Abstract

Modified adsorbents are obtained by the immobilization of 1-(3-triethoxysilylpropyl)thiosemicarbazide (TSC), 1-(3-triethoxysilylpropyl)-1-phenylthiosemicarbazide (1-FTSC), and 3-1-(3-triethoxysilylpropyl)-4-phenylthiosemicarbazide (4-FTSC) on the surface of natural microporous aluminosilicates (ASs). The morphology and elemental composition of the surface of the modified ASs are studied by scanning electron microscopy (SEM) and analysis of energy-dispersive X-ray spectra (EDXSs). The degree of silanization of ASs is determined by the structure of organosilicon thiosemicarbazides and decreases in the series AS–TSC > AS–4-FTSC > AS–1-FTSC. The presence of characteristic for TSC, 1-FTSC, and 4-FTSC structural groups in the composition of the modified samples is confirmed by IR spectroscopy. The AS–TSC, AS–1-FTSC, and AS–4-FTSC modified aluminosilicates are characterized as adsorbents for the extraction of Ni(II) ions from aqueous solutions. The time of establishment of adsorption equilibrium is 60 min in the AS–TSC adsorbent–adsorbate system and 120 min for the AS–1-FTSC adsorbent–adsorbate, AS–4-FTSC adsorbent–adsorbate, and AS adsorbent–adsorbate systems. The maximum values of adsorption of Ni(II) ions are 1.71 mmol/g (100.8 mg/g), 0.25 mmol/g (15.0 mg/g), 0.37 mmol/g (21.9 mg/g), respectively, for the samples of AS–TSC, AS–1-FTSC, and AS–4-FTSC. The obtained data on adsorption are in the best possible way described by the Langmuir and Freundlich models. Presumably, the adsorption of heavy metal ions on the surface of the AS–TSC, AS–1-FTSC, and AS–4-FTSC modified zeolites is accompanied by the formation of chelate complexes (with the 1 : 1 composition) formed due to the donor–acceptor interaction of the metal ions with the nitrogen and sulfur atoms of the thiosemicarbazide fragment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Industrial wastewater makes the main contribution to the pollution of surface watercourses and soils. According to toxicological assessments, heavy metals hold second place among the pollutants, being second only to herbicides [1]. In this connection, adsorption and ion exchange find wide application for the removal of heavy metal ions from aqueous solutions. Adsorbents based on natural and synthetic aluminosilicates possess a whole range of unique properties, which determines the multifunctionality of their practical application including decontamination of industrial wastewater and other water bodies [2–4]. Modification of natural aluminosilicates with inorganic and organic compounds is the most common method for increasing their efficiency [5–13].

Work [5] presents a critical review of the studies on the adsorption of Ni(II) and Zn(II) ions by natural and modified bentonite and vermiculite and considers the effect of various parameters on the adsorption process, kinetics of the system, and equilibrium conditions. The results of adsorption of Ni(II) ions by a Na–ZSM-5 mesoporous zeolite modified with tetrapropylammonium bromide and sodium dodecyl sulfate are presented in [6]. The modified zeolites were characterized by scanning electron microscopy (SEM), X-ray diffraction, IR spectroscopy, and the BET method. The obtained results showed the efficiency of the modified zeolites in comparison with the initial zeolite. The Langmuir and Freundlich adsorption models were used for the mathematical description of the adsorption equilibrium.

In [7], natural Cuban clinoptilolite modified to the ammonium form (NH4–Cli) was used for the removal of manganese, cobalt, and nickel from industrial ammoniac wastewater. The obtained NH4–Cli form of the zeolite was characterized by IR spectroscopy and X-ray diffraction. The values of the change in the free energy and equilibrium constant make it possible to draw the conclusion that the order of selectivity at room temperature decreases in the series Mn–Cli > Co–Cli > Ni–Cli. The authors arrived to a conclusion that the differences in these exchange processes are associated with the difference in the interaction of cations with their ligands in the solution, as well as the zeolite framework and availability of the ion-exchange sites inside clinoptilolite.

In [8], natural clinoptilolite from a Chinese deposit was treated with sodium hydroxide in a hydrothermal reaction. The Na–P and Na–Y zeolites obtained depending on the reaction time were characterized with respect to the cation-exchange capacity and BET surface area. The kinetics of sorption of Ni(II) by the initial and modified zeolites is best of all described by a pseudo-first-order model. The theoretical adsorption capacity of Na–clinoptilolite, Na–P, and Na–Y Ni(II) with respect to Ni(II) was 3.744, 12.367, and 24.857 mg/g, respectively.

Modification by polymerization of polypyrrole inside and outside the surface of a clinoptilolite zeolite has been studied in [9]. The obtained polypyrrole–clinoptilolite nanocomposite was used as an adsorbent for Ni(II). The authors of the study showed that chelating and ion-exchange interactions are the determining mechanisms of adsorption. The results of the experiments demonstrate the possibility of using the nanocomposite as a cost-efficient and effective adsorbent for the removal of Ni(II) ions.

Work [10] is devoted to the extraction of Co(II) and Ni(II) ions from wastewater by natural and modified clinoptilolites. The authors synthesized an X zeolite that demonstrated a high adsorption capacity with respect to cobalt and nickel ions in comparison with natural clinoptilolite. The Na+ and NH4+ forms of clinoptilolite were the best-modified forms for the removal of the studied cations. The desorption of Co(II) and Ni(II) ions was performed by treating the zeolites with hydrochloric acid, and the values reached 74 and 85%.

In the study [11], a ZSM-5 mesoporous zeolite modified with phosphoric acid was transformed into the sodium form using an aqueous solution of NaHCO3. The obtained PNa2–ZSM-5 form of the zeolite demonstrated a higher adsorption capacity with respect to Ni(II) ions than the initial Na–Y zeolite. The data of the experiments corresponded to the Langmuir model as well as the Freundlich model and confirmed that the sorption of Ni(II) ions proceeds spontaneously and endothermically.

In [12], a phosphate-intercalacted nano montmorillonite was used as an active adsorbent for the removal of nickel and zinc upon saline groundwater remediation. It has been found that the simultaneous presence of Ni(II) and Zn(II) decreases the adsorption capacity. The competitive Langmuir model and Murali and Aylmore models described binary adsorption well.

Strong immobilization of functional groups in the modification products is provided by the silylation of silicate materials [13]. The silylation process is the interaction between an inorganic matrix and alkoxy silanes, the alkoxy groups of which react with the OH group present on the surface of solid substrates [13]. The modification of zeolites with APTES and MPTMS silanes containing amino and mercapto groups, respectively, leads to an increase in the adsorption activity of the zeolites with respect to heavy metal ions due to the presence of –NH2 and –SH groups in the composition of silanes [13, 14]. The use of such an approach makes it possible to introduce functional groups that manifest ion-exchange and complex-forming properties into the composition of aluminosilicates [15].

The aim of this work was the preparation of aluminosilicates modified with organosilicon thiosemicarbazides for the extraction of Ni(II) ions from aqueous solutions and electroplating industry wastewater.

EXPERIMENTAL

Natural aluminosilicates from the Eastern Transbaikal deposit were used as the study object. According to the data of X-ray diffraction analysis and IR spectroscopy, the aluminosilicates from the Transbaikal deposit under study consist of calcium heulandite Ca[Al2Si7O18]·6H2O as well as impurity rocks, sanidine KAlSi3O8 and cristobalite SiO2 [16–18]. The studied zeolites belong to the group of framework aluminosilicates, the crystal lattice of which is formed by the [SiO4]4− and [AlO4]5− tetrahedra combined into a three-dimensional framework by common apices [19]. The presence of cavities and channels in the microstructure of the mineral, as well as quite high freedom of motion of the cations and water molecules, determine the unique properties of aluminosilicates. In an aqueous medium, aluminosilicates readily replace their cations (Ca2+, Na+, K+, etc.) by other cations present in the solution. A preliminarily sieved away on a screen zeolite fraction with a size of 0.5 mm was used in the experiments.

1-(3-Triethoxysilylpropyl)thiosemicarbazide (TSC), 1-(3-triethoxysilylpropyl)-1-phenylthiosemicarbazide (1-FTSC) and 1-(3-triethoxysilylpropyl)-4-phenylthiosemicarbazide (4-FTSC) obtained by the condensation of 3-(triethoxysilyl)propylamine with the corresponding organosilicon thiosemicarbazides were used for the modification of aluminosilicates [20].

The immobilization of TSC, 1-FTSC, and 4‑FTSC on the surface of the aluminosilicate was performed as follows: 10 g of air-dry aluminosilicate (AS) was added to 90 g of hexane. 10 g of TSC (10 g of 1‑FTSC or 10 g of 4-FTSC) was added to the obtained mixture in small portions over 10 min to obtain the corresponding modified aluminosilicates. The mixture was heated up to 50°C under stirring for 1 h. The product was filtered off and successively rinsed with hexane and ethyl alcohol to remove the excess of free TSC (1-FTSC or 4-FTSC). The aluminosilicates with immobilized TSC (1-FTSC or 4-FTSC) were dried in air for 12 h and, then, in a drying oven at 110°C for 1 h.

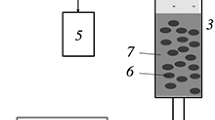

The morphology of the aluminosilicates was determined by scanning electron microscopy (SEM) on a Hitachi TM3000 electron microscope with the magnification of up to 30 000× and resolution of up to 25 nm. The surface elements were determined by the analysis of the energy-dispersive X-ray spectra (EDXSs) (Quantax 70). A Quanta 200 FEI SEM-EXD electron microscope was used for the electron scanning of the sample. The IR spectra of the materials were obtained on a Specord 75IR spectrophotometer.

The adsorption properties of the modified aluminosilicates with respect to Ni(II) ions were studied on the model solutions prepared from reagent grade NiSO4·7H2O and distilled water. The choice of the initial concentration of the model solutions was justified by the real composition of the industrial electroplating industry wastewater containing heavy metal ions. The concentration of Ni(II) ions in the solutions was determined by standard procedures [21, 22].

The adsorption capacity of the aluminosilicates under study was studied by a static method. A method of constant weighed amounts (0.2 g) and variable concentrations (from 1 up to 100 mg/L) was used in the work. The solutions under study were prepared with a volume of 20 mL. The weight ratio of the liquid and solid phases was 1 : 100. The value of adsorption (A, mmol/g) was calculated by the formula

where C0 and Ceq are the initial and equilibrium concentrations of the metal in the solution, mmol/L; V is the volume of the solution, L; and m is the weight of the sorbent, g.

The acidity of the model solutions was maintained in a range of pH 5–7 using a pH-340 pH meter. The temperature was maintained using a UTU-4 thermostat, the studies were conducted at 298 K. Stirring was executed using a magnetic stirrer at a rate of 300 rpm. The conditions of stirring were maintained constant in all the experiments.

RESULTS AND DISCUSSION

The modification of the initial aluminosilicate with organosilicon thiosemicarbazides is a result of the hydrolysis and condensation of organosilicon compounds with the surface hydroxo groups of the AS by Scheme 1.

Scheme 1 . Modification of AS aluminosilicate with TSC, 1-FTSC, and 4-FTSC organosilicon thiosemicarbazides.

The fixation of TSC, 1-FTSC, and 4-FTSC on the surface of the substrate is confirmed by the data of SEM and EDX. The relief of the surface of natural aluminosilicates including heulandite AS (Fig. 1a) is quite nonuniform due the coexistence of various crystal phases and impurities of amorphous materials [23]. An insignificant change in the surface structure of the material occurs as a result of chemical modification of AS (Figs. 1c, 1e, 1g). The surface of the aluminosilicate becomes more uniform and less porous after modification. The main elements of AS are O 51.72%, Si 38.51%, Al 4.75%, and C 4.17% (Fig. 1b).

The degree of coverage of the aluminosilicate with the modifier characterizes the concentration of the elements of the organosilicon coupling agent on the surface of the adsorbent. The surface of the AS–TSC modified aluminosilicate consists of O 23.52%, Si 17.12%, C 31.03%, N 21.23%, and S 7.10% (Fig. 1d). The high concentration of nitrogen and sulfur as well as the absence of aluminum and sodium on the surface of AS–TSC means that, in the region under study, the surface of the substrate is fully covered with a layer of TSC. It should be noted that there is no nitrogen and sulfur in AS initial aluminosilicate (Fig. 1b). In the case of the modified sample of AS–4-FTSC (Fig. 1h), the concentration of nitrogen (13.47%) and sulfur (4.08%) in the surface layer is somewhat lower, and for the sample of AS–1-FTSC (Fig. 1f) (N 3.82%, S 1.30%), substantially lower when compared to the sample of AS–TSC. This is in agreement with the increase in the weight of the aluminosilicates in the process of modification which is 17.08, 3.4, and 9.8% for AS–TSC, AS–1-FTSC, and AS–4-FTSC, respectively.

The difference in the degrees of silanization of the aluminosilicates may be associated with the effect of the bulky phenyl substituent in the composition of 1‑FTSC and 4-FTSC on the completeness of the hydrolysis and condensation of organosilicon thiosemicarbazides in accordance with Scheme 1. The lowest degree of silanization is observed in the case of the sample of 1-FTSC, the phenyl substituent in which is the most proximate to the triethoxysilyl group that provides the formation of a chemical bond between the surface of the aluminosilicate and organosilicon modifier.

The adsorption activity of the samples of AS–TSC, AS–1-FTSC, and AS–4-FTSC with respect to Ni(II) ions correlates with the concentration of the modifier in their composition.

In the case of adsorption of Ni(II) ions by the samples of AS–TSC, AS–1-FTSC, and AS–4-FTSC under comparable conditions (pH 5.5, τ = 1 h, C0 = 5 mg/L, V = 50 mL, m = 0.2 g), the concentration of nickel in the surface layer of the aluminosilicates increases in accordance with the increase in the degree of silanization of the aluminosilicates (Fig. 2).

For more complete evaluation of the adsorption capacity of the modified aluminosilicates with respect to Ni(II) ions, the analysis of the kinetic curves and isotherms of adsorption was performed.

Figure 3 presents the kinetic curves of adsorption of Ni(II) ions. The time of establishment of adsorption equilibrium was 60 min in the AS–TSC adsorbent–adsorbate system and 120 min for the AS–1-FTSC adsorbent–adsorbate, AS–4-FTSC adsorbent–adsorbate, and AS adsorbent–adsorbate systems.

Figure 4 presents the isotherms of adsorption of Ni(II) ions. According to the classification proposed by Brunauer, Emmett, and Teller (the BET classification), the obtained equilibrium isotherms can be assigned to the isotherms of type I [24]. This type of isotherm is characteristic for monomolecular adsorption on microporous solid materials. A linear increase in the adsorption is observed in the first section of the curve, in the process of which the formation of an adsorbate monolayer on the surface of the adsorbent and filling of the micropores occur. An almost horizontal section corresponding to higher concentrations refers to the surface of the adsorbent fully saturated with the adsorbate. Under these conditions, if just a monomolecular adsorbate layer can be formed on the surface of the adsorbent, the amount of adsorbed substance virtually no longer depends on concentration.

The adsorption capacity was 0.28 mmol/g (16.6 mg/g), 0.24 mmol/g (14.4 mg/g), and 0.27 mmol/g (15.9 mg/g) for the samples of AS–TSC, AS–1-FTSC, and AS–4-FTSC, respectively (Fig. 4). The modification of aluminosilicates with TSC, 1‑FTSC, and 4-FTSC organosilicon coupling agents leads to a 2.8-, 2.4-, and 2.7-fold increase in the adsorption activity of the obtained adsorbents with respect to Ni(II) ions in comparison with the natural samples.

It is known that the equilibrium in an adsorption system depends on the nature of the adsorbent–adsorbate interaction [25]. The Langmuir, Freundlich, etc. adsorption models differently describe these interactions. Because of this, it was reasonable to find out the possibility of applicability of the aforementioned models in the interpretation of the obtained experimental data.

The experimental data were processed using the Langmuir equation [26]. The isotherms of adsorption in the coordinates of the linear form of this equation are presented in Fig. 5.

The maximum value of adsorption A∞ was determined from the graphic linear dependences (Fig. 5) by the value of the straight line segment intersecting the axis of ordinates, and the adsorption equilibrium constant K, the values of which are presented in Table 1, was determined by the slope ratio of the straight line.

For the AS–TSC modified aluminosilicate, the value of limiting adsorption was 100.8 mg/g (Table 1). The values of the correlation coefficients R2 evidence that the Langmuir model more adequately describes the adsorption of Ni(II) by the samples of AS–TSC and AS–1-FTSC.

The empiric Freundlich equation is used in the region of average fillings of the nonuniform surface of the adsorbent. Linear dependences of the logarithmic form of the Freundlich equation were constructed for the modified aluminosilicates under study [26] (Fig. 6), from which constants K and n were determined (Table 2).

The adsorption sites by the Freundlich model possess different values of energy, and filling of the active adsorption sites with the maximum energy occurs in the first place. Constants KF and n make it possible to compare the adsorption capacity of modified aluminosilicates. At a concentration of Ni(II) ions in a solution of 1 mol/L, the value of adsorption of these ions will be equal to constant KF and parameter n indicates the intensity of the adsorbent–adsorbate interaction.

As is seen from Table 2, the adsorption of Ni(II) ions is adequately described by the Freundlich isotherm; high values of R2 were obtained for all the samples under study. This means that the adsorption of Ni(II) ions proceeds on the nonuniform surface by a complex mechanism.

The analysis of the IR spectra of the initial AS zeolite and modified samples of AS–TSC, AS–1-FTSC, and AS–4-FTSC was performed (Fig. 7).

The IR spectra of AS, AS–TSC, AS–1-FTSC, and AS–4-FTSC (Fig. 7) contain characteristic bands of porous silicate materials [27, 28]. The most intensive bands corresponding to the stretching vibrations of the primary structure units of aluminosilicates, i.e., SiO4 and AlO4 tetrahedra, manifest themselves in all the spectra with the maxima at 1050, 1048, 1050, and 1047 cm−1 (asymmetric stretching vibrations); 791, 789, 790, and 787 cm−1 (symmetric stretching vibrations of the Si–O and Al–O bridges); and 467, 465, and 464 cm−1 (deformation vibrations) [27, 28]. The absorption bands corresponding to the vibrations of the thiosemicarbazide fragments of the samples of AS–TSC, AS–1-FTSC, and AS–4-FTSC manifest themselves at about 2060 cm−1 (the medium-intensity absorption band of secondary amines), at 1550 cm−1 (deformation vibrations of NH and vibrations of C–N of secondary amines), and in the region of 1350–1370 cm−1 (stretching vibrations of C=S).

Figure 8 presents the IR spectra of the modified aluminosilicates after the adsorption of Ni(II) ions. The IR spectra of the AS–TSC, AS–1-FTSC, and AS–4-FTSC modified adsorbents (Fig. 7) and AS–TSC–Ni, AS–1-FTSC–Ni, and AS–4-FTSC–Ni (Fig. 8) are almost identical in terms of the characteristic absorption bands. A decrease in the intensity and a significant shift are observed for the absorption bands of the nitrogen-containing fragments (NH, C–N) and thiocarbonyl groups (C=S) in the spectra of AS–TSC–Ni, AS–1-FTSC–Ni, and AS–4-FTSC–Ni, which may indicate the formation of a coordination bond between the Ni(II) ions and nitrogen and sulfur atoms of the TSC fragments.

The combination of the obtained results, as well as the analysis of the isotherms of adsorption of Ni(II) ions and data of IR spectroscopy, makes it possible to suppose that the adsorption of the heavy metal ions on the surface of modified aluminosilicates is accompanied by the formation of chelate complexes (with the 1 : 1 composition) due to the donor–acceptor interaction of the metal ions with the nitrogen and sulfur atoms of the thiosemicarbazide fragment (Scheme 2).

Scheme 2 . Structure of the chelate complexes of Ni(II) ions on the surface of AS–TSC.

Such a type of interaction is characteristic for ligands functionalized with thiosemicarbazide in general and for Si–organic adsorbents containing N- and S-active groups.

The obtained results of the studies confirm high effectiveness of the use of the obtained AS–TSC, AS–1-FTSC, and AS–4-FTSC adsorbents for the extraction of Ni(II) ions from aqueous solutions and electroplating industry wastewater.

CONCLUSIONS

(1) AS–TSC, AS–1-FTSC, and AS–4-FTSC modified adsorbents are obtained by the immobilization of 1-(3-triethoxysilylpropyl)thiosemicarbazide (TSC), 1-(3-triethoxysilylpropyl)-1-phenylthiosemicarbazide (1-FTSC), and 1-(3-triethoxysilylpropyl)-4-phenylthiosemicarbazide (4-FTSC) on the surface of a natural aluminosilicate. The degree of silanization of the AS is determined by the structure of organosilicon thiosemicarbazides and decreases in the series AS–TSC > AS–4-FTSC > AS–1-FTSC.

(2) The modification of the aluminosilicate with an organosilicon coupling agent, TSC (1-FTSC, 4-FTSC), leads to a 2.8-, 2.4-, and 2.7-fold increase, respectively, in the adsorption activity of the obtained adsorbents with respect to Ni(II) ions in comparison with the natural samples. The adsorption capacity is 0.28 mmol/g (16.6 mg/g), 0.24 mmol/g (14.4 mg/g), and 0.27 mmol/g (15.9 mg/g) for the samples of AS–TSC, AS–1-FTSC, and AS–4-FTSC, respectively.

(3) Presumably, the adsorption of heavy-metal ions on the surface of AS–TSC, AS–1-FTSC, and AS–4-FTSC modified aluminosilicates is accompanied by the formation of chelate complexes (with a 1 : 1 composition) due to the donor–acceptor interaction of the metal ions with the nitrogen and sulfur atoms of the thiosemicarbazide fragment. Such a type of interaction is characteristic for the ligands functionalized with thiosemicarbazide in general and for Si–organic adsorbents containing N- and S-active groups.

REFERENCES

Custodio, M., Cuadrado, W., Penaloza, R., Montalvo, R., Ochoa, S., and Quispe, J., Water (Basel, Switz.), 2020, vol. 12, p. 1946.

Khan, A., Khan, S., Khan, M.A., Qamar, Z., and Waqas, M., Environ. Sci. Pollut. Res., 2015, no. 22, p. 13772.

Singh, N., Gupta, V.K., Kumar, A., and Sharma, B., Front. Chem., 2017, no. 5, p. 70.

Zeolite Chemistry and Catalysis, ACS Monograph 171, Rabo, J.A., Ed., Washington, DC: American Chemical Society, 1976.

Malamis, S. and Katsou, E., A, J. Hazard. Mater., 2013, vol. 252, p. 428.

Mirzababaei, S.N., Taghizadeh, M., and Alizadeh, E., Desalin. Water Treat., 2016, vol. 57, no. 26, p. 12204.

Rodriguez-Iznaga, I., Rodriguez-Fuentes, G., and Petranovskii, V., Microporous Mesoporous Mater., 2018, vol. 255, p. 200.

Wang, Y. and Chao, X., Fresenius Environ. Bull., 2015, vol. 24, no. 12, p. 4316.

Olad, A., Ahmadi, S. and Rashidzadeh, A., Desalin. Water Treat., 2013, vol. 51, nos. 37–39, p. 7172.

Malekpour, A., Edrisi, M., and Hajialigol, S., J. Radioanal. Nucl. Chem., 2011, vol. 288, no. 3, p. 663.

Panneerselvam, P., Bala, V.S., and Thinakaran, N., E-J. Chem., 2009, vol. 6, no. 3, p. 729.

Choi, J., Septian, A., and Shin, W.S., Minerals, 2020, vol. 10, p. 980.

Wamba, A.G.N., Kofa, G.P., Koungou, S.N., Thue, P.S., Lima, E.C., Reis, G.S., and Kayem, J.G., J. Environ. Chem. Eng., 2018, vol. 6, p. 3192.

Kukwa, R.E. and Dann, S.E., Desalin. Water Treat., 2019, vol. 153, p. 136.

Pomazkina, O.I., Filatova, E.G., and Pozhidaev, Yu.N., Prot. Met. Phys. Chem. Surf., 2017, vol. 53, no. 3, p. 416.

Filatova, E.G., Pozhidaev, Yu.N., and Pomazkina, O.I., Prot. Met. Phys. Chem. Surf., 2020, vol. 56, no. 5, p. 911.

Filatova, E.G., Izv. VUZov, Prikl. Khim. Biotekhnol., 2015, no. 2 (13), p. 97.

Pomazkina, O.I., Filatova, E.G, and Pozhidaev, Yu.N., J. Water Chem. Technol., 2018, vol. 40, no. 4, p. 196.

Breck, D.W., Zeolite Molecular Sieves: Structure, Chemistry, and Use, New York: Wiley, 1973.

Vlasova, N.N., Oborina, E.N., Belousova, L.I., and Larina, L.I., Prot. Met. Phys. Chem. Surf., 2018, vol. 54, no. 1, p. 71.

Lur’e, Yu.Yu. and Rybnikova, A.I., Khimicheskii analiz proizvodstvennykh stochnykh vod (Chemical Analysis of Industrial Waste Waters), Moscow: Khimiya, 1974.

Marczenko, Z., Spectrophotometric Determination of the Elements, Ellis Horwood Series in Analytical Chemistry, New York: Wiley, 1976.

Kantiranis, N., Sikalidis, K., Godelitsas, A., Squires, C., Papastergios, G., and Filippidis, A., J. Environ. Manage., 2011, vol. 92, p. 1569.

Rouquerol, J., Rouquerol, F., Llewellyn, P., Maurin, G., and Sing, K.S.W., Adsorption by Powders and Porous Solids: Principles, Methodology and Applications, Elsevier, 2013.

Tsivadze, A.Yu., Rusanov, A.I., Fomkin, A.A., et al., Fizicheskaya khimiya adsorbtsionnykh yavlenii (Physical Chemistry of Adsorption Phenomena), Moscow: Granitsa, 2011.

Shchukin, E.D., Pertsov, A.V., and Amelina, E.A., Kolloidnaya khimiya (Colloid Chemistry), Moscow: Yurait, 2013.

Flanigen, E.M., Khatami, H., and Szymanski, H.A., Adv. Chem., 1971, vol. 101, p. 201.

Król, M., Mozgawa, W., Jastrzębski, W., and Barczyk, K., Microporous Mesoporous Mater., 2018, vol. 156, p. 181.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by E. Boltukhina

Rights and permissions

About this article

Cite this article

Filatova, E.G., Chugunov, A.D., Pozhidaev, Y.N. et al. Natural Aluminosilicates Modified with Organosilicon Thiosemicarbazides for the Extraction of Nickel(II) Ions. Prot Met Phys Chem Surf 58, 469–477 (2022). https://doi.org/10.1134/S2070205122030078

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205122030078