Abstract

The results of the formation of an original material based on thin films of metal nanoclusters and the investigation of its chemical composition, surface morphology, and structure are presented. Monodisperse thin films comprised of individual nanoclusters of Ta, Mo, and Ni metals were manufactured by gas-phase magnetron sputtering. Images of the surface were obtained by scanning electron microscopy and it was shown that the Ta and Mo films had a well-developed porous structure and consisted of separate nanoclusters contacting each other only at the interface. The chemical composition of the resulting films immediately after deposition (in situ) and after exposure to the atmosphere (ex situ) was investigated by X-ray photoelectron spectroscopy. It was shown that the exposure to the atmosphere led to the oxidation of the obtained films, namely, to the formation of oxide shells in nanoclusters that formed the films. The possibility of creating thin-film photodetectors based on nanocluster films to detect the decay of isomeric nuclear transition in 229Th nuclei is discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The creation of photosensitive elements capable of detecting single photons is currently arousing interest as these devices are applied in various fields of science starting from laser ranging to biophotonics, from time-resolved Raman spectroscopy to the study of quantum effects [1]. One of the potential applications of such single-photon detectors is the detection of the decay of the excited low-lying isomeric state in the 229Th nucleus [2]. Having an anomalously low energy in the range 7.8 ± 0.5 eV, it is of interest from the point of view of both fundamental scientific research and the development of new instruments and devices the implementation of which can influence the scientific and technological progress of mankind. The two most significant applications are the creation of a fundamentally novel nuclear time and frequency standard and the development of a laser on the nuclear optical range transition, i.e., a gamma-ray laser. The main difficulty is that the value of the isomeric transition energy was obtained by indirect measurements while the direct detection of the transition involves serious difficulties and has not been achieved successfully so far. This is accounted for by the radioactivity of the 229Th isotope. It is absent in nature and it can be produced only in nuclear reactions. The narrowness of its spectral line and a weak strength of the transition oscillator, which makes searching for an accurate transition energy value by scanning the 7.8 ± 0.5 eV range, not very promising. To solve the problem, various mechanisms for excitation of nuclear isomeric transition have been proposed and various physical systems containing the 229Th isotope have been used. One of the approaches that allows excitation in a broad-band mode and the detection of the isomeric state in 229Th nuclei is the method based on the impact of an electron beam on thorium-containing targets. However, due to numerous factors such as the radioactivity of 229Th, a small excitation cross section of isomeric 229Th nuclei under electron impact (~10–33 cm2), the position of the energy of the photons resulting from the decay of the isomeric state within the vacuum ultraviolet radiation range (~180 nm), and a relatively long predicted lifetime of the excited state (~\(1.8 \times {{10}^{3}}\) s [3]), a necessity arises of enhancing the effectiveness of detecting photons resulting from the decay of the excited isomeric state in the 229Th nucleus up to the formation in an ideal case of the single-photon detector directly on a thorium-containing sample.

In this study, we propose exploring the possibility of the formation under electron-beam irradiation of thin-film materials with a thickness below the characteristic electron absorption depth comprised of metal nanoclusters surrounded by an oxide shell to create an avalanche photodiode on their base. The presence of a metal nucleus ensures in this case effective absorption of photons with different energies including the vacuum ultraviolet region of interest while the presence of the oxide shell and the general porous structure of nanoclusters ensure a nonzero forbidden bandwidth of the material. When a potential difference applied to the opposite edges of the formed film to ensure a field strength of ~105 V/cm, the energy bands in the film are distorted and the photoelectron generated in the film under the action of the field in question, being accelerated, will produce secondary electrons, which will result in the formation of an avalanche current in the nanocluster film [4].

The aim of this study is the formation of an novel material based on thin films of metal nanoclusters, the investigation of its chemical composition, surface morphology and structure, and the exploration of the possibility of producing films comprised of metal nanoclusters surrounded by an oxide shell to be used as UV-band photosensitive materials to detect the radiation caused by the decay of the excited low-lying state in 229Th nuclei.

EXPERIMENTAL

The thin-film samples comprised of Ta, Mo, and Ni metal nanoclusters on the surface of SiO2/Si(001) silicon oxide with a thickness of 1 μm were produced by gas-phase cluster deposition using a Nanogen-50 cluster source with a MesoQ quadrupole mass filter by Mantis Deposition Ltd., UK, integrated into the preparation chamber of an Multiprobe MXPS VT AFM-25 ultra-high vacuum surface analyzer by Omicron NanoTechnology GmbH, Germany. The choice of nanocluster materials was determined by the necessity of using refractory metals to achieve effects related to the decreasing melting temperature of the nanoclusters with decreasing sizes of the latter [5]. Furthermore, oxides of the above materials have a forbidden bandwidth within the range 3.9–4.5 eV [6–8], which is lower than the expected energy of the photon resulting from the decay of the isomeric state in the 229Th nucleus. The nanoclusters were produced by magnetron sputtering of Ni and Co targets with a purity of 99.99% and Ta and Mo targets with a purity of 99.95% in an inert gas flow, viz., Ar within the range 15–60 st. cm2 and He within 5–80 st. cm2 with purity of the buffer gases of at least 99.995% at a pressure of 10–3–10–4 mbar. During the cooling of the target atoms as they passed through the aggregation region, the metallic phase nucleated followed by the growth of nucleation sites. The nucleation process in the source led to the formation of nanoclusters predominantly with a single negative charge. The MesoQ quadrupole mass filter placed at the aggregation region outlet allowed for the analysis of the sizes and mass-filtering of negatively charged clusters in the real-time mode. The sizes of nanoclusters produced in the source can range from 1 to 10 nm. In the filtering mode, the mass spectrometer allows producing a bunch of nanoclusters with a very narrow size distribution with a spread of about 2%. This allowed production of monodisperse nanocluster films comprised of nanoclusters of required sizes formed of the target material. A voltage of +800 V was applied to the SiO2/Si(001) substrate to increase the adhesion of nanoclusters to the substrate surface. The voltage of such a magnitude ensured a “mild” deposition mode, which allowed the deposition of a film that consisted of individual undeformed nanoclusters. As a result, samples of monodisperse Ta, Mo, and Ni films containing nanoclusters of typical sizes in the range 8 ± 1 nm were obtained. In the course of deposition, the substrate temperature remained at room temperature. The nanocluster deposition time up to the complete covering of the substrate, which the criterion is the absence of lines that correspond to the substrate in the spectra obtained by X-ray photoelectron spectroscopy (XPS), can be roughly found from the following reasoning. From knowing the diameter of nanocluster d, which is adjusted by the mass filter, the size of the deposition spot (S ~ 3 × 3 mm2), the depth of the XPS analysis (λ ~ 2–3 nm [9]), and the value of the cluster current at mass filter outlet Icl, the time required for the complete covering of the substrate by nanoclusters td has the form:

where e is the absolute electron charge value. The chemical composition and electronic structure of the formed nanocluster films deposited onto the SiO2/Si(001) surface were measured in situ immediately upon deposition by XPS in the analyzing chamber of the UHV Multiprobe MXPS VT AFM-25 system (p ~ 2 × 10–10 mbar). To excite the photoelectrons, an MgKα1,2 X-ray source was used with energy \(h{v} = 1253.6\) eV. The spectrometer was calibrated by the positions of XPS lines of bulk gold Au4f7/2 with a binding energy of 84.00 eV. The surface concentration of the chemical elements was calculated by the well-known method [10] as follows:

where \({{I}_{i}}\) is the intensity of the base XPS spectrum line of the ith element and \({{q}_{i}}\) is the sensitivity factor (\({{q}_{{O1s}}} = 2.93\), \({{q}_{{Ni2p3/2}}} = 14.61\), \({{q}_{{Mo3d5/2}}} = 5.62\), \({{q}_{{Co2p3/2}}} = 12.62\), \({{q}_{{C1s}}} = 1\), and \({{q}_{{Ta4f}}} = 8.62\) [11]). To investigate the influence of the oxidation of the nanocluster film samples on their electronic properties, all samples were exposed to the atmosphere for 10 min at a humidity of 50% at most.

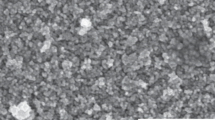

The morphology of nanocluster samples was studied by scanning electron microscopy (for samples with a nanocluster size of 8 nm, this restriction was imposed due to the resolution of the scanning electron microscope used). In the experiments, a JSM 7001F scanning electron microscope by Jeol, Japan, was used.

RESULTS AND DISCUSSION

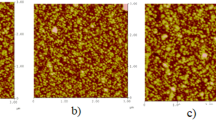

Characteristic images of the surface of the produced Ta, Mo, and Ni nanocluster films, with a size of sputtered nanoclusters of 8 nm, obtained by scanning electron microscopy, are shown in Fig. 1. It can be seen from Fig. 1 that the nanocluster films have a highly porous structure and are comprised of individual nanoclusters that contact each other only at the interface. According to the figure, Ta and Mo nanoclusters have a spherical shape and are densely packed while Ni nanoclusters probably coagulate during the deposition since the structure cannot be clearly distinguished in the SEM images. The characteristic sizes of nanoclusters in Ta and Mo films are estimated at 10–14 nm, which exceeds the size of the nanoclusters produced by sputtering. This fact can be accounted for by an increase in the size of nanoclusters exposed to the atmosphere and oxidized and by the minimum resolution of the SEM used in the study being restricted to 2 nm and, as a consequence, by the edge effects on the resulting images.

Typical in situ XPS spectra of the Ta, Mo, and Ni nanocluster film samples deposited onto the SiO2/Si surface are shown in Fig. 2. As can be seen from Fig. 2, in the spectrum there are no lines that correspond to the substrate; consequently, we can suggest that the substrate is covered completely. Analysis shows that during deposition, chemically pure metal films are produced with a small content (below 5%) of impurities such as C and O.

Typical XPS spectra of the core lines of Ta, Mo, and Ni nanocluster films prior to and after the exposure to the atmosphere are shown in Fig. 3. It can be seen from the figure that prior to the exposure to the atmosphere, the XPS spectrum contains only the core lines that correspond to the metallic phase, while upon oxidation, the lines that correspond to the oxide phase appear in the spectrum. Analysis of the obtained XPS spectra suggests that no complete oxidation of the nanocluster film occurs since in the XPS spectra the peaks that correspond to the metal phase remain visible (see Fig. 3). To analyze the oxidation mechanism, angle- resolution XPS spectra were measured. An example of such spectra for Ta is shown in Fig. 4. One can see that the XPS spectra do not change their shape with the changing position angle of the sample (25° and 75°). Consequently, it can be suggested that, when the produced samples are oxidized, nanoclusters that comprise the former are oxidized from the surface forming an oxide shell, the so-called “core—shell” nanoclusters [12]. The thickness of the oxide layer was estimated by the ratio between the peaks of the metal and oxide phases. For the nanocluster film samples under investigation, the thickness of clusters 8 nm in diameter was about 2 nm. Consequently, it can be suggested that during gas-phase magnetron deposition, porous Ta and Mo films can be produced that consist of individual nanoclusters ~8 nm in diameter, the oxidation of which in air results in the formation of an oxide shell ~2 nm thick on the nanoclusters that constitute films, which can be used in the future to manufacture thin-film photodetectors based on nanocluster metal films.

CONCLUSIONS

In this study, the results of the formation of monodisperse thin films comprised of Ta, Mo, and Ni metal nanoclusters produced by gas-phase magnetron sputtering onto SiO2/Si(001) surfaces and the investigation of their electronic properties are presented. It is shown that the Ta and Mo nanocluster films represent porous structures comprised of individual nanoclusters contacting each other at the interface. Ni nanocluster films do not exhibit such a structure, which is probably a result of the coagulation of Ni nanoparticles on the substrate surface. Consequently, the use of Ta and Mo films for constructing an avalanche photodetector based on thin nanocluster films is acceptable within the proposed model. Analysis of XPS spectra of the samples obtained has shown that sputtering yields chemically pure films. It has been shown that, being exposed to the atmosphere, the obtained nanocluster films are oxidized forming an oxide shell around the metal nucleus of the nanocluster. The further research will be aimed at investigating the electronic properties of the obtained nanocluster films, in particular, the forbidden bandwidth.

REFERENCES

M.-J. Lee and E. Charbon, Jpn. J. Appl. Phys. 57, 1002A3 (2018).

P. V. Borisyuk et al., Eur. J. Mass Spectrom. 23, 146 (2017).

P. V. Borisyuk et al., arXiv:1804.00299 (2018).

K. N. Kwok, Complete Guide to Semiconductor Devices (Wiley-International, New York, 2002).

F. Ruffino et al., Nanoscale Res. Lett 3, 454 (2008).

K. Kukli et al., Thin Solid Films 260, 135 (1995).

X. Liu et al., J. Alloys Compd. 509, 408 (2011).

A. Krier et al., Phys. Status Solidi Appl. Mater. Sci. 205, 129 (2008).

D. Gall, J. Appl. Phys. 119, 085101 (2016).

D. Briggs and J. Grant, Surface Analysis by Auger and X-Ray Photoelectron Spectroscopy (IM Publ., Chichester, 2003).

J. Scofield, J. Electron Spectrosc. Relat. Phenom. 8, 129 (1976).

S. D’Addato and M. C. Spadaro, Phys. Scr. 93, 033001 (2018).

Funding

This study was supported by the Russian Science Foundation, project no. 18-79-00257.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by O. Lotova

Rights and permissions

About this article

Cite this article

Vasilyev, O.S., Borisyuk, P.V. & Lebedinskii, Y.Y. Formation of Thin-Film Nanoparticle Materials for Single-Photon Avalanche Detectors. Phys. Atom. Nuclei 83, 1484–1488 (2020). https://doi.org/10.1134/S1063778820090288

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063778820090288