Abstract

The behaviour of cork under three point bending stress in the radial direction was evaluated in relation to porosity (range 2.0–15.4%) and density (range 0.160–0.220 g cm−3). The study was made using water-boiled cork planks of two commercial quality classes (good and poor quality) collected at an industrial mill. Cork samples were cut with the largest dimension in two directions, axial and tangential, and with the load zone in the inner part and the outer part of the plank.

The stress-strain curves obtained in bending were similar for the different test specimens and similar to those observed for tensile tests in cork but the mechanical resistance of cork in bending was higher than in tension and lower than in compression. The direction of the internal stress in samples submitted to bending was a highly significant factor of variation. The curves showed an initial linear elastic region with a mean Young’s modulus of 14 MPa for the tangential direction and 21 MPa for the axial direction, followed by a region of a gradual cork yielding up to a peak load, and failure at an average stress of 1.2 MPa and a strain of 14%. There was significant difference in the bending properties of cork samples obtained from cork planks of different quality classes.

Density and porosity were not individually well correlated with the mechanical parameters. It was however possible to model Young’s modulus by combining porosity and density.

Zusammenfassung

Untersucht wurde das Verhalten von Kork in radialer Richtung im Drei-Punkt-Biege-Versuch in Abhängigkeit der Porosität (im Bereich von 2,0–15,4 %) und der Dichte (im Bereich von 0,160–0,220 g cm−3). Untersucht wurden in Wasser gekochte Korkplatten zweier Handelsklassen (gute und schlechte Qualität), die in einem Betrieb entnommen wurden. Die Proben wurden mit ihrer größten Abmessung in axialer bzw. tangentialer Richtung ausgeformt und mit der innen liegenden beziehungsweise außen liegenden Seite im Biege-Zugbereich geprüft.

Die Spannungs-Dehnungskurven der verschiedenen Proben verliefen ähnlich, und sie entsprachen denjenigen der Zugversuche. Die Biegefestigkeit war jedoch höher als die Zugfestigkeit und niedriger als die Druckfestigkeit. Einen großen Einfluss hatte dabei die Orientierung der Proben. Die Proben wiesen einen zunächst linear elastischen Bereich auf, mit einem mittleren E-Modul von 14 MPa bei den in tangentialer Richtung ausgeformten Proben und von 21 MPa für die axialen Proben, mit einem anschließenden nicht-linearen Bereich bis zu einer Bruchfestigkeit von im Mittel 1,2 MPa und einer Bruchdehnung von 14 %. Die Biegeeigenschaften der Korkproben der beiden Handelsklassen waren signifikant verschieden.

Die Parameter Dichte und Porosität waren jeder für sich mit den mechanischen Eigenschaften nicht hoch korreliert. Es war jedoch möglich, den E-Modul als Funktion von Dichte und Porosität zu modellieren.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cork has gained a recent interest because it is a natural material that combines a rather unusual set of properties, including appealing aesthetics, with a contribution to the ecological sustainability of fragile regions. Cork is the outer bark of the cork oak tree (Quercus suber L.) which is stripped at periodic intervals usually of 9 years. It is a low density cellular material with a large compressibility and dimensional recovery, insulation properties, very low permeability to liquids, and chemical stability and durability (Pereira 2007).

Cork is a honeycomb formed by small thin-walled closed cells (4–20×107 cells/cm3), on average hexagonal prisms, that are orderly stacked base by base forming rows aligned in the tree radial direction and without intercellular voids (Pereira et al. 1987). The cell walls are flexible, allowing undulation and corrugation. Chemically, cork is predominantly made up of suberin in association with lignin and, to a lesser extent, cellulose and hemicelluloses (Pereira 1988; Pereira et al. 1987).

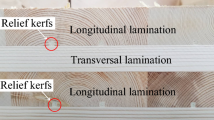

Natural variability is given by the presence of pores resulting from lenticular channels that cross the cork planks in a radial direction (Pereira et al. 1996), the occasional occurrence of thick lignified and nonsuberized cells and the occurrence of annual rings with outward decreasing width in the radial direction.

The mechanical properties of cork were mostly studied in compression, due to its relevance for the performance of cork stoppers in wine bottling (Anjos et al. 2008; Rosa and Fortes 1998; Gibson et al. 1981; Gibson and Ashby 1997) and also in chemical composition (Anjos and Marques 2009; Pereira 2007; Riu et al. 2006). The tensile behaviour of cork is very much less documented and only recently analysed for tangential and axial stresses (Anjos et al. 2010a, 2010b). Overall it was found that the mechanical behaviour of cork is related to its structural features. For some applications, cork has better mechanical behaviour than flexible polymer foams and comparable to some rigid polymer foams (Castro et al. 2010; Matos and Simplício 2006).

The bending properties of cork have not been studied yet, although bending is important for some applications of cork, i.e., for shoe soles, in specialized cork furniture, as well as in the living tree where the cork layer is subjected to bending growth stresses. In this paper, the results of three-point bending of samples obtained from cork planks with different quality are reported and the influence of density and porosity is analyzed. The samples and the bending tests were selected in order to cover the anisotropy of response i.e., the tensile stress in bending was applied in both tangential and axial directions, as well as the effect of the radial location of load application, i.e., in the outer and inner part of the plank.

2 Material and methods

The samples used in this study were cut from four cork planks of good quality (class 1) and four cork planks of poor quality (class 4) collected at an industrial mill after the usual industrial pre-processing consisting of 1h water boiling and air drying.

The test samples were cut from each cork plank with the dimensions of 150 mm×20 mm×20 mm with the largest dimension in the tree tangential (T samples) or axial (A samples) directions, as shown in Fig. 1a. The bending tests were carried out by applying the load in the radial direction, perpendicular to the tangential surface of the samples, and on each of the two surfaces corresponding to different radial positions in the plank: in the inner part (the belly side of the plank located to the inner part of the stem) (I), and in the outer part (the back side located externally) (O), as shown in Fig. 1b.

Therefore, four different sets of samples were tested:

TO—sample with the largest dimension in the tangential direction; load applied in the radial direction, on the outer tangential surface of the sample; the direction of tensile/compression is tangential;

TI—sample with the largest dimension in the tangential direction; load applied in the radial direction, on the inner tangential surface of the sample; the direction of tensile/compression is tangential;

AO—sample with the largest dimension in the axial direction; load applied in the radial direction, on the outer tangential surface of the sample; the direction of tensile/compression is axial;

AI—sample with the largest dimension in the axial direction; load applied in the radial direction, on the outer tangential surface of the sample; the direction of tensile/compression is axial.

For each type of test 12 replications were made, for both quantity classes, with a total of 96 samples analysed. The specimens were equilibrated in the laboratorial environment to 7% mean moisture content, weighed and the density was calculated.

For this experiment, a three-point bending configuration was applied with two fixed supports and a transverse mid-point deflection caused by load application. The bending test used a crosshead speed of 2 mm min−1, corresponding to a strain rate of 1.4×10−3 s−1 applied in the radial direction of the samples. Young’s modulus was calculated from the average slope of the stress-strain curve between the loads of 10 N and 100 N, corresponding to strains between approximately 1% and 2.5%, according to previously developed methodology for compression and tension of cork samples (Anjos et al. 2008, 2010a, 2010b).

The porosity of the samples was determined prior to the bending tests by image analysis on the two tangential surfaces perpendicular to the direction of the bending stress. The image was acquired using a colour video camera (3CCD) and analyzed with the Pericolor-Matra software using image analysis and mathematical morphology methodological tools (Soile 1995). The porosity was reported as a coefficient of porosity, in %, representing the area of pores divided by the total area, and in number of pores per unit area (number/cm2) and calculated as the mean of the two faces.

The results were statistically analysed by analysis of variance using as fixed variation effects the quality class, the direction of stress and the radial position in the plank, and their interaction, and with principal component analysis.

3 Results and discussion

The stress-strain curves for bending up to fracture are presented in Fig. 2 for the two cork plank quality grades and for tension applied in the axial and tangential direction of the cork specimens (A and T), and surfaces of load application (I and O). The corresponding resistance parameters are summarized in Table 1.

Stress-strain curves for bending of cork specimens obtained from cork planks of different commercial quality (class 1 and class 4, respectively good and poor quality) with tension/compression. Symbols see Fig. 1

Spannungs-Dehnungs-Kurven der unterschiedlich orientierten Proben aus Korkplatten der Handelsklassen 1 und 4 (gute und schlechte Qualität). Bezeichnungen siehe Abb. 1

The curves show an initial linear elastic region until approximately a strain of 2% and a stress of 0.3 MPa, corresponding to a mean Young’s modulus of 14 MPa for the tangential direction and 21 MPa for the axial direction. This is followed by a region of decreasing slope corresponding to a gradual cork yielding up to a peak load, after which a near complete failure occurred in the zone under the neutral line in tension at an average stress of 1.2 MPa and a strain of 14%.

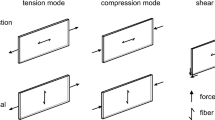

The stress-strain curves under bending have a similar development to those reported for the tensile behaviour of cork (Anjos et al. 2010a, 2010b). However, the modulus of elasticity was intermediate between that obtained under tensile and compression stress: 19–24 MPa and 23–37 MPa in tangential and axial tensile stress, respectively (Anjos et al. 2010a, 2010b; Rosa and Fortes 1991) and 12 MPa and 16 MPa in tangential and axial compression (Anjos et al. 2008; Gibson and Ashby 1997). This is the consequence of the presence of both stress types within the sample when subjected to bending. The bending behaviour of cork seems to be more influenced by the tensile region, where the fracture occurred in all cases, than by the compression region.

The elastic differences between compression and tension of cork can be explained by the undulated structure of cell walls (Pereira et al. 1987; Gibson et al. 1981). The stiffness of undulated plates, the cork cell walls can be compared with, increases when the amplitude of the undulations decreases. In compression, the walls bend and increase the amplitude, i.e., the corrugation of the cell walls increases, while in tension the cells are stretched and decrease the cell wall undulations (Anjos et al. 2008; Gonzalez-Adrados and Pereira 1996).

The bending behaviour of cork was similar for both quality classes, although specimens from the poor quality plank (class 4) showed in general somewhat lower stress values for the same strains, and smaller values for the stress and strain at fracture (Table 1). However the most important difference was given by the direction of the internal tension and compression stresses. Cork showed lower resistance when stresses developed in the tangential direction (TO and TI) in relation to those in the axial direction (AO and AI). This is in accordance with the results obtained for tangential and axial tensile tests of cork (Anjos et al. 2010a, 2010b) and are mainly related with the geometry of the pores that are on average elongated along the axial direction (Pereira et al. 1996).

The fracture occurred across the section of the cork specimens, approximately perpendicular to the direction of the load and of the internal stresses. Fracture started always at the pores and propagated along the cork mass until running along the total sample width. In some cases, the fracture line deviated when encountering pores with sclerenchymatic cells or lignified inclusions in the cork tissue.

A somewhat higher resistance was found in the samples from poor quality cork when the tensile region developed in the inner part of the sample, e.g., fracture strain of 15% in comparison with 12% when the tensile region was in the outer part of the sample (Table 1).

3.1 Influence of density and porosity

Figure 3 shows the variation with density of the Young’s modulus (E), fracture stress (σ) and fracture strain (ε) for the bending tests of all the cork samples. There was no overall pattern of variation although an increase of the bending properties was observed until about a mid density point after which a decrease occurred associated with a large variability especially of fracture stress and strain. This can be assigned to the more frequent presence of lignified inclusions and sclerified cells in cork samples with higher densities which are also associated with poor quality of cork planks. When considering only the good quality samples, significant coefficients of correlation between Young’s modulus and density were obtained (TO: R 2=0.878; AO: R 2=0.926; TI: R 2=0.808; AI: R 2=0.720).

Previously it has been shown that the density influences the compressive and tensile properties of cork although the variability was also reported to be large especially for the higher values of densities and associated with the presence of pores and defects (Anjos et al. 2008, 2010a, 2010b; Gibson and Ashby 1997).

The variation of the Young’s modulus, fracture stress and strain with the porosity measured on the faces perpendicular to the bending stress is shown in Fig. 4. The scattering of points was very large and no variation trend could be found. Also no correlation was observed for the variation of mechanical properties (Young’s modulus, fracture stress and fracture strain) with the number of pores.

Anjos et al. (2008, 2010a, 2010b) also studied the effect of porosity in the mechanical behaviour of cork under compression and tension, and concluded that the anatomical characteristics of the cork porosity, namely lenticular channels and the occurrence of sclerenquimatic cells, were important to explain the great variability that was observed. Specifically the tensile behaviour (Anjos et al. 2010a) had a large dependence on the structural defects of the material in relation to their type and dimensions, i.e., pores, cracks or notches. The occurrence of these defects and their distribution present a large variability between cork samples (Anjos 2002), which make it more difficult to predict the mechanical behaviour of cork.

The consideration of both density and porosity allowed however better modelling of cork elastic behaviour in bending. In that work the some equation developed by Anjos (2002) was used:

where E is the Young’s modulus, E s the Young’s modulus of cell walls (MPa), ρ/ρ s is the ratio of density to cell wall density, and b 1, b 2 and b 3 are constants.

The results of the adjustment of the measured data to the model are the following:

-

for the TO samples, a correlation coefficient of R 2=92.36 with b 1=0.007, b 2=0.78 and b 3=−2.18;

-

for the TI samples, a correlation coefficient of R 2=93.39 with b 1=0.056, b 2=1.77 and b 3=−0.44;

-

for the AO samples, a correlation coefficient of R 2=79.22 with b 1=0.336, b 2=2.65 and b 3=−1.01

-

for the AI samples, a correlation coefficient of R 2=73.09 with b 1=0.067, b 2=1.73 and b 3=0.196

The results show that it is possible to predict the Young’s modulus of cork when the internal stress is in the tangential direction.

3.2 Variance and principal component analysis

The variance analysis for the bending parameters of cork show that for the Young’s modulus the direction of the internal tension was the more important factor that explained 61% of the total variance while the quality grade of the plank was also a significant factor of variation, but only explained 4.7% of the total variance. Similar results were obtained for fracture stress and strain. For fracture stress the interaction between quality class and stress direction was also very significant and explained 14% of the total variance. These results agree with what was found for compression and tension of cork (Anjos et al. 2008, 2010a, 2010b).

The principal component analysis confirms the previous conclusions: a large variability, but with a good separation in the behaviour for the stress directions, and a separation (although not as clear) of both quality classes.

4 Conclusion

Cork is anisotropic in bending and higher resistance is observed when the internal tension stress is in the axial direction in comparison to the tangential direction. This should be taken into account when applying cork that will be subjected to bending. The mechanical resistance of cork in bending is higher than in tension and lower than in compression.

The bending properties of cork namely Young’s modulus, fracture stress and fracture strain are influenced by cork density and porosity. On average cork from good quality planks has higher bending strength than from poor quality planks.

References

Anjos O (2002) Mechanical behaviour of cork and its relation with the quality. PhD thesis, Instituto Superior Técnico (IST)

Anjos O, Marques J (2009) Relation of the chlorophenols and chloroanisol cork content and the soil chemical composition. Geochim Cosmochim Acta 73(N13S):A45

Anjos O, Pereira H, Rosa ME (2008) Effect of quality, porosity and density on the compression properties of cork. Holz Roh-Werkst 66(4):295–301

Anjos O, Pereira H, Rosa ME (2010a) Tensile properties of cork in axial stress and influence of porosity, density, quality and radial position in the plank. Eur J Wood Prod. doi:10.1007/s00107-009-0407-0

Anjos O, Pereira H, Rosa ME (2010b) Tensile properties of cork in the tangential direction: variation with quality, porosity, density and radial position in the cork plank. Mater Des 31(4):2085–2090

Castro O, Silva JM, Devezas T, Silva A, Gil L (2010) Cork agglomerates as an ideal core material in lightweight structures. Mater Des 31:425–432

Gibson LJ, Ashby MF (1997) Cellular solids—structure and properties, 2nd edn. Cambridge University Press, Cambridge

Gibson LJ, Easterling KE, Ashby MF (1981) The structure and mechanics of cork. Proc R Soc Lond A 377:99–117

Gonzalez-Adrados J, Pereira H (1996) Classification of defects in cork planks using image analysis. Wood Sci Technol 30(3):207–215

Matos MJ, Simplício MH (2006) Innovation and sustainability in mechanical design through materials selection. Mater Des 27:74–8

Pereira H (1988) Chemical composition and variability of cork form Quercus suber L. Wood Sci Technol 22(3):211–218

Pereira H (2007) Cork: biology, production and uses. Elsevier, Amsterdam

Pereira H, Lopes F, Graça J (1996) The evaluation of the quality of cork planks by image analysis. Holzforschung 50(2):111–115

Pereira H, Rosa ME, Fortes MA (1987) The cellular structure of cork from Quercus suber L. IAWA Bull 8(3):213–218

Riu M, Mestres M, Busto O, Guasch J (2006) Determination of total chloroanisoles in different kinds of cork stoppers. Anal Chim Acta 563(1–2):310–314

Rosa ME, Fortes MA (1991) Deformation and fracture of cork in tension. J Mater Sci 26(2):341–348

Rosa ME, Fortes MA (1998) Densidade da cortiça: factores que a influenciam. Cortiça 593:65–69

Soile P (1995) Morphological image analysis. Principles and applications. Springer, Berlin

Acknowledgements

We thank Subercentro Cortiças, Lda. in Ponte de Sor, Portugal, for the cork planks and Pedro Pina for his help to develop the image analysis algorithm.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anjos, O., Pereira, H. & Rosa, M.E. Characterization of radial bending properties of cork. Eur. J. Wood Prod. 69, 557–563 (2011). https://doi.org/10.1007/s00107-010-0516-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-010-0516-9