Abstract

As the packaging of choice for many therapeutic proteins, prefilled syringes have been widely used in biopharmaceutical industry as primary containers, where silicone oil is applied to ensure their proper functionality. Adequate lubrication from sufficient amount of silicone oil and its appropriate distribution across syringe barrels is crucial for successful administration of drug product (DP) from the prefilled syringes; however, silicone oil is also susceptible to leaching from the syringe surface into the formulation with the potential to interact with therapeutic proteins, which could lead to the formation of visible and sub-visible aggregates and/or particles that are potentially immunogenic. Accurate determination and careful control of silicone oil levels in both empty syringes and protein drug products are therefore critical in process development to ensure syringe functionality, drug product quality, and patient safety. On the other hand, analysis of silicone oil can be challenging especially when the analysis is performed on formulated protein drug products, where matrix effects could be significant. It is demonstrated in this study that silicone oil in empty syringes or formulated drug products can be extracted effectively using organic solvents and quantitatively determined using high-performance liquid chromatography (HPLC) coupled with a universal detector. It was also shown that direct extraction of silicone oil from formulated protein drug products can be very challenging, but pretreatment of the protein drug products with pepsin enzymatic digestion facilitated the extraction process, which enabled the analysis of silicone oil in the drug product at low ppm levels.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Prefilled syringes (PFS) have become the preferred primary containers for protein therapeutics in parenteral formulation because of advantages such as precise dosing, elimination of overfill, and simplicity of use when compared to conventional primary containers such as glass vials and ampoules (1). Proper function of PFS depends heavily on a thin film of silicone oil applied to the inner surface of the syringe barrel, where silicone oil functions as a lubricant facilitating the plunger to slide down the barrel for successful drug administration. Typically, a thin layer of silicone oil is generated on the interior surface of the syringe barrel using either a spray-on or baked-on process, which deposits varied amount of silicone oil with levels typically between 0.05 and 1 mg per syringe barrel. However, generation of a uniform thin film on the syringe barrel with such a low amount of silicone oil is a challenging process with significant consequences. For example, insufficient lubrication due to a local deficiency of silicone oil on the barrel could lead to a failed delivery of drug product (DP) to the patient. Therefore, monitoring and characterization of the silicone oil level and its distribution on the barrel of PFS during the development, production, and storage of syringes are critical to ensure the quality of the PFS systems.

Despite the critical role it plays in the functionality of PFS, silicone oil presents as a significant challenge in parenteral drug formulation and delivery with PFS. There is mounting evidence that certain protein formulations are susceptible to form visible and sub-visible aggregates and/or particles in the presence of silicone oil (2,3,4,5). Absorption of proteins at the interface between water and silicone oil, either on the syringe barrel or leached into solution, was proposed to be the major factor for protein aggregation and particle formation in syringes. Silicone oil leached into the formulation may dominate in its interaction with the therapeutic proteins because of the large surface areas of the small droplets it forms and could play a major role in protein aggregate/particle formation. The induced protein particles can be a safety concern because they may trigger an undesired immune response such as allergic reactions and/or autoimmune disorders when injected into patients (6,7). In addition to protein aggregation/particle formation induced by leached silicone oil, silicone oil itself a known residue in PFS could have a negative impact to product quality with potential risk to patient safety. Studies evaluating the potential impact of silicone oil to patient were published with conflicting results; while some studies suggested no increased risk of immunogenicity with silicone oil droplet generated from simulated handling of drug product mimicked by drop shock (8), other studies (9,10) showed potential immune response from sub-micron- and micron-size silicone oil droplets leached into the PFS after drop shock conditions. To eliminate potential safety risk associated with the leached silicone oil, silicone oil–free PFS has been developed with polymeric material such as cyclic olefin polymer (11). However, glass PFS are still dominant in the current PFS market. When a glass PFS is chosen as the drug delivery device, accurate quantitation of silicone oil in drug products becomes important in drug formulation development and optimization to ensure drug product quality and patient safety.

A commonly used form of silicone oil for medical applications is poly (dimethyl siloxane) (PDMS) [(CH3)2Si-O]n (12). Analysis of silicone oil is challenging because of its chemical inertness and generally existence as a mixture of polymers. In a recent study, Fourier transform infrared (FTIR) spectroscopy has been employed to measure the total silicone oil level in PFS after solvent extraction of the syringe barrel (13). The thickness of silicone oil film at different locations of the barrel was also determined in that study using reflectometry after sampling along the syringe barrel. It was demonstrated in this study that quantitation of total silicone oil on the syringe barrel can be alternatively achieved using size exclusion (SEC) HPLC coupled with a universal detector (14,15,16,17,18,19) with higher throughput and the distribution of silicone oil along the syringe barrel can also be revealed using a segment extraction strategy.

Compared to that in empty syringes, analysis of silicone oil leached into formulated protein drug products from PFS is particularly challenging due to its trace levels and the complex matrices in which it exists. Challenges in the analysis are also compounded by other issues such as losses due to the hydrophobic nature of silicone oil and contamination from inorganic silicon sources. Various analytical techniques such as IR spectroscopy (20), Rapid ID (20), Schlieren optics (20), Raman spectroscopy (21), GC/MS (22), NMR (23), and atomic absorption spectroscopy (24) have been used successfully for silicone oil analysis within complex matrix but suffered from a range of limitations such as low specificity, sensitivity, applicability to only low molecular silicone, and/or time-consuming sample preparation. To the best of our knowledge, no method has been reported to analyze silicon oil in protein drug products at trace levels that are typically encountered in protein drug product packaged in PFS. Based on enzymatic pepsin digestion of therapeutic proteins followed by solvent extraction and size exclusion HPLC analysis, a novel analytical approach is described in this study which is capable of quantitation of silicone oil at low ppm levels in protein drug products.

MATERIALS and METHODS

Materials

One milliliter and 0.6 mL siliconized and un-siliconized pre-fillable glass syringe barrels and plungers were obtained from an undisclosed manufacturer. Un-siliconized glass laboratory syringes used for toluene solvent transferring were obtained from Unimetrics. Silicone oil standards with average molecular weights of 17 K were obtained from Alfa Aesar (Tewksbury, MA, USA). Toluene used as HPLC mobile phase and solvent for silicone oil extraction of syringe barrels was HPLC grade purchased from Burdick and Jackson (Morris Plains, NJ, USA). HPLC grade ethyl acetate used in silicone oil extraction in drug product was also obtained from Burdick and Jackson. Pepsin and 1 N HCl were obtained from Sigma Aldrich (St. Louis, Mo, USA).

Extraction of Silicone Oil from Glass Barrels and the Plunger-Product Contact Surface

To extract total silicone oil from syringe barrels, the entire glass barrel was submerged inside a cylindrical glass test tube containing 9 mL of toluene after the syringe needle along with the needle shield was removed from the needle-glass interface (Fig. 1). The test tube was capped with a glass beaker to minimize solvent loss. To extract silicone oil from the plunger-product contact surface, the needle and needle shield were similarly removed from un-siliconized syringe, and then a siliconized plunger was subsequently inserted into the un-siliconized glass syringe barrel from the flange side of the syringe. The plunger-product surface was extracted for 10 min after the addition of 100 μL of toluene to cover the entire exposed plunger surface inside the syringe. The extraction solvent was subsequently transferred to an HPLC autosampler vial for analysis. Another 100 μL of toluene was added to the plunger-product surface area as rinse, immediately removed, and combined with the solvent from previous extraction.

Segment Extraction of Silicone Oil from the Syringe Barrel

After needle and needle shield removal, the exterior of the barrel was marked at 0.5 cm increments from the flange side of the syringes and a siliconized plunger was manually inserted to Segment 1 position as shown in Fig. 1. Toluene was applied to Segment 1 using a laboratory syringe that was carefully inserted into the PFS without touching other segments. After 10 min at room temperature, toluene was removed using a laboratory syringe and placed into an HPLC autosampler glass vial with a Teflon laminated cap. A second aliquot of toluene was added to Segment 1 as rinse, immediately removed, and combined with the first extraction aliquot. To extract the remaining segments, the plunger was glided to the next segment and extraction procedure described above was repeated for Segments 2–9.

Extraction of Silicone Oil Spiked in Formulated Drug Products

Formulated protein drug products, which have never been exposed to silicone oil, were spiked with 1 ppm, 2 ppm, or 5 ppm silicone oil by adding 10 μL of 100 ppm, 200 ppm, or 500 ppm, respectively, of silicone oil standards dissolved in ethyl acetate into a glass test tube loaded with 990 μL of protein drug product. The spiked samples were covered with a glass lid and parafilm and mixed via vortex for 10 s. For silicone oil extraction, 1 mL of pepsin solution at a concentration of 50 mg/mL in 0.1 N HCl was added, and then the spiked DP samples were incubated at 40°C for 4 h. After incubation, the samples were cooled down to room temperature and extracted with ethyl acetate of varied amounts via vortex for 2 min, during which the samples were also covered with a glass lid and parafilm. Spiked DP samples without addition of pepsin were directly extracted with ethyl acetate as controls. The samples were subsequently centrifuged at 3500 rpm for 20 min, after which the total volume of the organic layer was measured and 120 μL of the extract was transferred for HPLC analysis. When a second extraction was desired, the water layer was carefully transferred using Pasteur pipets into a new glass test tube, into which new aliquots of extraction solvent were added. The second extraction was performed using a similar procedure as described above.

SEC-HPLC-ELSD/CAD Analysis of Silicone Oil Extraction

Agilent HPLC (1100 series) with size exclusion column was used for silicone oil analysis. Evaporative Light Scattering Detector (ELSD) (Sedex 75, Sedere, France) was used to quantitate total silicone oil extraction from empty syringes, while silicone oil extracted from spiked DP was analyzed by charged aerosol detector (CAD) (Corona Ultra RS, Thermos Scientific, Waltham, MA). Except for the detector, other HPLC parameters were identical in both analyses. Silicone oil standards dissolved in ethyl acetate with varied concentrations from 5 to 100 ppm were employed to build calibration curves for quantitation of total silicone oil extracted from empty syringes, while standards with concentration from 0.2 to 5 ppm were used to generate calibration curves for the quantitation of silicone oil extracted from spiked DP. One hundred microliters of the extract was injected onto the SEC column (Phenomenex, 00H-0441-K0, 300 × 7.8 mm, 5 μ, 50 Å for quantitation of silicone oil extract from the drug product or Phenomenex, 00H-0445-K0, 300 × 7.8 mm, 5 μ, 10,000 Å for total quantitation of extract from empty syringes) and separated with an isocratic flow rate of 1.0 mL/min using 100% toluene for 10 min. The temperature, N2 pressure, and signal gain were set for ELSD at 50°C, 3.4 bar, and 7, respectively. In CAD detection, the key parameters of nebulizer temperature, filter, and power function were set to 35°C, 3.0, and 1.0, respectively.

RESULTS AND DISCUSSION

Silicone Oil Analysis Using Solvent Extraction and SEC-HPLC

Specificity of the Method

Because of the challenges in silicone oil analysis, some methods started with a solvent extraction step to concentrate and/or isolate silicone oil from its matrix/interference, which provides an effective way to increase method sensitivity and specificity. Some specific physicochemical features of the silicone oil can be used during detection to further increase the specificity of the method after extraction. For example, the 1261 cm−1 infrared spectra absorbance peak (symmetrical (CH3)2-Si deformation band) of PDMS was used for silicone oil quantitation with FTIR (9). Depending on the applications, the extraction step alone may provide specificity high enough for quantitation when the matrix/interference was negligible, as is the case in the current study of empty PFS, or an extraction step can be coupled with a separation technique such as HPLC to provide a specificity high enough to discriminate against all interferences, as shown in this study for the analysis of silicone oil in the formulated drug product. If sufficient specificity can be achieved before the detection step, a universal detector such as ELSD or CAD can be used for high sensitivity. The use of a size exclusion separation step in the current study was intended to separate any potential small molecule interference co-extracted with the silicone oil. A SEC-HPLC/ELSD chromatogram of silicone oil extracted from a glass syringe using toluene is shown in Fig. 2a, where no interference is observed. Similarly, no major interferences were observed in the HPLC/ELSD analysis of solvent extract of protein DP 1 that was never exposed to silicone oil (Fig. 2b, lower trace) and silicone oil was the only major peak detected in solvent extract of the protein DP 1 spiked with 10 ppm of silicone oil (Fig. 2b, upper trace).

Linearity, Limit of Detection, Limit of Quantitation, and Precision of SEC-HPLC/ELSD and SEC-HPLC/CAD Methods

The performance of the analytical methods proposed for silicone oil analysis was characterized by using a set of silicone oil standards in various concentrations. Standards of 5, 10, 25, 50, and 100 ppm were used for SEC-HPLC/ELSD tests, while standards of 0.2, 0.3, 0.5, 1, and 5 ppm were used for SEC-HPLC/CAD tests. A linear relationship between the detector responses and the concentrations of the standards were observed with correlation coefficients (R2) > 0.9 for both methods (Table I). Based on signal to noise ratio (S/N) (Table I) of the HPLC peaks from the silicone oil standards, the limit of detection (LOD) and limit of quantitation (LOQ) of the assay were estimated to be 2 and 5 ppm, or 0.2 and 0.5 μg of silicone oil on column, respectively, for the SEC-HPLC/ELSD method, while the LOD and LOQ were estimated to be 0.2 and 0.5 ppm, or 20 and 50 ng of silicone oil on column, respectively, for the SEC-HPLC/CAD method. Using the standards with concentration at the level of LOQ, the precisions of the two methods were determined to be 5% and 11% for SEC-HPLC/ELSD and SEC-HPLC/CAD, respectively, from the analysis of five replicates. The high sensitivity from CAD is particularly useful in the analysis of silicone oil leachates in DP packaged in PFS as its concentration is often below the LOQ of ELSD. Therefore, SEC-HPLC/CAD was used in this study to analyze solvent extract of DP spiked with silicone oil at low concentrations, while SEC-HPLC/ELSD was used to analyze silicone oil from empty syringe where silicone oil exists at much higher levels.

Analyses of Silicone Oil in Empty Syringes

Extraction of Syringes

Silicone oil can be readily extracted from the inner surface of the syringe barrel by submerging the syringe into a glass test tube filled with toluene. Before the extraction, the needle along with the needle shield was first removed from the syringe (Fig. 1) to eliminate the silicone oil applied to the exterior of the needle and also the adhesive material that was used to attach the needle to the syringe body. Initial exploration of the extraction condition was performed at room temperature with a static extraction of 24, 48, and 72 h without physical mixing, which showed no difference in the amount of extracted silicone oil. A second set of experiments testing the effect of physical mixing on the extraction was performed with three conditions of no mixing, hand shaking for 5 min, and sonication at 37°C for 5 min, after initial static extraction of 24, 48, and 72 h. Similar results were obtained from all conditions in this testing, which suggests that the thin layer of silicone oil on the barrel surface can be readily extracted with toluene. Because of the ease of extraction with toluene, static extraction for 10 min was selected in further experiments, which achieved a near complete extraction of silicone oil from the barrel as indicated by the analysis of a second extraction showing a residue level below 2 ppm, the LOD of the method, which translated into an extraction efficiency of >96% for a syringe with silicone oil determined to be 559.8 μg/syringe.

Quantitation of Total Silicone Oil on Syringe Barrels

Total amount of silicone oil on a syringe barrel is an important quality attribute of PFS and therefore normally included in the syringe specifications. SEC-HPLC/ESLD can be used as a quality control tool to monitor the total silicone oil on syringe barrels ensuring high-quality PFS to be released for drug product fill. Furthermore, monitoring PFS from different lots could also reveal potential process deviation during the siliconization process in the syringe manufacturing. As shown in Fig. 3, where the average (n = 10) amount of silicone oil on the syringe barrel from a specific PFS lot was plotted as a function of 39 PFS lots produced from undisclosed manufacturer, important product and process information can be derived from the silicone oil levels of different PFS lots measured with SEC-HPLC/ELSD. From the production history of the syringe lots shown in Fig. 3, where the lots were listed in the chronological order, it is apparent that the syringe manufactured in the first 16 PFS lots suffered from a large inter-lot variation in the silicone oil levels, which ranged from 0.13 to 0.33 mg/barrel. An improvement in the process was suggested by the smaller inter-lot variation in the average silicone oil level of the lot, which varied from 0.24 to 0.36 mg/barrel except for one outlier of lot#28. A closer examination of the data revealed a smaller intra-lot variation after the possible process improvement as the intra-lot RSD% averaged from all lots before and after the process change decreased from 20.75 to 13.49%. An increase in the average amount of silicone oil on the barrel was also revealed from the SEC-HPLC/ELSD analysis as the average amount of silicone oil of 0.21 mg/barrel before process change increased to 0.31 mg/barrel in the after-change lots. The analysis also revealed a significant deviation from the process during the production of lot#28, which has an average silicone oil level of 0.10 mg/barrel, significantly lower than that from other lots. Consistent with the low levels of silicone oil from SEC-HPLC/ELSD measurement, major problems such as syringe stalling were observed from the filled syringes with this lot, while no issues were found with syringes from lot 32, which was also filled and tested.

Distribution of Silicone Oil on Syringe Barrel

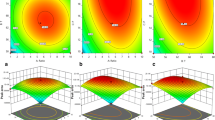

Although total silicone oil quantitation with SEC-HPLC/ELSD provided valuable information about syringe quality and the manufacturing process as discussed above, the information about the distribution of silicone oil on the inner surface of the syringe was lost in such measurements. The distribution profile of silicone oil can be obtained when a segment extraction strategy is applied to the syringe barrels with SEC-HPLC/ELSD analysis of each segment extraction. In a segment extraction, a small aliquot (e.g., 100 μL) of extraction solvent was applied to part of the barrel inner surface each time with multiple micro-extractions being made along the barrel in a sequential manner. Because of the high sensitivity of the analytical assay, the small amount of silicone oil in the micro-extraction can be successfully determined. As shown in Fig. 4a, where a nine-segment extraction was conducted on 10 newly manufactured syringes, there was an uneven distribution of silicone oil along the syringe barrel, as suggested by the differences in the levels of silicone oil in each segment. The silicone oil levels progressively decreased from the syringe flange side to the needle side, i.e., from Segment 1 to 9, which contained 153 and 12 μg of silicone oil, respectively. It was noteworthy that Segment 1 contained silicone oil from both the glass barrel and the plunger, while silicone oil from the remaining segments was from the barrel alone. Since 54 μg of silicone oil was contributed from the plunger as determined from a separate experiment, Segment 1 contained approximately 99 μg of silicone oil from glass barrel. Measurement of silicone oil uniformity along the barrel was significant because proper distribution of silicone oil across the syringe surface is critical to syringe functionality as lack of sufficient lubrication due to local deficiency of silicone oil could lead to an incomplete delivery of drug product. Segment extraction and SEC-HPLC/ELSD analysis have been successfully used to find the root cause of an incident of syringe stalling, which was attributed to the low amount of silicone oil close to the end of the syringe on the needle side.

Non-uniform distribution of silicone oil could result from the spray-on siliconization process used to manufacture the syringes and/or from gravity force, which mobilized the silicone oil along the syringe barrel during the storage period, in which the syringe needle was normally stored in an upright position. While the non-uniformity observed above resulted most likely from the manufacturing process since the syringes examined were newly produced, re-distribution of silicone oil along the syringe surface during storage has been observed with segment extraction. As shown in Fig. 4b, where a 6-segment extraction was performed on another type of PFS, re-distribution of silicone oil along the syringe surface during storage was clearly demonstrated. Similar to a new syringe as shown in Fig. 4a, a progressively changing silicone oil distribution profile was observed when the syringes were stored for 4 months vertically with needle in upright position (Fig. 4b 4 U). It seemed that the silicone oil migrated towards the needle side when syringes were stored with needle pointing downward (Fig. 4b 4D) and the silicone oil film becomes more uniform because of the re-distribution after storage with needle in downward position for 12 months ((Fig. 4b 12D).

Analysis of Silicone Oil in Drug Products

Compared to that in empty syringes, silicone oil in drug product was more challenging to analyze because of matrix interference from the formulated drug products. Isolation of silicone oil from the drug product through liquid-liquid extraction can significantly eliminate the sample complexity, but efficient extraction of silicone oil from a formulated DP can also be challenging per se. The challenge in analyzing silicone oil in protein drug products comes also from the low concentrations of silicone oil leached from a siliconized prefilled syringe barrel. The levels of leached silicone oil varied from one protein product to another, often in the levels of low ppm or even below, depending on many factors including the physicochemical properties of the protein, its specific formulations, protein concentration, and storage time. In the effort to develop a general method for silicone oil analysis in protein drug products, extraction conditions were first explored using a formulated protein DP1 (Table II). A silicone oil level of 10 ppm was spiked into this protein drug product that was never exposed to silicone oil. Because of its very low solubility in water and low cost, toluene was first used as the extraction solvent. However, direct extraction of this spiked drug product with toluene resulted in an emulsion solution after vortex. The formation of emulsion was less severe when extracted with ethyl acetate, when compared to toluene and several other solvents. Because of the limited emulsion formation with this protein DP and several other DP, ethyl acetate was selected as the extraction solvent for all other experiments.

Effective recovery of silicone oil from drug products depends largely on its partition between ethyl acetate and the formulated DP solution during extraction. Although silicone oil has limited solubility in pure water, its solubility can be significantly increased in formulated drug product because of its interaction with the excipients and/or the therapeutic protein. For example, as a common excipient used in syringe formulation, polysorbate 20 or polysorbate 80 may interact with silicone oil because of their amphiphilic properties. Hydrophobic interaction may also exist between silicone oil and the hydrophobic patches on the surface of a globular therapeutic protein molecule such as monoclonal antibodies. Considering the diversity of the formulations and the therapeutic proteins, the degree of their interaction with silicone oil may also vary. Therefore, under similar extraction conditions varied recovery rates of silicone oil from different formulated drug products were expected as shown in Fig. 5, in which the recovery rates of silicone oil were shown for six formulated protein drug products spiked with 5 ppm silicone oil. Among the six drug products being investigated, DP1–5 are monoclonal antibodies, while DP6 belongs to protein of approximately 30 kDa with relatively high hydrophobicity. DP4 and DP5 are the same antibodies similarly formulated but in different concentration with DP4 being 140 mg/mL and DP5 being 70 mg/mL. From a single extraction of 1 mL of drug product directly with 1 mL of ethyl acetate without sample pretreatment, the recovery rate is relatively low spanning a range from about 25 to 55%. Because of the low recovery, simple sample pretreatment such as dilution and pH adjustment were performed on drug products to shift the partition of silicone oil towards the organic phase during the extraction, but only limited success was achieved.

A hypothesis was proposed that silicone oil interacts with therapeutic proteins in the drug product, which prevented efficient recovery of silicone oil. Enzymatic digestion of the proteins into small peptides could break this interaction and potentially improve the recovery rates. As shown in Fig. 5, observations consistent with this hypothesis were obtained when the drug products were subjected to pepsin digestion followed by ethyl acetate extraction. Recovery from single extraction was improved for the six drug products to different extent with the largest increase being from DP1, whose recovery rate increased from 25 to 75%, while DP3 benefited much less from pepsin digestion. For the five antibody drug products, the benefits from using pepsin digestion seem to correlate with antibodies concentrations in the formulations with larger benefits being from antibodies of higher concentrations, as evident from the larger recovery improvement from DP 1 and DP 4, both of which were formulated in 140 mg/mL, compared to DP 2, 3, and 5, which are all formulated in 70 mg/mL. The concentration dependence of the recovery improvement upon pepsin digestion is supportive of the hypothesis of protein interaction with silicone oil leachate in the drug product, as a larger amount of proteins in the DP may lead to a higher degree of interaction. It is noteworthy that silicone oil extraction in formulated drug product is a complicated process, which can be influenced by multiple factors including solution properties. The solution properties of the drug product can be changed by the production of small peptides from digestion, the addition of pepsin for digestion, and the adjustment of solution pH for optimized digestion, all of which could affect the partitioning of silicone oil during extraction. While the mechanism through which the silicone oil recovery from spiked drug product improved with pepsin digestion is still unclear, the benefits from a pepsin digestion step were clearly indicated from this study.

The recovery of silicone oil after pepsin digestion can be further improved by using a larger amount of extraction solvent. The recovery rates from single extraction of 1 mL of drug product DP1, spiked with 5 ppm silicone oil, with different solvent volumes of 250, 500, 1000, and 2000 μL were 8.1, 66.2, 65.5, and 82.9 %, respectively. A very low recovery observed for the solvent volume of 250 μL was most likely due to the relatively high solubility of ethyl acetate in the formulated DP (ethyl acetate solubility in water: 8.3 g/ 100 mL at 20°C), which resulted in low volume recovery of the extraction solvent. The use of 2 mL of solvent in the extraction of 1 mL of drug product leads to a recovery of silicone oil >80% from single extraction, while the use of 1 mL or 0.5 mL of solvent in the extraction of 1 mL of drug product resulted in similar recoveries in single extraction. Theoretically, multiple extractions provide a higher recovery compared to single extractions with same amount of extraction solvent. When 1 mL of the test drug product was extracted in two steps with 250, 500, and 1000 μL per step, the combined recovery rates were 30.5, 84.0, and 93.5 %, respectively. Although recovery can be improved with large amount of extraction solvent and/or multiple extractions, the disadvantages were higher cost of solvents for the former strategy and more labor intensive for the latter. Another caveat of using very large amount of solvent to improve recovery is that the extracted silicone oil could be too diluted in the solvent to be detected by HPLC/CAD directly. Although this challenge can be met by concentrating the extract via solvent evaporation, it significantly increases the sample preparation time.

Good recoveries were also obtained from the protein drug product DP1 spiked with silicone oil at lower levels. As shown in Fig. 6, the recovery rates from a single extraction of 1 mL drug products DP1 spiked with silicone oil of 5, 2, and 1 ppm were 79.8, 62.4, and 49.5%, respectively, when extracted with 1 mL of ethyl acetate. When the spiked drug product was extracted twice with 1 mL of solvent in each extraction, the combined recovery rates increased to 89.4, 78.1, and 70.5 for the spiked levels of 5, 2, and 1 ppm, respectively. Recovery of silicone oil from DP1 spiked at the level of 0.5 ppm proved to be difficult when 1 mL of drug product was extracted with 1 mL of solvent, as the recovered silicone oil existed at a concentration near the detection limit of the HPLC method. However, as discussed above, an enrichment process may be used to concentrate the extracted silicone oil to overcome the challenge associated with the detection limit of the current analytical method but with an increased sample preparation time.

Recovery rates of silicone oil from single extraction of 1 mL of protein DP1 with 1 mL of ethyl acetate or combined recovery rates from two consecutive extractions of 1 mL test protein drug product with 2 mL of ethyl acetate (1 mL of ethyl acetate for each step) with silicone oil spiked at 1, 2, or 5 ppm

CONCLUSION

A new method based on solvent extraction and SEC-HPLC analysis has been successfully developed to quantitate silicone oil on glass pre-fillable syringes and in formulated protein drug products. Total silicone oil quantitation in empty syringes could serve as an important tool in quality control and process monitoring of syringe production, while analysis of silicone oil distribution across the syringe barrel surface with a segment extraction strategy could pinpoint a local deficiency of silicone oil on the syringe barrel, which can be problematic for syringe functionality. Uneven distribution of silicone oil across the syringe barrel could result from the syringe manufacturing processes and/or from the migration of silicone oil along the syringe barrel during their storage. The level of silicone oil was found to be higher on the flange side of the syringe barrel and lower on the needle side, while vertical storage of syringes for a certain period of time with needle facing down promoted a more even distribution of silicone oil across the barrel. Depending on the nature of the formulated protein drug products, direct extraction of silicone oil can be quite challenging. Pepsin digestion of protein drug product was shown to be critical for successful extraction of silicone oil from some protein drug products, although the mechanism though which the recovery of silicon oil was improved with pepsin digestion is still not fully understood. Post-digestion extraction combined with SEC-HPLC/ELSD measurement provided a sensitive method for silicone oil analysis in drug product at the level of low ppm.

References

Thompson I. New-generation auto-injectors: completing the scale of convenience for self-injection. Drug Delivery Report. 2005; Autumn/Winter:47-9.

Li J, Pinnamaneni S, Quan Y, Jaiswal A, Andersson FI, Zhang X. Mechanistic understanding of protein-silicone oil interactions. Pharm Res. 2012;29:1689–97.

Thirumangalathu R, Krishnan S, Ricci MS, Brems DN, Randolph TW, Carpenter JF. Silicone oil- and agitation-induced aggregation of a monoclonal antibody in aqueous solution. J Pharm Sci. 2009;98:3167–81.

Ludwig DB, Carpenter JF, Hamel J, Randolph TW. Protein adsorption and excipient effects on kinectic stability of silicone oil emulsions. J Pharm Sci. 2010;99:1721–33.

Jones LS, Kaufmann A, Middaugh CR. Silicone oil induced aggregation of proteins. J Pharm Sci. 2005, 2005;94:918–27.

Rosenberg AS. Effects of protein aggregates: an immunologic perspective. AAPS Journal. 2006;8:E501–7.

Joubert MK, Luo Q, Nashed-Samuel Y, Wypych J, Narhi LO. Classification and characterization of therapeutic antibody aggregates. J Biol Chem. 2011;286:25118–33.

Joh NH, Thomas L, Christian TR, Verlinsky A, Jiao N, Allotta N, et al. Silicone oil particles in prefilled syringes with human monoclonal antibody, representative of real-world drug products, did not increase immunogenicity in in vivo and in vitro model systems. J Pharm Sci. 2020;109:845–53.

Krayukhina E, Yokoyama M, Hayashihara KK, Maruno T, Noda M, Watanabe H, et al. An assessment of the ability of submicron- and micron-size silicone oil droplets in dropped prefillable syringes to invoke early- and late-stage immune responses. J Pharm Sci. 2019;108:2278–87.

Melo GB, et al. Critical analysis of techniques and materials used in devices, syringes, and needles used for intravitreal injections. Prog Retin Eye Res. 2020;18:100862.

Werner BP, Schöneich C, Winter G. Silicone oil-free polymer syringes for the storage of therapeutic proteins. J Pharm Sci. 2019;108:1148–60.

Smith AL, Winefordner JD, Kolthoff IM. The analytical chemistry of silicones. Inc.: John Wiley & Sons; 1991.

Bee JS, Frey VV, Javed U, Chung J, Corcoran ML, Roussel PS, et al. Characterization of the initial level and migration of silicone oil lubricant in empty prefilled syringes for biologics using infrared spectroscopy. PDA J Pham Sci Tech. 2014;68:494–503.

Dixon R, Peterson D. Development and testing of a detection method for liquid chromatography based on aerosol charging. Anal Chem. 2002;74:2930–7.

Hutchinson JP, Li J, Farrell W, Groeber E, Szucs R, Dicinoski G, et al. Universal response model for a corona charged aerosol detector. J Chromatogr A. 2010;1217:7418–27.

De Villiers A, Górecki T, Lynen F, Szucs R, Sandra P. Improving the universal response of evaporative light scattering detection by mobile phase compensation. J Chromatogr. A. 2007;1161:183–91.

Charlesworth JM. Evaporative analyzer as a mass detector for liquid chromatography. Anal Chem. 1978;50:1414–20.

Mourey TH, Oppenheimer LE. Principles of operation of an evaporative light-scattering detector for liquid chromatography. Anal Chem. 1984;56:2427–34.

Oppenheimer LE, Mourey TH. Examination of the concentration response of evaporative light-scattering mass detectors. J Chromatogr A. 1985;323:297–304.

Wen ZQ, Vance A, Vega F, Cao X, Eu B, Schulthesis R. Distribution of silicone oil in prefilled syringes probed with optical and spectroscopic methods. PDA J Pham Sci Tech. 2009;63:149–58.

Cavic-Vlasak BA, Thompson M, Smith DC. Silicones and their determination in biological matrices a review. Analyst. 1996;121:53R–63R.

Kala SV, Lykissa ED, Lebovitz RM. Detection and characterization of poly(dimethylsiloxane)s in biological tissue by GC/AED and GC/MS. Anal Chem. 1997;69:1267–72.

Semchyschyn DJ, Macdonald PM. Limits of detection of polymethylsiloxane in 29Si NMR spectroscopy. Magn Reson Med. 2000;43:607–10.

Kennan JJ, Breen LLM, Lane TH, Taylor RB. Methods for Detecting Silicones in Biological Matrixes. Anal Chem. 1999;71:3054–60.

Acknowledgements

The authors would like to thank Ron Forster, Matt Hammond, David Semin, Jette Wypych, and Patrick Gammell for their support to this study.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Ronk, M., Fujimori, K. et al. Analysis of Silicone Oil in Prefilled Syringes and Biopharmaceutical Drug Products Using High-Performance Liquid Chromatography. AAPS PharmSciTech 22, 75 (2021). https://doi.org/10.1208/s12249-021-01947-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-021-01947-6