Abstract

The structure and diffusion properties of combined ultrafibrous matrices containing microspheres for prolonged release of lysozyme are studied in the work. The matrices are biocompatible and they are not cytotoxic. The matrices are obtained via electrospinning. These materials are suitable for solving problems of tissue engineering, since they combine ultrafine fibers of poly(hydroxybutyrate) promoting effective attachment and growth of cells and poly(hydroxybutyrate) microparticles capable of prolonged release of a bioactive compound. These properties allow one to recommend these matrices for tissue engineering.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

The application of biopolymers has broad prospects in medicine, primarily owing to their ability to decompose in the body without the formation of toxic products. Polyhydroxyalkanoates (hereinafter PHA) are one of the largest classes of chemical compounds used as a material for production of biodegradable products. They are characterized by a high degree of biocompatibility and biodegradability with the formation of carbon dioxide and water. The production of polymers of this class by the method of microbiological synthesis makes it possible to regulate their properties according to a specific bioengineering or environmental problem [1]. Poly(hydroxybutyrate) (hereinafter PHB) was the first to be discovered among PHAs. It demonstrates high mechanical strength and moderate hydrophilicity and is the most studied polyhydroxyalkanoate, which explains its popularity as a compound used for production of biodegradable medical devices and packaging materials [2–4].

Such articles are most often based on biopolymer matrices, otherwise scaffolds, representing fibers with the diameter of their filaments varying usually from 0.1 to 10 μm. There are a number of methods for producing such fibers, for example, leaching, pore formation using gases or phase separation, and electrospinning (otherwise ESF process). The latter method is noteworthy for the fact that it does not require complex equipment and high energy costs, while it has flexibility in setting parameters, allowing one to obtain products with controllable characteristics in a wide range [5]. Fibers obtained during the ESF process have higher surface-to-volume ratio, as well as high porosity, which promotes cell attachment and growth [6, 7]. The advantages listed explained the choice of electrospinning as a method for producing fibers and PHB as a material for performing this work.

The medical devices themselves based on PHA fibers obtained by electrospinning are distinguished by a wide variety. These can be biodegradable retention sutures, biodegradable fixing screws for orthopedic surgery, periodontal membranes for dentistry, etc. [8, 9]. Pharmaceutical forms for prolonged release of medicinal substances are also produced on the basis of PHA. Currently, the possibility of creating combined matrices, where biopolymer microparticles are encapsulated in the fiber structure, is of wide interest. Such microparticles may contain substances whereby it is necessary to affect cells, for example, growth factors. The medical devices based on such combined matrices can significantly increase the activity of reparative processes in the body [10, 11].

The aim of this work was to obtain and investigate microfibrous matrices containing microspheres for prolonged release of a model protein, lysozyme, as well as to obtain microparticles of various types for loading them with lysozyme.

EXPERIMENTAL

W/O Emulsifying

The water-oil emulsifying method was used to produce both types of microparticles. A solution of PHB was mixed with an emulsifier solution. In this case the polymer, as a hydrophobic phase, forms separate clusters—particle agglomeration. In order to prepare the porous microparticles from PHB, a PHB solution (Biomer®) (М = 300 kDa; c = 40 mg/mL) and a solution of (NH4)2CO3 in water (cw/v = 5%) were first prepared. Then, 750 μL of (NH4)2CO3 solution was added to 4 mL of polymer solution and mixed for 5 min on a high-speed homogenizer at 15 000 rpm. The resulting mixture was poured dropwise into a 1% solution of poly(vinyl alcohol) at constant mixing. After complete evaporation of chloroform, the particles were separated from the emulsifier by centrifugation and washing with distilled water. To make sure that the resulting particles did not contain a foaming agent ((NH4)2CO3), they were placed in a phenolphthalein solution. The absence of pink coloring confirmed the absence of ammonium carbonate. Thereafter, the particles were lyophilized.

To obtain alginate microparticles, 250 mg of lysozyme and 50 mg of pluronic were added to 12 mL of a 2% aqueous solution of sodium alginate. After mixing the resulting mixture for 15 min, 18 mL of a 3.3% solution of lecithin in heptane was added to it. Further, 3.2 mL of a 25% CaCl2 solution was added to the colloid. Then the mixture was stirred on a homogenizer at 11 000 rpm for 15 min. Calcium chloride acts as a crosslinker and plays a structure-forming role [12]. The resulting microparticles were separated from the emulsifier by three-stage centrifugation and washing with isopropanol. Then they were dried in a thermostat.

Labeling of Lysozyme by FITC

To further visualize the presence of alginate microparticles in the thickness of the resulting matrices, part of the microparticles was loaded with fluorescein-labeled lysozyme (FITC) during production. The binding of the protein to the dye was carried out according to the standard procedure [13]. Lysozyme was dissolved in 16 mL of 0.2 M borate buffer (pH 8); the dye was dissolved in 4 mL of the same buffer at heating. Upon further addition of the dye to the protein solution, the latter precipitated. The solution was titrated with hydrochloric acid until the precipitate was completely dissolved. Thereafter, the solution was dialyzed for two days against 0.01 M acetate buffer (pH 3.4) in order to purify it from unbound dye.

Electrospinning

A solution of PHB in chloroform (7%) was poured into a glass container placed in an installation for performing the ESF process [14]. A voltage of 10 kV was applied to the solution through a metal electrode. The liquid flowed out through the capillary under the action of gravity and excess pressure in the gas in the container. The jet was deposited on a dense and elastic material in order to avoid the appearance of defects. The electrospinning process should take about 8 h to obtain matrices with a thickness of 0.5–1 mm. The particles were placed inside the matrix using a “sandwich” technology. Electrospinning was briefly interrupted after 4 h of molding, and the dry particles were uniformly distributed over the desired area in the appropriate amount. The mass of particles per unit area was selected so that their presence would not harm the structure of the electrospinning cloth. For porous PHB microparticles, the ratio was 12 mg/cm2; for alginate microparticles, it was 1.5 mg/cm2.

Absorption of Lysozyme on Porous Particles and Matrices from PHB

The efficiency of lysozyme adsorption on porous microparticles from PHB and PHB fibers obtained by electrospinning was compared. For this purpose, weighed portions of 100 mg of particles and fibrous material were prepared. The particles were additionally deaerated in 10 mL of distilled water using a freeze dryer. Both particles and fibers were treated with 0.133 mM NaOH, whereupon they were washed tenfold with phosphate-buffered saline (PBS, pH 7.4; hereinafter, a buffer solution with a concentration of 0.12 M is taken as 1×PBS). Samples were placed in 1/8×PBS prior to protein coating.

First, a stock solution of lysozyme in 1/8×PBS with a concentration of 25 mg/mL was prepared, and then a coating solution with a concentration of 0.25 mg/mL. At each incubation point, a microparticle sample and an electrospinning fiber sample were placed in 2 mL of the coating solution for one hour, after which the solution was replaced. In the solution passed through the sample, the protein concentration was measured spectrophotometrically at a wavelength of 280 nm. For each incubation point, the amount of bound protein was calculated.

After ten points of incubation of the samples in the protein solution, the lysozyme was washed off by incubating the samples in 1×PBS. The incubation time was determined by a standard technique, and it was for the first points 1, 3, 6, 24 h, respectively; then the buffer was renewed once a day. The amount of protein that washed off was also determined spectrophotometrically. After 11 points of washing off with buffer, the remaining part of the protein was washed off with a solution of 1 M NaCl.

Lysozyme Release from Alginate Microparticles

The protein was placed in alginate microparticles at the production stage. To analyze its release, the particles were incubated in the matrix and in pure form in 0.025 M potassium phosphate buffer. The release of lysozyme from matrices with an area of 2 cm2 containing 3 mg of particles and 3 mg of particles in pure form (four replicates for each sample), respectively, was compared. The protein concentration at each incubation point was measured spectrophotometrically at a wavelength of 280 nm. The points were recorded after 1, 3, and 24 h, with the exchange of the buffer.

SEM and Confocal Microscopy

The resulting combined matrices were gold plated on a spray apparatus. Samples with cells were dehydrated for 5 min in ethanol solutions of increasing concentration (30, 50, 70, 82, and 96%), then in a mixture of alcohol and acetone at 3 : 1, 1 : 1, 1 : 3, and finally in pure acetone. Then the samples with cells were dried at the critical point. Thereafter, the matrices were ready for examination with an electron microscope. The matrices containing alginate microparticles with lysozyme labeled with FITC were examined on a confocal microscope to visualize the emission of fluorescein isothiocyanate (absorbing and emitting light with a wavelength of 495/519 nm) and to confirm the presence of alginate microparticles in the thickness of the obtained samples.

CTT Test

To assess the cytotoxicity and biocompatibility of matrices containing porous microparticles from PHB, a CTT test was performed based on the estimation of the activity of mitochondrial enzymes by the intensity of the tetrazole dye color [15]. The test was performed on cells of the COS 1 line (green monkey fibroblasts). The matrices under investigation were sterilized with alcohol and placed in a 96-well plate; then a cell suspension (2000 specimens per well) in a DMEM medium was added to the well. The cultivation was carried out in a thermostat at 37°C and 5% CO2 content in the air. When the point of biocompatibility was registered, the matrices with adhered cells were transferred to a new well, and a solution of activated CTT reagent was added to it, so as not to take into account cells growing not on the matrix. In contrast, when evaluating cytotoxicity, the medium from the old well was removed and the CTT reagent was added to the same well. During the reaction time, the plate was placed in a thermostat for 2 h. Thereafter, the color intensity of the solution, which directly depends on the number of living cells, was measured on a spectrophotometer at a wavelength of 450 nm, taking into account the correction for the value at a wavelength of 620 nm. For each point, four replicates were taken, after which the mean value and the confidence interval were found.

RESULTS AND DISCUSSION

Production of Combined Matrices

Two types of microparticles were obtained by W/O emulsifying: porous microparticles from PHB and alginate microparticles loaded with the model protein lysozyme (Fig. 1). A fibrous material from PHB was obtained by electrospinning, into the thickness of which microparticles of one type or another were incorporated.

Structure Microscopy

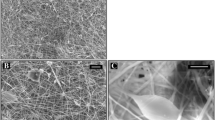

It was shown by the method of confocal and scanning electron microscopy that microparticles are fixed in the thickness of the obtained matrices, and their presence does not have a negative effect on the mechanical structure of the fiber and its integrity (Fig. 2).

Since in the case of microparticles the diameter of which does not exceed 30 μ an electron microscope allows one to detect only particles in the upper layers of the sample, in order to confirm their presence in the matrix, the FITC-labeled alginate particles were examined on a confocal microscope (Fig. 3).

Release and Adsorption of Lysozyme

Using alginate microparticles as an example, the release of the protein loaded into microparticles at the production stage was analyzed. The microparticles lose almost all protein even in the first hours of incubation. Moreover, the inclusion of particles in the matrix does not affect the kinetic profile of the release; that is, the electrospinning fibers do not interfere with the protein release (Fig. 4).

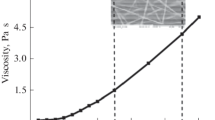

The adsorption of lysozyme on PHB fibers and porous microparticles from PHB showed that the particles bind protein much more efficiently. They bound about 90% of the coated protein, while the matrix bound only 20%. Subsequent incubation of the particles and matrix in a buffer of weak ionic strength showed that the rate of protein release from microparticles is lower than from the fibrous matrix; that is, the particles have a more pronounced capability of prolonged release of protein (Fig. 5). At the end of the experiment, the remaining protein was washed off with a high ionic strength salt solution.

The obtained result confirms that combined matrices are better suited for solving problems of tissue engineering, since they combine PHB fibers, promoting effective attachment and growth of cells, but incapable of being sufficiently effective carriers of a bioactive substance by themselves, and microparticles capable of gradual release of bioactive substances, but not being a suitable substrate individual for cell growth [16].

Biocompatibility and Cytotoxicity of Matrices

Finally, the CTT test based on the assessment of the activity of mitochondrial enzymes showed on cells of the COS 1 line that combined matrices are not cytotoxic, and also that biocompatibility does not differ for matrices with and without particles if the particles do not contain a biologically active component (Fig. 6).

Comparing the average optical density values obtained during the test among the samples for each of the days on both histograms, we can conclude that the values obtained do not differ significantly. All the time, the cells grew in the same way on all types of matrices.

Thus, using the electrospinning method, combined matrices were obtained the structure of which contained biopolymer microparticles capable of acting as carriers of a bioactive substance. The matrices have a strong structure; they are capable of prolonged release of substances and are biocompatible. In the future, using the developed technology, it is planned to create matrices with particles containing BMP (for bone tissue engineering) or fibroblast growth factors (for skin regeneration).

CONCLUSIONS

1. A technology for producing combined matrices consisting of microfibers and microparticles for controlled release of lysozyme was developed.

2. The addition of microparticles does not deteriorate the integrity of the microfiber matrix; the microparticles are integrated into its structure.

3. A technique for loading porous particles from PHB and microfiber matrices from PHB with lysozyme through its adsorption on the polymer was developed. It was shown that porous microparticles from PHB adsorb protein better than the fibers from PHB and they are capable of its prolonged release.

4. The matrix fibers do not interfere with protein release from microparticles.

5. The biocompatibility and cytotoxicity of combined matrices does not depend on the presence of microparticles if they do not contain a biologically active component.

REFERENCES

Bonartsev, A.P., Bonartseva, G.A., Shaitan, K.V., and Kirpichnikov, M.P., Poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate)—based biopolymer systems, Biochem. (Moscow), Suppl. Ser. B: Biomed. Chem., 2011, vol. 5, no. 1, pp. 10–21.

Gunatillake, P.A. and Adhikari, R., Biodegradable synthetic polymers for tissue engineering, Eur. Cells Mater., 2003, vol. 5, no. 1, pp. 1–16. https://doi.org/10.22203/ecm.v005a01

Cao, K., Liu, Y., Olkhov, A.A., Siracusa, V., and Iordanskii, A.L., PLLA-PHB fiber membranes obtained by solvent-free electrospinning for short-time drug delivery, Drug Delivery Transl. Res., 2018, vol. 8, no. 1, pp. 291–302.

Olkhov, A., Gur’ev, V., Akatov, V., Mastalygina, E., Iordanskii, A., and Sevastyanov, V.I., Composite tendon implant based on nanofibrillar polyhydroxybutyrate and polyamide filaments, J. Biomed. Mater. Res., Part A, 2018, vol. 106, no. 10, pp. 2708–2713.

Li, D. and Xia, Y., Electrospinning of nanofibers: Reinventing the wheel? Adv. Mater., 2004, vol. 16, no. 14, pp. 1151–1170.

Haider, A., Haider, S., and Kang, I.-K., A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology, Arabian J. Chem., 2018, vol. 11, pp. 1165–1188.

Ding, J., Zhang, J., Li, J., Li, D., Xiao, C., Xiao, H., Yang, H., Zhuang, X., and Chen, X., Electrospun polymer biomaterials, Prog. Polym. Sci., 2019, vol. 90, pp. 1–34.

Baradaran-Rafii, A., Biazar, E., and Heidari-Keshel, S., Cellular response of stem cells on nanofibrous scaffold for ocular surface bioengineering, ASAIO J., 2015, vol. 61, no. 5, pp. 605–612.

Shtilman, M.I., Polymeric Biomaterials. Part 1. Polymer Implants, Leiden, Netherlands: VSP, 2003.

Satyam, A., Kumar, P., Fan, X., Gorelov, A., Rochev, Y., Joshi, L., Peinado, H., Lyden, D., Thomas, B., Rodriguez, B., Raghunath, M., Pandit, A., and Zeugolis, D., Macromolecular crowding meets tissue engineering by self-assembly: A paradigm shift in regenerative medicine, Adv. Mater., 2014, vol. 26, no. 19, pp. 3024–3034.

Moisenovich, M.M., Pustovalova, O., Shackelford, J., Vasiljeva, T.V., Druzhinina, T.V., Kamenchuk, Y.A., Guzeev, V.V., Sokolova, O.S., Bogush, V.G., Debabov, V.G., Kirpichnikov, M.P., and Agapov, I.I., Tissue regeneration in vivo within recombinant spidroin 1 scaffolds, Biomaterials, 2012, vol. 33, no. 15, pp. 3887–3898.

Chan, L.W. and Heng, P.W.S., Effects of aldehydes and methods of cross-linking on properties of calcium alginate microspheres prepared by emulsification, Biomaterials, 2002, vol. 23, no. 5, pp. 1319–1326.

Hiramatsu, M., Okabe, N., and Tomita, K., Preparation and properties of lysozyme modified by fluorescein-isothiocyanate, J. Biochem., 1973, vol. 73, no. 5, pp. 971–978.

Kim, I.-D., Advances in electrospun functional nanofibers, Macromol. Mater. Eng., 2013, vol. 298, no. 5, pp. 473–474.

Sutherland, M.W. and Learmonth, B.A., The tetrazolium dyes MTS and XTT provide new quantitative assays for superoxide and superoxide dismutase, Free Radical Res., 1997, vol. 27, no. 3, pp. 283–289.

Ol’khov, A.A., Kucherenko, E.L., Kosenko, R.Yu., Markin, V.S., Perov, V.I., and Iordanskiy, A.L., Analysis of the structure of polyhydroxybutyrate-based fibrous matrices for prolonged drug release, Inorg. Mater.: Appl. Res., 2019, vol. 10, pp. 806–811. https://doi.org/10.1134/S2075113319040300

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Aleksanyan

Rights and permissions

About this article

Cite this article

Bonartsev, A.P., Ol’khov, A.A., Khan, O.I. et al. Matrices for Tissue Engineering Based on Ultrafine Fibers and Microparticles of Poly(hydroxybutyrate). Inorg. Mater. Appl. Res. 12, 974–979 (2021). https://doi.org/10.1134/S2075113321040080

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113321040080