Abstract

Molecular dispersions are a highly effective method of increasing bioavailability for a poorly soluble active pharmaceutical ingredient (API) and can be prepared on a large scale by hot melt extrusion (HME). Processing thermally labile active pharmaceutical ingredients (APIs) via HME is generally more difficult, with operating temperatures limited to below that of the API melting point. API melting is considered essential to facilitate the formation of a fully homogeneous amorphous system. Processing below the melting point renders the system much more susceptible to residual crystalline content; hence, HME is not suitable for APIs which degrade upon melting. In the following work, meloxicam (MEL) was used as a model API, possessing properties of high melting temperature and thermal lability. In this proof of concept work, a modified HME method, termed solvent-assisted HME, was used to overcome this issue and prepare an amorphous solid dispersion using HME, wherein a solvent was incorporated in the formulation blend during extrusion and removed post-processing. Formulations containing 10%wt meloxicam (MEL) and 90%wt polyvinylpyrrolidone vinyl acetate (PVPVA) copolymer were extruded using a twin-screw extruder at temperatures below the melting point of MEL. Dimethylformamide (DMF) solvent was added directly into the extruder barrel through a liquid addition port, resulting in extrudate products having a higher conversion of API to the amorphous form. The incorporation of solvent allowed a significant reduction in processing temperatures due to its increased mobility, while also driving the conversion of the API to its amorphous form. The solvent was successfully reduced through a secondary drying step using a vacuum oven. This advancement has demonstrated the potential for thermally labile APIs to be processed via HME expanding the applications of this technology.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Amorphous solid dispersions (ASDs) are a well-known method used to stabilize the amorphous form of an active pharmaceutical ingredient (API) by dispersing it in a matrix, usually a polymer or polymer blend (1). With a greater apparent solubility than its crystalline counterpart, the amorphous form offers a pathway to overcome the rate-limiting step associated with poor bioavailability. The polymer ASD formulation approach provides physical stability of the thermodynamically unstable amorphous form. If a homogeneous system is achieved and stabilized by intermolecular interactions, it can often lead to maintained supersaturation of the amorphous API in solution (2). Subsequently, recrystallization of the API is hindered due to reduced molecular mobility, facilitating increases in absorption (3, 4).

Polymer ASDs can be manufactured on a large scale using well-established technologies, such as spray-drying (SD) and hot melt extrusion (HME). Both processes are widely used in industry, with commercially available ASDs on the market produced by each (5). Although both technologies have the capacity for large-scale production, their methods of operation differ greatly, with each offering numerous advantages and disadvantages depending on the requirements for a particular system. Typically, the chemical and physical properties of the API are considered before deciding on the most feasible and effective method.

Historically, HME has differentiated itself as a manufacturing platform by offering solvent-free processing, making it an attractive technology in the global drive to shift to environmentally sustainable processing. It also offers itself as a more scalable technology, allowing continuous manufacture along with the incorporation of inline process monitoring to ensure quality is maintained (6). Subsequently, the elimination of batch processing can result in increased efficiency in terms of time, energy, and cost (7). In contrast, the SD approach is a highly solvent-intensive process, which can become an important deciding factor due to organic solvents being costly and harmful to the environment. However, more commonly SD manufacture can significantly reduce the presence of residual crystalline material in the product due to molecular dispersion of the components in a solvent prior to spraying and rapid evaporation to solid form (8).

An important factor swaying a decision to favor the SD approach is the thermal behavior of the API. Preparation via HME generally requires melting of the API into the molten polymer to achieve complete molecular dispersion, a requirement which cannot be met when considering an API that degrades upon melting. Necessary lowering of processing temperatures to below the melting point of the API typically results in a high portion of residual crystalline material, due to insufficient energy required to break down the crystalline lattice (9). Meloxicam (MEL) is an example of one such compound which degrades rapidly upon melting (10). A nonsteroidal anti-inflammatory API, like many pharmaceutical compounds, possesses low aqueous solubility, reducing its bioavailability. Rendering a Biopharmaceutical Classification System Class II compound, the use of an enabling formulation approach could overcome this solubility issue and improve bioavailability. Strategies to address this have been reported in the literature, with multiple cocrystal forms (11,12,13), and attempts to prepare polymer ASDs are recently shown to be moderately successful. ASD preparations of this API include freeze-drying (14), HME via in situ salt formation (15), and spray drying (16). However, confirmation of complete conversion to the amorphous form is yet to be shown.

Solvent-assisted hot melt extrusion (SA-HME) is a novel concept previously described by Huang et al. (17), wherein the incorporation of solvent in a popular solvent-less process aims to expand the vast usage of an already well-implemented process. Specifically, in this study, the issue with processing compounds which exhibit thermal lability has been targeted. MEL was used as a model API in the presented work, possessing properties of low solubility, high melting temperature, and thermal lability (10). It was hypothesized that the addition of small volumes of solvent during HME could aid mixing of the API-polymer mixture through dissolution of the components, while also plasticizing the system, to enable lower processing temperatures. Amorphous solid dispersions have been prepared via SA-HME below the melting temperature of MEL, showing how solvent addition during processing can influence conversion yields to the amorphous API form and reduce residual crystallinity. This proof-of-concept process presents an alternative approach to processing ASDs of a thermally labile compound on a large scale, overcoming the need for highly solvent-intensive methods such as spray drying.

MATERIALS AND METHODS

Materials

Meloxicam was purchased from eNovation Chemicals (NJ, USA). Polyvinylpyrrolidone-vinyl acetate copolymer (PVPVA, Kollidon VA64) was purchased from BASF (Ludwigshafen, Germany). Anhydrous dimethylformamide (99.8%) was purchased from Sigma Aldrich (St. Louis, USA).

Experimental Methods

Thermogravimetric Analysis (TGA)

TGA analyses were conducted using a Q500 thermogravimetric analyzer (TA Instruments, New Castle, DE), with nitrogen gas purged through the system at 50 mL/min. A heating rate of 10 °C/min was used for all analyses. Degradation temperature onsets were calculated by extrapolation of the weight loss curve.

Differential Scanning Calorimetry (DSC)

A Q1000 differential scanning calorimeter (TA Instruments, New Castle, DE) was used to analyze the thermal behavior of physical mixtures and milled extrudates. The instrument was calibrated for temperature using indium, and nitrogen gas was purged through the system at 50 mL/min; 3–5 mg of sample was accurately weighed into an aluminum pan and sealed with a non-hermetic lid before subjecting to a thermal heat ramp at 10 °C/min.

Powder X-Ray Diffraction (PXRD) Quantification

Powder X-ray diffraction patterns were collected using a PANalytical X’Pert Pro MPD (Malvern Panalytical Ltd, Malvern, UK). X-rays were generated from a Cu-kα radiation source, at a voltage of 45 mV and a current of 40 mA. A scanning range of 5–40°2-theta was carried out, with a step size of 0.008°2-theta and a scan speed of 15.2 s/step. Powdered samples were filled into aluminum sample holders using a backfilling technique to prepare a level surface of 16 mm diameter and 2.4 mm depth.

Calibration samples were prepared in triplicate by mixing a portion of crystalline MEL with PVPVA; 500 mg samples were prepared in the range 0–10%wt MEL, appropriate for 10%wt MEL loaded extrudates. Samples were then analyzed by PXRD, and a graph plotting the average height of MEL’s characteristic diffraction peak at 15.0°2-theta against the concentration of amorphous material in the sample was constructed.

Hot Melt Extrusion (HME)

A Pharma 11 twin-screw hot melt extruder (Thermo Fisher, Waltham MA) (40:1 L/D) was used to prepare all extrudates. Physical mixtures of MEL (10%wt) and PVPVA were fed at a fixed rate using a gravimetric feeder attachment into the feed zone. A total of 8 heating zones, including the die zone, were used for processing. For all extrusion trials, the feed zone was kept at a reduced temperature of 110 °C to ensure the flow of the blend through the barrel and reduce material build-up in this zone. The main barrel was controlled 150–180 °C, and the dead zone was also set to 140 °C to allow cooling of the material and solidifying of the extrudate upon exit. DMF was added at port 4 via a steady-state syringe pump at the required flow rate between 0 and 0.175 mL/min, and port 6 incorporated an open vent to allow the removal of volatile solvent (Fig. 1). For all extrusion processing, a screw speed of 200 rpm was used and a feed rate of 0.25 kg/h. Torque measurements were recorded as a percentage of the maximum, 12 Nm (6 Nm for each screw). Approximately 10 g of solid, cylindrical, extrudate sample was collected with a die of 2 mm diameter for each experimental run. Solid extrudates were placed in a 50-mL stainless steel grinding chamber with a 20-mm ball and then milled for 60 s at 15 Hz using a ball mill (MM301, Retsch, Germany). Milled powders were analyzed without further processing. Mechanical energy input was investigated with respect to the role they played in achieving conversion to amorphous MEL in an ASD. Three different screw configurations were assessed: one with a medium mixing intensity (screw configuration 1, SC1), a second with a higher mixing intensity (SC2), and finally a design with lower mixing intensity (SC3) (Table I).

For secondary drying investigations, milled powders were placed in a vacuum oven at 60 °C, 67 atm for 24 h, prior to solvent content analysis by TGA.

RESULTS AND DISCUSSION

With the increasing use of HME in the pharmaceutical industry, this work looks at expanding the technology platform further to allow processing of more systems, in particular manufacture of ASDs containing thermally labile compounds. Generally, SD would be considered for ASD preparation of a thermally labile API instead of HME, so that high temperatures could be avoided (18). However, along with poor aqueous solubility, MEL also exhibits poor solubility in most solvents (19), rendering it suboptimal for SD processing. The requirement for vast amounts of solvent to process on a large scale would make the process largely unfavorable due to increased processing costs and operational difficulties. When presented with a compound such as MEL, possessing both thermal lability and poor solubility across the solvent range, the problem becomes more complex.

Hot Melt Extrusion

Processing Temperature Selection

Preparation of a robust ASD requires sufficient interaction between the API and polymer, allowing stabilization of the high-energy amorphous API to prevent recrystallization during storage. MEL and PVPVA have previously been shown to have strong interactions, evidenced by a significant melt point depression (20). Through manipulation of favorable interactions, an API can be solubilized into a polymer below its melting point (21). Problems arise as the selection of suitable polymers is further limited and the product has a higher likelihood of containing some residual crystalline material. It has been suggested that the use of melt point depression by interaction with a suitable polymer can overcome the issue of degradation by operating at temperatures below the API melt onset (22). However, in this work, the incorporation of increasing PVPVA loaded physical mixtures with MEL has shown that a corresponding depression in degradation onset occurs simultaneously with melting (20). TGA thermograms show a degradation onset of 260.2 ± 0.3 °C for MEL, which is significantly lowered in the presence of PVPVA, shifting to 215.2 ± 0.6 °C at 10%wt MEL (Fig. 2, Table II), highlighting the importance of the melting event and designing a process within the limits (23). The corresponding DSC traces of MEL, the physical mixture, and processed solids are shown in Fig. 3.

Processability Design Space

To determine the processing space for MEL (10%wt) and PVPVA in the presence of DMF, investigations to assess the effect of barrel temperature and amount of DMF added on torque output recorded were performed (Table III). DMF was selected as the solvent for this investigation based on its boiling point and the proposed extrusion processing temperatures, a solvent that would not evaporate quickly upon addition. MEL also exhibits poor solubility across a range of solvents, which further restricted options (24). Solubility of MEL and PVPVA in DMF factor was considered based on the hypothesis that promotes amorphization through solubilization of components. DMF addition into the HME process was assessed initially in terms of how it affected the processing of the formulation in the extruder. As expected, a general trend of decreasing torque was observed with increasing temperature due to increased mobility in the system (Fig. 4) (25). At 150 °C, the MEL-PVPVA mixture was not processable in the absence of DMF, with torque exceeding the maximum (100% at 12 Nm). A 10 °C step increase in barrel temperature to 160 °C allowed the processing of the blend to obtain a uniform cylindrical extrudate. The approximate lower temperature limit for processing this blend under set parameters — screw configuration, screw speed, and feed rate — was identified, observing a torque output of 64 ± 3%. With incremental increases to 170 °C and 180 °C, further decreases in torque were observed as the blend became less viscous.

With an increasing portion of DMF added, a general trend in reduced torque was observed across all temperatures, 150–180 °C. Having shown that processing MEL/PVPVA at 150 °C was not feasible, the addition of DMF into the system at 0.05 mL/min resulted in a significantly decreased torque output of 65 ± 2%, allowing successful processing of this system, attaining a solid extrudate. A further decrease to 56 ± 2% was recorded when 0.1 mL/min DMF was added at 150 °C, as the solvent appeared to plasticize the system further. However, when 0.15 mL/min DMF was added into the system, the pressure in the die exceeded the set maximum, 90 bar, causing a stoppage of the run. A higher volume of material due to a lack of solvent removal at the port was thought to contribute to the increase in pressure, as a result, there was no recorded torque value for this experiment. Similar trends of increasing DMF addition resulting in decreasing torque output were observed across barrel temperatures at 160 °C, 170 °C, and 180 °C. Incremental increases in DMF addition rate was limited to 0.175 mL/min due to a lower quality of extrudate produced at higher addition rates; 0.2 mL/min addition rate produced unstructured and highly viscous extrudate material for those extruded at 160 °C, 170 °C, and 180 °C, due to the greater portion of the solvent in the formulation. Hence, it was determined that the upper limit of solvent addition for these temperatures was 0.175 mL/min to maintain structural integrity.

The major advantage of solvent addition during HME was immediately recognized, as DMF increased mobility of the system, potentially acting as a plasticizer. This significantly reduced the torque and die pressure in comparison with the formulation processed in absence of solvent, comparable with other reported low plasticizers with low-temperature glass transition or melting temperatures (25, 26). Ultimately, this led to a lowered viscosity of the system, meaning formulations could be processed at lower temperatures, providing an opportunity to decrease the risk of degradation. This was attributed to the fact that the polymer, which formed the majority of the formulation, was highly soluble in DMF. Although plasticizers can improve processability by lowering the glass transition, it was considered that the probability of crystallization of the ASD’s becomes more prominent (27, 28).

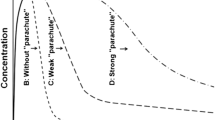

Preparation of Amorphous MEL

Samples prepared at 170 °C, with solvent addition rates in the range 0–0.175 mL/min, were further analyzed for amorphous content using PXRD (Fig. 5). A general trend showed that with increasing DMF addition rate during HME, a correlating increase in conversion of MEL to its amorphous form was achieved, i.e., a reduction in residual crystalline content. Significant escalation of amorphous material quantified post extrusion when DMF was added up to the maximum rate of 0.175 mL/min. Using SC1, with MEL/PVPVA processed in the absence of DMF, 62 ± 1% of the API content was converted to its amorphous form. Remarkably, this was enhanced to almost complete conversion, with 97% of MEL content in its amorphous form when the system was extruded with 0.175 mL/min DMF. It was proposed that the DMF would solubilize a portion of MEL and PVPVA, enabling the additional breakdown of the crystalline MEL. This hypothesis of a solvent acting as a catalyst for conversion was supported by the reduced residual crystalline content observed with an increasing portion of DMF addition during HME. At lower temperatures, the increased mobility provided by the incorporation of DMF was evident, possibly further promoting the likelihood of amorphous formation and interaction with PVPVA.

Mechanical energy input was varied to assess its contribution towards the preparation of the MEL/PVPVA ASD by modification of the screw configuration design. Incorporation of more mixing elements was used to create a higher mechanical input, and likewise, removal of those elements created a lower mechanical input (29). Screw configuration 1 (SC1), the original screw design, was compared against a more intensive mixing design (SC2) and a less intensive mixing design (SC3). Both SC2 and SC3 produced a similar trend across all DMF addition rates to that observed using the original SC1 — increasing DMF addition rates resulted in an increase in conversion to the amorphous form of MEL. By changing the screw design, the mechanical exertion on the blend changes. However, there was a limited effect on the amount of amorphous material quantified in the extrudates from each screw design across the DMF addition rate range (Fig. 5). Above a certain maximum processing temperature, it has been shown that the mechanical input may no longer have an effect in driving amorphous conversion (29); it is postulated that in this case, the addition of DMF, along with high temperatures, mitigates effects introduced from mechanical sources.

Solvent Removal

An important consideration when adding an organic solvent into a pharmaceutical process is the removal of the said solvent prior to preparation of the final dosage form (30). Ideally, a class III solvent would have been used in this investigation; however, with noted poor solubility of MEL across a range of organic solvents, in addition to the desired HME processing temperatures, DMF was considered a viable option. ASD preparation via SD requires large amounts of solvent, and although the majority is removing during the spraying process, commonly, a secondary drying step is implemented to remove residual quantities (31). Similarly, with the SA-HME process detailed in this work, the addition of solvent into a traditionally solvent-free process must be considered in the same context. Solvent content in the extrudates produced using SC1 is illustrated in Fig. 5. The incorporation of an open vent port in the HME barrel design was intended to serve the purpose of allowing the solvent to evaporate from the formulation prior to extrusion through the die and solidification. Due to processing above the vaporization point of DMF, 153 °C, it was thought that this would facilitate the removal of at least a portion from the formulation. Unfortunately, the solvent content of the milled extrudates, measured using TGA, was not significantly lower than the theoretical amount added during processing (Fig. 6). The open circle plot indicates the theoretical portion of DMF contained within the extrusion blend at each addition rate. At 0.175 mL/min for instance, it was calculated that DMF composed 3.9%wt of the total formulation. The square plot shows the DMF content measured in the extrudates obtained from each processing condition, indicating there was limited removal during processing. After drying the milled extrudates in a vacuum oven at 60 °C, a significant reduction in DMF content was observed, with 0.9 ± 0.7%wt DMF content measured. Optimization of the drying conditions would be required to lower the solvent level below ICH Q3C limits. To confirm that the drying process had no impact on crystallinity, the extrudate samples were analyzed by XRPD before and after drying (Fig. 7).

Solvent content recorded in HME milled extrudates MEL/PVPVA using TGA weight loss analysis, compared to the theoretical solvent added during HME. Open circle; theoretical solvent added during HME, square; solvent content recorded post-processing, triangle; solvent content recorded post-secondary drying

CONCLUSION

In this work, a new approach is presented, utilizing HME technology to prepare an ASD of MEL in PVPVA. Operating below the melting onset of MEL, it was possible to achieve a significant reduction in residual crystalline content. The addition of DMF solvent during HME processing enabled increased conversion to the amorphous form at lower temperatures, aided by the increasing mobility of the mixture. Although DMF removal during HME processing through a vented section was limited, incorporation of a secondary vacuum drying step resulted in a significant reduction of DMF content. This work expands the applicability of HME to compounds typically excluded due to high melting or degradation, but further investigation and optimization of the selected solvent and process conditions would be required to yield an acceptable product. Additional studies could be conducted to investigate alternative API-polymer–solvent tertiary systems, considering an organic solvent with lower toxicity and polymers with a lower Tg to enable the processing of thermally labile active pharmaceutical ingredients (APIs).

References

Zografi G, Newman A. Introduction to amorphous solid dispersions. In: Newman A, editor. Pharmaceutical amorphous solid dispersions. New Jersey: Wiley; 2015. p. 1–42.

Xie T, Gao W, Taylor LS. Impact of Eudragit EPO and hydroxypropyl methylcellulose on drug release rate, supersaturation, precipitation outcome and redissolution rate of indomethacin amorphous solid dispersions. Int J Pharm. 2017;531(1):313–23. https://doi.org/10.1016/j.ijpharm.2017.08.099.

Matsumoto T, Zografi G. Physical properties of solid molecular dispersions of indomethacin with poly(vinylpyrrolidone) and poly(vinylpyrrolidone-co-vinyl-acetate) in relation to indomethacin crystallization. Pharm Res. 1999;16(11):1722–8. https://doi.org/10.1023/A:1018906132279.

Kaushal AM, Gupta P, Bansal AK. Amorphous drug delivery systems: molecular aspects, design, and performance. Crit Rev Ther Drug Carrier Syst. 2004;21(3):133–93. https://doi.org/10.1615/CritRevTherDrugCarrierSyst.v21.i3.10.

Newman A, Nagapudi K, Wenslow R. Amorphous solid dispersions: a robust platform to address bioavailability challenges. Ther Deliv. 2015;6(2):247–61. https://doi.org/10.4155/tde.14.101.

Coates PD, Barnes SE, Sibley MG, Brown EC, Edwards HGM, Scowen IJ. In-process vibrational spectroscopy and ultrasound measurements in polymer melt extrusion. Polymer (Guildf). 2003;44(19):5937–49. https://doi.org/10.1016/S0032-3861(03)00544-5.

Maniruzzaman M, Nokhodchi A. Continuous manufacturing via hot-melt extrusion and scale up: regulatory matters. Drug Discov Today. 2017;22(2):340–51. https://doi.org/10.1016/j.drudis.2016.11.007.

Nežić I, Sander A, Meštrović E, Čavužić D. Production of stable amorphous form by means of spray drying. Part Sci Technol. 2019;37(5):628–38. https://doi.org/10.1080/02726351.2017.1417936.

Kelleher JF, Gilvary GC, Madi AM, Jones DS, Li S, Tian Y, et al. A comparative study between hot-melt extrusion and spray-drying for the manufacture of anti-hypertension compatible monolithic fixed-dose combination products. Int J Pharm. 2018;545(1–2):183–96. https://doi.org/10.1016/j.ijpharm.2018.05.008.

O’Neill MJ. Meloxicam. In: Co. M and, editor. The Merck Index - an Encyclopedia of chemicals, drugs, and biologicals. New Jersey: Whitehouse Station; 2006. p. 1006.

Cheney ML, Weyna DR, Shan N, Hanna M, Wojtas L, Zaworotko MJ. Coformer selection in pharmaceutical cocrystal development: a case study of a meloxicam aspirin cocrystal that exhibits enhanced solubility and pharmacokinetics. J Pharm Sci. 2011;100(6):2172–81. https://doi.org/10.1002/jps.22434.

Cheney ML, Weyna DR, Shan N, Hanna M, Wojtas L, Zaworotko MJ. Supramolecular architectures of meloxicam carboxylic acid cocrystals, a crystal engineering case study. Cryst Growth Des. 2010;10(10):4401–13. https://doi.org/10.1021/cg100514g.

Weyna DR, Cheney ML, Shan N, Hanna M, Zaworotko MJ, Sava V, et al. Improving solubility and pharmacokinetics of meloxicam via multiple-component crystal formation. Mol Pharm. 2012;9(7):2094–102. https://doi.org/10.1021/mp300169c.

Suzuki H, Yakushiji K, Matsunaga S, Yamauchi Y, Seto Y, Sato H, et al. Amorphous solid dispersion of meloxicam enhanced oral absorption in rats with impaired gastric motility. J Pharm Sci. 2017;107(1):446–52. https://doi.org/10.1016/j.xphs.2017.05.023.

Haser A, Cao T, Lubach JW, Zhang F. In situ salt formation during melt extrusion for improved chemical stability and dissolution performance of a meloxicam-copovidone amorphous solid dispersion. Mol Pharm. 2018;15(3):1226–37. https://doi.org/10.1021/acs.molpharmaceut.7b01057.

Bhende S, Jadhav N. Moringa coagulant as a stabilizer for amorphous solids: part I. AAPS PharmSciTech. 2012;13(2):400–10. https://doi.org/10.1208/s12249-012-9755-x.

Huang S. Application of hot-melt extrusion in the manufacturing of amorphous solid dispersions containing thermally labile drugs. University of Texas at Austin; 2017. https://repositories.lib.utexas.edu/handle/2152/47149. Accessed 24 Aug 2021

HengsawasSurasarang S, Keen JM, Huang S, Zhang F, McGinity JW, Williams RO. Hot melt extrusion versus spray drying: hot melt extrusion degrades albendazole. Drug Dev Ind Pharm. 2017;43(5):797–811. https://doi.org/10.1080/03639045.2016.1220577.

Seedher N, Bhatia S. Solubility enhancement of cox-2 inhibitors using various solvent systems. AAPS PharmSciTech. 2003;4(3):36–44. https://doi.org/10.1208/pt040333.

Haser A, Huang S, Listro T, White D, Zhang F. An approach for chemical stability during melt extrusion of a drug substance with a high melting point. Int J Pharm. 2017;524(1–2):55–64. https://doi.org/10.1016/j.ijpharm.2017.03.070.

Marsac PJ, Shamblin SL, Taylor LS. Theoretical and practical approaches for prediction of drug-polymer miscibility and solubility. Pharm Res. 2006;23(10):2417–26. https://doi.org/10.1007/s11095-006-9063-9.

Moseson DE, Taylor LS. The application of temperature-composition phase diagrams for hot melt extrusion processing of amorphous solid dispersions to prevent residual crystallinity. Int J Pharm. 2018;553(1–2):454–66. https://doi.org/10.1016/j.ijpharm.2018.10.055.

Stutzman J, Huang S, Williams RO, O’Brien J, O’Donnell KP, Delpon de Vaux SM. Processing thermally labile drugs by hot-melt extrusion: the lesson with gliclazide. Eur J Pharm Biopharm. 2017;119:56–67. https://doi.org/10.1016/j.ejpb.2017.05.014.

Castro GT, Filippa MA, Sancho MI, Gasull EI, Almandoz MC. Solvent effect on the solubility and absorption spectra of meloxicam: experimental and theoretical calculations. Phys Chem Liq. 2020;58(3):337–48. https://doi.org/10.1080/00319104.2019.1594224.

Repka MA, McGinity JW. Influence of vitamin E TPGS on the properties of hydrophilic films produced by hot-melt extrusion. Int J Pharm. 2000;202(1–2):63–70. https://doi.org/10.1016/S0378-5173(00)00418-X.

Ghebremeskel AN, Vemavarapu C, Lodaya M. Use of surfactants as plasticizers in preparing solid dispersions of poorly soluble API: selection of polymer-surfactant combinations using solubility parameters and testing the processability. Int J Pharm. 2007;328(2):119–29. https://doi.org/10.1016/j.ijpharm.2006.08.010.

Crowley MM, Zhang F, Repka MA, Thumma S, Upadhye SB, Battu SK, et al. Pharmaceutical applications of hot-melt extrusion: part I review article. Drug Dev Ind Pharm. 2007;22:909–26. https://doi.org/10.1080/03639040701498759.

Agrawal AM, Dudhedia MS, Zimny E. Hot melt extrusion: development of an amorphous solid dispersion for an insoluble drug from mini-scale to clinical scale. AAPS PharmSciTech. 2016;17(1):133–47. https://doi.org/10.1208/s12249-015-0425-7.

Ma X, Huang S, Lowinger MB, Liu X, Lu X, Su Y, et al. Influence of mechanical and thermal energy on nifedipine amorphous solid dispersions prepared by hot melt extrusion: preparation and physical stability. Int J Pharm. 2019;561(March):324–34. https://doi.org/10.1016/j.ijpharm.2019.03.014.

ICH. Q3C(R6) Impurities: Guideline for residual solvents. ICH Harmonised Guideline 2016. https://database.ich.org/sites/default/files/Q3C-R6_Guideline_ErrorCorrection_2019_0410_0.pdf. Accessed 24 Aug 2021

Paudel A, Worku ZA, Meeus J, Guns S, Van Den Mooter G. Manufacturing of solid dispersions of poorly water soluble drugs by spray drying: formulation and process considerations. Int J Pharm. 2013;453(1):253–84. https://doi.org/10.1016/j.ijpharm.2012.07.015.

Acknowledgements

The authors acknowledge funding for this project provided through a tripartite grant (USI 090) awarded by the Department for the Economy NI, Sciences Foundation Ireland, and the National Sciences Foundation (USA).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lagan, C., Huckle, J.E., Katz, J.M. et al. Solvent-Assisted Hot Melt Extrusion of a Thermally Labile, High Melting Point Compound. AAPS PharmSciTech 22, 235 (2021). https://doi.org/10.1208/s12249-021-02122-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-021-02122-7