Abstract

This study comprises the analysis of the influence of the moisture content of wood on the dynamic properties—sound velocity and dynamic MOE (considering the density)—of green and dry sawn timber. The main objective was to find applicable functions or factors for the adjustment of the determined properties on the reference condition (moisture content u=12%) for the moisture content range below and above fiber saturation. Therefore, two dynamic measurement methods—measurement of the natural frequency and ultrasonic runtime—were considered. Possible differences in the results, pros and cons of both methods should be identified on the one hand. On the other hand, the applicability of already published moisture adjustments to the given data of both methods should be proved.

Zusammenfassung

Diese Arbeit befasst sich mit der Untersuchung des Einflusses der Holzfeuchte auf die dynamischen Eigenschaften – Schallgeschwindigkeit und dynamischer E-Modul (Berücksichtigung der Rohdichte) – von Schnittholz, mit dem Ziel, für die genannten Eigenschaften durch geeignete Korrekturfunktionen in den Feuchtebereichen unterhalb und oberhalb Fasersättigung einen Bezug auf die Referenzholzfeuchte von u=12% zu erreichen. Es erfolgte der Vergleich zweier Messmethoden – der Eigenschwingungsmessung und der Ultraschalllaufzeitmessung – um einerseits etwaige Unterschiede in den Ergebnissen aufzeigen zu können und andererseits zu überprüfen, ob die zur Thematik bereits publizierten Feuchtekorrekturen, die meist auf Daten aus einer Ultraschalllaufzeitmessung basieren, auch auf die Daten aus Eigenschwingungsmessungen anwendbar sind.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The determination of dynamic properties—sound velocity v and dynamic modulus of elasticity (MOE) (with consideration of the density)—are significant methods in order to derive mechanical properties of wood like modulus of elasticity and strength. Two procedures are used for the grading of timber, the measurement of the natural frequency and the measurement of the ultrasonic runtime, which differ in the type of vibration—forced or free. In both measurement methods, the sound velocity is dependent on the moisture content u of the sawn wood.

For the ultrasonic runtime measurement, some research has already been performed and corresponding moisture corrections for different wood moisture levels (below and above fiber saturation (FSP)) were published, see Sandoz (1990, 1993) and Steiger (1995). For example, in Steiger (1995) the moisture corrections of ultrasonic wave speed for three wood moisture ranges are given as follows:

These adjustment functions are based on an investigation by Sandoz (1990) and are also implemented in a modified form in Sylvatest, a device for ultrasonic runtime measurement. The second publication (Sandoz 1993) defines two linear functions for the moisture adjustment of the ultrasonic wave speed. They are valid for a moisture content u below and above the threshold value of 32%.

For the moisture content adjustment of the stress-wave speed from natural frequency measurements no publications are known, probably under the assumption that both methods differ only slightly.

The second input parameter for the calculation of the dynamic modulus of elasticity—the density—is influenced by the moisture content of wood as well, especially above fiber saturation. No adequate correction function for density was available when the data of the present investigation was analysed. In the moisture content range below fiber saturation, ON EN 384 (2004) describes a moisture adjustment factor for the range between u=10 and 18%. It states a valid change in density of 0.5% for 1% change of moisture content.

This work comprehends the results of the investigation on the dependence on the parameters density, sound velocity of ultrasonic runtime and natural frequency measurements and the resulting dynamic moduli of elasticity on the moisture content of wood. The objective was the determination of appropriate moisture adjustment functions to compare the mechanical and dynamic properties, determined at a wood moisture u, to the reference moisture of u=12%.

2 Material, methods and procedure

2.1 Samples

The investigation was carried out with 310 ungraded spruce boards with a length of 4500 mm and different widths (202 mm and 98 mm) and thicknesses (49 mm and 41 mm), which were supplied in green condition (freshly cut), see also Table 1. The decrease of the cross section by shrinkage during the drying process was considered.

2.2 Methods

Two methods were applied to determine the dynamic properties. Natural frequency was measured with an industrially applied device (ViSCAN). The oscillation excitation was achieved by a steel ball, which was mounted on an air cylinder with a spring. The arising free longitudinal oscillation was measured contactless with a laser vibrometer. The first natural frequency f [Hz]—for calculation of the stress-wave speed—was determined by FFT analysis. The ultrasonic runtime—for calculation of the ultrasonic wave speed—was measured with a laboratory device (Sylvatest) and based on the determination of the run time t [μs] of the ultrasonic wave between transmitter and receiver, which is generated by piezoelectric transducers with a frequency of about 30 kHz.

2.3 Procedure

The first recording of cross-sectional dimensions and mass was carried out shortly after delivery of the green boards. Small defect free specimens were cut out for the determination of moisture content in green condition. After measuring the natural frequencies and ultrasonic runtimes, the boards were stored in a stack in a closed building at temperatures between 21°C and 24°C and a relative humidity of about 58%. Therefore, gentle drying of the boards could be guaranteed in order to reach moisture contents far below the fiber saturation point.

Five measurements were taken in the course of the drying process. Before the final measurement, all boards were kiln-dried within 10 days to reach the reference moisture content of u=12%. A second specimen was taken from each board after final measurement of the dynamic properties for re-calculating the moisture content for each measurement period with the given mass differences.

The analysis included the evaluation of the influence of moisture content on density, natural frequency and ultrasonic runtime, the resulting determined sound velocities (ultrasonic wave speed, stress-wave speed) and the associated dynamic moduli of elasticity.

3 Results

3.1 Density, sound velocity and dynamic moduli of elasticity at different moisture contents

Table 2 shows the results of the measurements 1–5 of density, sound velocity and the resulting dynamic moduli of elasticity at different moisture contents.

For measurements 1 to 4, the mean moisture content lies above fiber saturation with individual values ranging from 15% and 170%. Because of kiln-drying after measurement 4, a mean reference moisture content of u=12% could be reached. Apart from the continuous decrease in moisture content and thus density, an increase in sound velocity could be measured. In contrast to this fact, the mean dynamic moduli of elasticity remained nearly constant during the measurement periods 1 to 4. A significant increase of the mean values was observed at measurement 5, with a reference moisture content of about 12%.

3.2 Influence of the moisture content on the density

Figure 1 shows the relation between moisture content and density below and above fiber saturation.

A significant change in the behaviour of the properties (moisture content to ratio of ρ u /ρ 12) was identified around the fiber saturation point. Linear functions can be applied for both moisture content ranges (Eq. 6 and Eq. 7). The threshold value for the moisture content of u=28% was determined with a regression analysis.

The determined adjustment function for the moisture range below FSP corresponds well with the given moisture adjustment in ON EN 384 (2004), which is applicable for moisture contents between 10% and 18%. The comparison of the adjusted density and the density determined at reference conditions (u=12%) shows maximum relative deviations of about 5% (see Table 3).

3.3 Influence of the moisture content on the sound velocity depending on the measurement method

Figure 2 shows the relation between moisture content and sound velocity for both measurement methods. The main differences are found in the trend and the different spread of the data points. An evenly curved data band with a low dispersion in the upper range of moisture content was found for natural frequency measurements. The ultrasonic runtime measurements show a significant change of the data relation in the area of fiber saturation, coupled with a considerably higher dispersion of the data points in the upper range of the moisture content. A linear dependence of the ultrasonic wave speed on the moisture content can be observed over the whole range. The apparent linear dependence of the sound velocity below the fiber saturation point is common for both measurement methods.

The trends in Fig. 2 lead to the conclusion that a moisture content adjustment of the sound velocity has to be carried out separately for the moisture content ranges below and above fiber saturation. For correct data separation, the threshold moisture content has to be found, where the dependence of the dynamic parameters changes. By means of a regression analysis the threshold moisture contents could be identified: 32% for the method of natural frequency measurement and 28% for the method of ultrasonic runtime measurement.

Note

The statistical analysis clearly shows the moisture content threshold values 28% and 32%, though the FSP is between 30% and 34% according to Niemz (1993). The reason for the different results of the two dynamic measurement methods has not been fully identified yet.

3.3.1 Adjustment of sound velocity below FSP

Linear functions with nearly the same slope k could be determined for both measurement methods.

As a further consequence an averaged linear moisture adjustment function is used, see Eq. 10.

Considering the ratios of the adjusted sound velocity and the dynamic properties determined at reference conditions (u=12%), maximum deviations of about 5% can be observed (see also Table 4). Figure 3 shows the separation of the wood moisture range at u=32% (EF) and u=28% (US), respectively and the associated change of the (linear) relation of the properties. The slope of the imaginary trend line decreases and the spread of the data points increases above the fixed threshold moisture content.

The dashed line represents the moisture content adjustment according to Steiger (1995) and shows a lower slope k of the straight trend line. Thus, the sound velocity is slightly underestimated by this adjustment (see Table 4). This is valid for the linear function proposed by Sandoz (1993) as well.

3.3.2 Adjustment of sound velocity above FSP

A quadratic function for the natural frequency measurement and a linear adjustment function for the ultrasonic runtime measurement were determined to describe the correlation between moisture content and sound velocity above fiber saturation.

Figure 4 shows the correlation between moisture content and sound velocity for both measurement methods and the determined adjustment functions and the moisture adjustment by Steiger (1995) (dashed line). Significant differences are the low dispersion of data points of the natural frequency measurement and the steeper course of the quadratic function.

The adjustment method by Steiger (1995) shows a bi-linear course, separated into two moisture content ranges. Thus, the adjustment function or the constant factor can not be applied to the data of the present investigation. The given data do not show an additional change in the relations between moisture content and sound velocity above FSP on the one hand and exhibit a steeper trend on the other hand.

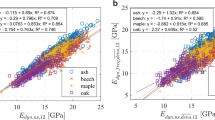

The comparison between adjusted and sound velocity values determined at reference conditions shows a very good adjustment. On the contrary, the significant underestimation by applying the moisture content adjustment proposed by Steiger (1995) and Sandoz (1993) is shown. In Table 5, Fig. 5 and Fig. 6 the correlation between adjusted and sound velocity determined at reference conditions is given for both measurements.

Correlation between adjusted and at reference condition (u=12%) determined stress-wave speed of the natural frequency measurement above FSP

Zusammenhang zwischen den bei der Referenzholzfeuchte (u=12%) ermittelten und den korrigierten Schallgeschwindigkeiten aus der Eigenschwingungsmessung für den Bereich über Fasersättigung

Correlation between adjusted and at reference condition (u=12%) determined ultrasonic wave speed of the ultrasound runtime measurement above FSP

Zusammenhang zwischen den bei der Referenzholzfeuchte (u=12%) ermittelten und den korrigierten Schallgeschwindigkeiten aus der Ultraschalllaufzeitmessung für den Bereich über Fasersättigung

The adjustment methods according to Eq. 11 and Eq. 12 provide good correlations between the properties (R 2>0.90, Fig. 5(a)–(b), Fig. 6(a)–(b)) whereas the correlations with the data adjusted according to Steiger (1995) and Sandoz (1993) show a lower coefficient of determination as well as a broader 95% confidence interval (Fig. 5(c)–(d), Fig. 6(c)–(d)).

3.4 Influence of the moisture content on the dynamic modulus of elasticity depending on the different measurement methods

Figure 7 shows the correlation between moisture content and dynamic modulus of elasticity for both measurement methods. The most significant difference is found in the moisture content range above fiber saturation. While the dynamic MOE of the natural frequency measurement shows no relation to the moisture content, the MOE of the ultrasonic runtime measurement shows a distinct dependence on the moisture content, coupled with a larger data scatter. It appears for both dynamic MOEs, that a significant change of the influence of moisture content takes place in the range of fiber saturation. The threshold could be fixed at a moisture content of u=28% by regression analysis, though FSP is between 30% and 34% according to Niemz (1993).

Moisture adjustment of the dynamic MOE can be achieved by different methods. On the one hand, the possibility to adjust the individual properties density and sound velocity (adjustment of both or only one input parameter) exists, on the other hand, it is possible to adjust the dynamic MOE directly by suitable functions or constant factors. These alternatives were applied and compared in this investigation.

3.4.1 Adjustment of dynamic modulus of elasticity below FSP

Direct adjustment of the dynamic MOE

The correlation between moisture content and dynamic MOE of both measurement methods could be fit best by linear trend lines, which have nearly the same slope k.

As a further consequence an averaged linear adjustment function is used for the adjustment of moisture content, see Eq. 15.

The comparison between adjusted dynamic MOE and MOE determined at reference conditions results in maximum deviations of 7%. Equation 15 enables a precise moisture content adjustment of the dynamic MOE on average (see Table 6).

Figure 8 shows the threshold for the moisture content at u=28% and the associated change of (linear) dependence of the dynamic MOE.

Adjustment of both input parameters

For comparison reasons, the adjusted dynamic MOE is calculated using the adjusted density (Eq. 6), the adjusted sound velocity (Eq. 10) and the moisture content adjustment of Eq. 1.

The maximum deviations between adjusted dynamic MOE according to Eq. 16 and dynamic MOE determined at reference conditions do not exceed 7%, for moisture content adjustment according to Eq. 17 8%. The adjustment of both properties with Eq. 16 leads to an underestimation of the mean values of the MOE determined by natural frequency measurement as well as the adjustment by Eq. 17 for the MOE of the ultrasonic runtime measurement, see Table 6.

Adjustment of one input parameter

For comparison reasons, three alternatives—adjustment of sound velocity with Eq. 10 and with Eq. 1 and adjustment of the density with Eq. 6—were taken into account.

The dynamic MOEs calculated using the adjusted sound velocities are overestimated between 1.5% and 4.6% on average. The maximum deviations of adjusted dynamic properties and dynamic MOE determined at reference conditions are 12%. In contrast, the individual adjustment of the density tends to result in an underestimation of the dynamic MOE between 13% and 14% on average (see Table 6).

As expected, the influence of the non-adjusted sound velocities is higher than the influence of the non-adjusted density for the moisture content range below fiber saturation.

3.4.2 Adjustment of dynamic modulus of elasticity above FSP

Direct adjustment of the dynamic MOE

The correlation between moisture content and dynamic MOE from natural frequency measurements results in a constant adjustment factor. The calculation of the dynamic MOE from ultrasonic runtime measurements results in a linear function (see Fig. 7).

In contrast to the ultrasonic runtime measurements, which show a positive correlation of the considered properties, no dependence of the dynamic MOE calculated from natural frequency measurements could be determined over the whole moisture content range above fiber saturation (see Fig. 9).

The comparison of the adjusted dynamic MOE from natural frequency measurement with the related dynamic properties determined at reference condition delivers maximum deviations of up to 9%. The constant factor allows a good moisture adjustment on average. The maximum deviations of the adjusted values for ultrasonic runtime measurements reach 16% with a resulting over-estimation of nearly 2% in the mean values, see Table 7.

Adjustment of both input parameters

The adjustment of sound velocity with Eq. 11 and Eq. 12 and density with Eq. 7, respectively,

delivers maximum deviations of up to 10% for the dynamic MOE from natural frequency measurement and 14% for the dynamic MOE from ultrasonic runtime measurement (see Table 7).

Adjustment of one input parameter

Two alternatives—adjustment of sound velocity and adjustment of density—were taken into account.

The calculated dynamic MOEs with adjusted sound velocity and non-adjusted density are overestimated by 40% on average. The maximum deviations reach up to 123%. The individual adjustment of the density leads to an underestimation of the dynamic MOEs of between approx. 30% (US) to 35% (EF) on average (see also Table 7).

Figures 10 and 11 show the correlation between the adjusted dynamic MOEs with various models and the dynamic properties determined at reference conditions for both measurement methods.

Correlation between adjusted and at reference conditions (u=12%) determined dynamic MOE of the natural frequency measurement above FSP

Zusammenhang zwischen den bei der Referenzholzfeuchte (u=12%) ermittelten und den korrigierten dynamischen E-Moduln aus der Eigenschwingungsmessung für den Bereich über Fasersättigung

Correlation between adjusted and at reference conditions (u=12%) determined dynamic MOE of the ultrasound runtime measurement above FSP

Zusammenhang zwischen den bei Referenzholzfeuchte (u=12%) ermittelten und den korrigierten dynamischen E-Moduln aus der Ultraschalllaufzeitmessung für den Bereich über Fasersättigung

The direct moisture adjustment with the determined linear function and the constant factor, respectively, and the adjustment of both calculated properties lead to a good correlation between the dynamic values (see Fig. 10(a)–(b) and Fig. 11(a)–(b)). The adjustment of sound velocities shows a significant overestimation of the dynamic MOEs (Fig. 10(c) and Fig. 11(c)) on the one hand, and the adjustment of density shows a massive underestimation of the determined dynamic MOEs (Fig. 10(d) and Fig. 11(d)) on the other hand. These facts are emphasised in the notable spread of the data points and the low correlation of the properties (coefficients of determination).

4 Conclusion

The present analysis shows, that the input parameters for calculation of the dynamic MOE—density and sound velocity—are substantially influenced by the moisture content of wood. The adjustment of all properties to the reference condition u=12% can be carried out by using adjustment functions and constant factors, respectively, whereas a definite threshold moisture content at fiber saturation has to be fixed. Previously published methods for moisture content adjustment of ultrasonic wave speed could be confirmed only in parts by the given data.

All properties, density, sound velocity and dynamic MOE for both measurement methods offer linear dependence on the moisture content below fiber saturation. The determined linear function for the adjustment of the density confirmed the moisture content adjustment in ON EN 384 (2004). The adjustments of sound velocities and dynamic MOEs could be fixed with average linear functions, which are applicable for both measurement methods. The published moisture adjustments by Steiger (1995) and Sandoz (1993) could be confirmed for the moisture content range below fiber saturation.

The wood moisture content range above fiber saturation required a different look at the properties of both measurement methods. The adjustment of the ultrasonic wave speed and the resulting dynamic MOE can be accomplished by using linear functions. In contrast, moisture adjustment of the stress-wave speed has to be carried out using a quadratic function, and for the resulting dynamic MOE a constant factor results in the best data fitting. The published adjustment methods for the moisture content range above fiber saturation were only suitable to a limited extent for application on the available data. The best moisture adjustment of density could be achieved by use of a linear function.

The present study shows, that the sound velocities of both measurement methods exhibit a nearly identical behaviour in relation to the influence of moisture content below fiber saturation. Therefore, the influence on both properties can be described by a linear function. The significant change of the influence on both sound velocities above fiber saturation has a massive consequence regarding the resulted dynamic MOEs. While the dynamic MOE of the ultrasonic runtime measurement also delivers a linear dependence of the moisture content, the dynamic MOE based on the stress-wave speed exhibits no moisture content dependency in the whole range above fiber saturation. This fact could be used best in the context of (pre-)grading of green timber for example. The difficult, industrially practicable recording of moisture content above fiber saturation could be omitted because of the moisture independence of the dynamic MOE. This property desired for the grading process at reference condition (u=12%) can be determined without knowledge of the moisture content in green condition.

References

ON EN 384 (2004) Bauholz für tragende Zwecke – Bestimmung charakteristischer Werte für mechanische Eigenschaften und Rohdichte

Niemz P (1993) Physik des Holzes und der Holzwerkstoffe. DRW-Verlag Weinbrenner GmbH & Co., Leinfelden-Echterdingen

Sandoz JL (1990) Triage et fiabilité des bois de construction – Validité de la méthode ultrason (Grading and reliability of timber—Validity of the ultrasonic method). Thése No. 851, Département de Génie Civil, Ecole Polytechnique Fédérale de Lausanne (only available in French)

Sandoz JL (1993) Moisture content and temperature effect on ultrasound timber grading. Wood Sci Technol 27:373–380

Steiger R (1995) Versuche an Fichten-Kanthölzern: Biegemoment-Normalkraft-Interaktion. IBK-Bericht Nr. 209, Institut für Baustatik und Konstruktion (IBK), Eidgenössische Technische Hochschule Zürich (ETH)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Unterwieser, H., Schickhofer, G. Influence of moisture content of wood on sound velocity and dynamic MOE of natural frequency- and ultrasonic runtime measurement. Eur. J. Wood Prod. 69, 171–181 (2011). https://doi.org/10.1007/s00107-010-0417-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-010-0417-y