Abstract

Hybrid membranes based on pyridine-containing polybenzimidazole (PBI–Py) and silica containing sulfonic groups on the surface have been synthesized by two methods, namely, by casting a polymer solution with ready-prepared oxide particles and with a precursor for their synthesis. The effect of the synthesis method on the morphology, conductivity under various conditions, and gas permeability of the hybrid membranes has been studied. It has been shown that the membrane modification with silica leads to an increase in conductivity at a low silica content (2–5 wt %) and an increase in gas permeability. The highest proton conductivity (58 mS/cm at 160°C) has been found for the sample synthesized by casting a PBI–Py solution with a precursor that contains 2 wt % of silica modified with sulfonic groups. Possible mechanisms of proton transport in the synthesized systems have been discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Polybenzimidazoles (PBIs) are among the most extensively studied materials used as an electrolyte in high-temperature polymer electrolyte fuel cells (HTPEFCs) [1]. Complexes of PBI with inorganic acids are capable of providing ionic transport regardless of the presence of water molecules in the membrane; therefore, fuel cells (FCs) based on these complexes can operate at temperatures above 100°C and a low relative humidity. This feature is a significant advantage of these materials over low-temperature FCs owing to a higher resistance of the catalyst to contaminants present in the fuel, a more rapid kinetics of electrode reactions, and a simpler FC design provided by the lack of need to maintain a high level of humidity. In addition, PBI membranes are characterized by a low permeability of methanol and gaseous fuel; FCs based on these membranes exhibit fairly high power properties [2, 3].

Currently, the use of PBIs in HTPEFCs is less common mostly because of the deterioration of their mechanical strength at a high acid content and a significant decrease in conductivity caused by the leaching of acid in the presence of water formed during the operation of FCs [4]. The first of the problems can be solved by introducing inorganic particles capable of increasing the membrane rigidity or by chemical “crosslinking” of the polymer units [5, 6]. To solve the second problem, new approaches to stabilizing the acid in the polymer matrix are being searched for. One of these approaches can be the introduction of additional nitrogen atoms into the polymer chain to increase the basicity of the polymer and the number of PBI–acid complexation sites. The synthesis of hybrid membranes with inorganic particles also provides an increase in the amount of bound acid. Thus, the introduction of silica and zirconia nanoparticles leads to the stabilization and retention of phosphoric acid in the PBI matrix and a decrease in the loss of conductivity during the operation of the FC [7–10]. In addition, the introduced inorganic particles can comprise acid groups [3, 11].

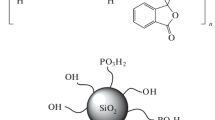

This study is focused on new hybrid materials synthesized in accordance with a procedure that combines the two approaches, namely, an increase in the basicity of the polymer and the introduction of inorganic particles containing acid groups, in particular, silica whose surface is modified with sulfonic groups. The polymer is pyridine-containing polybenzimidazole (PBI–Py); in this polymer, the number of basic nitrogen atoms in the monomer unit is increased to five compared with commercial meta-PBI [12].

EXPERIMENTAL

Polybenzimidazole Synthesis Procedure

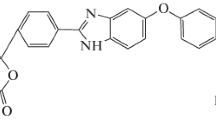

Pyridine-containing PBI was synthesized by polyheterocyclization as described in [13]. The following precursors were used: (1) 3,3',4,4'-tetraaminodiphenyl oxide (Rubezhansk Chemical Plant), which was preliminarily purified by recrystallization from deoxygenated water in an argon stream and dried in a vacuum (0.133 Pa) at 60–70°С (yield of 65.7%, Tmelt = 151.0–151.5°C), and (2) 2,5-pyridinedicarboxylic acid (Acros). The acid was used without further purification and dried in a vacuum (0.133 Pa) at 150°C (Tmelt(2) = 256°C (decomp.)). Polyphosphoric acid (PPA) from Aldrich was used without further purification (P2O5 content of no less than 84%). The synthesis scheme is shown in Fig. 1.

A mixture of 2.3027 g (0.01 mol) of 1 and 1.6712 g (0.01 mol) of 2 was ground in a mortar and then charged into 50 g of PPA at 80°C (4–5 h) under vigorous stirring in an argon stream. After that, the temperature was increased to 100°C for 1 h and then maintained at this level for 2 h. Six grams (>0.04 mol) of P2O5 was added to the mixture at 120°C; the resulting mixture was heated successively at 140°C for 2 h, 160°C for 2 h, and then at 180°C for 20 h. After that, the reaction solution was cooled to 140°C, diluted with 50 mL of 85% H3PO4, and poured into water. The fibrous precipitate of the polymer was crushed using an ultradisperser, filtered off, and washed with 5% aqueous ammonia and distilled water until neutral. The polymers were extracted with methanol on a Soxhlet extractor and dried in a vacuum at 100°C for 10 h. The amount of synthesized PBI–Py was 3.25 g (quantitative yield). The polymers are soluble in H2SO4, HCOOH, CF3COOH, N-methylpyrrolidone, and N',N'-dimethylacetamide with the addition of 1% of lithium chloride.

The reduced viscosity of the polymer was ηred = 3.2 dL/g (0.5% solutions in H2SO4, 25°С). This viscosity corresponds to the molecular mass of PBI of about 60–100 kDa [14].

The structure of PBI–Py is also confirmed by the Fourier transform infrared spectra (exhibiting no absorption bands of amino groups (3330 and 3440 cm–1) and carbonyls of carboxyl groups (~1700 cm–1)), which exhibit a broad diffuse peak in the region of 2500–3600 cm–1, which is responsible for the –NH groups of the benzimidazole ring and adsorbed moisture, and peaks at 1600, 1620, 1570, and 1530 cm–1 attributed to the heterocyclic aromatic system. The elemental analysis of the polymer completely corresponds to the claimed С19H11N5О molecule: calcd. (%): C, 70.15; H, 3.41; N, 21.53; found (%): C, 70.05; H, 3.61; N, 21.23.

A 5% polymer solution in N-methylpyrrolidone (4 g/100 mL) was prepared to synthesize the membranes.

Hybrid Membrane Synthesis Procedure

Hybrid membranes based on PBI–Py were synthesized by two methods. One of the methods consisted in the casting of polymer solutions containing ready-prepared particles of commercial sulfonated-surface silica (sulfo-SiO2), which is a silica gel functionalized with 3-propylsulfonic acid (Sigma-Aldrich, an exchange capacity of ~0.74 mmol/g, a surface area of 250 m2/g), or unmodified silica (SiO2) synthesized as described in [15]. According to transmission electron microscopy, the unmodified silica is represented by agglomerates (1–10 μm) of particles with a size of 15–30 nm; the surface area is 680 m2/g. A polymer solution with a given oxide content was preliminarily homogenized by ultrasonic treatment for 5 min and then dried on a glass substrate at 50–60°C for 72 h. The resulting films were removed from the glass and heated in a vacuum at 120°C for 4 h to remove the residual solvent.

The alternative membrane synthesis method consisted in the casting of a polymer solution containing precursors for synthesizing silica, namely, tetramethoxysilane (TMOS, Aldrich, ≥98.0%) or a mixture of TMOS with (3-mercaptopropyl)trimethoxysilane (TMOS-S, Aldrich, 95%) in a molar ratio of 4 : 1. After that, the methyl groups of silanes were hydrolyzed in an alkaline medium; in the case of TMOS-S, the SH groups were oxidized with 30% hydrogen peroxide to SO3H groups. Eventually, films with both nonfunctionalized silica (SiO2-prec) and sulfonated-surface silica (sulfo-SiO2-prec) were prepared. The silica content was varied in a range of 2–20 wt %.

In all cases, the resulting samples were thin optically homogeneous durable films. To impart conductive properties to the membranes, they were held in 60% phosphoric acid at room temperature for 170 h. After this procedure, the weight of the membranes increased by a factor of 2.5–3.

Investigation Procedures

Infrared absorption spectra of the samples were recorded on a Nicolet Magma-IR 750 Fourier transform infrared spectrometer in the region of 4000–400 cm–1; the samples were prepared in the form of thin films.

The degree of doping of the membranes with phosphoric acid x (number of H3PO4 molecules per repeating polymer unit) was determined according to the weight of absorbed acid as described in [16].

The morphology of the membranes was studied by scanning electron microscopy on a Carl Zeiss NVision 40 scanning electron microscope equipped with an Oxford X-Max X-ray detector.

X-ray diffraction analysis was conducted on a Rigaku D/MAX 2200 diffractometer using CuKα radiation.

The specific surface area of the silica samples was studied by capillary nitrogen adsorption (Brunauer–Emmett–Teller (BET) method) at –196°C on a Sorbtometr-M analyzer (OOO Katakon). The samples were preliminarily degassed at 200°C for 1 h.

The thermogravimetric analysis (TGA) of the membrane samples was conducted on a Netzsch TG 209 F1 thermobalance in platinum crucibles in argon. The heating rate was 10 deg/min; the temperature range was 25–300°C; the weighed portions were 15–20 mg. The oxide content in the membranes synthesized by casting with a precursor was determined by annealing the sample at 800°C until the complete combustion of the polymer and weighing the dry residue of the oxide.

Conductivity was measured using a Z500 PRO impedance meter (Elins, Russia) in a frequency range of 10 Hz to 2 MHz in a potentiostatic mode at a sinusoidal signal amplitude of 100 mV with graphite electrodes. Conductivity was measured in a temperature range of 25–160°С in increments of 10–15°С. Conductivity measurements in air at varying relative humidity (RH) and a constant temperature of 90°C were conducted in a Binder MKF115 climate chamber. Before the measurement, the membranes were held at each RH value for 1 h. Ionic conductivity was calculated by extrapolating the bulk conductivity component semicircles to the active resistance axis. For all the membranes, the fraction of direct current electronic conductivity did not exceed 0.01% of the total conductivity value.

The gas permeability of the synthesized membranes was studied by gas chromatography on a Kristallyuks 4000M chromatograph as described in [17].

RESULTS AND DISCUSSION

Hybrid Membrane Morphology

According to X-ray diffraction analysis, the PBI–Py membranes are X-ray amorphous. The introduction of silicas does not lead to a change in the degree of crystallinity of the polymer.

Upon the introduction of ready-prepared silica particles into the polymer matrix, the particles are concentrated on one side of the membrane; the other side is the unmodified polymer (Fig. 2a). Despite the prehomogenization of the solution by an ultrasonic treatment, the particles sediment during drying; therefore, the resulting membranes are characterized by an anisotropic distribution of particles across the depth. The films synthesized by casting the polymer with a precursor are characterized by a homogeneous structure with a uniform distribution of silica across the depth (Fig. 2b).

According to electron probe microanalysis, the sulfur-to-silicon ratio for the membranes with sulfo-SiO2-prec is 1 : 4.25, which actually corresponds to the initial load. This finding confirms the presence of silica with grafted sulfonic groups in the membrane.

Thermal Analysis and Degree of Doping with Phosphoric Acid

The products of annealing of the hybrid membranes with SiO2-prec and sulfo-SiO2-prec are fused silica nanoparticles (Fig. 3), in which, according to electron probe microanalysis, the molar ratio between Si and O elements is 1 : 2. It should be noted that the actual content of silica in the hybrid membranes synthesized by casting the polymer with a precursor was lower than the calculated values (Table 1). This fact can be attributed to the partial leaching of the precursor due to hydrolysis.

The typical TGA curves for the PBI–Py membranes doped with H3PO4 exhibit two steps of mass loss: below 130°C, the loss of weakly bound sorbed water takes place; above 170°C, phosphoric acid undergoes dehydration to form condensed HPO3 and H4P2O7 forms. The water uptake of the original polymers doped with phosphoric acid is about 16–18% for different sets of samples. In the case of introduction of 2–20 wt % of silica, the water uptake varies within 1%.

The degree of doping of the membranes with phosphoric acid is shown in Table 2. With an increase in the dopant concentration, a tendency to a slight decrease in x is observed; it is more pronounced in the case of modification with sulfo-SiO2-prec. A decrease in the degree of doping with acid with an increase in the silica content can be attributed to the fact that the silica particles occupy the free space inside the polymer and thereby hinder the incorporation of phosphoric acid. In addition, the presence of sulfonic groups on the oxide surface leads to a decrease in the sorption of phosphoric acid by the dopant surface and to the formation of salt bridges between the sulfonic groups and the nitrogen atoms of PBI, which also contributes to a decrease in the acid content in the membrane.

Proton Conductivity

An increase in relative humidity leads to an increase in the conductivity of all the PBI–Py hybrid membranes regardless of the modification method. The conductivity values of the membranes synthesized by casting with ready-prepared oxide particles are close to the conductivity of the original membrane (Fig. 4a). In the case of the membranes synthesized by casting a polymer solution with a precursor (Fig. 4b), the maximum increase in conductivity achieves 21% upon the introduction of 5 wt % of sulfonated oxide sulfo-SiO2-prec (at a temperature of 90°C and a relative humidity of 85%).

Dependences of conductivity on relative humidity at 90°С for the PBI–Py membranes synthesized by casting with (a) 2 wt % of ready-prepared silica particles and (b) 5 wt % of a precursor for synthesizing silica particles: (1) the original membrane, (2) SiO2, (3) sulfo-SiO2, (4) SiO2-prec, and (5) sulfo-SiO2-prec.

In PBI-based systems, the main role in the formation of conductivity is played by the introduced phosphoric acid. In addition, depending on the degree of doping with the acid, proton transfer can occur in accordance with different mechanisms [18]. One of the mechanisms is associated with proton transfer between phosphoric acid and the imidazole groups of PBI (owing to the acid “bound” by strong hydrogen bonds with the nitrogen atoms of the imidazole ring); it is characteristic of the degree of doping with phosphoric acid that is equal to the number of nitrogen atoms of the monomeric unit. At a sufficiently high acid content, where the x value exceeds the number of nitrogen atoms of the monomeric unit of the polymer, the conductivity is determined by the presence of excess undissociated (“free”) acid. In this case, the conductivity mechanism is similar—in many respects—to proton transfer by the Grotthuss mechanism in aqueous solutions through a system of hydrogen bonds. For the studied systems, х > 5 (Table 2); therefore, the proton jump occurs through the system of hydrogen bonds of phosphoric acid.

The introduction of silicas leads to a slight decrease in the degree of doping with acid; for the membranes with a low silica content (2–5 wt %), the x value remains almost unchanged. An exception is provided by the modification with large amounts of sulfo-SiO2-prec, the introduction of which leads to a significant decrease in the degree of doping with phosphoric acid (to 4.2). An increase in the conductivity of these membranes can be primarily attributed to the effect of the nature of the introduced particles, i.e., to the presence of sulfonic acid groups on the silica surface [18]. It is also probable that the SO3H groups of silica are involved in the formation of a system of hydrogen bonds, through which proton transfer occurs. In addition, oxide particles can act as an additional proton transfer site, which also contributes to an increase in conductivity. With an increase in relative humidity, the membranes absorb a larger amount of water; this factor leads to an increase in the degree of dissociation of phosphoric acid, the carrier concentration, and the proton conductivity. In this case, the viscosity of the solution inside the polymer decreases and thereby facilitates the proton transfer.

The typical temperature dependences of the conductivity of hybrid membranes synthesized without additional moistening exhibit a kink in the region of 70°С, after which the increase in conductivity becomes less pronounced. This finding is attributed to the dehydration of the membranes. This assumption is supported by the fact that, in the low-temperature region, the conductivity value measured during cooling is lower than the value measured during heating, whereas at high temperatures the conductivity values measured during cooling and heating are the same.

At high temperatures, without additional moistening, the introduction of silicas leads to an increase in the conductivity of the hybrid membranes regardless of the synthesis method (Fig. 5). In this case, proton transfer also occurs by the Grotthuss mechanism and is determined by the degree of doping with phosphoric acid and the oxide content [19, 20]. For the hybrid membranes synthesized by casting with ready-prepared particles, a peak in the dependences of conductivity on composition is observed upon the introduction of 2–5 wt % of silica. The conductivity value corresponding to this peak is 1.4 times higher than that for the initial sample (Fig. 5a). With a further increase in the silica content, the conductivity of the hybrid membranes decreases. In the case of using silica precursors for membrane modification, a significant increase in the membrane conductivity is observed (Fig. 5b). In this case, the difference in the morphology of the synthesized hybrid membranes significantly affects the compositional effect magnitude.

Since these membranes exhibit a high proton conductivity, they are promising for use as a polymer electrolyte in HTPEFCs without additional moistening.

Gas Permeability

Table 3 lists hydrogen permeability values for the PBI–Py hybrid membranes. The introduction of silicas and the presence of sulfonic groups on their surface lead to an increase in the gas permeability compared with that of the unmodified sample. A similar picture is frequently observed in hybrid gas-separation membranes containing no specific ion-exchange groups [21]. This fact is apparently attributed to the interaction of the polymer matrix with the surface of the oxide particles, which leads to a decrease in the mobility of the polymer chains and hinders their close packing owing to an increase in the average distance between them and the formation of voids inside the polymer or at the interface between the two phases (polymer/oxide), which leads to an increase in the gas permeability [22].

CONCLUSIONS

Hybrid membranes based on PBI–Py and various silica samples, particularly those containing sulfonic groups on the surface, have been synthesized. It has been shown that the membrane modification with silicas leads to an increase in the membrane conductivity regardless of the synthesis method. The compositional effect magnitude is affected by the membrane morphology more significantly than by the presence of grafted sulfonic groups on the silica surface. The highest conductivity values are observed for materials synthesized by casting the polymer with a precursor for synthesizing silica particles at a low silica content. The high proton conductivity values make the synthesized materials promising for use in HTPEFCs.

REFERENCES

I. A. Stenina and A. B. Yaroslavtsev, Inorg. Mater. 53, 253 (2017).

P. Mustarelli, E. Quartarone, and A. Magistris, Encyclopedia of Electrochemical Power Sources, Ed. by J. Garoche, C. K. Dyer, P. T. Moseley (Elsevier, Amsterdam, 2009), p. 734.

C. Wang, S. Wang, L. Peng, et al., Energies 9, 603 (2016).

E. Quartarone, A. Magistris, P. Mustarelli, et al., Fuel Cells 9, 349 (2009).

J. Yang, L. Gao, J. Wang, et al., Macromol. Chem. Phys. 218, 1700009 (2017).

J. Yang, H. Jiang, L. Gao, et al., Int. J. Hydrogen Energy 43, 3299 (2018).

A. A. Lysova, I. I. Ponomarev, and A. B. Yaroslavtsev, Solid State Ionics 188, 132 (2011).

A. A. Lysova, I. I. Ponomarev, and A. B. Yaroslavtsev, Russ. J. Inorg. Chem. 57, 1 (2012).

A. A. Lysova, I. I. Ponomarev, and A. B. Yaroslavtsev, Pet. Chem. 52, 514 (2012).

E. Quartarone, S. Angioni, and P. Mustarelli, Materials 10, 687 (2017).

Y. Tominaga and T. Maki, Int. J. Hydrogen Energy 39, 2724 (2014).

High Temperature Polymer Electrolyte Membrane Fuel Cells: Approaches, Status and Perspectives, Ed. by Q. Li, D. Aili, H. A. Hjuler, and J. O. Jensen (Springer International, Cham, 2016).

I. I. Ponomarev, Yu. Yu. Rybkin, E. I. Goryunov, et al., Russ. Chem. Bull. 53, 2020 (2004).

A. I. Fomenkov, I. V. Blagodatskikh, Iv. I. Ponomarev, et al., Polym. Sci., Ser. B 51, 166 (2009).

E. Yu. Safronova, A. B. Il’in, A. A. Lysova, and A. B. Yaroslavtsev, Inorg. Mater 48, 437 (2012).

Y. Özdemir, N. Üregen, and Y. Devrim, Int. J. Hydrogen Energy 42, 2648 (2017).

A. A. Lysova, Iv. I. Ponomarev, Yu. A. Volkova, et al., Pet. Chem. 58, 958 (2018).

Y.-L. Ma, J. S. Wainright, M. H. Litt, and R. F. Savinell, J. Electrochem. Soc. 151, A8 (2004).

J. S. Wainright, J. T. Wang, R. F. Savinell, and M. H. Litt, J. Electrochem. Soc. 142, L121 (1995).

Suryani and Y.-L. Liu, J. Membr. Sci. 332, 121 (2009).

A. B. Yaroslavtsev and Y. P. Yampolskii, Mendeleev Commun. 24, 319 (2014).

M. Sadeghi, M. A. Semsarzadeh, and H. Moadel, J. Membr. Sci. 331, 21 (2009).

ACKNOWLEDGMENTS

The scanning electron microscopy measurements were performed using shared experimental facilities supported by IGIC RAS state assignment. The authors are grateful to Dr. A. Baranchikov and H. Yorov for SEM measurements.

Funding

This work was supported by the Russian Science Foundation (project no. 16-13-00127).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by M. Timoshinina

Rights and permissions

About this article

Cite this article

Lysova, A.A., Stenina, I.A., Volkova, Y.A. et al. Effect of Surface-Sulfonated Silica on the Properties of Pyridine-Containing Polybenzimidazoles. Membr. Membr. Technol. 1, 271–277 (2019). https://doi.org/10.1134/S2517751619050056

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2517751619050056