Abstract

Experiments on the giant magnetoresistance effect observed in microwave reflection have been conducted in the frequency range of 26–38 GHz on (CoFe)/Cu superlattices exhibiting giant magnetoresistance. The amount of the effect has been determined (up to +3% maximum), and its magnetic field dependence has been found. The microwave reflection coefficient versus magnetic field dependence has been calculated. The measured variation of the reflection coefficient has turned out to be greater than calculated values. This discrepancy is associated with the fact that a superlattice is approximated by a homogeneous plate in calculations. The frequency dependence of the giant magnetoresistance effect in microwave reflection has been observed. It is explained by the influence of the impedance of a waveguide in which samples are placed to take measurements.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The microwave characteristics of magnetic metal superlattices are of both scientific and applied interest. The microwave giant magnetoresistance (μGMR) effect was first observed in [1]. It was found that the field dependence of the μGMR in microwave reflection is similar in form to that in microwave transmission through a superlattice. However, the μGMR in reflection is opposite in sign and less pronounced [2]. Different conditions for μGMR effect observation in a wide frequency range are considered in [3], where two partial cases were derived from the general expression for the coefficient of electromagnetic wave propagation through a metallic plate. One refers to microwaves passing through metallic nanostructures more than several nanometers thick. In this case, one-to-one correspondence between the μGMR effect and the dc GMR effect (hereinafter, “the GMR effect”) must be fulfilled. The one-to-one correspondence between the μGMR and GMR effects means that the μGMR is frequency-independent. The other limiting case concerns nanostructures with a total metal thickness less than several nanometers. Here, the one-to-one correspondence is absent.

The frequency dependence of the μGMR was studied in detail in [4], where it was shown that there are some circumstances causing the dependence of the μGMR on nanostructure thickness and microwave frequency. Calculations of the transmission and reflection coefficients performed in this study indicate that the second limiting case cannot take place in metallic nanostructures more than 0.5 nm thick. In the case of centimeter and millimeter waves propagating in metallic nanostructures from about 1.5 to about 200 nm thick, only the first limiting case may occur. The one-to-one correspondence between the μGMR and GMR effects was many times verified experimentally [3–6]. As a rule, changes in the transmission coefficient measured in the centimeter and millimeter wave ranges correlate well with the magnetoresistance of samples. The frequency dependence of μGMR in transmission is weak for most Fe/Cr superlattices. Only a few superlattices exhibit a slight attenuation of the μGMR effect with increasing frequency [3]. The nonfulfillment of the one-to-one correspondence between the μGMR and GMR effects is observed in the IR range [7] and at microwave frequencies for granulated systems [5].

Co/Cu and (CoFe)/Cu nanostructures and superlattices have a high magnetoresistance. The μGMR effect in Co/Cu and (CoFe)/Cu nanostructures was studied in [8, 9]. In Co/Cu systems, a weak frequency dependence of μGMR was observed, with μGMR decreasing with rising frequency [8]. In (CoFe)/Cu superlattices, the currently record value of microwave magnetoresistance (up to –80%) was observed [9]. Such a high magnetoresistance was achieved by (i) selecting Co0.88Fe0.12 alloy, which has high GMR; (ii) properly selecting the buffer layer material; and (iii) optimizing the fabrication technique to provide a necessary microstructure of samples. In [6], the μGMR was observed and calculated in spin valves containing CoFe layers exchange-coupled through a Cu spacer. The microwave reflection from spin valves containing Co layers and a Cu spacer was measured by the modulation technique [10].

The aim of our experiments was to study the μGMR effect in microwave reflection from (CoFe)/Cu superlattices, find the frequency dependence of μGMR in reflection, reveal reasons for this dependence, and jointly observe the μGMR and GMR effects in microwave reflection. Specifically, we studied the microwave properties of two [(Co0.88Fe0.12)/Cu]n superlattices with spacer thicknesses ts = 0.95 and 2.05 nm. At such thicknesses, the oscillatory dependence of the GMR on spacer thickness reaches maxima. In these samples, the magnetoresistance changes in magnetic fields with a different intensity. Microwave measurements were made in the frequency interval of 26–38 GHz. The field dependences of the reflection coefficient were taken.

1. SUPERLATTICES AND THEIR EVALUATION

[(Co0.88Fe0.12)/Cu]n superlattices were prepared by magnetron sputtering on an MPS-4000-C6 setup. The compositions of the superlattices were as follows:

Ta(5.0)/PyCr(5.0)/[Co88Fe12(1.5)/Cu(0.95)]24/Ta(5.0)—sample 1;

Ta(5.0)/PyCr(5.0)/[Co88Fe12(1.3)/Cu(2.05)]8/Co88Fe12(1.3)/PyCr(3.0)—sample 2.

The numeral in parentheses is the thickness of a given layer in nanometers, the subscript at brackets signifies the number of pairs of layers, and Py means Fe–Ni alloy. The thicknesses of the Cu spacer were taken such that the first and second maxima in the dependence of the GMR on spacer thickness are attributed to samples 1 and 2, respectively. Structures were grown on a 0.2-mm-thick Corning glass substrate. The growth technology of (CoFe)/Cu superlattices was described elsewhere [11]. A Ta(5.0) buffer layer adjacent to the substrate relieves inner stresses in the nanostructure and forms a structure that is optimal for high magnetoresistance. The upper Ta(5.0) layer in sample 1 and PyCr(3.0) layer in sample 2 prevent the nanostructure from corrosion. X-ray diffraction analysis of the samples was performed in the common use center (Institute of Metal Physics, Ural Branch, Russian Academy of Sciences) using a PanAnalytical diffractometer.

Diffraction patterns taken of both superlattices contain only one peak from (111) planes of the fcc lattice. This peak is common for Cu and Co88Fe12 alloy, because the fcc lattice parameters of Cu and this alloy are close to each other. Oscillations are observed around this peak. They indicate a high perfection of the layered structure of the superlattices (Fig. 1a). The superlattice period determined from the angular position of the oscillations is nearly coincident with its rated value. The absence of other peaks characteristic of the fcc lattice suggests the formation of an axial 〈111〉 texture in these samples, with its axis normal to the plane of the film (the orientation of the film was confirmed by rocking curve measurements). A perfect 〈111〉 texture is present in both superlattices.

The surface relief of the samples was examined by means of a Solver Next automated scanning probe microscope. It was shown that the surface of the samples is smooth with a peak-to-valley height of about 3 nm over a 1 × 1-μm scan area.

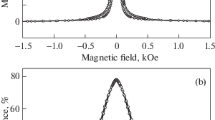

Magnetic measurements showed that saturation magnetization Ms in samples 1 and 2 equals 1625 ± 8 and 1638 ± 8 G, respectively. These values will be used in subsequent calculations. To analyze μGMR measurement data, it is necessary to know the magnetoresistance of the sample. It is known that the magnetoresistance of (CoFe)/Cu nanostructures will be high if the magnetic moments of CoFe layers are antiparallel in the absence of an external magnetic field [10]. The magnetoresistance was measured using the four-point probe method (Fig. 1b). For sample 1, in which the spacer thickness corresponds to the first maximum of the GMR, the magnetoresistance versus magnetic field curve tends to saturation at about 7 kOe. The magnetoresistance is calculated as r = [\(\mathcal{R}\)(H) –\(\mathcal{R}\)(0)]/\(\mathcal{R}\)(0), where \(\mathcal{R}\)(H) is the electrical resistance in magnetic field H. At saturation, r of this sample is about –44%. The magnetoresistance curve for sample 2 saturates at about 0.2 kOe, whole magnetoresistance r at saturation equals –22%. The spacer thickness in sample 2 corresponds to the second maximum of the GMR. The measured values of the magnetoresistance are consistent with data reported in [11].

2. MICROWAVE MEASUREMENT DATA

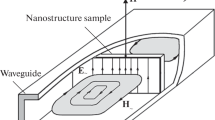

Microwave measurements were made using the method described in [2]. A sample was placed in a standard 3.6 × 7.2-mm rectangular waveguide so that it completely covers the waveguide’s cross section. The absolute value of reflection coefficient R and its change rm = [R(H) – R(0)]/R(0) in magnetic field H were measured by taking amplitude–frequency characteristics. During measurements, the external magnetic field lay in the plane of the sample and was directed along the narrower wall of the waveguide. Thus, the permanent and microwave magnetic fields were mutually orthogonal. Measurements were taken at room temperature.

The magnetic field dependence of the reflection coefficient was taken at different microwave frequencies. Results for sample 1 are presented in Fig. 2a. These changes are due to two reasons. The first reason is that the superlattice resistance varies in a magnetic field. This causes a monotonic increase in the reflection coefficient and delineates the μGMR effect. The second one is associated with ferromagnetic resonance (FMR). It shows up in a relatively narrow interval of magnetic fields and usually lowers the reflection coefficient because of microwave absorption at FMR. It is shown in Fig. 2a that the resonance field grows with frequency. Estimates made by formulas for the resonance spectrum [12] indicate that fields at which resonance variations are observed correlated with the spectrum of uniform-mode FMR. At frequencies of 35 and 38 GHz, the picture of events becomes more complicated. In fields slightly below the FMR field, the reflection coefficient grows. Earlier, in studies of microwave reflection from Fe/Cr superlattices [2] and (Co/Fe)/Cu spin-valve structures [9], such a phenomenon was not observed. Further investigations are needed to clarify the reason for the growth of the reflection coefficient. One may suppose that this increase is due to anti-FMR [12]. The following circumstances count in favor of this supposition: there exists a singularity in the form of a maximum of the reflection coefficient, which arises in fields below the FMR field and at frequencies above 32 GHz. Such behavior is expected to reveal itself at anti-FMR.

Let us consider the μGMR effect in sample 1 again. Figure 2a shows that in high fields the variation of the reflection coefficient generally grows with frequency. This fact is inconsistent with the theory of the μGMR effect [2, 4]. The reason for this inconsistency will be discussed in the next section. In sample 2, the magnetic saturation takes place in a field of 0.3 kOe; therefore, the domains of the μGMR effect and FMR are separated (Fig. 2b). In fields below 2 kOe, only the μGMR effect is observed. Here, one can also distinguish the frequency dependence of this effect, with the variation of the reflection coefficient growing with frequency. In higher fields, the variation of the reflection coefficient is due to a very wide FMR line. It should be noted that, in this sample, the reflection coefficient also grows in fields below the FMR field at 32 and 35 GHz. Here, this may be associated with magnetic antiresonance.

3. DISCUSSION

Calculations of microwave transmission through and reflection from a metal plate were the subject of a number of investigations (see, e.g., [13, 14]). These calculations were applied to analyze the μGMR effect [6]. In those studies, the transmission and reflection coefficients were determined as ratios of the transmitted wave and reflected wave intensities to the incident wave intensity, respectively. In this case, it is necessary to know the surface resistance of the sample to perform calculations. In our case, the reflection coefficient was determined as a ratio between the amplitudes of reflected and incident waves. Here, the surface resistance may be unknown. Both approaches are based on an approximation according to which a multilayer nanostructure is replaced by a homogeneous metal plate with the same conductivity and magnetic permeability. Our calculations were carried out in much the same way as in [2]. Reflection coefficient R depends on the ratio between the impedances of the nanostructure (Zm) and ambient (Z). By the ambient is meant either free space or a waveguide. In our experiments, the inequality d ≪ δ is valid. In the case of the normal skin effect, the impedance of a multilayer superlattice is given by Zm = [(1 + i)/δ]ρ, where ρ = ρ(H) is the resistivity of the nanostructure, δ = (2ρ/ωμμ0)1/2 is the skin depth, ω = 2πf is the circular frequency, and μ is the relative dynamic differential magnetic permeability. Hereinafter, by “magnetic permeability and resistivity” are meant effective values averaged over the volume of the superlattice. The impedance of a waveguide supporting a TE10 mode with a superlattice inside is given by

where λ = c/f is the wavelength in vacuum, λc = 2a is the critical wavelength of the TE10 mode, and a is the width of the wider wall of a rectangular waveguide. In our experiments, a = 7.2 mm. If measurements were taken in free space, rather than in a waveguide, expression (1a) would be replaced by the expression

According to [15], the formula for coefficient R of electromagnetic wave reflection can be written as

where km = (1 + i)/δ is the wavenumber in a conducting medium. The impedance of a well conducting nanostructure is much smaller than impedance Z: |Zm| ≪ Z. If the inequality 2Zmcosh(kmd) ≪ Zsinh(kmd) in the denominator of (2) is fulfilled, the reflection coefficient can be estimated by the formula

This case takes place in metallic nanostructures at microwaves. In this limiting case, reflection coefficient R may depend on frequency because of frequency dispersion of material constants and frequency dependence of waveguide impedance Z. This dependence of impedance Z is weak far from cutoff frequency fc = \(\frac{c}{{2a}}\), but it may have an influence if there are no other dispersion sources. For the parameter range within which changes in magnetic permeability may be ignored, one can derive from (3) an expression for the relative variation of the reflection coefficient:

In (4), ρ(0) is the resistivity and μ(0) is the magnetic permeability in the absence of a magnetic field. Quantity D(0) = \(\frac{{2\rho (0)}}{{Zd\mu (0)}}\) is much smaller than unity, D(0) ≪ 1, for metal plates more than 10 nm thick. If the reflection coefficient variation is due to only the magnetoresistance of the nanostructure at μ(0) ≈ 1, we have from (4)

It follows that the variation of the reflection coefficient is opposite in sign to magnetoresistance r. The change in rm is much smaller than |r| but varies with in external magnetic field in the same way as r. Formulas (4) and (5) are valid if the nanostructure is far from the FMR condition.

The reflection coefficient was calculated for superlattices considered in this study. Results of calculation by formulas (1a), (1b), and (5) are summarized in Table 1. Calculation was performed for frequency f = 35 GHz in fields of 12 and 2 kOe. In the former field, sample 1 was close to magnetic saturation, whereas in the latter field, sample 2 was at saturation. It is seen from Table 1 that the measured variation of the reflection coefficients for both superlattices is 50–60% greater than the calculated value. Figure 3a shows the experimental magnetic field dependence of the reflection coefficient for sample 2 and the estimation of the coefficient calculated by formula (5) for the impedance of the waveguide (formula (1a)) and free space (formula (1b)). In addition, the reflection coefficient was calculated by formula (2), which is more accurate. All dependences are of the same type but differ in amount of change. The measured variations turned out to be greater than the calculated ones. It seems that this discrepancy (primarily between experimental data and data calculated by formula (2)) is associated with adopted approximations, specifically, with the replacement of a multilayer superlattice by a homogeneous metal plate with equivalent conductivity. It should be noted that, when considering microwave propagation in (CoFe)/Cu superlattices, the measured μGMR effect exceeded its value calculated in the same approximation [16].

(a) Measured vs. calculated field dependences of the microwave reflection coefficient for Ta(5.0)/PyCr(5.0)/ [Co88Fe12(1.3)/Cu(2.05)]8/Co88Fe12(1.3)/PyCr(3.0) superlattice and (b) shape comparison between the field dependences of μGMR and GMR for Ta(5.0)/PyCr(5.0)/[Co88Fe12(1.5)/Cu(0.95)]24/Ta(5.0) superlattice.

Let us compare the shapes of the field dependences of μGMR in reflection and GMR. A comparison will be made for sample 1. The case with sample 1 is more difficult than that for sample 2, since the field dependences of μGMR in the former case contain FMR-related features. Comparison results are presented in Fig. 3b, where rm normalized to its maximum at saturation, namely, rm/(rm)max, is plotted on the Y axis. Figure 3b also compares the field dependence of GMR reversed in sign and the field dependence of the reflection coefficient measured at 26 and 35 GHz. It is seen that the field dependences of GMR and μGMR are nearly identical in shape except for regions close to the FMR condition. Near the FMR condition, the reflection coefficient decreases because of wave absorption [2]. Arrows in Fig. 3b show the FMR positions. The μGMR-induced monotonic field dependence of the reflection coefficient is almost the same as the field dependence of GMR. Results of calculation by estimation formula (5) exactly coincide with the field dependence of the normalized magnetoresistance at GMR (in Fig. 3b, they are omitted).

It is of interest to discuss reasons for the frequency dependence of the reflection coefficient presented in Fig. 2. This dependence is distinctly seen in the interval 1–12 kOe for sample 1 and near 2 kOe for sample 2. In this field, sample 2 is magnetically saturated, whereas the FMR condition is met in much higher fields. A tendency is observed in both cases: the amount of the μGMR effect grows with wave frequency. Simplified formula (5) does not involve the frequency dependence of μGMR effect if the conductivity does not depend on frequency. For relaxation time τ = 10–15–10–14 s, which follows from the conductivity value, the frequency dispersion at frequency f ~ 3 × 1010 Hz cannot take place, since 2πfτ ≪ 1. In [17], the frequency dependence of the conductivity of a thin metal sheet is attributed to the spatial, rather than temporal, dispersion of conductivity. However, this point of view was criticized and it was concluded that the conductivity is frequency independent in millimeter and submillimeter wave ranges [18]. It was shown [4] that the formation of standing waves in a dielectric substrate should be taken into consideration at upper frequencies of the millimeter wave range, which makes the reflection coefficient in the case of the μGMR effect frequency-dependent. The frequencies used in this study are much lower than those mentioned above, so that standing waves do not arise. Basically, the frequency dependence of the reflection coefficient is embodied in formulas (2) and (5) if waveguide impedance Z is calculated by formula (1a). Let us estimate the influence of the frequency dependence of waveguide impedance. Relative change rm in the reflection coefficient of either sample, which is associated with the μGMR effect, is normalized to changes at the lower frequency 26 GHz, rm/rm (26 GHz). Results are shown in Fig. 4. As has been already noted, the changes grow with frequency. Figure 4 also shows the frequency dependence of the normalized changes in the reflection coefficient that were calculated by formula (2) for the case when the impedance was calculated by formula (1) for the waveguide. The impedance of free space is frequency independent. Accordingly, the reflection coefficient does not depend on frequency as well. Comparing experimental data with calculation data presented in Fig. 4, one can conclude that they are in good agreement for sample 1 and coincide in order of magnitude for sample 2. In general, it can be argued that, in our conditions, the frequency dependence of the change in the reflection coefficient due to the μGMR effect to a great extent results from the frequency dependence of the waveguide impedance.

CONCLUSIONS

The μGMR effect in reflection was studied for two (Co88Fe12)/Cu superlattices with spacer thicknesses corresponding to the first and second maxima observed in the dependence of the amount of the GMR effect on spacer thickness. It was found that the field dependence of the reflection coefficient contains an FMR-induced contribution at microwaves. It turned out that μGMR-induced changes in the reflection coefficient tend to saturation in fields of sample magnetic saturation. The relative changes in the reflection coefficient due to the μGMR effect varies from 1 to 4%. In accordance with the theory, the changes are positive and vary with field similarly to the GMR effect. Changes observed experimentally exceed calculated values. The discrepancy is associated with the used approximation, according to which a superlattice is replaced by a uniform metal plate with an effective conductivity. It was found experimentally that μGMR-induced changes in the reflection coefficient are frequency-dependent. This frequency dependence can be explained by the frequency dependence of the impedance of a waveguide in which the sample is placed.

REFERENCES

Z. Frait, P. Sturć, K. Temst, Y. Bruynseraede, and I. Vavra, Solid State Commun. 112, 569 (1999).

V. V. Ustinov, A. B. Rinkevich, L. N. Romashev, and E. A. Kuznetsov, Tech. Phys. Lett. 33 (9), 771 (2007). https://doi.org/10.1134/S1063785007090179

V. V. Ustinov, A. B. Rinkevich, L. N. Romashev, A. M. Burkhanov, and E. A. Kuznetsov, Phys. Met. Metallogr. 96, 291 (2003).

D. V. Perov and A. B. Rinkevich, Phys. Met. Metallogr. 120 (4), 333 (2019). https://doi.org/10.1134/S0031918X19040100

D. P. Belozorov, V. N. Derkach, S. V. Nedukh, A. G. Ravlik, S. T. Roschenko, I. G. Shipkova, S. I. Tarapov, and F. Yildiz, Int. J. Infrared Millimeter Waves 22 (11), 1669 (2001). https://doi.org/10.1023/A:1015060515794

D. E. Endean, J. N. Heyman, S. Maat, and E. Dan Dahlberg, Phys. Rev. B 84 (21), 212405 (2011). https://doi.org/10.1103/PhysRevB.84.212405

J. C. Jackuet and T. Valet, Mater. Res. Soc. 384, 477 (1995). https://doi.org/10.1557/PROC-384-477

T. Rausch, T. Szczurek, and M. Schlesinger, J. Appl. Phys. 85 (1), 314 (1999). https://doi.org/10.1063/1.369448

A. B. Rinkevich, Ya. A. Pakhomov, E. A. Kuznetsov, A. S. Klepikova, M. A. Milyaev, L. I. Naumova, and V. V. Ustinov, Tech. Phys. Lett. 45 (2), 225 (2019). https://doi.org/10.1134/S1063785019030143

J. Dubowik, F. Stobiecki, and I. Gościańska, Czech. J. Phys. 52 (2), 227 (2002). https://doi.org/10.1023/A:1014475830396

M. A. Milyaev, L. I. Naumova, and V. V. Ustinov, Phys. Met. Metallogr. 119 (12), 1162 (2018). https://doi.org/10.1134/S0031918X1812013X

A. G. Gurevich and G. A. Melkov, Magnetization Oscillations and Waves (CRC, Boca Raton, 1996).

R. L. Ramey, W. J. Kitchen, Jr., J. M. Lloyd, and H. S.Landes, J. Appl. Phys. 39 (8), 3883 (1968). https://doi.org/10.1063/1.1656870

R. L. Ramey and T. S. Lewis, J. Appl. Phys. 39 (3), 1747 (1968). https://doi.org/10.1063/1.1656424

N. A. Semenov, Technical Electrodynamics (Svyaz’, Moscow, 1973) [in Russian].

V. V. Ustinov, A. B. Rinkevich, I. G. Vazhenina, and M. A. Milyaev, J. Exp. Theor. Phys. 131 (1), 139 (2020). https://doi.org/10.1134/S1063776120070171

W. Pan and X. Zhang, Int. J. Infrared Millimeter Waves 27 (3), 455 (2006). https://doi.org/10.1007/s10762-006-9054-2

S. Lucyszyn, Int. J. Infrared Millimeter Waves 28 (3), 263 (2007). https://doi.org/10.1007/s10762-007-9204-1

ACKNOWLEDGMENTS

The authors thank M.V. Makarova and E.A. Kravtsov for X-ray investigations of nanostructures performed in the Center for Collective Use at the Institute of Metal Physics, Ural Branch, Russian Academy of Sciences.

Funding

The investigations were carried out in the framework of project no. AAAA-A18-118020290104-2 “Spin” and project no. AAAA-A19-119012990095-0 “Funktsiya.” Section 2 was supported by the Russian Science Foundation, grant no. 17-12-01002.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by V. Isaakyan

Rights and permissions

About this article

Cite this article

Rinkevich, A.B., Kuznetsov, E.A., Perov, D.V. et al. The Giant Magnetoresistance Effect in Microwave Reflection from (CoFe)/Cu Superlattices. Tech. Phys. 66, 298–304 (2021). https://doi.org/10.1134/S1063784221020171

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063784221020171