Abstract

It was aimed to investigate the shelf-life of single baked (one stage heating at 280–300 °C) mustafakemalpasa (MKP) cheese sweets coated with edible films such as κ-carrageenan, chitosan, corn zein and whey protein concentrate (WPC). The sweets prepared were coated, packed in polystyrene bags and stored at room temperature (20 ± 1 °C). The shelf-life of sweet samples was determined by microbiological analyses, aw, titratable acidity, pH and sensory analysis. The microorganisms exhibited growth dependent upon the water activity levels during storage. The most significant growth was seen in moulds and yeasts. The minimum aw values for the growth of mould and yeasts were 0.85. Coating with chitosan and κ-carrageenan showed no significant effect on shelf-life of MKP sweets. The shelf-life of these samples was limited by 3 days same as control (non-coated) and deterioration occurred when the aw value reached 0.90. The coatings with WPC and corn zein prolonged the shelf-life of sweets from 3 to 10 days.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mustafakemalpasa (MKP) sweet is a traditional Turkish dessert made from dough containing fresh unsalted cheese (40–70%), semolina flour (40–50%), baking powder, water and eggs. According to geographical registration certificate (ITP 2001), the diameter of the sweets ranges from 0.59 to 0.98 inches. MKP sweet consists of maximum 10% moisture, 3% protein, 1.95% total lipid, 85.2% carbohydrate, 3% total ash, 0.75% titratable acidity, 80.2 mg/100 g calcium (Ca) and 0.41 mg/100 g ferrous (Fe) (ITS 1996).

The name of the dessert has been attributed to the town owning the same name, Mustafakemalpasa, Bursa, Turkey. The dough of MKP sweet is given the uniform spherical shapes and baked on trays in ovens until the brown colour is developed. The MKP sweets are sold in dried form to the consumers. The sweets can only be consumed after boiling in sugar syrup containing 60–80% sucrose.

Main characteristic of MKP sweet is the use of special unsalted cheese. At first, the milk is heated up to 65 °C in jacketed tanks for the production of fresh cheese. The heating takes about 30 min to reach this target temperature. Then, it is cooled to 34 °C, rapidly, fermented with cheese rennet for 1–1.5 h and filtered through the gauze for whey (serum) separation. A fresh cheese curd is minced prior to using. The baking process is needed to reduce moisture content to less than 10%. The sweets can be baked either as single baking (only one stage heating) or double baking (two stage heating) in the ovens. The single baking process consists of heating at 280–300 °C for 15–20 min, while the double-baking process consists of heating at 130–150 °C for 45–60 min in addition to pre-heating at 280–300 °C for 15–20 min.

The baked MKP sweets are packed in polyethylene bags and kept at room temperature (20 ± 1 °C). Double-baked sweets have a longer shelf-life of up to 6 months; although the consumers prefer single-baked products. The main problem in single-baked products is higher moisture content limiting the shelf-life to 3 days due to the higher water activity that promotes the yeast and mould growth.

The shelf-life of bakery products is largely related to their water content (Nobile et al. 2003). Mould spoilage is common in the bakery industry and in many cases mould growth determines the product shelf-life in intermediate-moisture baked goods. Although, baking destroys most moulds and yeasts, the post-process contamination is unavoidable by mould spores from the atmosphere or from the surfaces during cooling and packaging (Guynot et al. 2002, 2003).

It was reported that the water activity (aw) of Spanish bakery products which have intermediate moisture ranges from 0.71 to 0.79, with pH between 4.3 and 8.8. The most widespread and important moulds present in the bakery products are species of Aspergillus, Penicillium and Eurotium (Guynot et al. 2002). The moulds isolated from MKP sweets are Penicillium (46.0%), Aspergillus (33.3%), Neurospora (4.8%) and Alternaria (3.2%) (Korukluoglu et al. 2001).

Research reports on shelf-life of sweet bakery products are limited (Guillard et al. 2004a, b; Longares et al. 2004; Bravin et al. 2006). Considering the increase in the interest of prolonged-shelf-life of the products, significant pressure is mounting to modify product formulations or preserving methods (Williams and Mittal 1999). Edible coatings or films might offer a potential solution to form a barrier to moisture absorption during storage. The objective of this study was to prolong the shelf-life of MKP sweet by using four different coating solutions to obtain stabile edible films all around the sweet samples, to compare their water activity levels, microbiological changes and sensory properties during storage at room temperature (20 ± 1 °C).

Materials and methods

MKP sweets were produced in a private plant (DGS, Dinc Food Industry Inc., Tatkavaklı Beldesi, Mustafakemalpasa Town, Bursa city, Turkey).

Coating materials used were κ-carrageenan (C 1263-from Eucheuma cottonii, Type III, Sigma-Aldrich, Inc., St. Louis, MO, USA), chitosan (48165, highly viscous, Fluka Chemie GmbH, Buchs, Switzerland), corn zein (Z 3625, Sigma-Aldrich, Inc., St. Louis, MO, USA) and whey protein (CP Kelco, Simplesse 100, Atlanta, GA, USA).

Production of MKP sweets

Fresh unsalted cheese was mixed with semolina flour, egg and NaHCO3 as raising agent. The mixture was kneaded for 20 min, cut into uniform shapes and then placed on trays. The shaped dough was single baked at 280–300 °C for 15 min. The sweets after cooling were stored at room temperature (20 ± 1 °C) in polyethylene bags. Only dried (coated) and single baked MKP sweets were used for microbiological and chemical analyses. As practiced traditionally, the dried samples were boiled in 70% sugar syrup for 15–20 min before sensory evaluation.

Coating of KP sweets

Coating solutions were prepared as follows:

- Whey protein concentrate (WPC) solution:

-

10% whey protein dissolved in water and heated at 90 °C for 30 min (McHugh and Krochta 1994).

- Corn zein solution:

-

10 g corn zein, 2 g glycerol, 65 ml of 95% ethanol were heated for 10 min and applied while still hot (Gennaidos and Weller 1994).

- κ-Carrageenan solution:

-

2% of κ-carrageenan, 0.1% of KCI, 0.75% of polyethyleneglycole and 0.75 g glycerin were dissolved in distilled hot water (Wu et al. 2000)

- Chitosan solution:

-

3 g of chitosan was dissolved in 150 ml of formic acid solution (1% in water) and added 0.75% glycerin. This solution was heated up to 100 °C with stirring (Wu et al. 2000).

As proposed by Williams and Mittal (1999), the immersion method was used for the coating of edible films as it was easy to implement. The baked sweets were dipped in each coating solution for 20 s. The coating system was equipped with a basket into which the samples were placed and a mesh screen was used to separate the samples from the coating solution to ensure uniform coating. The dipped samples were dried using hot air in a convective oven (200 °C) for 2 min to complete the coating.

Microbiological analysis

The samples were analyzed in triplicate for total viable bacteria and yeast-mould counts. Sweet samples coated with four different edible films were taken at random during the storage period of 28 days. Each sweet sample (10 ± 0.1 g) was homogenized for 3 min in 90 ml sterile NaCl solution (0.85 g/l) using a lab-blender. Sequential decimal dilutions were then made with sterile 1 g/l peptone water and plated in duplicates. Total viable counts were determined from Plate Count Agar (PCA, Difco Lab, Detroit MI, USA) incubated at 30 °C for 3 days under aerobic conditions. Yeast and moulds were grown on Potato Dextrose Agar (PDA, Difco Lab, Detroit MI, USA) at 25 °C for 5 days. Results were expressed as log cfu/g.

Chemical analyses and sensory evaluation

The titratable acidity (lactic acid%) and pH were determined according to AOAC (1990a, b). Sensory analyses were done by participation of 7 panelists (ITP 2001). Colour/appearance and taste/flavour from 0 to 5 points and texture from 0 to 3 points were scored for the sensory analyses. Water activity (aw) was measured by water activity apparatus (aw Wert-Messer, Lufft Durotherm, G. Lufft Mess und Regeltechnik GMBH, Fellbach, Germany) at 20 °C by using barium chloride. All analyses were carried out in triplicate.

Statistical analyses

Statistical analyses were done by using SPSS (Statistical Package for the Social Sciences) software for Windows Release 10.0.1 (10/27/1999) Standard Version (SPSS, Inc., Chicago, IL, USA). The mean differences, significance of differences and correlation coefficients among the coated samples regarding analyses were tested by using paired samples t-test (Snedecor and Cochran 1987).

Results and discussion

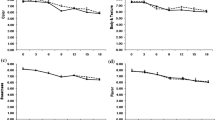

The mean values and correlation coefficients given in Table 1, show that the MKP coated with WPC, corn zein, κ-carrageenan and chitosan showed similar changes during storage period as separate groups. When the statistical parameters among the means were considered as in Table 2, the mean differences between the samples coated with WPC and corn zein, κ-carrageenan and chitosan were not significant; whereas, the differences between WPC and κ-carrageenan, WPC and chitosan, corn zein and κ-carrageenan, corn zein and chitosan were significant (p < 0.001). In addition, the correlation coefficients between WPC and corn zein with chitosan and κ-carrageenan were higher than others and close to 1. These significant relationships in two separate groups (chitosan/κ-carrageenan and WPC/corn zein) can also be seen from the overlapping of the curves obtained from water activity and the proximity of the curves obtained from yeast and mould counts, total viable counts, titratable acidity and pH values (Fig. 1).

The higher means belonging to total viable, yeast and mould counts and aw values were obtained from the samples coated with either κ-Carrageenan or chitosan (Table 1). κ-Carrageenan or chitosan coated samples were spoiled earlier than the samples coated with WPC and corn zein (Fig. 1). The most significant growth was seen in moulds and yeasts. If the yeast and mould counts were considered, the counts in samples coated with chitosan and κ-carrageenan showed a rapid increase in 3 days of storage and exceeded 3 log cfu/g, whereas the samples coated with WPC and corn zein reached the same counts after 10 days of storage. The yeast and mould growth seen in the MKP samples coated with either κ-carrageenan or chitosan was due to high aw and moisture gain despite the coatings. These two coating materials (κ-carrageenan and chitosan) were not suitable for the MKP sweets. As found by Williams and Mittal (1999), these coating solutions did not provide good barrier against the moisture in the air. Unexpectedly, the moisture in the air reached into these sweets even in 3 days as seen in Fig. 1. The middle two curves of aw belonging to κ-carrageenan and chitosan in Fig. 1 overlapped and reached 0.85 at the end of 3 days. These samples were deteriorated similar to non-coated (control) samples.

Non-coated control samples, as defined in the related standard (ITS 1996), and as usual, were deteriorated at the 3rd day because of the extensive growth of mould, yeast and bacteria. Mould/yeast and viable counts of non-coated control samples were 4.2 and 2.2 log cfu/g, when the deterioration occurred. At day 0, the water activity of the (non-coated) control samples were between 0.72 and 0.75. In these samples, the spoilage began at 0.85 aw and when the aw reached 0.90 the extensive deterioration was observed. In a previous study, it was found that none of the mould isolates multiplied at less than 0.80 aw (Abellana et al. 2001).

Compared to non-coated (control) samples, the shelf-life of samples coated with either κ-carrageenan or chitosan was prolonged to a maximum of 3 days without deterioration similar to as control. The samples coated with WPC and corn zein did not deteriorate and kept their sensory properties up to day 10 at room temperature (20 ± 1 °C) (Table 3). At the beginning of the storage period, the aw values of the samples were 0.72–0.75, whereas these increased to 0.90 when the deterioration occurred after 10 days. The counts of mould and yeast as well as total viable microorganisms began to increase at 5 days of storage. When aw increased to 0.85 at day 5, the deterioration started slightly in the samples coated with WPC and corn zein. When comparing the aw values, we considered that the deterioration occurred at the same aw value as seen in the (non-coated) control samples. These changes were also in agreement with titratable acidity and pH values.

The increase in yeast and mould growth can arise from water permeability of glycerine based films. The coating films prepared by glycerine showed higher water vapour permeability. As reported by Gennaidos et al. (1993), glycerine affects the water vapour permeability since it is hydrophilic and thus favours water adsorption through films. In our research, the films containing higher amount of glycerine were κ-carrageenan and chitosan. The prolonged shelf-life seen in the samples coated with WPC and corn zein was probably due to higher water barrier and hydrophobic properties of these films (Pol et al. 2002).

Conclusion

The samples coated with either chitosan or κ-carrageenan were spoiled in 3 days of storage similar to non-coated control samples. The normal shelf-life of single baked MKP sweets was prolonged to 10 days by coating with either WPC or corn zein, without significant loss in organoleptic properties.

References

Abellana M, Sanchis V, Ramos AJ (2001) Effect of water activity and temperature on growth of three Penicillium species and Aspergillus flavus on sponge cake analogue. Int J Food Microbiol 71:151–157

AOAC (1990a) Official methods of analysis. 15th edn, Association of Official Analytical Chemists, No: 942.15 Acidity titratable, Washington DC, p 918

AOAC (1990b) Official methods of analysis. 15th edn, Association of Official Analytical Chemists, No: 945.42 pH of Bread, Washington DC, p 794

Bravin B, Peressini D, Sensidoni A (2006) Development and application of polysaccharide-lipid edible coating to extend shelf-life of dry bakery products. J Food Eng 76:280–290

Gennaidos A, Weller CL (1994) Moisture adsorption by grain protein films. Trans ASABE 37:535–539

Gennaidos A, Brandenburg AH, Weller CL, Testin RF (1993) Effect of pH on properties of wheat gluten and soy protein isolate films. J Agric Food Chem 41:1435–1439

Guillard V, Broyart B, Bonazzi C, Guilbert S, Gontard N (2004a) Effect of temperature on moisture barrier efficiency of monoglyceride edible films in cereal-based composite foods. Cereal Chem 81:767–771

Guillard V, Guillbert S, Bonazzi C, Gontard N (2004b) Edible acetylated monoglyceride films: effect of film-forming technique on moisture barrier properties. J Am Oil Chem Soc 81:1053–1058

Guynot ME, Ramos AJ, Sala D, Sanchis V, Marin S (2002) Combined effects of weak acid preservatives, pH and water activity on growth of Eurotium species on a sponge cake. Int J Food Microbiol 76:39–46

Guynot ME, Sanchis V, Ramos AJ, Marin S (2003) Mold-free shelf-life extension of bakery products by active packaging. J Food Sci 68:2547–2552

ITP (2001) Geographical registration certificate of mustafakemalpasa sweet. Institute of Turkish Patent C2001/006, Ankara, No: 49

ITS (1996) Turkish standard for mustafakemalpasa dessert (TS 12102). The Institute of Turkish Standards, Ankara

Korukluoglu M, Yigit A, Ozmen N (2001) Moulds isolated from mustafakemalpasa sweet. Food 3:92–94

Longares A, Monahan FJ, O’riordan ED, O’sullivan M (2004) Physical properties and sensory evaluation of WPI films of varying thickness. LWT Food Sci Technol 37:545–550

McHugh TH, Krochta JM (1994) Milk-protein based edible films and coatings. Food Technol 48(1):97–103

Nobile MAD, Buonocore GG, Limbo S, Fava P (2003) Shelf-life prediction of cereal-based dry foods packed in moisture-sensitive films. J Food Sci 68:1292–1300

Pol H, Dawson P, Acton J, Ogale A (2002) Soy protein isolate/corn-zein laminated films: transport and mechanical properties. J Food Sci 67:212–217

Snedecor GW, Cochran WG (1987) Statistical methods, 8th edn. Iowa State University Press, Ames, p 507

Williams R, Mittal GS (1999) Water and fat transfer properties of polysaccharide films on fried pastry mix. LWT Food Sci Technol 32:440–445

Wu Y, Rhim JW, Weller CL, Hamouz F, Cuppett S, Schnepf M (2000) Moisture loss and lipid oxidation for precooked beef patties stored in edible coatings and films. J Food Sci 65:300–304

Acknowledgement

Authors thank Zeki DINK from DINK Food Industry, Inc. (Mustafakemalpasa, Bursa, Turkey) and Veyis OZTURK from Nestle/Turkey Karacabey Factory for the technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guldas, M., Bayizit, A.A., Yilsay, T.O. et al. Effects of edible film coatings on shelf-life of mustafakemalpasa sweet, a cheese based dessert. J Food Sci Technol 47, 476–481 (2010). https://doi.org/10.1007/s13197-010-0081-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-010-0081-6