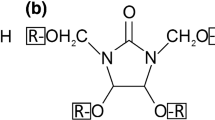

Sesenduk and jelutong wood were obtained from Ayer Hitam Forest Reserve Puchong, Selangor. Air-dried sesenduk and jelutong (approximately 15 % moisture content) were trimmed into strips with dimensions of 200 mm long × 50 mm width × 5 mm thick. Low molecular weight phenol formaldehyde (LmwPF, mw 600) resin which was specially synthesized at Malayan Adhesives and Chemical (MAC) Sdn. Bhd., Shah Alam was used as treating solution. Urea which was obtained from MAC was incorporated into the resin. Two resin solutions were prepared for this study which is a solution with pure LmwPF (30 % w/v) and a solution of 30 % LmwPF with 30 % urea (30 % based on solid PF).

A total of 40 samples were assigned to impregnation and compregnation treatments, five samples for each treatment combination. Five samples of untreated sesenduk and jelutong wood, respectively, served as control. Impregnation process was carried out by impregnating the wood strips using LmwPF resin. Empty cell process (Lowry process) was used to treat the wood. A 690 kPa of external pressure was applied to the vacuum-pressure apparatus for 1 hour. Next, treated samples were pre-cured in an oven at 65 ± 2 °C for 6 h. For compregnation, the samples were compressed under hot press at 150 °C for 30 min to achieve 80 % compression ratio (CR) after the impregnation process. A set of 4 mm stopper bar was used to control the final thickness. Both impreg and compreg samples were then conditioned in a conditioning room at 25 ± 2 °C and 65 ± 2 % RH until constant weight was achieved. Decay fungus, Pycnoporus sanguineus was used in this test. Testing was carried out according to ASTM D1413-07e1: Standard Test Method for Wood Preservatives by Laboratory Soil-Block Cultures. Test block were weighed prior to the decay resistance test. A bottle containing the test block was incubated in an incubation room for 12 weeks. After the incubation period, the test block was removed from the culture bottle and the fungus was carefully removed. The blocks were weighed and left on trays in a conditioning room until they reached equilibrium weight. After that, the block was weighed again and the weight loss of the test blocks was calculated using the equation below:

where Wa = conditioned weight of the test block before exposure to fungus (g) and Wb = conditioned weight of the test block after exposure to fungus (g).

The data were analysed using statistical package for the social sciences procedure for the analysis of variance (ANOVA) at 95 % confident level (P ≤ 0.05). Least significant difference test was then used to further determine the significant level of average values for each treatment.

3 Results and discussion

Table 1 shows the ANOVA result of the effects of species, treatment method and addition of urea on the weight loss of both sesenduk and jelutong wood against white rot fungi. No significant interaction was found between all three variables. Density, weight percent gain (WPG) and mean weight loss of treated and untreated wood are shown in Table 2. According to Table 2, weight loss for both untreated sesenduk and jelutong wood were 31.68 and 41.94 %, respectively. Based on the result, weight loss of both sesenduk and jelutong wood are more than 30 % under laboratory conditions and hence they are classified as “perishable”, which means non-durable. Treated samples showed significantly lower weight loss than untreated samples (Table 2). Phenolic resin treatment had successfully improved the resistance of sesenduk and jelutong wood by 96.65–99.39 %. Fungus growth was inhibited due to poisonous nature of phenol (Okino et al. 2005). Generally, treated jelutong wood showed lower weight loss compared to treated sesenduk. This phenomenon could be related to the WPG of the treated wood. Jelutong was reported to have an average of 3–10 vessels per mm2 while sesenduk was claimed to have only 1–3 vessels per mm2 (Richter and Dallwitz 2000). Difference in number of vessels might limit the penetration of phenolic resin into the lumen and cell wall of sesenduk as vessel and parenchyma are the major elements that can provide effective fluid flow during impregnation process. On the other hand, density of wood species is also one of the factors that decide the amount of chemicals that can be introduced into the wood. Positive correlation was found between density and WPG, suggesting that lower density wood gains higher amounts of chemical and vice versa (Islam et al. 2012). Jelutong wood, with lower density, attained better resin retention and hence leading to better resistance against Pycnoporus sanguineus compared to sesenduk wood. Impregnated wood showed better resistance against P. sanguineus compared to compregnated wood. From Table 2, one can see that compregnated wood gained lower resin compared to that of the impregnated wood. Resin might squeeze out during the hot pressing process due to the partially insufficient curing period after impregnation. As for that, lower WPG might lead to lower resistance against P. sanguineus. Addition of 30 % urea in LmwPF resin improved the resistance of wood against P. sanguineus insignificantly. Veverka et al. (2007) concluded that urea is, or produced toxic agent (NH3) that inhibited the growth of a wide variety of fungi. They concluded that, by the stimulation of antagonists and direct toxic effect, populations of a pathogen can be decreased.

4 Conclusion

Overall, treatment of sesenduk and jelutong using LmwPF resin significantly enhanced the decay resistance of the wood. Jelutong wood was found to have better resistance against white rot fungi compared to sesenduk wood. Besides that, impregnated wood was more resistant to P. sanguineus compared to compregnated wood. Lower weight loss was observed for both sesenduk and jelutong wood when urea was incorporated in LmwPF resin. In conclusion, the techniques (impregnation and compregnation using LmwPF resin as well as application of urea) used in this study were able to enhance the biological properties of sesenduk or jelutong wood.

References

Islam MS, Hamdan S, Rusop M, Rahman MR, Ahmed AS, Mohd Idrus MAM (2012) Dimensional stability and water repellent efficiency measurement of chemically modified tropical light hardwood. Bioresources 7(1):1221–1231

Jackson WF (1965) The durability of Malayan timbers. In: Malaysian Forest Service Trade Leaflet No.28. The Malaysian Timber Industry Board and Forest Research Institute Malaysia, Kuala Lumpur

Okino EYA, Souza MR, Santana MAE, Da Alves MV, De Souza ME, Texeira DE (2005) Physicomechanical properties and decay resistance of Cupressus ssp. cement-bonded particleboards. J Cem Concr Compos 27:333–338. doi:10.1016/j.cemconcomp.2004.02.046

Richter HG, Dallwitz MJ (2000) Commercial timbers: descriptions, illustrations, identification, and information retrieval. In English, French, German, Portuguese, and Spanish Version, 25 June 2009. http://delta-intkey.com

Veverka K, Stolcova J, Ruzek P (2007) Sensitivity of fungi to urea, ammonium nitrate and their equimolar solution UAN. Plant Prot Sci 43(4):157–164

Zaidon A (2009) Improvement of raw materials from underutilized timber species through chemical and densification treatments for value added laminated products. Report No. 06-01-04-SF0656. Ministry of Science and Technology, Putrajaya

Acknowledgments

This study was self-funded. The authors would like to express gratitude to Faculty of Forestry, Universiti Putra Malaysia for providing the required equipment to carry out the experiment.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, S.H., Ashaari, Z. Durability of phenolic-resin-treated sesenduk (Endospermum diadenum) and jelutong (Dyera costulata) wood against white rot fungus. Eur. J. Wood Prod. 73, 553–555 (2015). https://doi.org/10.1007/s00107-015-0912-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-015-0912-2