Abstract

The effect of a cocatalyst in alkene homo- and copolymerizations with transition metal catalysts of different types was studied. The results of studies of polymerizations of ethylene, propylene, and higher linear 1-alkenes and copolymerizations of ethylene with linear 1-alkenes using catalysts of different types in combination with a binary cocatalyst Al(C2H5)2Cl/Mg(C4H9)2 at [Al] : [Mg] > 2.5 were summarized. The traditional Ziegler–Natta catalysts (TiCl4, Ti(Oi-C3H7)4, and TiCl3 ) and titanium postmetallocene complexes with various organic ligands were studied. The binary cocatalyst significantly increased the activity of the traditional catalysts compared with that of Al(C2H5)2Cl and the activity of postmetallocene complexes compared with that of polymethylaluminoxane (MAO). The active centers of these catalytic systems differ in their kinetic parameters, stereospecificity, and copolymerization ability. The efficiency of the Al(C3H5)2Cl/Mg(C4H9)2 cocatalyst can be explained by the in situ formation of finely dispersed MgCl2 and immobilization of the cationic active centers on its surface.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

The combinations of AlR2Cl and \({\text{MgR}}_{2}^{'}\) at a molar ratio of [Al] : [Mg] > 2.5 are effective cocatalysts for all types of metal complex catalysts in alkene polymerizations [1]. The present paper summarizes the results of recent studies of polymerizations of ethylene, propylene, and higher linear 1-alkenes and copolymerizations of ethylene with linear 1-alkenes in the presence of various metal complex catalysts in combination with the Al(C2H5)2Cl/Mg(C4H9)2 binary cocatalyst. The traditional TiCl4, Ti(Oi-C3H7)4, and TiCl3 catalysts and titanium postmetallocene (PMC) complexes with various organic ligands were studied. For comparison, we used the conventional activators of metal complex catalysts Al(C2H5)2Cl and polymethylaluminoxane (MAO).

EXPERIMENTAL

Materials

Ethylene and propylene of polymerization degree of purity (99.9 vol %, Moscow oil refinery) were used without further purification. TiCl4, Ti(Oi-C3H7)4, and Al(C2H5)2Cl (0.8 M heptane solution) and Mg(C4H9)2 (0.5 M heptane solution, Acros) were also used without further purification. Toluene (analytical grade), 1-hexene, and 1-octene were boiled over Na and distilled in an argon flow. 1-Decene was kept over molecular sieves and blown with argon.

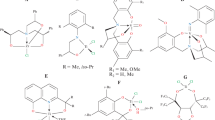

Table 1 shows the PMC complexes used in this work. The syntheses of the ligands and complexes were described in [2–4]. Complexes II, III, and V were introduced in the reaction medium in pure form; complexes I and IV were added in the form of suspensions in toluene without isolating the MgCl2 by-product.

Polymerzations

All polymerizations were performed in a 200 mL steel reactor with a stirrer. Before the experiments, the reactor was evacuated for 1 h at the temperature of experiment. Propylene was polymerized in the mode of the reactor completely filled with the liquid monomer using the procedure described in [5]. In the case of polymerization of ethylene and copolymerization of ethylene with 1-alkenes, the reactor was filled with toluene (or n-heptane) or a mixture of a solvent with 1‑alkene; the volume of the liquid phase was 100 mL. Then, Al(C2H5)2Cl and Mg(C4H9)2 were added in sequence to the reaction medium. The resulting mixture was saturated with ethylene, and then an ampule with the catalyst was broken inside the reactor. The pressure in the reactor during the experiments was kept constant, compensating for ethylene consumption by feeding from a calibrated vessel. The resulting polymers and copolymers were treated with a mixture of ethanol with HCl (10% solution), then repeatedly washed with water and alcohol, and dried to constant weight.

The activity of the catalysts was evaluated from the polymer yield per mol of Ti (kg/mol Ti). The effective rate constant of polymerization was calculated as keff = Rpol/(CmonCTi) (L/mol Ti min), where Rpol is the polymerization rate (M min), and Cmon and CTi are the concentrations of the monomer and Ti compound (M).

Analysis of Polymers

The molecular weight (MW) and MW distribution (MWD) of the polymers were measured by gel permeation chromatography (GPC) in 1,2,4-trichlorobenzene at 135°C on a Waters GPCV-2000 chromatograph with a PL-gel column. The MW was calculated from the universal calibration curve using polystyrene standards.

The procedure for separating the GPC curves into the curves of individual Flory components was described previously [6, 7]. The Flory component is a polymer product produced by one type of active site.

The 13C NMR spectra of the 5% polymer solutions in o-dichlorobenzene at 99°C were recorded on a Bruker AVANCE III 400 instrument (frequency 100.613 MHz). The signals in the spectra of the copolymers of ethylene with 1-alkenes and polypropylene (PP) were attributed based on published data [8–12]. The contents of 1-alkene in the copolymers and of steric pentads and heptads in PP were determined from the 13C NMR spectra of the samples.

The IR spectra of the polymers were recorded on a Perkin-Elmer Fourier spectrometer. The content of 1‑alkenes in the copolymers \(C_{{\text{M}}}^{{{\text{copol}}}}\) (mol %) was determined from the ratio of the absorbance of the 1380, 1368, and 722 cm–1 bands (D1380/D1368 and D1380/D722) using the calibration curves [13]. The absorbance ratios of the 998, 841, and 973 cm–1 bands (D998/D973 and D841/D973), which characterize the presence of isotactic sequences of propylene units longer than 11–13, 13–15, and 3–5 monomer units in the polymer chain, respectively, were used as the stereoregularity parameters of PP [14, 15].

The polymer melting curves were recorded on a Netzsch DSC-209 F1 DSC analyzer (3–5 mg samples) at a heating rate of 10°C/min. For detailed analysis of the composition and structural inhomogeneities of the polymers, we used the data obtained during the second melting of the samples (heating rate 2°C/min) after slow crystallization. The crystallinity χ of polyethylene (PE), PP, and ethylene copolymers was calculated from the heat of fusion ΔHf as (ΔHm/\(\Delta H_{{\text{f}}}^{^\circ }\)) × 100%, where \(\Delta H_{{\text{m}}}^{^\circ }\) for PE and PP is 293 and 167 J/g, respectively.

The XRD patterns of the polymers were recorded on a DRON-2 diffractometer (Cu(Kα) radiation, Ni filter, scan rate 1°(2θ)/min). The crystallinity of the samples was found from the ratio of the integrated intensity of the crystalline component and the total intensity.

RESULTS AND DISCUSSION

Catalytic Systems Based on TiCl4, Ti(Oi-C3H7)4, and TiCl3

Homopolymerization of ethylene and copolymerization of ethylene with 1-hexene. Table 2 presents the main results of the polymerization of ethylene and copolymerization of ethylene with 1-hexene (E/H). Al(C2H5)2Cl and Al(C2H5)2Cl/Mg(C4H9)2 were used as cocatalysts. The use of Al(C2H5)2Cl in combination with Mg(C4H9)2 led to an abrupt activation of these catalysts in all instances. When the Ziegler catalyst TiCl4–Al(C2H5)2Cl (without Mg(C4H9)2) was used, the yield of PE was 223 kg/mol Ti; in the case of Ti(Oi-C3H7)4, only traces of the polymer were obtained under these conditions. However, the addition of Mg(C4H9)2 at a molar ratio of [Al] : [Mg] ~ 3 led to a sharp increase in the yield of PE to ~1.4–1.5 t/mol Ti.

The kinetics of ethylene polymerization is markedly non-steady-state in both cases: at 50°C, the polymer product mostly forms already within the first 10 min of the reaction. Figure 1 shows the kinetic curves of ethylene polymerization in the presence of Ti(Oi-C3H7)4–Al(C2H5)2Cl/Mg(C4H9)2 and TiСl4–Al(C2H5)2Cl/Mg(C4H9)2.

The yield of copolymers was ~2 t/mol Ti h when the TiCl4–Al(C2H5)2Cl/Mg(C4H9)2 system was used at 50°С and from 0.8 to ~3 t/mol Ti h in the case of the Ti(Oiso-C3H7)4–Al(C2H5)2Cl/Mg(C4H9)2) system depending on the composition of the monomer mixture. The content of 1-hexene in the copolymers varied from ~1 to ~15–20 mol %. At high 1-hexene concentrations in the presence of these systems, a comonomer effect was observed, namely, an increase in catalyst activity in ethylene polymerizations with 1‑alkene additions. This effect is well known for both heterogeneous Ziegler–Natta catalysts and metallocene and PMC catalysts [16–18].

The ability to efficiently copolymerize 1-alkenes with ethylene is an important characteristic of any Ti-based catalyst used for the synthesis of medium- and low-density PE. A comparison of the compositions of the monomer mixture and copolymer made it possible to approximately evaluate the copolymerization constants r1 in the case of reactions with low 1-hexene contents:

where kE-E and kE-H are the rate constants of ethylnene and 1-hexene addition to the growing polymer chain with a terminal ethylene unit >Ti–CH2–CH2–polymer.

Ethylene has the highest reactivity in chain propagation reactions compared to all 1-alkenes, and r1 is always higher than 1. For the reactions catalyzed by TiCl4 and Ti(Oi-C3H7)4, r1 is 16–20 and ~60, respectively.

The 13C NMR spectra of PE and E/H copolymers were analyzed; the signals were attributed according to the data of [9]. It follows from the analysis of the 13C NMR spectrum of PE that this is a linear polymer: its spectrum contains an intense signal of the –CH2– groups at 29.8 ppm and weak signals of the saturated linear terminal groups. The E/H copolymers with \(C_{{\text{H}}}^{{{\text{copol}}}}\) = 1.3, 2.1, and 6.0 mol % mainly consist of long sequences of ethylene monomer units ~EEEEEEE~ (the signal of δ,δ-CH2 at 29.8 ppm) and isolated 1‑hexene units ~EEEHEEE~ (the signals of CH(EHE) at 38.1 mppm and 3B4 of CH2(EHE) at 29.5 ppm). Only the spectrum of the copolymer with \(C_{{\text{H}}}^{{{\text{copol}}}}\) ~ 21 mol % (Fig. 2) contains weak signals of the ~EEHHE~ sequences (the signal of (CH(EHH) at 35.8 ppm, 3B4 of CH2(EHH) at 29.1 ppm, and of α,α‑CH2(EHHE) at 40.2 ppm). The intensity ratio of these signals allows us to roughly determine the product of the copolymerization constants r1r2 [19]. For example, the [HHE] : [EHE] and [EHHE] : [EHE] signal ratios for the copolymer with \(C_{{\text{H}}}^{{{\text{copol}}}}\) ~ 21 mol %, obtained in the presence of the TiCl4–Al(C2H5)2Cl/Mg(C4H9)2 system in n-heptane, are 0.52 and 0.14, respectively; for the copolymer of the same composition obtained in toluene, these ratios are 0.45 and 0.15. Using the statistical equations for the contents of various triads and tetrads in the copolymers of ethylene with 1-alkenes as functions of  and r1r2 [19], it was determined that r1r2 is in the range 0.8–1.0. This means that the distribution of monomer units in the chains of the E/H copolymers is mainly statistical.

and r1r2 [19], it was determined that r1r2 is in the range 0.8–1.0. This means that the distribution of monomer units in the chains of the E/H copolymers is mainly statistical.

13C NMR spectrum of the E/H copolymer with \(C_{{\text{H}}}^{{{\text{copol}}}}\) ~ 21 mol %. The TiCl4–Al(C2H5)2Cl/Mg(C4H9)2 system. The position of the CH2 groups relative to CH is indicated by Greek letters; the position of the CH2 groups in butyl (B) side groups relative to CH3 is indicated by numbers.

An increase in the 1-hexene content in the E/Р copolymers leads to a decrease in their molecular mass and effective melting temperature Tm and also to an abrupt decrease in the heat of melting ΔHm and crystallinity χ, as typically occurs for copolymerization of ethylene and 1-alkenes in general (Table 3) [18, 19]. According to the GPC data, both PE and E/H copolymers have a wide MWD, which reflects the presence of different types of active centers in the catalysts, which differ in kinetic parameters (Fig. 3a). All these polymer products are mixtures of components with different MWs. The decomposition of the GPC curves into the Flory components allows us to evaluate the number of types of active centers and the relative amount of the polymer produced by each type of centers. Figure 3b and Table 4 give the examples of separation of the GPC curves of the PE and E/H copolymers into the Flory components obtained in the presence of the Ti(Oi-C3H7)4–Al(C2H5)2Cl/Mg(C4H9)2 system. According to these data, the introduction of 1-hexene into the polymerization medium leads to two effects: a certain decrease in the Mw value of each Flory component and a relative increase in the fraction of active centers producing macromolecules with low MWs (components III and IV).

The presence of various types of active centers suggests that macromolecules can differ not only in the MW characteristics, but also in composition [19]. To verify this assumption, the DSC method was used. It was shown [20] that the position of the maximum on the DSC melting curve and the shape of the melting curve of ethylene–1-alkene copolymers depend on the composition of the copolymers and the degree of their compositional inhomogeneity. The compositionally homogeneous copolymers obtained on single-site metallocene catalysts have relatively narrow melting curves, and their Tm values decrease rapidly with the increasing 1-alkene content in the copolymer. In contrast, the inhomogeneous copolymers synthesized in the presence of multicenter heterogeneous catalysts have wide melting curves (sometimes they consist of several components), and their Tm are relatively weakly dependent on the copolymer composition. This approach allows us to separate any copolymer synthesized in the presence of a multicenter catalyst into two main components: the partially crystalline component with a low 1-alkene content (it can be obtained on one or several types of active centers) and the amorphous component. Figure 4 shows the melting curve of the E/H copolymer with \(C_{{\text{H}}}^{{{\text{copol}}}}\) = 6.0 mol %, obtained in the presence of the TiCl4–Al(C2H5)2Cl/Mg(C4H9)2 system, and this curve separated into five components. The parameters of these components are given in Table 5. The crystalline part of this copolymer (\(C_{{\text{H}}}^{{{\text{copol}}}}\) ~ 3.1 mol %) is ~50% of the total polymer product, the rest being a completely amorphous copolymer not detectable by DSC.

Polymerizations of propylene. Table 6 gives the main results of propylene polymerization in the presence of TiCl4, Ti(Oi-C3H7)4, and δ-TiCl3 catalysts using Al(C2H5)2Cl and the Al(C2H5)2Cl/Mg(C4H9)2 combination as cocatalysts. As in the cases of ethylene homo- and copolymerization, the use of a binary cocatalyst leads to abrupt activation of these catalysts. The Ti(Oi-C3H7)4–Al(C2H5)2Cl system did not show any activity at all. When the classical Ziegler catalyst TiCl4–Al(C2H5)2Cl was used, the yield of PP was only ~8 kg/mol Ti. When the Al(C2H5)2Cl/Mg(C4H9)2 combination was used, it increased to ~10 t/mol Ti in both cases. When the binary cocatalyst was used, the yield of PP in the presence of δ-TiCl3 also increased ~25 times.

All the products are highly molecular, partially crystalline polymers with Тm = 151–153°C (Table 7). Fractionation in boiling heptane makes it possible to separate PP into two fractions: a soluble fraction (amorphous polymer) and insoluble fraction partially consisting of a crystalline isotactic polymer. The presence of two fractions suggests that the active centers of the catalysts differ in stereospecificity.

The wide MMD of propylene polymers and their fractions reflects the inhomogeneity of the active centers in the kinetic parameters. Figure 5 shows an example of the GPC curve of the polymer synthesized in the presence of the Ti(Oi-C3H7)4–Al(C2H5)2Cl/Mg(C4H9)2 system at 50°C and the curves of its soluble and insoluble fractions. The separation of the GPC curves of the PP fractions into the Flory components showed that each fraction is a mixture of six components with different MMs that correspond to active centers of six types. The average MMs of insoluble fractions are always higher than the MMs of soluble fractions.

Propylene polymers obtained in the presence of TiCl4 and Ti(Oi-C3H7)4 with Al(C2H5)2Cl/Mg(C4H9)2 as a cocatalyst are almost completely amorphous and atactic materials; their fractions insoluble in heptane account for only 10–15%.

Figure 6 shows the 13C NMR spectra of the fractions of PP synthesized in the presence of the TiCl4–Al(C2H5)2Cl/Mg(C4H9)2 system at 50°C. The spectrum of the soluble fraction is typical for the spectra of atactic PP [8–10]. A comparison of the spectra of the two fractions in Figs. 6a and 6b shows that the insoluble fraction contains the same signals of stereoirregular sequences in the range 22.1–19.2 ppm and in the same proportions as the soluble fraction. This suggests that the insoluble fraction is a mixture of two sterically different polymers: amorphous atactic and crystalline isotactic polymers. This atactic component has the same structure as the soluble fraction, but higher MM, which explains its low solubility. The spectrum of the crystalline component was isolated by subtracting the spectrum of the soluble fraction from the spectrum of the insoluble one. After this procedure (Fig. 6c), only three signals of stereoirregular sequences remained in the spectrum: mmmr, mmrr, and mrrm in a ratio of ~2 : 2 : 1 at 21.03, 20.52, and 19.28 ppm. Pentads of this type and in this ratio are characteristic of the chains of predominantly isotactic PP with isolated stereoerrors, i.e., for sequences of the ···mmmmrrmmm··· type. These stereoerrors are typical for PP obtained on heterogeneous Ziegler–Natta catalysts and on rac-bis(indenyl)zirconium bridged complexes. We can conclude from these data that the mechanism of stereocontrol of chain growth on the given catalytic systems is enantiomorphic, when each random steric error is corrected in the next act of polymer chain propagation, for example, ···DDDDLDDDD···.

The content of the crystalline component created by the isospecific sites does not exceed 5–7%. The bulk of the polymer product is atactic PP (over 85% in the soluble fraction and ~50% in the insoluble fraction).

Atactic PP is an important commercial product used for the production of construction adhesives, sealing and caulking compounds, road coatings, and adhesive films. The possibility of selective synthesis of atactic PP using systems based on commonly available titanium compounds (TiCl4 or Ti(Oi-C3H7)4) and Al(C2H5)2Cl/Mg(C4H9)2 binary cocatalyst is of interest from practical viewpoint. The advantages of this system are high activity, low cost, and ease of synthesis. All the components of this system are cheap commercial products soluble in aromatic and aliphatic hydrocarbons.

Catalytic Systems Based on Ti Postmetallocene Complexes

Homo- and copolymerizations of ethylene with 1‑alkenes. Table 8 shows the main results of copolymerization of ethylene with 1-alkenes on Ti PMC complexes using the Al(C2H5)2Cl/Mg(C4H9)2 and MAO cocatalysts. The systems with the Al(C2H5)2Cl/Mg(C4H9)2 binary cocatalyst were more active and had higher copolymerization ability than the systems with MAO. Thus, the yield of E/H copolymers was 1.7–4.3 t/mol of Ti for the system IV–Al(C2H5)2Cl/Mg(C4H9)2 containing from 3.5 to ~22 mol % 1-hexene; while the use of MAO in the presence of complex IV gave copolymers with \(C_{{\text{H}}}^{{{\text{copol}}}}\) = 0.3 and ~8–9 mol % in yields of 670–850 kg/mol of Ti.

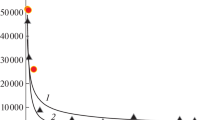

The catalytic systems based on the PMC complexes of Ti are kinetically unstable. Their instability is especially pronounced when the Al(C2H5)2Cl/Mg(C4H9)2 binary cocatalyst is used. The effective flow rate constant of ethylene keff in the presence of system IV–Al(C2H5)2Cl/Mg(C4H9)2 decreased approximately tenfold, from ~38 000 to ~3900 L/(mol Ti min) within the first 10 min of the reaction (Fig. 7).

For copolymers of ethylene and 1-alkenes synthesized in the presence of complexes IV with the binary cocatalyst, the copolymerization constants r1 were evaluated by Eq. (1):

Monomer pair | ethylene/1-hexene | ethylene/1-octene | ethylene/1-decene |

r 1 | 16–32 | 41–46 | 46–53 |

The r1 value gradually increases with the length of the linear alkyl group in 1-alkene; i.e., the reactivity of 1-alkenes decreases in the series 1-hexene > 1-octene > 1-decene. A similar effect is also known for copolymerization of ethylene with 1-alkenes in the presence of heterogeneous Ziegler–Natta catalysts [21].

All the polymers obtained with PMC complexes of Ti have a wide MMD: the PE and copolymer samples consist of five or six Flory components with different MMs [22]. The content of the most high-molecular components (Mw ~ (2.0–2.2) × 106) in PE obtained using MAO is significantly higher (~22%) than in the sample synthesized with Al(C2H5)2Cl/Mg(C4H9)2 (~9%). As a result, for the first polymer (~950 000), Mw is significantly higher than for the second (~530 000). The introduction of 1-alkenes in the PE chain always leads to a decrease in its molecular weight (Table 9). The content of various Flory components in copolymers of similar compositions is independent of the type of 1-alkene.

An analysis of the 13C NMR spectra shows that the active centers of the catalytic systems based on the PMC complexes of Ti and binary cocatalyst have a pronounced tendency toward the creation of alternative copolymers: r1r2 < 1. The 1-alkene molecules in the copolymers are mainly represented by isolated units in the ~EEEMEEE~ sequences. Unlike the statistical copolymers of the same composition, the copolymers have no MMM triads, and the number of MM diads in them is very small.

Propylene polymerizations. According to Table 10, the replacement of MAO (the standard activator for PMC complexes) by the Al(C2H5)2Cl/Mg(C4H9)2 binary cocatalyst led to a significant increase in the activity of these catalysts. In the case of complexes I and IV, the reactor was completely filled with the polymer already in ~10 min after the start of the reaction. The activity of complex III also increased approximately fourfold. Only traces of oligomers were obtained on complex II in the presence of MAO, while the use of the Al(C2H5)2Cl/Mg(C4H9)2 combination led to the formation of a solid high-molecular product.

As in the case of simple titanium catalysts (TiCl4 and Ti(Oi-C3H7)4), PP synthesized in the presence of PMC complexes of Ti was a complex mixture of a completely amorphous atactic polymer and a partially crystalline isotactic polymer. However, the content of the fraction insoluble in boiling heptane and the crystallinity in the samples obtained in the presence of PMC complexes were much higher.

According to the data of Table 11, the MW of PP synthesized using the MAO cocatalyst is significantly higher than in the case of the Al(C2H5)2Cl/MgBu2 combination. Thus, Mw of the polymers obtained for the I–MAO and I–Al(C2H5)2Cl/Mg(C4H9)2 systems are 319 000 and 150 000, respectively.

The results of the separation of the GPC curves of the soluble and insoluble PP fractions show that the MWs of the Flory components of each fraction synthesized in the presence of MAO are higher than the MWs of the components of the Flory fractions obtained using the Al(C2H5)2Cl/Mg(C4H9)2 combination (Table 12). The content of high molecular components in each fraction is also higher in the case of the use of MAO. As a result, the average MWs of each fraction and the MW of the total polymer are significantly different:

I–MAO: Mw (insol.) = 676 500, Mw (sol.) = 298 200, \(M_{{\text{w}}}^{{{\text{av}}}}\) = 319 000;

I–Al(C2H5)2Cl/Mg(C4H9)2: Mw (insol.) = 272 100, Mw (sol.) = 92 500, \(M_{{\text{w}}}^{{{\text{av}}}}\) = 150 000.

This tendency is characteristic of propylene polymers obtained for all PMC complexes of Ti. In the presence of the Al(C2H5)2Cl/Mg(C4H9)2 combination, the stereoregularity of the polymers also changes significantly. Thus, when complex I is used, both the IR parameters of PP stereoregularity and the content of the heptane-insoluble fraction in it increase. The stereoregulating effect of Al(C2H5)2Cl/Mg(C4H9)2 is especially significant when complex III is used. In combination with MAO, an amorphous polymer completely soluble in boiling heptane is obtained on this catalyst. When the Al(C2H5)2Cl/Mg(C4H9)2 combination is used, the partially crystalline isotactic PP with Tm = 151°C containing 34% insoluble fraction is obtained. Thus, the properties of the polymer can be substantially varied by using the cocatalyst.

Polymerizations of higher linear 1-alkenes. Table 13 lists the main results of polymerization of three linear 1-alkenes. The experiments were performed in the monomer medium at 2°C. Under these conditions, complex IV was activated not only by Al(C2H5)2Cl/Mg(C4H9)2 and MAO, but also by Al(C2H5)2Cl alone. However, the IV–Al(C2H5)2Cl system had the lowest activity in all instances. The binary cocatalyst was most effective in the polymerization of 1-decene; in the polymerizations of 1-octene and 1-hexene, the efficiency of the Al(C2H5)2Cl/Mg(C4H9)2 combination and MAO was approximately the same. Like PP obtained on the PMC complexes of Ti, all the polymers of higher 1-alkenes have a medium level of isotacticity and a wide MWD.

Discussion. Chemical Aspects of Alkene Polymerization

Any titanium compound of the TiX4 type actively reacts with organoaluminum compounds AlR3 and AlR2Cl, forming many products that are soluble solid materials [23]. An analysis of the reaction products of TiCl4 and Al(C2H5)2Cl showed that the chemical composition of the precipitate gradually changes from the initial [TiCl3C2H5] to [TiAl2Cl5] [24–30]. The valence state of Ti (a mixture of TiIV, TiIII, and TiII) and the efficiency of the TiCl4–Al(C2H5)2Cl catalyst also change depending on the duration of the contact. The reactions between Ti(OR)4 and organoaluminum compounds also give many various products with a very complex chemical composition [31–33].

The interaction in the TiX4–AlR3 and TiX4–AlR2Cl systems can generally be described by the following reactions:

1. Alkylation of TiX4:

Reactions (2) are very fast and irreversible [31–34]. At high [Al] : [Ti] ratios, the alkylations of titanium compounds generally continue:

2. In some cases, X3Ti–R are involved in condensations. If R = C2H5, the condensation leads to the formation of binuclrear Ti complexes:

3. Reduction of organotitanium compounds X3TiIV–R and X2TiIVR2 with aluminoorganic compounds to TiIIIX3 and X2TiIII–R. All the Ti complexes formed in reactions (2)–(4) and reductions generate numerous complexes with one or two AlR2X or AlRXCl molecules. Some of the soluble binuclear and trinuclear TiIII complexes such as [TiX3] ⋅ 2AlR2X, [TiX3]AlR2X, and [X2Ti–R]AlRXCl were characterized in detail [30–33].

The Ti complexes with bidentate and multidentate ligands can be represented by the general formula LTiCl2 or L2Ti. When these complexes are mixed with the \({{{\text{Al}}{{{\mathbf{R}}}_{{\text{2}}}}{\text{Cl}}} \mathord{\left/ {\vphantom {{{\text{Al}}{{{\mathbf{R}}}_{{\text{2}}}}{\text{Cl}}} {{\text{Mg}}{\mathbf{R}}_{2}^{'}}}} \right. \kern-0em} {{\text{Mg}}{\mathbf{R}}_{2}^{'}}}\) combinations at a ratio of [Al] : [Mg] > 2.5, they are quickly alkylated to LTi(Cl)–R or LTiR2 by the reactions similar to (3).

The efficiency of the AlR2Cl and \({\text{Mg}}{\mathbf{R}}_{2}^{'}\) combinations as cocatalysts can be explained by two factors. The first factor is that AlR2Cl and \({\text{Mg}}{\mathbf{R}}_{2}^{'}\) quickly react, forming the finely dispersed MgCl2, whose surface has Lewis acidity [1, 2]:

All the cocatalysts used were prepared at a ratio of [Al] : [Mg] > 2.5. Thus, the titanium compound TiX4 or the complex LTiX2, which were added to the Al(C2H5)2Cl/Mg(C4H9)2 mixture at the last stage of catalyst preparation, can react both with an excess of AlR2Cl and with AlR2R' formed in reaction (5). When the products X3TiIV–R, X2TiIII–R, and LTi(Cl)–R or their complexes with organoaluminum compounds are adsorbed on the acid surface of MgCl2, they can be ionized, forming cation centers containing the Ti+–C bond:

These cation centers are generally regarded in the literature as catalytically active sites in polymerizations in the presence of Ziegler–Natta catalysts [24]. The second possible reason for the high efficiency of \({{{\text{Al}}{{{\mathbf{R}}}_{{\text{2}}}}{\text{Cl}}} \mathord{\left/ {\vphantom {{{\text{Al}}{{{\mathbf{R}}}_{{\text{2}}}}{\text{Cl}}} {{\text{Mg}}{\mathbf{R}}_{2}^{'}}}} \right. \kern-0em} {{\text{Mg}}{\mathbf{R}}_{2}^{'}}}\) combinations used as cocatalysts is the formation of contact ion pairs [MgR']+ [\({{{\mathbf{R}}}_{{\text{2}}}}{\mathbf{R}}_{{\text{2}}}^{{{'}}}{\text{Al}}\)]− and [MgR']+ [RR'AlCl⋅⋅⋅\({\text{Al}}{\mathbf{RR}}_{{\text{2}}}^{{{'}}}\)]−. These ion pairs can transform the alkylated products X3TiIV–R, X2TiIII–R, or LT(Cl)–R into cation active centers of another type, for example:

All the catalytic systems consisting of TiCl4, Ti(OR)4, or PMC complexes of Ti and \({{{\text{Al}}{{{\text{R}}}_{{\text{2}}}}{\text{Cl}}} \mathord{\left/ {\vphantom {{{\text{Al}}{{{\text{R}}}_{{\text{2}}}}{\text{Cl}}} {{\text{Mg}}{\mathbf{R}}_{2}^{'}}}} \right. \kern-0em} {{\text{Mg}}{\mathbf{R}}_{2}^{'}}}\) binary cocatalysts contain active centers of various types, which differ in the kinetic parameters, stereospecificity, and copolymerizing ability. It can be assumed that these active sites form in reactions (2)–(11) from various compounds: XxTi–R, XyTiR2, and LTi(Cl)–R containing both TiIV and TiIII.

CONCLUSIONS

1. The Al(C2H5)2Cl/Mg(C4H9)2 combination at a molar ratio of [Al] : [Mg] > 2.5 is an effective cocatalyst for titanium compounds such as TiCl4 and Ti(Oi-C3H7)4 and for PMC complexes of Ti in polymerizations of ethylene, propylene, and higher 1-alkenes and in copolymerizations of ethylene with 1-alkenes.

2. The efficiency of the Al(C2H5)2Cl/Mg(C4H9)2 combination as a cocatalyst in 1-alkene polymerizations is explained by the in situ formation of finely dispersed MgCl2 and immobilization of cation active centers on its surface.

3. The products of polymerizations are highly molecular linear PE; mostly amorphous atactic PP; highly molecular polymers of higher 1-alkenes (1-hexene, 1-octene, and 1-decene); and copolymers of ethylene with higher 1-alkenes.

4. The active centers of these catalytic systems differ in the kinetic parameters, stereospecificity, and copolymerizing ability.

5. The chain growth reaction on the isospecific centers proceeds according to the enantiomorphic mechanism typical of propylene polymerizations in the presence of heterogeneous Ziegler–Natta and metallocene catalysts.

REFERENCES

Y. V. Kissin, R. I. Mink, A. J. Brandolini, and T. E. Nowlin, J. Polym. Sci., Part A 47, 3271 (2009).

L. A. Rishina, N. M. Galashina, S. C. Gagieva, et al., Eur. Polym. J. 49, 147 (2013).

L. Rishina, S. S. Lalayan, S. C. Gagieva, et al., Polymer 54, 6526 (2013).

L. A. Rishina, Y. V. Kissin, S. S. Lalayan, et al., J. Polym. Sci., Part A 55, 1844 (2017).

L. A. Rishina, N. M. Galashina, S. Ch. Gagieva, V. A. Tuskaev, B. M. Bulychev, and Yu. N. Belokon’, Polymer Sci., Ser. A 50, 110 (2008).

Y. V. Kissin, J. Polym. Sci., Part A 33, 227 (1995).

Y. V. Kissin, Alkene Polymerization Reactions with Transition Metal Catalysts (Elsevier, Amsterdam, 2008), Chap. 2.

T. Hayashi, Y. Inoue, R. Chujo, and T. Asakura, Polymer 29, 138 (1988).

E. T. Hsieh and J. C. Randall, Macromolecules 15, 1402 (1982).

F. S. Schilling and A. E. Tonelli, Macromolecules 13, 270 (1990).

V. Busico, R. Cipullo, G. Monaco, et al., Macromolecules 30, 6251 (1997).

V. Busico, R. Cipullo, G. Monaco, et al., Macromolecules 32, 4173 (1999).

T. E. Nowlin, Y. V. Kissin, and K. P. Wagner, J. Polym. Sci., Part A 26, 755 (1988).

Y. V. Kissin, V. I. Tsvetkova, and N. M. Chirkov, Eur. Polym. J. 8, 529 (1972).

Y. V. Kissin and L. A. Rishina, Eur. Polym. J. 12, 757 (1976).

T. E. Nowlin, R. I. Mink, and A. J. Brandolini, J. Polym. Sci., Part A 37, 4255 (1999).

M. P. McDaniel, E. D. Schwerdtfeger, and M. D. Jensen, J. Catal. 314, 109 (2014).

Y. V. Kissin, J. Polym. Sci., Part B 49, 195 (2011).

B. A. Krentsel, Y. V. Kissin, V. I. Kleiner, and L. L. Stotskaya, Polymers and Copolymers of Higher α-Olefins (Hanser, New York, 1997), Chap. 8.

Y. V. Kissin and D. L. Beach, J. Polym. Sci., Part A 22, 333 (1984).

N. M. Chirkov, P. E. Matkovskii, and F. S. D’yachkovskii, Polymerization Induced by Complex Metalloorganic Catalysts (Khimiya, Moscow, 1976) [in Russian].

L. A. Rishina, S. S. Lalayan, S. Ch. Gagieva, et al., J. Res. Updates Polym. Sci. 3, 216 (2014).

L. Rodriguez, Tetrahedron Lett. 17, 7 (1959).

F. X. Werber, C. J. Benning, W. R. Wszolek, et al., J. Polym. Sci., Part A 6, 743 (1968).

K. Ziegler, H. Martin, and I. Stedefeder, Tetrahedron Lett. 20, 15 (1959).

C. G. Overberger, F. Ang, and H. Mark, J. Polym. Sci. 35, 381 (1959).

L. A. Rishina, E. N. Zhuravleva, Yu. V. Kissin, et al., Vysokomol. Soedin., Ser. A 16, 1459 (1974).

J. Varadi, I. Czajlik, A. Baan, et al., J. Polym. Sci., Part C 16, 2069 (1967).

I. Czajlik, J. Varadi, and A. Baan, J. Polym. Sci., Part B 4, 661 (1966).

G. Natta, L. Porri, A. Carbonaro, et al., Macromol. Chem. 77, 126 (1964).

D. H. Dawes and C. A. Winkler, J. Polym. Sci., Part A 2, 3029 (1964).

T. C. Dzhabiev, F. S. D’yachkovskii, and A. E. Shilov, Vysokomol. Soedin., Ser. A 13, 2474 (1971).

I. Ono and T. Keii, J. Polym. Sci., Part A 4, 2441 (1966).

Funding

This study was performed under state assignment and supported by the Russian Scientific Foundation (project no. 18-13-00375).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by L. Smolina

Rights and permissions

About this article

Cite this article

Rishina, L.A., Kissin, Y.V., Gagieva, S.C. et al. New Cocatalyst for Alkene Polymerization Reactions with Transition Metal Catalysts. Russ. J. Phys. Chem. B 13, 789–802 (2019). https://doi.org/10.1134/S1990793119050087

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1990793119050087