Abstract

There is a tremendous increase in the demand for converting biomaterials into high-quality industrially manufactured human body parts, also known as medical implants. Drug delivery systems, bone plates, screws, cranial, and dental devices are the popular examples of these implants - the potential alternatives for human life survival. However, the processing techniques of an engineered implant largely determine its preciseness, surface characteristics, and interactive ability with the adjacent tissue(s) in a particular biological environment. Moreover, the high cost-effective manufacturing of an implant under tight tolerances remains a challenge. In this regard, several subtractive or additive manufacturing techniques are employed to manufacture patient-specific implants, depending primarily on the required biocompatibility, bioactivity, surface integrity, and fatigue strength. The present paper reviews numerous non-degradable and degradable metallic implant biomaterials such as stainless steel (SS), titanium (Ti)-based, cobalt (Co)-based, nickel-titanium (NiTi), and magnesium (Mg)-based alloys, followed by their processing via traditional turning, drilling, and milling including the high-speed multi-axis CNC machining, and non-traditional abrasive water jet machining (AWJM), laser beam machining (LBM), ultrasonic machining (USM), and electric discharge machining (EDM) types of subtractive manufacturing techniques. However, the review further funnels down its primary focus on Mg, NiTi, and Ti-based alloys on the basis of the increasing trend of their implant applications in the last decade due to some of their outstanding properties. In the recent years, the incorporation of cryogenic coolant-assisted traditional subtraction of biomaterials has gained researchers’ attention due to its sustainability, environment-friendly nature, performance, and superior biocompatible and functional outcomes fitting for medical applications. However, some of the latest studies reported that the medical implant manufacturing requirements could be more remarkably met using the non-traditional subtractive manufacturing approaches. Altogether, cryogenic machining among the traditional routes and EDM among the non-traditional means along with their variants, were identified as some of the most effective subtractive manufacturing techniques for achieving the dimensionally accurate and biocompatible metallic medical implants with significantly modified surfaces.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With the constant growth of the world’s population and globalization, a constant rise in people’s living standards is being noticed, increasing the chances of lifestyle-related physical sicknesses, for example, cardiovascular and orthopedic diseases. Each day, many human bone or tissue fracture cases, possibly caused by sports injuries, falls, and vehicle accidents, are dealt with by medical practitioners across the globe. However, every type of injury or damaged tissue may not require surgical interventions due to the human body’s self-renewing and regenerative abilities to conduct the healing process. For instance, minor damages to epithelial skin or a bone can receive easy healing without any surgery, unlike the spinal cord, articular-cartilage, neural-retina, cardiac muscle, lung, kidney glomerulus, etc., requiring either transplantation or reconstructive/regenerative surgery for complete restoration. In addition, the human body’s self-healing potential tends to decrease or disappear over time due to many reasons such as aging, decreasing progenitor population within the body, poor repairing ability of tissues, and inflammation caused by the injured tissue. Therefore, in this regard, medical science, in association with material science and engineering, has been consistently attempting to introduce smart and novel materials that are biocompatible or biologically compatible with the human body, also known as biomaterials, to deal with such challenges, physical damages or fracture fixation/arthrodesis.

A recent report, having included the impact of COVID-19, demonstrated the present and forecasted growth of the global biomaterials market between 2018 and 2026. The study pointed to North America and the Asia Pacific as the most significant and fastest-growing biomaterials markets, respectively, with a compound annual growth rate (CAGR) of 13.69%. However, India is expected to display the most rapid growth in Asia to rising dental, cardiovascular, and orthopedic surgeries [1]. An extensive range of these biomaterials, including metals and their alloys, polymers, composites, and ceramics, is used to manufacture implantable medical devices. These medical devices, popularly known as biomedical implants or structures, have a great potential to prolong the survivability and comfort of the life of patients essentially suffering from diseased or missing body tissues.

Moreover, using these implants, the organs can be substantially supported, body functions can be monitored, and medication can be delivered at specific locations in the body [2]. In this regard, patients with damaged/lost tissues, and resultant challenges, are dealt with the assistance of biomedical implants such as ventricular assist devices, bone plate, cardiovascular devices, screws, and maxillofacial devices. The functional abilities of these implants can cause them to replace a part or even the entire biological organ, however, with a finite lifespan and uses due to inferior biocompatible, immune repression, physiologic harm of associated tissues, and other similar characteristics [3]. Thus, the implants are designed and fabricated on the basis of an accurate selection of the potential biomaterials. In this relation, due to superior mechanical, fatigue, wear, and corrosion properties, Ti-6Al-4 V alloy, 316L stainless-steel (SS), Co-Cr–Mo, and nickel-titanium-shape memory alloy (NiTi-SMA) metallic implant biomaterials are often given preference over other biomaterials such as polymers and ceramics [4].

2 Biomaterials and biocompatibility

The constantly growing demand for biomedical implants depicts the expectations of a more comfortable life. These implants comprise a specific engineering material category, known as “biomaterials” or “biocompatible materials.” This category was duly recognized as an outcome of the Ist meeting on materials used in medicine at Clemson University in 1969, maintaining its incomparable contribution. Biomedical implants are mainly the emulation (biomimetic) of natural body parts, adopted to treat the afflicted or lost biological structure, regain its original structure, and work efficiently. In this regard, the term biocompatibility can be defined as the potentiality of a material to execute its anticipated activities associated with a particular remediation (without causing any unwanted local/systemic influences in the beneficiary’s body), leading to a superior cellular response and optimized therapy amid a specific use [5]. Biomaterials were elucidated by the American National Institute of Health, as, “Any substance or combination of substances, other than drugs, synthetic or natural in origin, which can be used for any period, which augments or replaces partially or any tissue, organ or function of the body, to maintain or improve the quality of life of the individual." Also, as outlined by [6], “Biomaterials or biocompatible materials do not produce any toxic/immune or malignant effect when exposed to the body (depending on the short-term or long-term use) and find their wide applications in biomedical implants and prosthetics to enhance a smooth functioning between the implant and the human body.” Moreover, the ISO (International Organization for Standardization) 10,993–1:2018 standard for the Biological Evaluation of Medical Devices—Part 1 defines biocompatibility as the “ability of a medical device or material to perform with an appropriate host response in a specific application.” In addition, the latest definition of biomaterials, receiving a signed agreement in 2018, stated, “a biomaterial is designed to take a form that can direct, through interactions with living systems, the course of any therapeutic/diagnostic procedure” [7].

Hence, the biocompatibility testing of a biomaterial discovers its technical fitness for human use by critically checking the potentially harmful physiological effects. The biocompatibility can be examined through a series of analyses starting with cytotoxicity in vitro testing (ISO 10993–5), which is conducted to examine the toxicity and chemicals generally by bringing the sample biomaterial directly in contact with the cultured mammalian cells. Further, according to ISO 10993–18, the leachable materials are extracted from the sample biomaterial at an elevated temperature, followed by the assessment of the extracts. Subsequently, ISO 10993–4:2017 and ASTM F756 are used to assess the hemocompatibility, which ascertains the possibility of a sample to induce injurious effects on red blood cells, thrombosis, coagulation, platelets, and the complement system. Subsequently, depending upon the type of application, suitable in vivo testing(s) such as skin-irritation testing, sensitization testing, and implantation testing can be performed [8].

In short, biocompatibility can be referred to as the potential of a biomaterial to function, exhibiting an adequate host reaction without displaying an inflammatory or allergic reaction during a particular application. The term “host” refers to a living organism or system (microenvironment), and “host-response” can be briefly defined as the behavior of a host towards a foreign biomaterial. For instance, the resistance to bacterial colonization. Hence, the interactive physical attributes of a biomaterial with the adjacent host principally determine biocompatibility. The use of a non-biocompatible material can adversely affect the body's immune system, making it prone to attacks by viruses, fungi, and bacteria. Additionally, according to Fig. 1, for satisfactory clinical performance, the biocompatibility of a biomedical implant needs to be pivotally supported by the implant’s own physical, mechanical, and degradation properties, sterilization (freeing implant’s surface from all types of microorganisms), toxicological aspects (examination and treatment of any toxin or intoxicating substance), surgical procedure, site of implantation, and load-bearing capacity [9]. For instance, (i) a hip-prothesis needs to be rigid and is not expected to fail before 20 years irrespective of the type of loading, and (ii) a tissue’s heart-valve leaflet needs to be tough and should be able to flex sixty-times/minute without any tearing in the remaining life of the patient.

3 Interaction of biomaterials with the living-organism

Further, as shown in Fig. 2, some of the major activities occurring at the surface can be categorized as water-surface interaction, protein-adsorption, cell-adherence and spreading, and proliferation. In the initial phase, during the first few nanoseconds (ns), the water molecules react with the biomaterial surface, and on the basis of the wetting features of the surface, the surface can be endorsed as a “hydrophilic” (contact angle < 90°) or “hydrophobic” (contact angle > 90°) surface. A hydrophilic surface has a strong affinity towards water molecules and thus promotes their spreading and maximizes their contact with the surface. In contrast, a hydrophobic surface repels the water molecules and minimizes their contact with the surface, causing the formation of droplets. The angle at which the water molecules’ interface meets the biomaterial surface is termed as “contact angle.” Further, the second phase comprises the adsorption of several proteins in a few seconds (s) on the surface with the rapid migration of small proteins, followed by the big ones, forming a considerably thick protein layer [10]. Subsequently, the third phase consumes a few hours (hrs) of cells’ interaction along with the soaked-up protein layer and later with the surface’s topography. In this stage, the biomaterial’s surface gets exposed to numerous molecular interactions. It can be substantially affected by the biological molecules (cell membrane, cytoskeleton, and extracellular matrix proteins) and biophysical surroundings. The following evolved physicochemical characteristics such as stiffness, wettability or wetting properties, functional groups (such as trimethylammonium (hydrophilic) and n-butyl groups (hydrophobic)), topography (surface protrusions and depressions), and ion enrichment of the surface. Proliferation occurs in the last (fourth) phase and is continuing development of the previous stages and thus, may require a few days (for example, biodegradable screw) or even several years (for example, total hip replacement). However, the occurrence of both the third and the fourth phases largely depends upon the surface’s topographic and wetting properties [11].

Biomaterial's interaction with the living-organism [11]

Further, in this regard, Fig. 3 attempts to demonstrate how the physicochemical characteristics of the biomaterials are intensely employed to govern the various molecular and cellular indicating pathways [12]. The mechanical-electrochemical aspect of these interactions may also lead to quick corrosion, disseminating ions, by-products, and particulate fragments in periprosthetic tissue. The biomaterial’s surface is thus expected to contribute interim mechanical support and exhibit a profound affinity towards the targeted cells in terms of emitting physical and chemical signals to trigger the neo-tissue development.

Diagrammatic illustration of key-surface physicochemical characteristics in biological responses towards a biomaterial [12]

4 Classification of biomaterials

Biomaterials can be categorized primarily based on the following.

4.1 Generation

Three generations have witnessed the advancements in the development of biomaterials for medical applications over the years. In the early 1930’s SS and cobalt-chromium alloys and 1940’s polymers were introduced as the acceptable biomaterials. The first total-hip prosthesis was released in 1938, and the first blood vessel (made up of Vinyon and Copolymer) in 1952. Similarly, the following years 1953, 1958, 1960, and 1976 reported the inventions of vascular grafts, total-hip replacement, heart valves, and artificial heart, respectively. In this regard, Fig. 4 displays the different generations and their respective goals in the last few decades (1940–2021).

Progressive growth in cell and molecular biology, materials science, chemistry, and engineering has been identified as some of the primary reasons for the consistent evolution of biomaterials. The first generation biomaterials were developed to combine the functional features to acceptably meet the tissue’s requirements without any detrimental behavior of the surrounding biological environment. Due to the inertness, materials such as silicone rubber and SS were counted as biocompatible. In comparison, the second generation biomaterials came into existence due to advances in the first generation and were targeted to develop an uninterrupted reaction with the adjacent tissue. Based on the bioactivity of these materials, implants such as drug-eluting endovascular stents were developed. In addition, degradable materials such as polymeric biomaterials were also evolved in that period. Further, the expanding state-of-the-art gave rise to the fabrication of the third generation biomaterials, intending to stimulate the regeneration of functional or living tissues.

4.2 Elemental composition

-

Metals and alloys such as SS, titanium (Ti) and Ti alloys, cobalt (Co) alloys, shape memory alloys, and magnesium (Mg) alloys.

-

Ceramics such as aluminum oxide (Alumina), zirconium oxide (Zirconia), Ti oxide (Titania), bio-glass, carbon (pyrolytic), carbon (graphite), carbon (vitreous), and vitro-ceramic.

-

Polymers such as polyethylene (PE), polyamide (PA), polyetheretherketone (PEEK), polyethylene terephthalate (PET), polymethylmethacrylate (PMMA), polystyrene (PS), polytetrafluorethylene (PTFE), polyurethane (PU), and synthetic rubber.

-

Composites such as carbon-PTFE and alumina-PTFE.

4.3 Host-tissue’s response

-

Bioinert materials have the slightest or little interaction with their neighboring tissues. For example, Ti, Ti alloys, and Zr.

-

Bioactive materials can develop direct chemical bonding with the surrounding bone or even soft tissues in particular cases. For example, Glass–ceramics.

-

Bio-tolerant materials possess fibrous tissue encapsulation at the implant interface. For example, SS and tantalum.

Further, in the last few decades, biomedical implants have been finding an extensive application at different human body locations for the desired purposes. Some notable examples can be easily witnessed in orthopedics, neural prosthetics, pacemakers, and drug delivery systems [13, 14]. Therefore, based on the applications, these implant materials are expected to possess excellent corrosion resistance, surface integrity, mechanical strength, and compatibility with bones and surrounding tissues. Figures 5 and 6 represent different biomedical implants or devices, whereas Fig. 7 displays the X-ray images of various body parts with implanted devices. The durability of an implant largely depends on selecting the input biomaterial [15]. The manufacturing of implants from these biomaterials through potential techniques can directly impact the metallurgical, mechanical, and biocompatibility characteristics [16, 17]. Therefore, selecting a suitable manufacturing technique for a particular biomaterial needs to be predetermined. Moreover, finishing processes such as grinding, or polishing should achieve the desired surface finish (as the surface quality directly influences these implants' mechanical performance) [18].

For instance, orthopedics is demanding biomedical implants, such as highly engineered hip joint prostheses, on a larger scale from the manufacturers. The hip joint prosthesis facilitates smoother mobility and causes less pain inside the body of arthritic patients. The femoral head of such prosthesis should have physical properties such as high surface finish, sufficient resistance towards friction, corrosion, wear, high mechanical strength, and enough compatibility to make the chances of inflammation and rejection null and void.

5 Metallic implant biomaterials and their common behavior

Generally, for load-bearing dental and orthopedic applications (such as bone repair), the biomedical implants, in addition to the satisfactory biocompatibility, need to exhibit high yield, fatigue, tensile, compressive, and shear strength along with sufficient ductility, hardness, and fracture toughness. Therefore, metallic implant biomaterials are superior and more suitable for such applications than the traditional ceramic and polymeric biomaterials. However, the release of ions (from the metallic surface), chemical reaction of a metallic surface with the body enzymes and acids, and high elastic modulus can cause toxicity, oxidative corrosion or galvanic corrosion, and stress shielding (bone resorption), respectively, leading to the implant failure. Consequently, adjacent tissue’s vascularity can deteriorate [28]. Some widely used metallic implant biomaterials and their mechanical properties are displayed in Table 1.

5.1 SS

Stainless-steel (SS) implants are considered to be one of the cheapest and easiest to manufacture medical devices. However, about ten times higher stiffness of SS than human bone often induces bone resorption due to stress shielding. Moreover, the conductive oxides of SS can cause inflammation. Nonetheless, nickel-SSs exhibit superb mechanical properties and ease of work hardening. In the annealed condition, they exhibit higher strength than other conventional SSs in implant manufacturing. This may cause the formation and advancement of more robust and tougher implants, as per the particular patient's need [40].

5.2 Ti-based alloys

Despite the high cost, the biomedical grade titanium (Ti), and its alloys, such as commercially pure titanium (CpTi) and Ti-6Al-4 V alloy, have always been some of the most reliable choices of the users due to their appealing properties such as outstanding biocompatibility, mechanical properties, wear, and corrosion resistance, high strength-to-weight ratio, lower stiffness, and elastic modulus [41]. Titanium is widely used as a competent biomaterial in biomedical implants such as joint replacement, bone plate, screw, pacemaker, and dental implant. Ti and its alloys generally offer a satisfactory osteointegration and configure an adequately rich oxide layer, displaying a remarkable resistance to corrosion [42]. In this series, Ti-6Al-4 V was identified as one of the most useful alloys of titanium [41]. However, there are several issues with Ti and Ti alloys that do not allow their basic form. For instance, the contrast between the composition of Ti alloys and human bone opposes the fiber capsule formation around the implant, leading to the weak chemical bone-bonding amid osseointegration [41].

Additionally, the spontaneous formation of a highly stable, thin, and biocompatible nanoporous layer of titanium oxide enhances titanium alloys’ corrosion resistance and hinders the ions from getting released from the metallic surface into the body [43]. However, in the case of a weak passivation oxide layer, wear, and corrosion properties, the particles, and ions may get released from the Ti-implant and accumulate on the adjacent/host tissue. Subsequently, the problems of inflammation, hypersensitivity, and toxicity can be induced. Also, the almost negligible resorption of titanium implants over time obstructs the diagnostic imaging process, and thus, the visualization of surrounding tissues becomes very difficult [44].

5.3 Co-based alloys

Therefore, to overcome such challenges, the researchers attempted to develop another alternative and its variants, chemically inert and known as cobalt-chrome (Co-Cr) alloys. The implants made up of Co-Cr alloys can also be used in dentistry and orthopedics, just like Ti-alloys. A review stated that the Co-Cr alloy implant rod possessed superior fatigue strength and corrosion resistance to Ti-alloy after posterior spinal arthrodesis. However, Co-Cr alloy implants with high nickel content may cause allergy and exhibit low biocompatibility with the host tissue [43, 45]. F75 (Co–Cr–Mo), F90 (Co–20Cr–15 W–10Ni), F562 (Co–35Ni–20Cr–10Mo), and F1537 (Co–28Cr–6Mo) are some of the widely used variants of Co-based alloys for implant applications.

5.4 NiTi SMAs

In recent years, another alloy comprising an association of approximately equiatomic proportions of nickel and titanium alloys, termed as nickel-titanium (NiTi) shape memory alloy (SMA), has attracted numerous researchers' attention as a result of its shape memory and superelastic characteristics. The NiTi SMA was also termed as “Nitinol” after the U.S. Ni–Ti-Naval Ordnance Laboratory. Nitinol is lightweight and exhibits high strength and corrosion resistance, shape-changing capabilities, no cytotoxicity, and even relatively lower cost than gold-cadmium SMAs [46]. The diffusionless thermal conversions between the austenitic and martensitic phases are primarily responsible for the well-known shape-memory effect of a NiTi SMA (Nitinol). According to Fig. 8 [47], with cooling, the progression from O to A presents the transformation of the predominant austenitic phase, giving rise to martensite start temperature (Ms), into complete martensitic phase (martensite finish temperature (Mf)). Whereas the progression from A to B shows the reorientation and detwinning of the martensitic phase towards the deformation of the material. Further, the progression from B to C displays the elastic-unloading (as soon as the load is lifted) in the reoriented and detwinned martensite, confirming the deformation of Nitinol. However, heating of pure martensitic phase leads to austenite start temperature (As), leading the conversion into complete austenite phase at austenite finish temperature (Af). The reversible and insatiable behavior of this transformation along with martensite's deforming ability with no breaking of inter-atomic bonds, leads Nitinol to come back to its initial state imputed amid its austenitic phase [48]. In the similar manner, the progression from O to E and E to O present the conversion from austenite into martensite through an induced stress and vice versa, respectively. Nitinol displays a substantially lower elastic modulus and stiffness (closer to human bone) before transitioning to the martensitic phase than other Ti-alloys. Moreover, the superelastic properties of Nitinol wire facilitate greater comfort to the patient and lesser bone resorption than SS and Co-Cr wires during the application of continuous force on teeth by the dentist [49]. Also, NiTi stents find application in the reinforcement of blood vessels. The fundamental reasons behind the versatile performance of Nitinol can be principally found in terms of its featherweight, inertness, and shape memory features that are promising for its biomedical applications such as orthodontics and stents [50].

Schematic display of stress–strain-temperature behavior shown by Nitinol [47]

In some previous investigations, Nitinol implants assisted with a faster recovery of bone than SS, Ti, and Co-Cr implants due to its feature of reducing stiffness in the exact proportion of a bone, causing a superior load-bearing in the healing mechanism [46, 51, 52]. However, despite all such excellent features, the high amount of nickel may cause carcinogenic and allergic reactions [53].

5.5 Mg-based alloys

Further, the installation of an implant may be on a long-term or short-term basis. The implants can either replace the missing body part or support the injured ones on a permanent (non-degradable) or temporary (degradable) basis. Heart pacemakers, cardioverter defibrillators, dental devices, spine screws, rods, and disks are examples of non-degradable and degradable implants [2]. A relatively higher value of Young’s modulus of the non-degradable metallic implants, for instance 200 GPa, being highly stiff, can deteriorate fractured bone’s (10–45 GPa) density noticeably [54]. This is the reason why, the non-degradable implants, for example chemotherapy ports, are often detached after a specified timespan. However, the implant’s removal might further involve the endanger of failure and side effects [2]. In this regard, according to Fig. 9, several causes play their roles in implant failure, which increases the chances of revision surgeries. These surgeries are not very successful and cause much discomfort to the patient. An engineered biomedical implant insertion inside the human body causes the implant surface to interact with the blood, fluids, tissues, proteins, and cells, even up to the micro-level. Such interactions may lead to the generation of fiber-like covering around the inserted implant and ascertain the recovery time of the body's damaged tissue or organ. Thus, such unpredictable attributes led the researchers to discover some capable substitutes, that were later recognized as degradable implantable devices, that could avoid the anticipated hazards of post-surgical procedures. Also, the patient gets freed from the tense thought of secondary surgery if it can be avoided by removing the implant. In this series, in terms of superior degradability, Young’s modulus (40–45 GPa), biocompatibility, and density (1.75–18.5 g/cm2), magnesium and its alloys were found to be the better alternatives to the degradable polylactide and polydioxanone and other similar synthetic polymers [55, 56]. Additionally, the alloying of Mg with Ag, Ca, Cu, and Sr results into a relatively faster bone-formation and cell simulation [57]. However, Mg and its alloys are often challenged by their early degradation that can partially heal or recover the damaged bone.

Causes of deterioration of implants compelling for revision surgery [59]

5.6 Bulk metallic glass (BMG)

Besides the abovementioned metallic alloys and crystalline metals, bulk metallic glass (BMG) has also been considered a suitable biomedical implant material due to its favorable toughness, tensile strength, elasticity, low internal friction, and sufficient resistance towards corrosion and wear. However, the absence of crystallinity causes problems in the production of BMG [58].

5.7 Merits, demerits, and applications of metallic implant biomaterials

Further, Table 2 presents some standard merits, demerits, and applications of the primarily or conventionally used metallic implant materials.

6 Basic design considerations for biomedical implants

The basic design procedure of biomedical implants includes considering the biomaterials’ bulk and surface attributes/properties. The bulk attributes comprise the physical and mechanical properties such as crystallinity, thermal transition points, elasticity, strength, ductility, fatigue, and hardness of the biomaterial that are generally dictated by its physicochemical characteristics. The bulk attributes of an implant are displayed throughout its lifetime. The biomaterial can mimic the physicochemical properties of the tissue to be augmented or replaced by altering its bulk attributes.

On the other hand, the surface features of the implant can noticeably affect the host tissue. These surface interactions can accelerate healing and lead to toxicity, inflammation, infection, and tumorigenesis in the host tissue. Moreover, the unfavorable body environment can adversely affect the implant and its performance through many physical–mechanical effects (such as wear, corrosion, fatigue, and stress-induced cracking) and biological effects (such as enzymatic degradation, adsorption of tissue constituents, and calcification), leading to implant failure. Hence, the surface attributes, such as chemical composition, wettability, topography, biocompatibility, corrosion resistance, and cytotoxicity, determine the cell response towards the surface [10]. Therefore, the various ISO (International Organization for Standardization), ASTM (America Society for Testing and Materials), BSI (British Standards Institution), AISI (American Iron and Steel Institute), and BIS (Bureau of Indian Standards) standards are adopted for the regulation purpose while designing and manufacturing the biomedical implants. For instance, ISO 25539–2:2020 is to be considered to examine the overall performance of cardiovascular implants- endovascular devices and the surface preparations including texture/coating, need to chiefly consider ASTM F86-21, ASTM F2791-15, and F-2743–11 standards [69].

Besides, as shown in Fig. 10, the basic procedure of achieving a biomedical implant in its intended application involves several facilitators. It encompasses the study of a biomaterial’s properties, implementing various engineering tools on the biomaterial to process and fabricate a biomedical implant/device, getting the necessary approval from the concerned healthcare agencies, and obtaining permission from the concerned industries for product development and its commercialization.

The facilitators involved in the first step are generally researchers, whereas the second step requires physicians, engineers, and metallurgists/ceramicists/polymer chemists, and machinists. Subsequently, there comes a role of bioengineers and surgeons/physicians in the third step, followed by the approval of regulatory specialties/agencies and legislators. The last step incorporates the role of physicians/dentists/optometrists/pathologists [70].

7 Surface modification of metallic implant biomaterials

As discussed in the previous sections and subsections, the surface of a biomaterial exhibits an inviolable affinity towards a large number and varieties of proteins and thus is prone to attract a plasma protein, mainly albumin, fibrinogen, and fibronectin. However, such a tendency of a biomaterial’s surface can often lead to developing some undesirable alterations, such as an excess adherence of fibrinogen, in the surface attributes of the biomaterial, resulting in denaturation. Therefore, in such cases, the unwanted rise in the degree of neoepitopes exposure following cell and tissue reactions needs to be treated to guard the biomaterial's surface during its anticipated service life for satisfactory performance. Moreover, some processing defects can also adversely affect the surface attributes of the biomaterials, leading to failure. For instance, titanium (Ti) is widely used as a competent biomaterial in medical implants such as joint replacement, bone plate, screw, pacemaker, and dental implant. However, there are several issues with Ti and Ti alloys that do not allow their basic form. The contrast between the composition of Ti alloys and human bone opposes the fiber capsule formation around the implant, leading to the weak chemical bone-bonding amid osseointegration [41].

Moreover, the sub-surface of Ti alloys remains prone to plastic shear and work hardening, which are unfavorable for the desired bone growth. In addition, even if a protective oxide (passive) layer gets formed on the Ti alloy implant surface due to specific chemical reactions, the low adhesive strength of Ti alloys might result in an easy peeling off the protective layer when exposed to substantial loading and human body fluid. Therefore, the unprotected implant surface may liberate the toxic elements from its surface into the body fluid and induce thrombus and inflammation [41, 71]. Also, some processing defects, such as poor machining, may adversely affect these desirable properties of Ti and its alloys and induce poor surface integrity, leading to implant loosening and final failure [72]. Besides, the relative motion between the bone and implant, in addition to the body fluid environment, triggers excess adhesive and abrasive wear, causing an impairment of the protective layer integrated into the implant surface [73].

Therefore, in this regard, “surface modification” of biomaterials is a potential solution to secure the biomaterial’s surface against harmful reactions and elements and improve its existing attributes/properties remarkably. Surface modification can noticeably improve the biomaterial’s/implant’s performance by altering its physical, chemical, mechanical, and biological properties. Moreover, the damaged tissue is more responsive when interacting with a modified implant surface [74]. Additionally, the surface modification of titanium implants results in their considerably improved osteointegration and antibacterial properties [73]. One of the latest articles thematically reviewed the most recent developments in the surface modification of titanium and its alloys via physical and chemical approaches, specifically for biomedical applications. In this relation, Fig. 11 presents various methods used to modify the biomaterials’ surfaces with their respective advantages, disadvantages, and applications. The significant advantages of the various surface modification techniques, such as plasma immersion ion-implantation and deposition, physical-vapor-deposition (PVD), chemical-vapor-deposition (CVD), and micro-arc oxidation (MAO), were discussed in detail. However, the review also revealed some of the main limitations of the techniques mentioned above: poor bonding strength of the coated layer, the unstudied impact of the thermal effect on the modified surface, and considerable toxicity, leading to poor biological performance [73].

Various surface modification methods with their respective advantages, disadvantages, and applications [73]

In this relation, another review systematically presented the recent progress and prospect of biomedical Ti alloys and found equal-channel-angular-extrusion (ECAP), accumulative-roll-bonding (ARB), and friction-stir-processing (FSP) as some of the most significant severe plastic deformation (SPD) tools for the improved bioactivity of Ti alloys in vivo [41].

7.1 Surface modification of metallic implant biomaterials via traditional subtractive manufacturing techniques

Based on some of the outlined negative aspects of the previously mentioned surface modification techniques, the researchers and scientists have realized the pressing need to develop some adequate substitutes or alternatives over the years to improve the surface properties of the biomaterials. In this relation, “subtractive manufacturing” has been proposed as one of the most influential processing methods to achieve a favorable and considerable surface modification on the surface of biomaterial/implant/device primarily via severe plastic deformation (SPD) and development of a passivating layer on the machined surface [75,76,77]. The process economy accompanying a massive output makes subtractive manufacturing or machining techniques such as milling, turning, and drilling the primary choice of the manufacturers. However, the surface defects (such as thermal cracks and corrosion pits) found on the finally produced medical implant can lead to failure or faster degradation under the joint influence of stress and corrosive environment. This gives rise to fatigue cracking and wear at defective sites [78]. Therefore, a manufactured part's functional behavior can be predicted primarily by those attributes that ultimately quantify the surface integrity and the magnitude of manufacturing-induced compressive residual stresses (induced by more mechanical deformation and less thermal influence). These residual stresses are responsible for enhanced surface hardness, leading to improved corrosion features. The physical, mechanical, chemical, and metallurgical aspects can be tailored during a particular manufacturing process of interest. Finally, surface integrity on the implant’s surface can ascertain the probability of its success or failure. A generalized range of typical values of surface roughness expected on biomedical implants or parts is 1.5 to 4 µm [79, 80].

In addition, the physiochemical properties such as topography, wetting behavior, and elemental composition on the topmost layer of an implant surface basically ascertain its effectiveness in a biological setting. Thus, even slight changes in such properties are able to cause considerable variations in the reactivities of the implant as well as the cell at the point of their interaction [81, 82]. However, the topographical features such as surface roughness are mainly responsible for the cells’ response such as osteogenic differentiation of cells, cell growth, and proliferation rates [82, 83]. In this regard, cutting speed, feed rate, cutting tool pressure, and lubrication and their various levels were identified as some of the major machining factors inducing specific topographies on the machined metallic biomaterials [84].

7.1.1 Effect of cutting tool’s properties and lubrication/cooling (lubri-coolant) during machining

Traditional subtractive manufacturing techniques are best defined as subtracting excess material from the workpiece in the form of chips using a sharp-edged cutting tool by applying forces on the workpiece, thus removing the material under suitable manufacturing conditions. The process input variables should be adequately selected to achieve the desired outcomes during the traditional subtractive manufacturing of biomaterials. Figure 12 shows the inclusion of some forming processes and machining techniques, followed by finishing processes, in attaining the prosthesis's metallic components [85].

However, due to undesirable properties such as low thermal conductivity and elastic modulus, chemical reactivity (with a cutting tool), high hot hardness, and flammability, the difficult-to-cut biomaterials exhibit poor machinability, challenging their effective machining [86]. Hence, to deal with the issue, several latest investigations optimizing machining input variables, researching chip-morphology, evaluating vibration and forces at the tool-biomaterial interface, studying the impact and behavior of cryogenically treated (cryo-treated) cutting tool, applying various types of cooling techniques were included and elaborated by a review based on Ti alloys [87]. The survey of the recent literature indicated the application of non-coated and coated cutting tools, which also play an important role [88, 89]. Moreover, cutting tools with coating such as AlTiN, TiAlN, AlCrN, TiAlSiN, and NbN and without coating were also used in some recent studies [89,90,91,92]. Besides, the applications of cryogenics as a treatment medium to enhance the existing properties (such as mechanical, chemical, metallurgical, thermal, and electrical) of uncoated as well as coated cutting tools and as a cooling agent amid machining of difficult to machine Ti alloys, were elucidated by several recent articles [92,93,94,95]. In addition, the wear properties of the carbide cutting tools were significantly improved as a result of cryogenic treatment that led a uniform spread of carbides [96,97,98,99]. Further, as highlighted by one of the latest reviews, cutting tools with textured surfaces are some leading tribological research fronts, improving the ease of machining. Since a considerable number of metallic biomaterials fall in the category of difficult-to-machine materials, the variation in tool texture’s features such as width, depth, and density, may lead to remarkable enhancements in chip-formation, cutting force, generated heat, lubri-cooling action, surface finish quality, and consequently, tool life. The textures comprising linear-grooves and dimple-geometries (obtained by laser ablation) were identified as the most competent textures [100]. However, so far, the literature has reported the use of textured cutting tools only with Ti-based biomaterials [101]. Two recent articles presented the effective use of micro-textured tungsten and cemented carbide cutting tools with MO disulfide + SAE 40 oil and ZJ846 lubri-coolants, respectively, against Ti-6Al-4 V alloy. In both the studies, a notable improvement in cutting force, surface roughness, chip-morphology, and tool life were witnessed [102]. Besides this, the exceptionally excellent cutting abilities of the advanced cutting tool materials such as cermet, polycrystalline cubic boron nitride (PCBN), ceramic, and polycrystalline diamond (PCD), are nowadays popularly known in the manufacturing community. As demonstrated by several studies, stainless steel and Ti-6Al-4 V alloy were quite easily machined with PCBN [103,104,105,106,107], PCD [105, 107,108,109] with enhanced cutting force, chip-behavior, tool safety, and surface quality. However, the ultra-high hardness (around 10,000 HV) of these cutting tools always challenges their manufacturing techniques [110]. In this regard, traditional abrasive-grinding and non-traditional electric discharge grinding (EDG) were identified as two effective methods to develop such ultra-hard cutting tools. EDG, being the variant of a conventional electric discharge machining (EDM) technique, erodes the excess material from the facial cutting tool such as PCD [111] and PCBN [112], via unceasing and repeated sparks generally with the assistance of a rotary copper-nickel alloy wheel (electrode). The rotary electrode simultaneously channelizes the dielectric into the space between electrode and workpiece and expels the debris from the same [109]. This leads to obtain an increased material removal and reduced wear and short-circuiting (by decreasing the probability of arcing and non-uniform sparking) [113]. Moreover, an EDG process achieves a superior material subtraction (up to 400 mm3/min) to a traditional abrasive-grinding process [111]. A study revealed that the wheel rotation could notably influence the heat affected layer, surface finish, and edge-undercut [113].

Further, an immense use of cryogenic cooling strategies, noticeably decreasing the machining temperatures (developed due to the cutting tool and workpiece surface interaction), was witnessed by the past couple of decades. However, the heat removal capacity and produced surface finish are determined using the direction and approach angle of the cryo-lubri-coolant. The cryo-lubri-coolant might hit the cutting tool-chip interface or cutting tool flank-workpiece interface [114]. Figure 13 diagrammatically shows a cryogenic machining-system with several components when a Ti-6Al-4 V alloy was being turned [115].

Schematic display of cryogenic machining system [115]

An improved heat-transfer (forty-notch higher) and cooling rate (up to 8 °C/ms) was witnessed as the gas was eliminated in the released jet (found in the sub-cooled boiling zone) comprising partial liquid-phase/drops at the exit of nozzle and with approximately 50% liquid when arrives at the target [116,117,118]. Moreover, the cryo-lubri-coolants displayed higher dynamic viscosity and specific heat in their liquid phase than gaseous phase [119, 120]. In addition, the heat-transfer coefficients with numeric values as 20,000 W/m2K, 2000 W/m2K, and 20 W/m2K were noticed during the cutting of Ti-6Al-4 V alloy using cryo-lubri-coolant, dry compressed air, and free convection, respectively [114]. Also, being environment-friendly, health-friendly, and cost-effective, the cryo-lubri-coolant-assisted machining is identified as sustainable manufacturing [121]. Further, the machining of Ti alloys was reviewed in detail that consisted of application of several cooling strategies. It was found that conventional cutting fluid did reduce the formation of burrs and built-up edge (BUE) but ended up with chipping and flank wear of the cutting tool. Therefore, the application of minimum quantity lubrication (MQL), hybridized MQL + nano-fluids (Al2O3, graphite, and molybdenum disulfide), minimum quantity cooling lubrication (MQCL), cold-water mist jet (CWMJ), cooled air-lubrication, vegetable oil + cooled-air, graphene-doped nanofluid mist-spray cooling, hybridized MQL + graphene nanoparticles and cryogenic machining (using either CO2 or LN2) were enumerated [122]. For example, greater amount of heat transfer and superior surface quality were noticed while TC9 alloy was being turned using CWMJ. Besides, at low cutting speeds and feed rates, a superior performance of MQL was observed over wet, cooled air-lubrication, hybridized vegetable oil + cooled air, and MQCL environments [123] and also shielded the cutting tool coating [124]. In contrast, the hybridized MQL with graphite nanofluids brought more amount of cutting temperatures down than the hybridized Al2O3 and molybdenum disulfide [114, 125]. In addition, cryogenic cooling noticeably dissipated the heat, however, the hybridized MQL + Al2O3 + multi-walled carbon nanotube decreased the cutting forces by 11.8% [126]. Also, graphene’s excellent thermal conductivity in graphene-doped-nanofluid mist spray and its hybrid variant led to notably remove the excess heat [111]. The cryogenic machining again performed better than MQL and its variants in terms of enhanced heat transfer, and cutting tool wear [122, 127].

7.1.2 Some relevant findings amid enhanced traditional machining of metallic implant biomaterials

As outlined by the study, the optimal value of surface roughness (0.9 µm) during turning a selective laser melted (SLMed) 316L SS by cementite carbide-cutting tools (SNMG form) was achieved at 200 m/min cutting speed 0.1 mm/rev feed-rate, and 1.25 mm depth-of-cut. The surface integrity was improved with the rise in cutting speed, as shown in Fig. 14 [128]. However, the same became worse with the rise in depth-of-cut and feed rate. The tensile residual stresses were more affected by cutting speed and feed rate [129].

a Experimental setup, b grain structure, and c melting pool of as-built SLMed part; d porosity noticed on as-built SLMed part, e turned part at 50 m/min cutting-speed, and f turned part at 200 m/min cutting speed [128]

Concerning the subtractive manufacturing of 316L SS, based on recent findings, researchers’ interest is slowly shifting towards hybrid manufacturing (additive followed by subtractive manufacturing). In this regard, the hybrid manufacturing of 316L SS biomedical parts using additive (SLM) followed by subtractive manufacturing (finish turning) resulted in 88% surface roughness reduction. Moreover, the post-turned SLMed surface and subsurface were noticed with substantially reduced porosity density and considerably refined grains and strain-hardened layer [128]. Some latest research stated the significant role of macro and micro-milling in the subtractive processing of 316L SS for biomedical applications. A study of an additive manufactured 316L SS included cutting forces when the feed direction changed concerning the layer inclination. The resulting melt borders from the additive manufacturing obstruct the dislocation distortion [130]. Another research reported a considerable impact on the anisotropy of powder bed fusion (PBF) micro-manufactured 316L SS with the alteration in feed direction and surface roughness values. The larger tool diameter (800 µm) achieved improved results [131]. In the case of SS, one of the prime complexities in machining SS is that it characteristically produces high cutting temperatures, which results in the depletion of part life and weakening of the workpiece’s surface properties. Moreover, the traditional cooling methods are ineffectual in restraining these critical issues of quick tool wear and high cutting temperature. In a comparative investigation of wet and cryogenic turning, the results came out to favor cryogenic cooling when 44–51% reduction in cutting temperature, 16% reduction in cutting force, and 22–34% reduction in surface roughness were recorded [132].

Besides, titanium and its alloys are other categories of metallic implant biomaterials challenging to be machined. The premier obstacles in machining this material are the elevated cutting temperatures and instant tool deterioration at the machining time. Undeniably, several tool materials express instant wear and tear even when operated at adequate cutting speed. In the present scenario, the machining practice is cutting speed is reduced to less than 1 m/s so that the tool deterioration may be minimized. A single layer coating of Al2O3 is preferred due to its lower thermal conductivity than a tungsten carbide insert. This layer avoids heat dissipation from the intense temperature and stress at the cutting point. There are other options for machining titanium alloys, such as carbide and nitride, yet they are not employed due to their chemical resemblance. Therefore, the cryogenic machining practice is employed for its twofold excellence in enriching chemical stability and reducing the cutting temperature while machining hard-to-machine metallic biomaterials. This practice is effective enough to increase the efficiency of titanium machining [133].

Further, it was depicted that cryogenic machining was the alternative to dry and flood machining of Ti-6Al-7Nb, resulting in an improved surface finish to be used as biocompatible medical implants [77]. It was also realized that the machined surface degraded because of adhesion formed as a product of dry machining and softening of the constructed surface due to the rapid rise in penetrating temperature. Due to some slight variations between dry and flood-cooled machining in terms of micro-level firmness of the surface and its underlying area, the best surface roughness was noticed in the case of cryogenic machining, which was 35% better than dry and 6% than flood-cooled machining as a result of SPD (as illustrated in Fig. 15).

a Cryogenic turning setup. Microstructure of surface and subsurface amid b cryogenic, c flood cooled, and d dry turning [77]

Sun et al. [134] discussed the ramification of cryogenic compressed air cooling on the tool wear and the subsequent progression of cutting forces amid the turning of Ti-6Al-4 V alloy using two different speeds. A carbide insert (CNMX1204A2-SMH13A) was used to conduct the process of turning at an approach angle of 45°, the rake angle of +15°, the effective rake angle of +9°, and inclination of −6°. Due to the dimensions of the built-up edge, chip and flank wear were reduced significantly by the cutting forces at more values of cutting speed. Therefore, cryogenic compressed air cooling was comparatively found better. Orthogonal cutting of Ti-6Al-4 V alloy having a more effective feed rate (0.1–0.25 mm) at high speed was examined in terms of the dynamics and generation of chip geometry. Implants were manufactured through turning with the help of a displaceable cutting plate made of coated cemented carbide. It was concluded that depth of cut and chip design play essential roles in mainly turning hard metallic biomaterials. A recent study on the dry turning of biomedical Ti-6Al-4 V-ELI with SNMA120408 uncoated inserts via experimentation and finite element modeling obtained phenomenal results. In Fig. 16, the SEM micrographs demonstrated the major fractures leading to chipping segment generation and the plastic flow of the workpiece surface via observed feed marks on the turned samples. Moreover, the subsurface analysis revealed that the substantial microstructural changes occurred due to the differently produced high heat energies with variation in cutting speed [135].

a Major fractures leading to chipping segment generation. Machining induced imperfections on biomedical Ti-6Al-4 V-ELI surface at b 65 m/min, c 112 m/min, and d 124 m/min cutting speed [135]

In a study on ultrasonic assisted-drilling of Ti-6Al-4 V, Pujana et al. [136] observed a 10–20% reduction in feed force. However, the drill bit experienced a higher temperature than the conventional drilling setup. Figure 17 presents the thermograms of the observations without and with the assistance of ultrasonic vibrations.

Drill thermograms a without and b with ultrasonic assistance while entering into the Ti-6Al-4 V specimen. Drill thermograms c without and d with ultrasonic assistance while exiting the Ti-6Al-4 V specimen. Chip generation e without and f with ultrasonic assistance [136]

Further, in the case of cobalt alloys, it was reported by Yang et al. [75] that under both conditions, either dry or cryogenic, when the refinement of grains occurs in the surface layer of Co-Cr–Mo (ASTM F75 cast alloy), the respective microstructures also change (Fig. 18). Also, on the surface, which was cryogenically burnished, a noteworthy increment in the relative intensity was achieved, which could considerably improve the erode defiance of Co-Cr–Mo alloy presents burnishing (with the assistance of liquid nitrogen and burnishing tool) and Co-Cr–Mo alloy properties. Another study conducted by Ferreira et al. [137] milled the Co-28Cr-6Mo alloys at varying speeds to observe the changes in the thermal gradients, roughness, cutting forces, and hardness. The results endorsed a high impact of higher cutting speeds on the response outcome.

Besides, Nitinol SMAs possess some unique traits such as the transformation of phase, shape memory, and superelasticity, through which they are significantly employed in various industries. An experimental study conducted by Kaynak et al. [138] examined several dry and cryogenic machining considerations, named quality and roughness of surface, topography, phase transformation, and microstructure of induced surface integrity in SMA’s machining. The study concluded that the machined components’ surface eminence was significantly enriched in cryogenic machining compared to dry machining. Figure 19 presents the cryo-turning view and SEM micrographs of dry and cryo-turned surfaces. In cryo-turned specimen, relatively higher temperatures and broader peaks were observed when matched with the specimen undergoing dry machining (during the transformation from martensite to austenite). This result gestures that the influence of cryogenic machining is denser on the surface principal aspects of SMAs because high disconnection density and residual stresses are introduced on their surfaces and sub-surfaces, as shown in Fig. 19.

a Cryo-turning; SEM micrograph of surface and sub-surface of the turned surface of NiTi alloy during b dry and c cryo-turning [139]

Kaynak et al. [140] focused on turning NiTi alloy under dry, preheated, and cryogenic conditions and highlighted the influence of cryo-turning on phase state and transformation, which was evident in the form of broader peaks and 29% bigger austenite finish transformation temperature at high cutting speed. However, the total conversion of martensite to austenite took place in dry turning at each speed. In Fig. 20, the broader peaks and higher transformation temperature are easily noticeable in cryo-turned samples than other turned samples. Moreover, the variation in peak and transformation nature with a change in cutting speed is also clearly visible, as shown in Fig. 20.

DSC plots show machining operations’ nature under varying heat flow, temperature, and cutting speed [140]

Further, when considering magnesium and its alloys as the potential degradable metallic implant biomaterials, corrosion resistance is one of the prime documented aspects that need to be dealt with since the manufactured part/component has to deal with the human body. In addition, during Mg alloy implants’ subtractive manufacturing, another common challenge that the manufacturers face is their low melting point. Therefore, there are chances of ignition or even explosion as soon as the machining zone temperature reaches around 450 °C [141]. Moreover, not every coolant can be used during magnesium’s machining and its alloys to reduce this temperature since some can unexpectedly react and cause explosions by forming gases such as hydrogen [142]. Hence, the traditional subtractive manufacturing of Mg and its alloys is preferred under specific cooling environments. In this regard, cryogenic machining simplified the complexities of corrosion and ignition in some recent literature [143,144,145]. Danish et al. [146] conducted a simulated and comparative study on cryogenic assisted and dry turning of Mg alloy AZ31. They demonstrated the efficient and faster elimination of generated heat (up to 60%), followed by a decrease in surface roughness (by 56%) amid cryogenic-turning. Figure 21 shows the experimental setup and some findings. In similar studies performed by Bertolini et al. [147] and Davis and Singh [148] on Mg alloy AZ31B and AZ91D, respectively, comprising low-temperature sustainable lubrication/cooling, in addition to superior surface integrity, the cryogenically turned/milled surfaces were also noticed with a featureless layer, suggesting improved passivation against corrosion of that surface. The authors found that the enhanced cooling improved the surface roughness up to 48.07% and generated a more uniform passivation layer.

(i) Cryogenic turning setup, (ii) cryogenic turning, (iii) thermal images, and (iv) simulated results of temperature distribution amid turning of Mg alloy AZ31 [146]

Davis and Singh [149] used three different milling environments (wet, cryogenic, and hybrid) and the end mill tool in the untreated and cryo-treated form to mill Mg alloy AZ31B to improve its surface integrity. The findings improved surface integrity at the high-speed using cryo-treated end mill amid hybrid (wet + cryogenic) cooling. Figure 22 shows the different milling environments, obtained featureless oxide passivation layer on the surface hybrid-milled by cryo-treated end mill, energy-dispersive X-ray spectroscopy (EDS) showing the elements present on the finally manufactured surface, and the worn-out end mill cutting edges. Hybrid milling improved the end mill life, contributing to surface integrity enhancement. In continuation, the latest research performed by Davis et al. [150] machined Ti-6Al-4 V alloy also used the combination of the cryo-treated carbide end mill and different lubri-cooling environments and consequently achieved improved surface characteristics including morphology, chemistry, roughness, and microhardness. Moreover, the best achievement of this research was the observation reporting a remarkably improved in vitro cell proliferation and growth on the hybrid-lube-coolant-machined surface. In this regard, Fig. 23 compares and displays the modified surface with CpTi alloy and demonstrates the enhanced cell response after 4 and 7 days on the machined surface with the superior performance of the end milling.

(i) Schematic diagram of three different milling environments of machining Mg alloy AZ31B, (ii) SEM demonstration of the featureless oxide layer on the surface hybrid-milled (wet + cryo) by cryo-treated end mill, (iii) EDS and SEM image of the surface hybrid-milled by cryo-treated end mill, and (iv) SEM images displaying tool wear in both the end mills [149]

Fluorescence (stained with DAPI (blue)) and SEM images are presenting ADSCs after 4 and 7 days of cell culture on CpTi and hybrid-lubri-coolant-milled surfaces (obtained with cryo-treated end mill) [150]

7.1.3 A rigorous chronological survey on the strategies used to modify the metallic implant biomaterials using traditional machining techniques

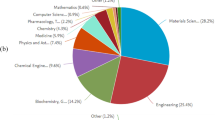

This section presents an elaborated review focused on some significant attempts made in the last 20 years (in chronological order) to achieve surface modification on metallic implant biomaterials via traditional machining approaches. In this regard, Table 3 and Fig. 24 demonstrate the primary approaches (in terms of lubrication/cooling and cutting tool) adopted to modify the metallic implant biomaterials via traditional machining techniques substantially. The significant findings have been pointed. However, only a few studies report an improvement in the biological behaviors of the traditionally machined workpiece biomaterials. Based on the findings observed in the previous literature recorded in Table 3 and graphical analysis of Fig. 24, the chiefly used metallic implant biomaterials for biomedical implant applications and manufactured by traditional subtractive manufacturing techniques were Ti-based alloys, followed by NiTi-based, Mg-based, SS, and Co-Cr-based alloys. However, a tremendously increasing trend in using NiTi-based and Mg-based alloys as implant biomaterial could be witnessed easily in the last ten years in Table 3. Moreover, according to Fig. 24, the low-temperature sustainable approach of cryogenic machining has appeared with its dominant use over the conventionally used cutting fluids.

In addition, a slow but notable rise in the incorporation of hybrid lubrication/cooling (lubri-cooling) methods could also be observed, indicating the increasing scope of the same in the days to come. Hence, some of the main merits/applications, demerits, challenges, and possible solutions amid the traditional machining of Mg, NiTi, and Ti-based metallic implant biomaterials, can be further elucidated with the help of Table 4.

7.2 Surface modification of metallic implant biomaterials via non-traditional subtractive manufacturing techniques

Besides high toughness and strength, some of the significant challenges in the traditional machining of metallic implant biomaterials lie in the extreme sensitivity of these materials such as Mg (due to high flammability), NiTi (due to susceptibility to the temperature-induced transition of phase), and Ti-based alloys (due to high hardness) towards cutting-induced temperature variations, high strain-rate, and consequent phase transformations [54, 135, 176]. In this regard, the advanced manufacturing processes constituting the non-traditional subtractive manufacturing techniques such as laser machining (LM), waterjet machining (WJM), and electric discharge machining (EDM) are the potential alternatives for effective machining of Nitinol [177, 178]. The non-traditional subtractive manufacturing techniques subtract unwanted and surplus material by different electrical, chemical, mechanical, thermal, or combinations of these energies without applying the cutting tools used in traditional machining techniques. Following are some commonly employed non-traditional machining techniques to modify the metallic implant biomaterials’ surfaces for implant applications.

7.2.1 AWJM technique

Abrasive water jet machining (AWJM) is a cold processing technique that comprises efficient shaping tools and fulfils the necessities of material removal structuring for metallic implant biomaterials. Silica sand, garnet, silicon carbide, and aluminum oxide commonly use abrasive particles in AWJM. The AWJM favors high flexibility with a relatively sensitive material removal rate, amicability with the ambient conditions, and exhibits inexpensive and high machining adaptability. In this type of subtractive manufacturing, the ultra-high pressurized water is forced through a very tiny opening, generating a high speed (800 m/s) water flow [179]. The inclusion of abrasive particles in this high-speed water flow raises the standard of machining capability considerably. In this relation, a review revealed the versatility of AWJ on all the commonly used metallic implant biomaterials, including stainless steel, Ti-based, Co-based, NiTi, and Mg-based alloys [180]. Also, an experimental study achieved enhanced fatigue life, compressive residual stress, and surface finish after AWJ assisted peening in the orthopedic application of stainless steel 304 and Ti-6Al-4 V alloy.

Moreover, a recent investigation on AWJ-milling on stainless steel 304 was carried out to produce an implant rough spot groove surface pattern [181]. In another study, the surface roughness and irregularities improved using artificial neural networks amid AWJM of Mg alloy AZ91D. Abrasive flow rate and jet feed-velocity primarily affected the surface characteristics [182].

Further, abrasive water jet machining at micro-level (µ-AWJM) using #220 to #320 abrasive mesh size is a recent state-of-the-art subtractive micro-manufacturing technique. Unlike many other thermally manufactured products, the µ-AWJMed products not only exhibit a high degree of surface integrity and profile geometry, but they are also free from stresses and heat-affected zone(s), which can further improve the functionality of metallic implants. µ-AWJM consumes lesser processing time than many other micro-subtractive manufacturing processes, such as micro-electric discharge machining (µEDM). However, it consumes more time than macro-AWJM and µ-AWJM set up developed by M/s. OMAX corporation can miniaturize the products in the domain of 200 to 300 µm with the aid of a nozzle with a tiny diameter (< 200 µm) [183]. Figure 25 demonstrates the schematic diagrams of two different AWJ setups and µ-AWJMed orthopedic implants. One recent research conducted on µ-AWJM of Co-Cr–Mo to produce micro-channels concluded µ-AWJM as one of the most potential and promising techniques for the tribological surface texturing of artificial joints. Figure 26 shows some essential technical details of the strategic parameters and desired outcome, followed by the achieved findings [184].

(a) Injection and (b) suspension type of AWJ; (c) orthopedic implants made up of titanium alloys and stainless steel [185]

Experimental plan and outcome [184]

Since AWJM is known for inducing imperceptible temperature variation in the produced parts, NiTi alloys’ mechanical and metallurgical responses drastically change even with a slight change in the phase transition. Therefore, it became essential to validate the influence of AWJM on the phase transition of NiTi alloys. In this relation, a comparative experimental work included water jet machining (WJM) of Ni49.8Ti50.2 with and without garnet abrasive particles of #80 mesh size. Figure 27 presents a phase transformation diagram, SEM image of one of the surfaces exhibiting martensitic transformation, and finally achieved improved results. The joint evaluation of operating temperatures (of the two WJM processes) and NiTi alloys' phase transformation temperatures revealed a significant AWJM approach for controlled-depth milling. The application of high-speed abrasives on a particular spot could raise the localized temperature above 86 °C (As), leading to the transformation of martensite into austenite. However, the temperature beyond Af (110 °C) reversed (pseudoelasticity) due to stress-induced transformation. The literature does not report much research on AWJM of NiTi alloys since its most effective variant AWJ-milling loses the surface quality due to grit embedment with increasing penetration depth, which weakens fatigue strength in Ti alloys [186].

a Phase diagram and stress–strain curve, b transformed martensite on AWJ-milled surface, and c AWJ-milled actual and simulated results with improved surface finish [186]

7.2.2 LBM

The last four decades have recorded industrial subtractive manufacturing via laser beam machining (LBM) as one of the most dominating non-traditional material subtraction processes for achieving complex geometrical features on the product. However, some investigations on LBM of biocompatible Ti-6Al-4 V and 316L stainless steel revealed that the laser beam's unwanted and undesired convergence and divergence, especially during low-power application fiber laser, resulted in the formation of large kerf taper. Moreover, cracks and a rise in the grain size (present in the heat-affected zone) were reported [187, 188]. Therefore, such failures in machining metallic implant materials can limit their implant applications seeking tight dimensional fit. Hence, in this relation, attempts were made in an experimental work where a 50-W fiber laser was used to machine 316 L stainless steel to apply an additional process variable, known as cutting wedge angle. The increase in cutting wedge angle widens the kerf and reveals the kerf taper. Hence, by obtaining optimum settings of all the process variables, the most crucial cutting wedge angle, 316 stainless steel, could be machined with high dimensional accuracy [189].

Additionally, recent research on laser (Q-switched Nd: YAG pulsed laser) milling could decrease the surface roughness of micro-impressions (with slot depth of 12 µm) of Ti-6Al-4 V from 6.38 µm to 0.965 µm (Ra) with a considerable material subtraction with the help of a mathematical model. It was also observed that the finish of laser-milled surfaces got improved at low levels of current intensity (approx. 75–80%) and mid-levels of track displacement (10 μm), layer thickness (2 μm), and scanning speed (300 mm/s) [190]. Besides, in the laser subtractive process, the temperature raised by the laser itself can alter the metallurgical, mechanical, physical properties of the targeted spot on the workpiece and thermally damage the same and accumulate ablated debris if it remains ungovernable. Moreover, such thermal deterioration becomes a prime and pivotal concern in micro-machining. A recent study compared the water and ice-assisted laser micro-machining of Ti-6Al-4 V alloy, keeping the inexpensive, safe, and recyclable water features in mind. Figure 28 shows schematic and SEM images of some of the significant findings. This work’s outcome divulged that the water-assisted laser ablation could achieve the cleaner machined groove with slower laser traverse speed and more passes than the ice-assisted one. However, the gas bubble generation water wave and high refractive index value caused more laser beam dispersion [191].

Laser micromachining of Ti-6Al-4 V using ice and water [191]

In the case of subtractive manufacturing of NiTi alloys via LBM, this machining process can manufacture the mechanical stress-free cardiac stents and fabricate microchannels in the medical implants. Moreover, it can also enhance the osseointegration of orthopedic implants morphologically [192, 193]. However, as a result of high heat application and setting of process variables of LBM, heat affected zone (influencing the strain restoration), hysteresis, high ablation rate, recast layer, and burr formation are some of the significant challenges while machining NiTi alloys using LBM [194, 195]. A previous study reported the micro-cutting on NiTi alloy sheets (350 µm thick) via an Nd:YAG laser (355 nm). The taper angle could be substantially reduced. Another research consisted of pulsed Nd:YAG laser precision cutting of NiTi alloy sheet for biomedical implant application. The influence of LBM process variables on surface integrity and dimensional accuracy was examined. The results revealed the finally achieved kerf width in the range of 150 to 300 µm and a taper angle less than 2°. Moreover, the machined quality was achieved in the range of 10–30 µm [195] presents the images displaying the outcome due to variation in input variables (Fig. 29).

Representation of various cut surfaces under the influence of variation in process variables [195]

Besides, a recent experimental investigation using the response surface method (RSM) and genetic algorithm (GA) found the considerable influence of layer thickness on the taper angle, top-width error (TWE), and spatter thickness during the laser subtractive manufacturing of NiTi microchannel. Besides, scan speed and strategy also substantially affected the output parameters (taper and spatter). Figure 30 presents some of the significant observations via SEM micrographs during the study. Figure 30g displays a 3D bubble chart towards maximizing the output parameters’ objective function. The lower extreme in the solution space projects the optimal solution. 12.5 and 30.8 µm were the minimized optimal taper values and spattered, respectively [196].

SEM micrographs showing the measurement of a TWE and taper and b spatter [196]

7.2.3 USM

Unlike many other non-traditional subtractive manufacturing techniques, ultrasonic machining (USM) is neither a chemical nor a thermal process, and therefore, it brings neither chemical nor metallurgical changes on the machined surface. USM can machine any hard-to-machine material irrespective of its hardness (> 40HRC) and electrical conductivity or insulation properties. The transformation of electrical energy with low frequency into an electrical signal with high frequency is the primary mode of working of USM. Further, the transformed signal is supplied to the transducer, transfiguring the same into mechanical vibrations. The next stage consists of transmitting these vibrations to the tool via an energy-focusing unit. The USM setup also comprises an abrasive slurry (a blend of abrasive particles such as Al2O3 and SiC in oil or water) circulated in the system impinged in the machining zone. The material subtraction occurs through micro-chipping as a result of joint hammering action of tool (subjected to a static load) vibration and abrasive slurry’s (which is between the tool and workpiece) abrasion characteristics [197].

Rotary-USM (RUM) is one of the commonly used variants of USM. A study investigated the effect of various input process variables ultrasonic power, feed rate, and spindle speed primarily on stainless steel's surface integrity amid RUM. The surface finish was noticed with acceptable values at 30% ultrasonic power and lower feed rate and spindle speed. Additionally, the experimental setup consisted of a fiber optic sensing and data acquisition system and a coolant system [198]. As outlined by research on the RUM of Ti-6Al-4 V, unlike feed rate, a rise in ultrasonic power and spindle speed led to a considerable reduction in surface roughness [199] (Fig. 31). Another investigation observed a noticeable influence of slurry concentration and grit size during ultrasonic drilling of Ti-6Al-4 V [200].

RUM setup [199]

7.2.4 EDM

Electric discharge machining (EDM) is often identified as one of the most adequate non-traditional machining processes engaged to machine difficult-to-process metallic biomaterials under tight tolerances [201, 202]. EDM’s working principle is based on spark erosion since it uses electrical energy to generate an electric spark, followed by the removal of excess material. The process involves huge amount of heat induced by the thermal energy. EDM is able to produce refined micro-structures, 3D (three-dimensional) shapes, complex intricacies, reduce cracks and burr formation, and create high tolerances [203, 204].

Among various non-traditional machining approaches, EDM is known for its unique ability to achieve an elemental composition comprising considerable oxides and carbides on the produced surfaces of metallic biomaterials. Such a surface chemistry in addition to improved morphological and topographical features, can be obtained by an EDM possesses. Further, the EDMed surfaces are often detected with enhanced biocompatibility, hardness, and resistance to wear and corrosion [205, 206]. The significance of EDMed biomaterial surface is often observed in the produced nanostructures, favoring enhanced human osteoblastic cell’s biological attachment [207]. A study discovered that the EDMed surface exhibited noticeably improved bone-forming cell response, leading to enhanced cell differentiation and attachment due to the high hydrophilicity of the produced surfaces [208]. Besides the biocompatibility attributes (highlighted in the recent literature), EDM can handle the temperature issues with the Mg alloy workpiece by using the dielectric medium [209]. The significance of electric discharge machining (EDM) was acknowledged in manufacturing the biocompatible surface of nano-structure. Its influence on the human osteoblastic cell’s biological attachment was also mentioned [207]. EDM can generate three-dimensional shapes and complicated geometries and does not require any preparation beforehand. Instead, it can convert the layer to be machined into a layer of oxide and coat considerable carbides of predetermined thicknesses. It improves biocompatibility, provides a more effective means for cell growth, and enhances hardness and thus resistance to wear and corrosion. EDM can be defined as a non-traditional machining technique that works on the principle of spark erosion as it utilizes electrical energy to produce an electric spark and removes the material by immense heat caused by the thermal energy. In an EDM process, the heat flux or thermal energy gets developed due to electrons and ions' interaction with the workpiece and tool surface. An extreme and instantaneous rise in the temperature from 10,000 to 20,000 °C is observed [180]. An intense localized heat flux basically results in material subtraction. In a previous study, the best results for surface roughness amid machining of Ti-6Al-4 V alloy were obtained at the tool electrode's negative polarity [210].