Abstract

The objective of this research was to incorporate recycled aggregate into pervious concrete to create a very sustainable concrete product for many applications. The research methodology interested replacing natural aggregate with recycled aggregate in the pervious concrete production at 4 different replacement levels of 25, 50, 75 and 100 %, with two different water-to-cement ratios of 0.27 and 0.32. Single sized recycled and natural aggregate, passing from 12.5-mm sieve and retained on 9.5-mm sieve, were used in the manufacturing of pervious concrete. Totally ten different concrete mixtures were produced and each of the concrete batches was tested for dry density, porosity, compressive and splitting tensile strength, water permeability and abrasion resistance. The properties of pervious concrete produced with recycled aggregate were also evaluated by statistical technique, namely GLM-ANOVA. The experimental results showed that the properties of pervious concrete were significantly affected by using recycled aggregate. Substituting the natural aggregate with recycled aggregate resulted in a considerable increment in permeability coefficient. However, it was observed that the mechanical properties of such concretes were adversely influenced up to a certain degree.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

All the concrete manufacturers are trying to make their products more economic and environment friendly with the increase of environmental consciousness. One of the leading efforts that are being to achieve this goal is recycling of old products in the concrete production. One important recycling material is the recycled aggregate obtained from demolished concrete structures. The Portland cement concrete association (PCA) reported that the concretes produced with recycled aggregate show very similar performance to conventional concrete containing natural aggregate [1]. However, there is not enough study about effect of recycled aggregate on pervious concrete. The pervious concrete is a special type of concrete consists of a gap-graded system, generally contains cement, coarse aggregate, little or no sand, admixtures, and water. The combination of these components will produce a hardened material that allows water to pass through the concrete easily [2, 3]. Moreover, the high water permeability of pervious concrete makes it to be considered as an environment friendly concrete. When the natural coarse aggregate replaced with recycled aggregate, the pervious concrete could be more considered as environment friendly concrete for sustainable construction. Pervious concrete has been regarded by the U.S. Environmental Protection Agency (EPA) as one of the best management practices (BMP) for the control of storm water runoff and its contaminants [4].

Pervious concrete is generally used in sidewalks, for low-traffic volume roads and for parking [2]. The main benefit presented by pervious concretes is its ability to transport large volumes of water through its highly connected pore structure to the ground, thus recharging groundwater and reducing or eliminating problems associated with storm-water runoff are the most important properties of pervious concrete [2, 5]. Other environmental benefits of pervious concrete include the ability to reduce tire-pavement interaction noise, improved road safety because it is able to enhance the skid resistance, and reduce urban heat-island effects [2, 3, 6–9].

Generally, cementitious material content in pervious concretes is between 270 and 415 kg/m3 [3] and water-to-cement ratio for this type of concrete is in the range of 0.26–0.40 [2, 3]. A single-sized aggregate gradation is commonly used to produce pervious concrete [3, 9]. The aggregates for pervious concrete are typically smaller than that of conventional concrete. Utilization of smaller sized aggregate in production makes the mix more workable and also provide smoother riding surface and high strength [2, 10]. Nevertheless, the smaller sized aggregate decreases the permeability of pervious concrete. Properties of pervious concrete exceedingly depend on many factors such as type and gradation of aggregate, cement content, water-to-cement (w/c) ratio, aggregate-to-cement (a/c) ratio, and type and degree of compaction [11]. The aim of mixture proportioning of pervious concrete is to achieve a good balance between void content, paste content, workability, and strength [2].

Fresh pervious concrete is typically stiff for this reason it cannot be pumped [3]. The slump is rarely a useful or appropriate method to determine mixture consistency. Some researchers advised fresh unit weight as the preferred measurement for quality control or quality assurance purposes [2, 7, 9, 12]. The density of pervious concrete is generally between 1,500 and 2,200 kg/m3 [3, 12–15] and the water permeability of pervious concrete typically ranges from 1.4 to 12.2 mm/s and the compressive strengths generally range between 2.8 and 28 MPa [2]. A porosity ranging between 15 and 30 % is acceptable for pervious concrete [2, 16–20].

The major drawback of pervious concrete is its lower compressive, flexural strength, and clogging by fine materials compared to conventional concrete and the cost of maintenance and cleaning is high for the pervious concrete. In addition to that, resistance to freeze–thaw cycles and deicing chemical attack are more critical than conventional concrete [2]. Increasing the cement paste area is one way to increase the overall mixture strength [21]. However, there is inversely proportional relation between the porosity and the strength of pervious concrete. Namely, decreasing the porosity amount in concrete increases the compressive strength. Despite all, pervious concrete with enough permeability and sufficient strength for many applications can be achieved with proper mix design [3].

Several research projects have been conducted on the use of recycled aggregate in the pervious concrete and studied the benefits, limitation, and possible defects [22, 23]. Rizvi et al. [24] produced pervious concretes with four different recycled aggregate levels of 15, 30, 50, and 100 %. Their results indicated that increasing the recycled aggregate content led to a decrease in compressive strength, an increase in porosity and thus increase in water permeability. Zhuge [25] and Murao et al. [21] also used recycled aggregate in pervious concrete production, their results indicated significantly lower compressive strength at similar porosity and permeability. Using the recycled aggregate instead of natural aggregate in concrete generally decreased the compressive strength and increases the creep, drying shrinkage, and porosity of pervious concrete [26, 27]. Tennis et al. [3] were studied on the pervious concrete and concluded that low abrasion resistance and raveling might be problems for pervious concrete, because of its rough surface. Ghafoori and Dutta [12] studied on the compaction of pervious concrete and reported that the mechanical properties of pervious concrete were influenced by the compaction energy and aggregate-to-cement ratio. The low compaction energy and high aggregate-to-cement ratio lead to low strength. Therefore, according to literature review, it can be concluded that the pervious concrete needs a proper mix design and carefully compaction.

In this research, the experimental investigation of void content, compressive and splitting tensile strengths, permeability performance and abrasion resistance of pervious concrete was aimed. The pervious concretes were produced at two different water-to-cement ratios of 0.27 and 0.32 with four different recycled aggregate replacement levels of 25, 50, 75, and 100 %. Totally, 10 pervious concrete mixtures were manufactured and they were tested after 28-day water curing period. The recycled aggregate utilized in this study were obtained from crushing the cubic concrete samples of which 28-day average compressive strength was 22.7 MPa. Moreover, the effect of w/c and replacement level of recycled aggregate on properties of pervious concrete was analyzed statistically with using GLM-ANOVA.

2 Experimental study

2.1 Materials

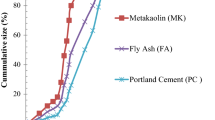

The materials used in this study were Portland cement, single sized natural and recycled aggregate with specific gravity of 3.15, 2.72 and 2.54, respectively. The CEM I 42.5R type of Portland cement was used in both manufacturing of recycle and pervious concretes. The physical properties and chemical compositions of Portland cement were given in Table 1.

The single sized natural coarse aggregate was obtained by sieving the natural coarse aggregate from 9.5 and 12.5-mm sieve and used in the pervious concrete production. The 24-h water absorption of single sized natural coarse aggregate was about 1.48 %.

2.2 Recycled aggregate

For the single sized recycled coarse aggregate, the concrete with 28-day average compressive strength of 22.7 MPa was crushed at the two-stage crushing system including the integration of jaw and cone crushers (Fig. 1a, b). At the first stage of this study, the cubic concrete specimens were produced with 280, 210, 841 and 1,024 kg/m3 of cement, water, fine and coarse aggregate, respectively. The natural river gravel and sand with the specific gravity of 2.73 and 2.43, respectively, were used in the recycle concrete production. To produce low strength concrete, 210 cubic specimens were cured in water for 7 days and were kept in laboratory conditions till 28 days. This process was applied on the concrete manufactured in laboratory to achieve same characteristics with concrete produced in site. The cubic specimens were tested for compressive strength after 28 days and the concretes with low strength were crushed by using the two-stage crushing system. The jaw cone was used as a primary crusher and concrete samples were put in which aggregate is shaped like folieceous under the compression effect (Fig. 1c). After the primary crushing, the folieceous shaped aggregates were converted to angular shaped aggregates by using the cone crusher which produces an impact effect with rotating axially (Fig. 1d). The required size of aggregate can be obtained after this process, but it does not single sized aggregate. The recycled aggregates obtained from crushing system were sieved from 9.5 to 12.5-mm sieve to get same size with single sized natural coarse aggregate. The single sized recycled aggregate has the specific gravity and water absorption of 2.54 and 5.07 %, respectively. After the sieving process, the recycled aggregate were washed to remove all impurity materials which might prevent good bond between the aggregate particles and the cement paste. The properties of both single sized natural and recycled aggregates and their pictures are given in Table 2 and Fig. 2, respectively.

2.3 Concrete mixing proportioning and casting

The cement contents for the pervious concrete series were designated as 420 and 270 kg/m3, respectively. Two different pervious concrete series were produced at water-cement ratios (w/c) of 0.27 and 0.32 and aggregate-cement ratios (a/c) of 3.70 and 5.75 as weight, respectively. The amount of aggregates in both concrete series was kept constant. The single sized natural aggregate was replaced with the single sized recycled aggregate at four different levels of 25, 50, 75, and 100 %. The natural aggregate was substituted with the recycled aggregate as weight to keep the a/c ratio constant. The concrete mix proportions for the pervious concrete are also given in Table 3. In the table, 27 and 32 refers to w/c ratios, while the NA and RA were used for designation of natural and recycled aggregate content, respectively. For example, 27NA100RA0 means that the pervious concrete produced with 100 % of natural aggregate and 0 % of recycled aggregate at w/c ratio 0.27.

The water absorptions of aggregates were determined for 30 min and 24 h water immersion and it was noticed that 30-min water absorptions of NA and RA were equal to approximately 95 and 90 % of 24-h water absorption, respectively. Therefore, both natural and recycled aggregates were immersed in water for 30 min and exceed water on the aggregate surface was rubbed out manually by a dry towel before each casting. By this way, saturated surface dry aggregate was obtained and the amount of mixing water was maintained as constant.

The concretes were mixed in the power-driven revolving pan with capacity of 30 liter with special mixing procedure for pervious concrete proposed by Wang et al. [18]. The recommended mixing procedure by Wang et al. [18] for the pervious concrete was followed to ensure a good bond between the aggregate particles and the cement paste. The aggregate was first added to the pan and mixed for 30 s. Then, 5 % of Portland cement was poured on the aggregate and they were mixed for 1 min or till the fully coating of the aggregates by a thin layer of cement is observed. After that, the remainder cement and the water were added to mixer and they were mixed for approximately 2–3 min. As soon as mixing procedure finished, the pervious concrete was placed to the moulds with three layers and each layer was rodded 25 times. While the pervious concretes produced with w/c ratio of 0.27 were vibrated 2–3 s, the pervious concretes manufactured with w/c ratio of 0.32 were not vibrated due to having high workability. The concrete specimens were covered with plastic wrap and were kept in the laboratory conditions. After 24 h, they were demoulded and water curing was applied till testing day.

2.4 Test specimens and methods

The cubic specimens with 150-mm dimensions were used for compressive strength test and the prismatic specimens which have 70 × 70 × 100 mm dimensions were produced for abrasion test. The cylindrical specimens with 100 mm in diameter and 200 mm in height were produced for the dry density, void content, the splitting tensile strength and permeability tests. Three specimens were produced for each test and the results given in this study are the average of them.

The compressive strength test was carried out with respect to ASTM C39 [28]. The splitting tensile strength of pervious concrete was conducted in accordance with ASTM C496 [29] and the following equation was used to calculate the splitting tensile strength:

where f split, P, D, and L are the splitting tensile strength (MPa), the ultimate load (N), the diameter and the length of cylindrical specimen (mm), respectively.

ASTM C1754 [30] was followed for the calculation of density and void content of hardened pervious concrete. The densities of pervious concretes were determined by the following equation:

where K, A, D, and L are the 1273240 in SI units (mm3kg/m3g), the dry mass (g), the average diameter (mm), and the average length of the specimen (mm), respectively.

The density of water was first determined to calculate the void content of the specimen by interpolation of the values given in ASTM C29 [31]. Then, the void content of the specimens were calculated as:

where B and ρ w are submerged mass of the specimen (g) and the density of water at temperature of the water bath (kg/m3), respectively.

The water permeability coefficients for pervious concrete were determined by falling head method, using a specially made permeability apparatus as shown in Fig. 3. The cylindrical test specimen was firstly wrapped with a latex membrane tightly to stop the water leaking along the sides and to allow the water to flow through the cross-section of the specimen. The top of the specimen were fitted to glass tubes. The water permeability test was conducted under the falling of head from 400 to 300 mm. For each specimen, four readings were recorded and average of them was taken. After that, the permeability coefficients (k) of the pervious concretes, which follows Darcy’s law and assumes laminar flow, were evaluated by the following expression:

where k, a, L, A, t, h 0, and h 1 are the coefficient of permeability (mm/s), the cross-sectional area of the pipe (mm2), the length of the specimen (mm), the cross-sectional area of the specimen (mm2), the time taken for the head to fall from h 0 to h 1 (s), initial water head (mm), and the final water head (mm), respectively.

The Böhme abrasive wheel was used to measure the abrasion resistance of the pervious concrete as recommended in DIN52108 [32]. The Böhme abrasive test device has a steel disc with a diameter of 750 mm and rotating speed of 40 cycle/min. The device also contains a lever, which could apply 300 N on the specimens. The photographic view of Böhme abrasive wheel test device is shown in Fig. 4.

After weighing the prismatic specimen with the dimensions of 70 × 70 × 100 mm, it was putted on the abrasion part on the wheel and 20 g of wear dust which is corundum (crystalline Al2O3) was spread on the abrasion part of the disc. Then, the disc was rotated one period consisting of 22 cycles. After each period, the specimen was turned 90° without changing the abrasion face of the specimen. Totally 4-period rotating of abrasive wheel was applied to the specimen face. When 4-period rotating of the specimen finished, the abrasion face of the specimen and abrasive wheel was cleaned by soft brush. This process was named as a spin and totally 4 spins were carried out on the specimen. After the 352 cycles, the prismatic specimen weighed and then the abrasion of the specimen by deep wear was calculated with using the following equation:

where ΔL, Δm, δR, and A are the abrasive wear after 16 periods as the mean loss in specimen thickness (cm), the loss in mass after 16 cycles (g), the density of the specimen (g/cm3), and the area of surface that exposed to abrasion (cm2), respectively.

3 Results and discussion

3.1 Dry density and void content

The densities of the hardened pervious concretes versus replacement level of recycled aggregate are demonstrated in Fig. 5a. Density values for pervious concrete ranging between 1,781 and 1,976 kg/m3, which is 70–80 % of conventional concrete, was obtained in this study. Systematical reduction in density was observed with increasing the recycled aggregate content, since recycled aggregate has lower specific gravity than natural aggregate. Additionally, the surface texture of recycled aggregate is more angular than that of natural aggregate. This surface characteristic of recycled aggregate can easily be inspected visually. This angularity characteristic of recycled aggregate might block the compaction of aggregate particles when the concrete was rodded. Therefore, the lower density was obtained. Also, w/c ratio affected the dry densities of pervious concrete. The higher the w/c ratio resulted in lower dry density. This can be explained by the cement content. Utilization of high cement content in pervious concretes produced at w/c ratio of 0.27 filled the voids between aggregate particles. For that reason, denser pervious concretes were obtained.

Void contents of pervious concrete versus recycled aggregate content are plotted in Fig. 5b. The void content of pervious concrete was also affected by w/c ratio. The higher cement content designated at w/c of 0.27 resulted in lower void content for pervious concrete. Angular shape of recycled aggregate also played an important role in void content of pervious concrete. It caused a less compaction of the pervious concrete and produced more void in the pervious concrete. Increasing the recycled aggregate content increased the void content from 21.3 to 23.4 and 22.4 to 25.3 for the pervious concretes produced at w/c ratios of 0.27 and 0.32, respectively. While increasing the recycled aggregate content from 0 to 100 % resulted in about 9.9 % increment of void content for pervious concretes produced at w/c ratio of 0.27, this increment rate was about 13.0 % when pervious concrete manufactured at w/c ratio of 0.32. Increasing the w/c ratio from 0.27 to 0.32 resulted in 5.2 and 8.1 % increment of void content for pervious concrete produced with 100 % natural and recycled aggregate, respectively. The void content values of pervious concrete produced in this study are acceptable according to ACI55R [2]. Additionally, it can be said that there is a good relation between dry density and void content of pervious concrete according to Fig. 5c. The R-square value of 0.791 was attained in the experimental study.

Moreover, the valuation of whether an independent variable has an effect on the dependent variable is determined by a general linear model analysis of variance (GLM-ANOVA) with using software name Minitab [33]. The GLM-ANOVA is an important statistical analysis and diagnostic tool which aids to quantify the dominance of a control factor by reducing the control variance. The analysis was performed at a 0.05 level of significance to identify the statistically significant experimental parameters on the properties of pervious concrete. The effectiveness of the test parameters was determined by performing the GLM-ANOVA. The statistical analysis results are shown in Table 4. The P values indicate the significance of the test parameter on the properties of pervious concrete. When P value is less than 0.05, it means that the parameter is acceptable as a significant factor on the test result. The analyzed mixture proportion variables are identified as yes or no (Y/N) as either present or not present in the analysis. The dry density, void content, compressive and splitting tensile strength, permeability coefficient and abrasion resistance of pervious concrete were analyzed separately and assigned as dependent variable while the water-to-cement ratio and replacement level of recycled aggregate content were selected as independent factors. Also, percent contribution was used to get an idea about the degree of effectiveness of each independent factor on the dependent variable such that the higher the contribution, the effectiveness of the factors to that particular response was higher. Likewise, if the percent contribution is low, the contribution of the factors to that particular response is less. The percent contribution of each independent variable was calculated by the division of sequential sum of squares of independent variable to total sequential sum of squares.

Besides, the statistical evaluation revealed that both water-to-cement ratio and recycled aggregate content have a significant effect on dry density and void content. However, the recycled aggregate content affects the dry density void content of pervious concrete more than water-to-cement ratio when percent contribution is considered (Table 4).

3.2 Compressive strength

The compressive strength results of pervious concrete with regard to each replacement level are given in Fig. 6a. The higher compressive strength results were achieved in pervious concrete manufactured at a w/c ratio of 0.27. To produce a pervious concrete, a thin or very thin cement paste layers which coating the aggregates particles are needed and generally compressive failure path passes through the binder layer between the aggregate particles and interfacial transition zone between aggregate particles and cement paste since they are thin and weak. Therefore, enhancing the cement paste quality and increasing the thickness of cement paste layer is an effective way of improving compressive strength of pervious concrete. While increasing the thickness of cement layer leads to higher compressive strength, however, it decreases the void content and permeability of pervious concrete. The higher compressive strength for pervious concrete can be obtained by using smaller single sized aggregate in production. Because smaller single sized aggregate has greater surface area than coarser single sized aggregate. The higher surface area of aggregate resulted in more binding area. Nevertheless, using the smaller single sized aggregate also results in decrease void content and permeability when compared with the using the higher single sized aggregate. This problem, however, can be solved by making the proper mix design.

The reduction in compressive strength was observed with increasing the recycled aggregate content. It is caused by two important properties of recycled aggregate which differing it from natural aggregate. One is weak hardened cement paste on the aggregate particles and the other is the interfacial transition zone between hardened cement paste and original aggregate. Due to these two important characteristics of recycled aggregate, reduction in compressive strength could be observed. Moreover, when the recycled aggregate is utilized in the concrete production, one more interfacial transition zone occurs that is between recycled aggregate and cement paste of pervious concrete. This transition zone may also be weaker than that occurred between the cement paste of pervious concrete and natural aggregate and obtaining a lower compressive strength in pervious concrete with recycled aggregate may be caused due to this reason. The compressive failure path in pervious concrete generally passed through the cement matrix and interfacial transition zone when natural aggregate were used in the production. Because the weakest parts of the pervious concrete are generally the cement matrix and interfacial transition zone when the pervious concrete is exposed to compressive force (Fig. 7a). When Fig. 7a was viewed, it can be clearly seen that the pervious concrete produced with the single sized natural coarse aggregate has the cracks propagated within the cement matrix. However, replacing the natural aggregate with the recycled aggregate caused a different compressive failure path. Sometimes, failure path passed through the recycled aggregate and the interfacial transition zone between the aggregate and the hardened cement paste of recycled aggregate (Fig. 7a). This interfacial transition zone makes the recycled aggregate weaker when it is compared with the natural aggregate. For this reason, cracks propagated through the recycled aggregate. The compressive strength of pervious concretes changed between 20.0–13.9 and 17.4–12.8 MPa for w/c ratios of 0.27 and 0.32, respectively. In the literature, it is reported that the pervious concrete with compressive strength values ranged from 3.5 to 28 MPa is suitable for a wide range of applications [2, 3]. Namely, the compressive strength results obtained in this study are acceptable for pervious concrete.

Additionally, both water-to-cement ratio and recycled aggregate content have a significant effect on compressive strength of pervious concrete. As clearly seen in Table 4, the contribution of recycled aggregate content in the compressive strength variation is 81.2 %. It means that the recycled aggregate content is more significant parameter affecting the compressive strength of pervious concrete.

3.3 Splitting tensile strength

The splitting tensile strength results of pervious concrete are given in Fig. 6b. The splitting failure path of the pervious concrete is different from compression failure path. The splitting failure path passed through both aggregates and cement matrix (Fig. 7b), whereas compression failure generally passed through the cement matrix and/or interfacial transition zone. It is a general expectation in splitting tensile failure since the load is applied as point load on the specimen. The load directly passed through from cement matrix to aggregate and as a result the specimen is split. The pervious concrete produced with higher w/c ratio gave lower splitting tensile strength. It was caused due to the fact that the pervious concrete produced with lower w/c ratio has strong cement matrix than that of produced with higher w/c. Moreover, systematical decreasing in splitting tensile strength of pervious concrete was also observed with increasing the recycled aggregate content. The recycled aggregate has same effects on splitting tensile strength as in compressive strength and reducing of splitting tensile strength was caused by these effects. The most important one is that the recycled aggregate grains consist of the weak hardened cement paste and aggregate. Since the cracking path passed through the aggregates, the utilization of weak aggregate like recycled aggregate instead of natural aggregate results in decrease in splitting tensile strength. Splitting tensile strength values ranging between 1.00 and 1.29 MPa was achieved. The trend in splitting tensile strength of the pervious concrete is almost similar to that in conventional concrete of which splitting tensile strength is almost 10 % of its compressive strength. Splitting tensile strength of the pervious concrete manufactured in this study was between 6.45 and 7.80 % of its compressive strength. As a result, it can be said that the pervious concrete produced in this study supplies the limitations for the tensile strength of pervious concrete. In addition, the recycled aggregate content affects the dry density void content of pervious concrete more than water-to-cement ratio when percent contribution obtained from statistical evaluation is taken into account (Table 4).

3.4 Permeability

The permeability coefficients of the pervious concretes that were done using the head falling principle are shown in Fig. 8a. The permeability strongly depend on the aggregate type and gradation, cement content, water-to-cement and aggregate-to-cement ratios, and compaction. The results indicated that the utilization of higher a/c ratio resulted in high permeability coefficient. The lower a/c ratio at the same aggregate amount means higher cement content and the high amount of cement increases the thickness of cement paste and fills the voids between aggregate particles and the lower permeability is obtained. However, replacing the natural aggregate with recycled aggregate remarkably increased the permeability characteristic of pervious concretes. The permeability coefficient values of 5.6 and 8.3 mm/s were achieved in the pervious concrete produced at w/c of 0.27 and 0.32, respectively. Besides, increasing the recycled aggregate content from 0 to 100 % increased the permeability coefficient as much as 33.9 and 54.2 % for the w/c ratios of 0.27 and 0.32, respectively. Generally, the permeability coefficient values between 0.14 and 1.22 cm/s are acceptable for pervious concrete [2, 3], in this study, however, the pervious concretes were produced with high water permeability characteristic.

Using the recycled aggregate increased the void content of the pervious concretes; this is directly related with the permeability of the pervious concrete and increment in void content of pervious concrete was due to angularity of recycled aggregate. There is a relatively good relation between the permeability performance and the void content of the pervious concrete as shown in Fig. 8b. The high cement content decreased both the permeability and void content of the pervious concrete due to filling the porosity and increasing the cement past thickness. The R-square value of 0.793 indicates a good correlation between permeability and void content (Fig. 8b). Although there is a notable scatter in the plotted data, the water permeability generally increases when the void content increases. The high permeability of 12.8 mm/s was obtained when the void content was 25.3 %. The use of a single aggregate gradation was also related to the pore size distribution, pore roughness, and pore connectivity that affect the permeability of the pervious concrete in addition to the void content. However, increasing the permeability implies a higher void content and this decreases the load bearing capacity of the pervious concrete. The decreasing in the compressive strength of the pervious concrete could result in a shorter life of the pavement and also severity of distresses such as raveling and joint failure. It is absolutely essential in the pervious concrete since a very delicate balance should be struck between the strength and draining capacity. Moreover, the statistical evaluation indicated that both water-to-cement ratio and recycled aggregate content have a significant effect on permeability coefficients of pervious concretes when P values is considered. As seen in Table 4, water-to-cement ratio is the most important parameter with contribution value of 76.1 % in the permeability variation of pervious concretes.

3.5 Abrasion resistance

The abrasion of the pervious concretes by deep of wear versus replacement level of recycled aggregate is demonstrated in Fig. 9a. The results indicated that the durability performance of the pervious concrete was also affected by both the w/c ratio and the recycled aggregate content. The higher w/c ratio caused high abrasion of pervious concrete due to weak cement paste which holds the aggregate particles together. Also, increasing the recycled aggregate content systematically increased the abrasion in pervious concrete. It is obviously expected situation since recycled aggregates consist of weaker cement matrix and aggregate. The abrasion values of 1.23 and 1.44 mm were calculated for the pervious concrete produced with 100 % natural aggregate at w/c ratios of 0.27 and 0.32, respectively. Increasing the recycled aggregate from 0 to 100 % increased the abrasion of pervious concrete from 1.23 to 1.62 mm and 1.44 to 1.83 mm for the pervious concrete manufactured at w/c ratio of 0.27 and 0.32, respectively. The relation between void content-abrasion and compressive strength-abrasion of pervious concrete are plotted in Fig. 9b. The R-square values of 0.867 and 0.941 show a strong relation between abrasion and compressive strength and void content, respectively. According to R-square values, it can be concluded that increasing the void content decreases the compressive strength and decreasing the compressive strength decreases the abrasion resistance of the pervious concrete. Besides, the statistical evaluation revealed that both water-to-cement ratio and recycled aggregate content have a significant effect on splitting tensile strength when P values is considered. While the contribution of water-to-cement ratio is 63.4 %, that of recycled aggregate content is 36.4 %.

a Abrasion (by deep of wear) of the pervious concrete versus replacement level of recycled aggregate and b relationship between void content-abrasion and compressive strength-abrasion of pervious concrete (upper plotting belongs to relationship between void content and abrasion while bottom plotting belongs to relationship between compressive strength and abrasion)

4 Conclusions

The main concluding remarks based on the findings mentioned above are summarized below:

-

The densities of the pervious concrete mixtures produced in this study were in the allowable range according to ACI55R. It was noticed that using of recycled aggregate decreased the dry density of pervious concrete and a systematical decreasing in dry density was observed when the natural aggregate replaced with the recycled aggregate at designated levels. The decreasing rate of 8.5 and 10.2 % in dry density were observed when the recycled aggregate content was increased from 0 to 100 % for pervious concretes produced at w/c of 0.27 and 0.32, respectively.

-

The acceptable void contents for the pervious concrete were achieved at both w/c ratios of 0.27 and 0.32. Replacing the recycled aggregate with natural aggregate resulted in increment of void content. Besides, the results indicated that there is a good relation between dry density and void content of pervious concrete by means of R-square value of 0.791.

-

The compressive strength values of pervious concrete were also affected by w/c ratio as well as recycled aggregate content. The pervious concrete produced at lower w/c ratio performed better compressive strength than that produced at the higher w/c ratio. The compressive strength results obtained from this study were in the allowable range which is given for the pervious concretes. Increasing the recycled aggregate content resulted in systematical decreasing of compressive strength since the recycled aggregate contains a weak cement matrix and interfacial transition zone between aggregate and this weak cement paste.

-

Splitting tensile strength values of pervious concrete ranging between 1.00 and 1.29 MPa was achieved. When the w/c ratio and recycled aggregate content were increased, the splitting tensile strength of pervious concrete decreased.

-

The permeability characteristic of pervious concrete was also significantly affected by w/c and recycled aggregate content. The pervious concrete produced with lower a/c ratio performed low permeability characteristic. The high amount of cement in lower a/c ratio filled the voids between aggregate particles and this situation caused a lower permeability. However, permeability coefficient values obtained from the experimental study showed that all pervious concrete mixtures had high permeability coefficient values when they were compared to permeability coefficient proposed in ACI55R.

-

The relation between permeability and void content was also observed. The R-square of 0.793, which indicates a good relation between permeability and void content, showed that permeability of pervious concrete is related with void content of pervious concrete. Namely, the higher void content, the higher permeability performance.

-

Abrasion resistance of pervious concrete was also carried out with using the Böhme abrasive wheel test device. The abrasion results, by deep of wear, indicated that utilization of recycled aggregate decreases the abrasion resistance. However, decreasing the w/c enhanced the abrasion resistance. Also, the relation between abrasion and compressive strength of pervious concrete was also observed. The R-square value of 0.867, which indicates a strong relation, was achieved. For abrasion resistance of pervious concrete according to R-square, it can be concluded that the pervious concrete with high strength performed high abrasion resistance.

-

The statistical test results revealed that the all dependent variables were affected by the independent factors, water-to-cement ratio and replacement level of recycled aggregate, when the p values, obtained from ANOVA, were considered. When the contribution levels of the independent variables were observed, it was noticed that the dry density, void content, compressive and splitting tensile strength of pervious concretes were more affected by recycled aggregate content than w/c ratio, while the permeability and abrasion of pervious concrete were more affected by w/c ratio than recycled aggregate content when contribution of independent factors was considered.

References

Portland Cement Association (PCA) (2009) Materials: recycled aggregates, http://www.cement.org/tech/cct_aggregates_recycled.asp. Accessed 2 July 2009

ACI 522R-10 (2010) Pervious concrete, American Concrete Institute Committee, Farmington Hills

Tennis PD, Leming ML, Akers DJ (2004) Pervious concrete pavements. EB 302, Portland Cement Association, Skokie, Illinois, and National Ready Mixed Concrete Association, Silver Spring

Bury MA, Mawby CA, Fisher D (2006) Making pervious concrete placement easy: using a novel admixture system. Concrete in focus, pp 55–59

Meininger RC (1998) No-Fines pervious concrete for paving. Concr Int 10(8):20–27

Neithalath N (2004) Development and characterization of acoustically efficient cementitious materials, PhD thesis, Purdue University, West Lafayette

NRMCA (2006) Ready mixed concrete industry LEED reference guide, Silver Springs. http://www.rmc-foundation.org

Collins KA, Hunt WF, Hathaway JM (2008) Hydrologic comparison of four types of permeable pavement and standard asphalt in Eastern North Carolina. J Hydrol Eng 13(12):1146–1157

Yang J, Jiang G (2003) Experimental study on properties of pervious concrete pavement materials. Cem Concr Res 33:381–386

Crouch L, Cates M, Dotson V, Honeycutt K, Badoe D (2003) Measuring the effective air void content of portland cement pervious pavements, Cement, concrete, and aggregates, vol 25, No. 1, West Conshohocken

Crouch LK, Pitt J, Hewitt R (2007) Aggregate effects on pervious Portland cement concrete static modulus of elasticity. J Mater Civ Eng 19(7):561–568

Ghafoori N, Dutta S (1995) Laboratory investigation of compacted no-fines concrete for paving materials. J Mater Civ Eng 7(3):183–191

Zhuge Y (2006) A review of permeable concrete and its application to pavements. Mech Struct Mater 30:601–607

Shackel B, Pearson A (2003) Permeable concrete eco-paving as best management practice in Australian urban road engineering. In: Proceeding of the 21st ARRB and 11th REAAA Conference, 2003, Cairns

Kevern JT, Schaefer VR, Wang K, Suleiman MT (2008) Pervious concrete mixture proportions for improved freeze-thaw durability. J ASTM Int 5(2):12

Neithalath N (2007) Extracting the performance predictors of enhanced porosity concretes from electrical conductivity spectra. Cem Concr Res 37:796–804

Neithalath N, Weiss J, Olek J (2006) Characterizing enhanced porosity concrete using electrical impedance to predict acoustic and hydraulic performance. Cem Concr Res 36(11):2074–2085

Wang K, Schaefer VR, Kevern JT, Suleiman MT (2006) Development of mix proportion for functional and durable pervious concrete. NRMCA concrete technology forum: focus on pervious concrete, Nashville

Haselbach T, Freeman LM, Robert M (2006) Vertical porosity distributions in pervious concrete pavement. ACI Mater J 109:149

Marolf A, Neithalath N, Sell E, Wegner K, Weiss J, Olek J (2004) Influence of aggregate size and gradation on acoustic absorption of enhanced porosity concrete. ACI Mater J 101(1):82–91

Murao K, Yuasu Y, Misima N, Hatanaka S (2002) Experimental study on the strength of porous concrete with low quality recycled aggregate. J Archit Inst Jpn 8:823–824

Tu TY, Chen YY, Hwang CL (2006) Properties of HPC with recycled aggregates. Cem Concr Res 36:943–950

Zega CJ, Villagran-Zaccardi YA, Di Maio AA (2010) Effect of natural coarse aggregate type on the physical and mechanical properties of recycled coarse aggregate. Mater Struct 43:195–202

Rizvi R, Tighe SL, Norris J, Henderson V (2010) Incorporating recycled concrete aggregate in pervious concrete pavements. In: Proceeding from the National Transportation Research Board, Washington, D.C

Zhuge Y (2008) Comparison the performance of recycled and quarry aggregate and their effect on the strength of permeable concrete. 20th Australasian conference on the mechanics of structures and materials, Toowoomba, December 2008, pp 343–349

Poon CS (2004) Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem Concr Res 34:31–36

Domingo A, Lazaro C, Gavarre FL, Serrano MA, Lopez-Colina C (2010) Long term deformation by creep and shrinkage in recycled aggregate concrete. Mater Struct 43:1147–1160

ASTM C1754/C1754M.12 (2012) Standard test method for density and void content of hardened pervious concrete. ASTM International, West Conshohocken

ASTM C39/C39M-12 (2012) Standard test method for compressive strength of cylindrical concrete specimens, vol 04-02. Annual Book of ASTM Standard, Philadelphia

ASTM C496 (2011) Standard test method for splitting tensile strength of cylindrical concrete specimens, vol 04-02. Annual Book of ASTM Standard, Philadelphia

ASTM C29 (2010) Standard test method for bulk density (“Unit Weight”) and voids in aggregate. Annual Book of ASTM Standard, Philadelphia

DIN52108 (2002) Wear testing of inorganic, nonmetallic materials using the Böhme abrasive wheel

Minitab R12, Statistical tool, quality plaza, State College

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Güneyisi, E., Gesoğlu, M., Kareem, Q. et al. Effect of different substitution of natural aggregate by recycled aggregate on performance characteristics of pervious concrete. Mater Struct 49, 521–536 (2016). https://doi.org/10.1617/s11527-014-0517-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-014-0517-y