Abstract

The thermolysis of Mongolian coals of different ranks was studied using thermal analysis (TG/DTG). The stepwise decomposition under conditions of programmed heating to 1000°C in an atmosphere of argon was found. The kinetic parameters of pyrolysis were determined based on thermogravimetric analysis with the use of model-fitting (Coats–Redfern) and model-free (Ozawa–Flynn–Wall) calculation methods. Changes in the activation energy with the degree of decomposition of the organic matter of coals of different ranks were established. A kinetic compensation effect was revealed, which was, probably due to the multicomponent composition of coals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Mongolia has significant reserves of coals of different ranks. The possibilities of their technological processing are still poorly understood. In recent years, more and more attention has been paid to the development of technological processing to obtain high-quality and environmentally friendly energy carriers and raw materials for the production of various materials.

A wide range of products, including chemicals, in particular, aromatic hydrocarbons, which are widely used in the production of carbon, polymer, and plastic materials and composites, can be manufactured from coal. At present, the needs of these industries in bi- and polycyclic aromatics are mainly provided by the components of coke tar, a by-product of metallurgical coke production for the needs of ferrous metallurgy.

In recent years, a steady downward trend in the production of coal tar has been observed in most countries due to a reduction in the specific consumption of expensive metallurgical coke. At the same time, the demand for coal tar as a source of aromatic hydrocarbons and quality requirements are constantly increasing. Alternative processes for their production are coal semicoking and thermal dissolution, which make it possible to obtain a wide range of coal-chemical products for both fuel and chemical purposes.

The organic matter of coal (OMC) contains monomeric, oligomeric, and multimeric aromatic and heterocyclic molecules associated with various valence crosslinks and intermolecular interactions into a polymer-like solid of heterogeneous composition and irregular spatial structure. Detailed information on the kinetics of decomposition of the organic matter of coal under the influence of temperature is important for the development of efficient and selective conversion processes because of the complex composition of coals. Thermogravimetric analysis (TGA) in both isothermal and dynamic modes is widely used to study the kinetics of pyrolysis of organic materials [1–3]. A rapid method of dynamic thermogravimetry has become widespread. Methods proposed for the determination of the kinetic parameters of nonisothermal pyrolysis can be divided into model-fitting and model-free or isoconversion methods. With the use of a model-fitting method, it is sufficient to carry out one thermoanalytical measurement (the Freeman–Carroll [4] and Coats–Redfern [5] methods). In the general case, the problem of determining the constants is reduced to the selection and fitting of a mathematical model for the rate of reaction to the experimentally obtained kinetic curve or its individual sections. Model-free methods for calculating kinetic parameters (the Kissinger [6], Kissinger–Akahira–Sunoze [7], and Ozawa–Flynn–Wall [8, 9] methods) require the construction of kinetic curves at different heating rates. Their undoubted advantage is the possibility of determining kinetic characteristics for each degree of conversion of a substance, that is, for different stages of decomposition.

Mathematical models used to determine the kinetic characteristics of the destruction of polymers, as applied to the pyrolysis of coals, cause certain difficulties due to their complex structure and a wide variety of types of chemical bonds and simultaneously occurring reactions [1–3, 10]. Therefore, the development of recommendations for the selection and development of an adequate kinetic model of pyrolysis and the formation of a unified database of kinetic characteristics is an important research task.

The purpose of this work was to study Mongolian coals of different ranks by thermal analysis and to determine the kinetic parameters of thermolysis using model-fitting (Coats–Redfern) and model-free (Ozawa–Flynn–Wall) mathematical methods.

EXPERIMENTAL

Two samples of brown coal and two samples of coal were taken from coal deposits (Baganuur, Shive Ovoo, Nariin Sukhait, and Tavantolgoi) in Mongolia for this study. The samples used in the experiments were ground (particle size, <0.2 mm) and dried in a vacuum oven. The moisture content, ash content, volatile matter content, and vitrinite reflectance were determined using standard procedures. Elemental analysis was performed on a FlashEATM 1112 analyzer.

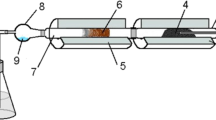

Thermogravimetric analysis was carried in corundum crucibles using an STA 449 F1 Jupiter instrument (NETZSCH, Germany) in a temperature range from 30 to 1000°C in a flow of argon (the flow rates of shielding and purge gases were 20 and 50 mL/min, respectively). The results of the measurement were processed using the NETZSCH. Proteus Thermal Analysis 5.1.0 software package supplied with the instrument. Kinetic characteristics were determined based on the TG data obtained at three different heating rates of 5, 10, and 20 K/min.

The kinetic processing of the results of the TG/DTG analysis was carried out using two methods for calculating the kinetic parameters: the model-fitting Coats–Redfern (CR) method and the model-free Ozawa–Flynn–Wall (OFW) method. The above methods for the calculation of kinetic parameters were used previously to study the kinetics of thermal decomposition of lignins [11] and brown coals [12].

RESULTS AND DISCUSSION

Characteristics of coals. Table 1 summarizes the characteristics of proximate analysis and the elemental composition of the coals used.

The coals had low sulfur and nitrogen content. The oxygen and carbon contents ranged from 22.4 to 5.4 and from 70.9 to 87.8%, respectively, depending on the type of coal; therefore, the coals were of different ranks.

The coals were of the vitrinite type with a vitrinite content of >80%. The vitrinite reflectance varied from 0.41 for coal B to 1.12% for coal T to reflect an increase in the concentration of polyaromatic fragments in the above series of coals and the degree of their metamorphism. The samples of coals B and S were noncaking, and coals N and T had caking properties with plastic layer thicknesses of 10 and 18 mm, respectively.

TG/DTG data. Figure 1 shows the thermogravimetric (TG) and differential thermogravimetric (DTG) analysis curves as the temperature dependence of weight loss and the rate of weight loss, respectively. Based on an analysis of the curves, we can recognize the following three main temperature stages of coal decomposition, which are given in Table 2:

(1) The first stage of the thermolysis of coals B and S was characterized by the removal of moisture and occluded gases in temperature ranges of 30–239 and 30–254°С, respectively, with a weight loss of 6.9%. Coals N and T were relatively stable in the above temperature range.

(2) The second stage corresponded to the active decomposition of the organic matter of coal with a high rate of release of volatile substances. At this stage, the main weight loss from 18.4% (for coal T) to 31.4% (for coal B) occurred. The maximum temperatures of the main decomposition shifted from 440°С for brown coals to 527°С for coal T (i.e., by 87°С) with the degree of coalification (Table 2); this fact indicated a significant decrease in the reactivity of coals in the course of thermal destruction in the above series.

(3) The third stage of thermolysis wais characterized by slow processes of further decomposition of organic substances. Low-rank noncoking coals B and S underwent deeper destruction than hard coals N and T, and the coke residue for coal B decreased to 55.0%, versus 74.7% for coal T.

Kinetic study. The thermogravimetric analysis data were used to calculate the kinetic parameters of thermal decomposition. The calculation of the main kinetic parameters of the release of volatile compounds was carried out using the following two methods: the model-fitting Coats–Redfern (CR) and model-free Ozawa–Flynn–Wall (OFW) methods. The reactivity of a substance can be characterized by the activation energy. The use of different kinetic approaches implies the acquisition of more substantiated activation energies and other kinetic parameters.

The determination of activation energy was based on the following generalized expression for the rate of solid-phase reaction under nonisothermal conditions:

where A is the preexponential factor (s–1), β is the heating rate (K/min), Eа is the activation energy (J/mol), R is the universal gas constant (J mol–1 K–1), Т is temperature (K), and f(α) is the mathematical model of a dimensionless kinetic function, which depends on the type and mechanism of the reaction. The quantity α in Eq. (1) is the relative degree of coal conversion, which is defined as α = \(\frac{{{{m}_{s}} - m}}{{{{m}_{s}} - {{m}_{f}}}}\), where ms and mf are the initial and final weights of a substance, and m is the weight of the substance at the point of measurement.

Coats–Redfern method. The basic equation is

where g(α) is the integral form of the function f(α) (see Eq. (1)).

The graphical representation of Eq. (2) for the determination of the kinetic parameters of thermogravimetric curves of a first-order reaction uses the following equation:

where the quantity \(~\ln \left[ { - \frac{{\ln (1 - \alpha )}}{{{{T}^{2}}}}} \right]\) is a linear function of 1/T. The activation energy is determined by the slope of the obtained straight lines. The applicability of a chosen model is estimated by the square of the correlation coefficient.

From the results of calculations given in Table 3, it follows that the activation energies of coals B and S continuously increased from 50 to 203 and from 75 to 210 kJ/mol, respectively, with the degree of conversion.

A decrease in the activation energy of coals N and T was observed after reaching α = 0.353 (462°C) and 0.378 (479°C), respectively. The temperature range characterized by a decreased activation energy for coal N was smaller than that for coal T by a factor of approximately 2.

Ozawa–Flynn–Wall method. The OFW method is based on the assumption that the reaction rate at a constant value of α depends only on temperature. In an analysis of nonisothermal kinetics, the following equation is used:

The ratio of the logarithm of the heating rate (ln β) to the reciprocal temperature (1/T) is represented by a straight line with a slope of –1.052Ea/R.

The data in Table 4 demonstrate changes in Еа in ranges from 33 to 350 (for coal B), 30–386 (for S), 119–398 (for N), and 126–475 (for T) kJ/mol and in the frequency factor (ln A) in ranges from 0.8 to 37.8, 5.7–41.5, 17.7–48.1, and 20.4–52.7 s–1, respectively.

The calculated values showed a high correlation coefficient (R2 ≥ 0.997) and good agreement with experimental data. Significant changes in the activation energy in the course of pyrolysis indicated a change in the rate-limiting stages of the reactions due to the multicomponent and polyfunctional composition of coals. The found values fall within a range reported by Solomon et al. [13].

Figure 2 shows the calculated values of Ea as a function of the degree of thermal decomposition of coal α. It can be seen that the initial stages of the thermal decomposition of brown coals B and S proceeded with low activation energies, which can be due to the primary cleavage of the weakest oxygen-containing bonds in coals. The further decomposition of organic matter with the release of volatile substances with increasing temperature proceeded with ever higher activation energy; that is, the thermally more and more stable molecular fragments were involved in the destruction process.

The thermal decomposition of hard coals (N and T) was described by more complex kinetic curves. The initial stages of destruction proceeded with a higher activation energy than that in the case of brown coals. This can be due to the fact that hard coals contained a significantly smaller amount of oxygen, and stronger aliphatic C–C bonds underwent destruction already at the initial stage. As the temperature was increased, increasingly stronger bonds, including bridging crosslinks between aromatic fragments, were degraded. The subsequent stage of decomposition proceeded with a reduced activation energy. In the decomposition of coals T and N, this stage began after reaching α = 0.4 and 0.2, respectively.

An explanation of the kinetics of thermolysis of hard coal in comparison with that of brown coal can be related to the fact that the decomposition of the organic matter of hard coal leads to the formation of a significant amount of polycondensed aromatic molecules and oligomers. These latter, due to their low volatility, form a liquid plastic mass together with the molten bitumen contained in the original coal, in which decomposed solid coal particles are dispersed. When the thermolysis occurred in the liquid phase, the competing processes of polycondensation with the nucleation and development of semicoke as a new solid product significantly intensified. At each moment of the reaction, decomposing coal, a liquid phase undergoing changes, and a new solid phase formed coexist in the plastic mass of coal. The process of destruction, which proceeded with an increased activation energy, prevailed at the initial stage of the thermal decomposition of OMC. As the plastic mass was accumulated and the reaction passed into the liquid phase, the competing polycondensation processes, which are usually exothermic [13] and proceed with low activation energies, significantly intensified.

The temperature range of the existence of a plastic state is different for coals of different stages of metamorphism. According to Fedorova et al. [14], Tavantolgoi coal began to soften at a temperature of 429°C and the solidification of the plastic mass occurred at 499°C, which is consistent with a temperature range of the stage of thermolysis with a decreased activation energy. As judged from the dynamics of the activation energy of lower rank coal N, this range was almost two times smaller for this coal. After the solidification of the plastic mass, coal particles became agglomerated in the resulting semicoke structure. As the temperature was increased, the subsequent thermolysis reactions occurred in the solid phase with increased activation energies, as in the case of the solid-phase decomposition of brown coals.

The stage of the thermal decomposition of coal in the temperature range of the plastic state and the nucleation of a new solid phase with a decreased activation energy can also be caused by the effect of diffusion of liquid polycondensed aromatic molecules from the bulk of the agglomerated coal particles on their release into the gas phase.

Note that each of the methods used for the determination of activation energy separately does not always give completely satisfactory results. The main reason for this is the use of various approximations and assumptions in an effort to simplify the model for calculating the main kinetic parameters. In this regard, the use of several approaches to determine the activation energy of coal thermolysis affords more reliable quantitative results. A comparison between the results of calculations of the activation energies of coal pyrolysis performed by the CR and OFW methods (Tables 3 and 4, respectively) showed that, at approximately the same conversions, the CR activation energies were 20–30% lower than the values obtained by the OFW method; in this case, the square of the correlation coefficient was also lower. In addition, unsatisfactory kinetic solutions obtained with the use of model-fitting methods were noted in a number of publications [15, 16]. At the same time, both of the methods revealed a decrease in the apparent activation energies in the range of average temperatures for caking coals. The high correlation of the experimental data (R2 ≥ 0.997) obtained by the OFW method allowed us to state the applicability of the proposed model-free methods to the evaluation of the kinetics of pyrolysis of coals under the selected conditions.

A correlation between the activation energy and the preexponential factor calculated by the OFW method was found. Figure 3 shows that this dependence for all coals is described by a linear regression equation of the form ln A = a + bE, where a and b are experimental constants. Table 5 summarizes the numerical values of the constants a and b, which were obtained by processing the data by the least-squares method, and the corresponding correlation coefficients.

The derived relations with high correlation coefficients reflect the manifestation of a kinetic compensation effect, which can be associated with different concentrations of certain molecular groups in coals and with different activation energies of their thermal decomposition.

CONCLUSIONS

Data on the composition and thermal properties of coal samples of various degrees of coalification from Mongolian deposits were obtained. The dynamics of decomposition of organic matter was studied by thermal analysis in a dynamic mode at different heating rates.

Based on the TG/DTG analysis data, the apparent activation energy as the main reaction kinetic parameter of pyrolysis was estimated using the model-free (Ozawa–Flynn–Wall) and model-fitting (Coats–Redfern) kinetic methods. The high correlation of the experimental data (R2 ≥ 0.997) obtained by the Ozawa–Flynn–Wall method allowed us to consider the applicability of the proposed model-free method to the evaluation of the kinetics of coal pyrolysis under the selected conditions.

The model-free Ozawa–Flynn–Wall method was used to determine changes in the activation energy of the thermal decomposition reactions of coal at different stages of the decomposition of organic matter for coals of different ranks.

Using these methods, we determined the activation energies of coal pyrolysis at various degrees of conversion, which allowed us to interpret the thermal analysis data in detail and to highlight the stages of pyrolysis.

We found a kinetic compensation effect and derived linear regression equations for the activation energy and the preexponential factor.

REFERENCES

Shin, S., Im, S.I., Nho, N.S., and Lee, K.B., J. Therm. Anal. Calorim., 2016, vol. 126, p. 933.

Xu, Y., Zhang, Y., Wang, Y., Zhang, G., and Chen, L., React. Kinet. Mech. Cat., 2013, vol. 110, p. 225.

Mar’yandyshev, P.A., Chernov, A.A., Popova, E.I., and Lyubov, V.K., Solid Fuel Chem., 2016, vol. 50, no. 3, p. 167. https://doi.org/10.3103/S0361521916030095

Freeman, E.S. and Carrol, B., J. Phys. Chem., 1958, vol. 62, p. 394.

Coats, A.W. and Redfern, J.P., Nature, 1964, vol. 201, p. 68.

Kissinger, H.E., Anal. Chem., 1957, vol. 29, no. 11, p. 1703.

Kissinger, H.E., J. Res. Nat. Bur. Stand., 1956, vol. 57, p. 217.

Flynn, J. and Wall, L., J. Polym. Sci. Part B: Polym. Phys., 1966, vol. 4, p. 323.

Ozawa, T., Bull. Chem. Soc. Jpn., 1965, vol. 38, p. 1881.

Du, Z., Sarofim, A.F., and Longwell, J.P., Energy Fuels, 1990, vol. 4, p. 296.

Fetisova, O.Yu., Mikova, N.M., and Chesnokov, N.V., Kinet. Catal., 2019, vol. 60, no. 3, p. 273. https://doi.org/10.1134/S0023158419030054

Fetisova, O.Yu., Kuznetsov, P.N., and Chesnokov, N.V., Khim. Interesakh Ustoich. Razvit., 2019, vol. 27, no. 6, p. 677. https://doi.org/10.15372/KhUR2019190

Solomon, P.R., Serio, M.A., and Suuberg, E.M., Progr. Energy Combust. Sci., 1992, vol. 18, p. 133.

Fedorova, N. I., Manina, T. S., Ismagilov, Z. R., and Avid, B., Solid Fuel Chem., 2015, vol. 49, no. 3, p. 129. https://doi.org/10.3103/S0361521915030064

Ashraf, A., Sattar, H., and Munir, S., Fuel, 2019, vol. 240, p. 326.

Masnadi, M.S., Habibi, R., Kopyscinski, J., Hill, J.M., Bi, X., Lim, C.J., Ellis, N., and Grace, J.R., Fuel, 2014, vol. 117, p. 1204.

Funding

This work was supported by the Russian Foundation for Basic Research (grant no. 19-53-44001) and the Mongolian Science and Technology Foundation (grant no. ShUGKh/OKhU/-2019/13) and carried out within the framework of a state contract at the Institute of Chemistry and Chemical Technology, Siberian Branch, Russian Academy of Sciences (project no. AAAA-A17-117021310220-0) using the equipment of the Krasnoyarsk Regional Center of Collective Use of the Krasnoyarsk Science Center of the Siberian Branch of the Russian Academy of Sciences and at the Institute of Chemistry and Chemical Technology of the Mongolian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by V. Makhlyarchuk

About this article

Cite this article

Fetisova, O.Y., Kuznetsov, P.N., Purevsuren, B. et al. A Kinetic Study of the Stepwise Thermal Decomposition of Various Coals from Mongolia. Solid Fuel Chem. 55, 1–7 (2021). https://doi.org/10.3103/S0361521921010031

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0361521921010031