Abstract

The excessive use of glufosinate˗ammonium herbicide and carbofuran insecticide in agriculture leaves residues on agricultural samples and contaminates groundwater and surface water bodies through surface runoff and through leaching. To monitor pollution from the use of these pesticides, two simple, accurate and precise optical methods for their determination have been developed and validated in the commercial formulation and agricultural samples, viz., water, grains and vegetables. The first method is based on the reaction of the amino function of both pesticides with carbon disulfide and Ni(II) acetate in an aqueous acetonitrile medium and the measurement of color developed at 380 and 365 nm for glufosinate˗ammonium and carbofuran, respectively. Beer’s law was valid within a concentration range of 0.4–8 and 0.4–9 µg/mL for glufosinate˗ammonium and carbofuran, respectively. The second spectrofluorimetric method is based on the condensation of the primary amino group of glufosinate˗ammonium and carbofuran with acetylacetone and formaldehyde (Hantzsch reaction) in the presence of buffer of pH 5.5 producing a yellow˗colored product. The fluorescence intensity of the reaction products was measured at an emission wavelength of 470 nm after excitation at a wavelength of 380 nm for glufosinate-ammonium and 388 nm for carbofuran. The linearity range found was 0.13–5 and 0.14–6 µg/ mL for glufosinate˗ammonium and carbofuran respectively. All the variables affecting the reactions, such as hydrolysis time, heating time, pH, concentration and volume of reagent were carefully studied and optimized. The high recoveries of glufosinate-ammonium and carbofuran from spiked water, grain and vegetable samples in both methods indicate good accuracy and precision of the methods.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Carbamate and organophosphorus pesticides (OP) constitute a large class of synthetic compounds that have become increasingly important due to their broad-spectrum activity and extensive use. These compounds are used to increase agricultural productivity, as therapeutic agents to protect public health from insect-borne diseases, and as insecticides to protect agricultural, residential and non-residential areas [1]. Despite their enormous benefits, these chemicals are extremely toxic, and their extensive use poses a serious threat to the environment and leads to adverse effects on human health as well as on non-target species [1–3]. Among OP and carbamate pesticides, glufosinate-ammonium and carbofuran are widely used pesticides due to their broad applications.

Glufosinate˗ammonium, ammonium-2-amino-4-(hydroxymethylphosphinyl) butanoate (Scheme 1), is a broad-spectrum, non-selective, contact organophosphate herbicide [4, 5]. It is used globally to control a wide range of weeds and to desiccate crops before harvesting [4, 5]. Besides its wide applications, its acute exposure can cause toxicities of the central nervous system and respiratory system [6]. Glufosinate˗ammonium is highly soluble in water (>500 g/L at pH 5–9, 20°C) [7] and hence can permeate the soil surface through leaching, which leads to contamination of water bodies, and its vast consumption leaves its residues on agricultural products [8].

Carbofuran, 2, 3-dihydro-2, 2-dimethyl-7-benzofuranyl methyl-carbamate (Scheme 1), is a broad-spectrum and systemic insecticide belonging to the carbamate family [9, 10]. It is used worldwide for the control of leaf-eating and soil-dwelling insects in agriculture and for domestic and industrial purposes [9–11]. Besides its enormous applications, carbofuran is toxic and causes negative effects on human health and also poses threat to non-target species [9–13]. It is also classified as a “Toxicity Category-I” compound via inhalation and oral exposure routes, by Environmental Protection Agency (EPA) [11].

Scheme 1 . Chemical structures of glufosinate˗ammonium (I) and carbofuran (II).

Being water-soluble (solubility of 351 mg/L at 25°C), it finds its way into water sources and leads to contamination [14] of groundwater resources and raises health concerns due to its toxic effects.

Therefore, there is a need for the judicious use of these pesticides to restrict their concentration in soil, water and agricultural samples. This necessitates the development and validation of simple, reliable and rapid methods of wide applicability for the determination of glufosinate˗ammonium herbicide and carbofuran insecticide to monitor their pollution and health hazards.

Several analytical approaches to glufosinate˗ammonium and carbofuran detection have been developed, based on chromatography [4, 5, 15–18], voltammetry [19, 20], chemiluminescence [21], sensor [22], fluorescence [23–25] and spectrophotometry [26–30].

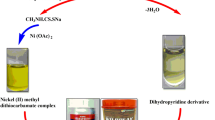

Most of these analytical methods are of high precision and accuracy, but the high cost of instruments and the requirement of skilled technicians limit their wide application. Therefore, in laboratories of limited means, methods based on spectrophotometry and spectrofluorimetry become the techniques of choice due to their low cost and less time of analysis. In case of carbofuran, most of the spectrophotometric methods reported in literature are complex due to requirement of colored reagents and chemical derivatization [26–30], and very less work is reported by spectrofluorimetric methods [23–25]. However, in case of glufosinate˗ammonium, no optical methods have been reported for its determination to the best of our knowledge. Therefore, there is a demand for a cost-effective, simple and accurate analytical method for their detection. In view to fulfill the above objective, two new, simple and sensitive spectrophotometric and spectrofluorimetric methods have been developed for the determination of glufosinate˗ammonium and carbofuran in the environmental samples. In the proposed spectrophotometric analysis, the advantage of the colored complex formed due to the formation of Ni(II) dithiocarbamate complex has been taken. The colored complex was formed by the reaction of the amino function of glufosinate˗ammonium and carbofuran with CS2 and Ni(II) acetate in an aqueous acetonitrile medium, and its measurement at 380 and 365 nm for glufosinate˗ammonium and carbofuran, respectively, has been the basis of spectrophotometric analysis. The proposed spectrophotometric method offers high sensitivity and involves a non˗extraction procedure. The spectrofluorimetric method involves the measurement of fluorescence intensity of a colored product at 470 nm for both the pesticides. The colored product formed is due to condensation of the primary amino group of glufosinate˗ammonium and carbofuran with acetylacetone and formaldehyde in the presence of buffer of pH 5.5. The main advantages of the proposed methods are their simplicity, rapidity, cost˗effectiveness and a non˗extraction procedure. The methods have been successfully validated for the determination of glufosinate˗ammonium and carbofuran in commercial formulations to ensure the quality of the marketed samples of the pesticides and were also successfully applied on spiked water samples and agricultural products to get reliable residue data.

EXPERIMENTAL

Apparatus. A Perkin Elmer LS 55 fluorescence spectrometer (Perkin Elmer, United Kingdom) with 1 cm matched quartz cells was used for fluorescence intensity measurements. All spectral measurements were processed by FL-WinLab software. The spectrophotometric measurements were made on a Carry 100 Bio UV-Vis spectrophotometer (Varian Australia, Mulgrave-Victoria, Australia). A domestic microwave oven, (Samsung electronics, New Delhi, India) was used to carry out hydrolysis. The pH measurements were made on a Cyber Scam 2500 pH meter (Eutech instruments, Singapore). A Lab pro 113 15 L water bath was used for heating.

Reagents and samples. The analytical standards of glufosinate˗ammonium, 95% and carbofuran, 98% procured from Sigma-Aldrich, Bangalore were used. Nickel(II) acetate (Central Drug House, Delhi, India, LR) was used to was used to prepare, its 0.001 M solution in distilled water. Acetonitrile (Merck, Mumbai, India), carbon disulfide (AR grade, Merck, India), sodium bicarbonate (Merck, LR), sodium sulfate anhydrous (Merck, Mumbai, India, AR), sodium chloride (Merck, Mumbai, India, AR), acetylacetone (LR, Laboratory Rasayan), glacial acetic acid (Merck, GR) and formaldehyde (AR, HIMEDIA) were used as supplied. Glacial acetic acid (Merck, GR) with the concentration of ~1 M, was prepared in distilled water. Sodium hydroxide (Merck, AR), 1 N solution, was used. A buffer of pH ~ 5.5 (50 mL of 1 M sodium hydroxide was mixed with 57.4 mL of, 1 M acetic acid and diluted to 500 mL with distilled water) was used [31]. The pH of the above buffer was checked and adjusted by a pH meter before use. A reagent solution for spectrofluorimetric analysis was prepared daily by mixing 0.8 mL of acetylacetone and 2 mL of formaldehyde in 27.2 mL of distilled water. A herbicide formulation “Basta” containing 13.5% glufosinate-ammonium and a formulation of carbofuran “Furadan” containing a 3% active ingredient were procured from the local market.

Preparation of calibration graph for pure compound by spectrophotometric method. Aliquots (0.1–2 mL) of a standard solution of glufosinate-ammonium (0.2 mM in distilled water) and 0.1–2 mL of the standard solution of carbofuran (0.2 mM in acetonitrile) were taken separately in 10 mL measuring flasks, and the volume was made to 2 mL with distilled water and acetonitrile for glufosinate˗ammonium and carbofuran, respectively. Each solution was mixed with 1.0 mL of CS2 (10% in acetonitrile followed by 1.0 mL of aqueous sodium bicarbonate (1 M), and then the volume was made to 5 mL with distilled water in glufosinate˗ammonium and with acetonitrile in carbofuran and kept in a microwave oven for 60 s (1000 W). Then, the solution was treated with 1 drop of acetic acid and 1 mL of 0.001 M nickel (II) acetate solution, and the total volume was made to 10.0 mL with distilled water for glufosinate˗ammonium and with acetonitrile for carbofuran. The absorbance of yellow˗colored solution was measured at 380 and 365 nm for glufosinate˗ammonium and carbofuran, respectively, against a reagent blank (Fig. 1). The calibration curve was prepared by plotting absorbance values against concentration of the pesticides. The calibration characteristics are given in Table 1.

Preparation of calibration graph for pure compound by spectrofluorimetric method. Aliquots (0.1–4 mL) of a standard solution of glufosinate-ammonium (0.1 mM in distilled water) and 0.1–4 mL of a standard solution of carbofuran (0.1 mM in acetonitrile) were taken separately in 25 mL measuring flasks, and the volume was made to 4 mL with distilled water for glufosinate˗ammonium and with acetonitrile for carbofuran. Each solution was mixed with aqueous sodium hydroxide (1 mL, ~0.2 M) and kept in a microwave oven for 90 s. Then, the solution was mixed with 3 mL of the buffer of pH ~5.5 followed by the addition of 5 mL of reagent solution (0.8 mL of acetylacetone and 2 mL of formaldehyde in 27.2 mL of distilled water). The mixture was heated in a water bath for 45 min, and the final volume of the colored solution was made to 15 mL with distilled water for glufosinate˗ammonium and with acetonitrile for carbofuran. The emission intensity of the solution was measured at 470 nm with an excitation at 380 and 388 nm for glufosinate˗ammonium and carbofuran, respectively. The typical excitation˗emission spectrum observed is shown in Fig. 2. The calibration curves were prepared by plotting fluorescence intensity values against the concentration of the pesticides, and the calibration characteristics are given in Table 2.

Formulation analysis. A formulation “Basta” containing 13.5% active ingredient of glufosinate˗ammonium and a formulation of carbofuran “Furadan” containing 3% active ingredient procured from an authorized pesticide dealer were used. A single large sample of glufosinate˗ammonium formulation equivalent to 10 mg of the active ingredient was dissolved and shaken with 10 mL of distilled water and filtered. The residue was washed 2–3 times with distilled water, and the filtrate and washings were diluted to a known volume of 25 mL with distilled water. 2.5 mL of this solution was taken and further diluted to 100 mL. A similar procedure was followed for carbofuran formulation by taking acetonitrile as a solvent. Suitable aliquots of the above solution were taken for analysis and processed in the same manner as described for pure compounds. The assay results are given in Table 3.

Determination of glufosinate˗ammonium and carbofuran in grains, vegetable and water samples. Suitable aliquots of a standard solution of glufosinate˗ammonium and carbofuran having a concentration of 10 μg/mL were added separately to a known weight (5 g) of grains (wheat and rice), vegetables (carrot, potato and cauliflower) and water sample (25 mL). The samples (grains and water) were well mixed and extracted with 2–3 portions of chloroform (5 mL). The combined extracts were shaken for 5 min and filtered. In the case of vegetables after thorough mixing, each sample was blended with 50 mL of chloroform in the same containers according to the general procedure of Schenk et al. [32]. The samples were filtered through coarse filter paper (Whatman Grade no. 4), and each filtrate was transferred into 250 mL separating funnels. Sodium chloride (5 g) was added to each sample, the contents were shaken for one minute, and the phases were allowed to separate for 15 min. The lower aqueous phase and any emulsion were discarded. Anhydrous sodium sulphate (4 g) was added, and the funnel was shaken for 30 s. The dried extract was filtered through coarse filter paper. The solvent from the filtrate (grains, vegetables and water) was removed by heating at 40°C in a water bath. The residue was dissolved in distilled water in glufosinate˗ammonium and in acetonitrile for carbofuran and processed for analysis as above by spectrophotometric and spectrofluorimetric methods. The amounts of glufosinate˗ammonium herbicide and carbofuran insecticide were calculated based on calibration graphs, and the results of recovery experiments are presented in Tables 4–7.

Interference studies. Various aliquots of diverse ions, amines (5 mM) and pesticides solution (0.5 mM) were added to the standard solution containing 5 μg of glufosinate˗ammonium and carbofuran separately prior to hydrolysis. Each solution was processed for analysis in the same manner as described for both pesticides by spectrophotometric and spectrofluorimetric methods.

RESULTS AND DISCUSSION

Standardization of the reaction conditions for the spectrophotometric method. The proposed method has been studied under the optimized experimental conditions to achieve maximum absorbance and stability of colored complex before its application to the determination of glufosinate˗ammonium and carbofuran in commercial formulation, grains, vegetables and water.

Effect of time of hydrolysis. To achieve the maximum color intensity, the hydrolysis time in the microwave was varied from 10 to100 s. A hydrolysis time of 60 s gave the maximum color intensity and stability of the complex formed (Fig. 3). Hydrolysis time of less than 60 s gives less intensity of the color, indicating non-completion of the reaction.

Effect of solvent. The effect of different diluting solvents such as water, ethanol, methanol, acetonitrile and acetone was studied. The maximum stability of the complex was observed to be obtained by taking water as a solvent for glufosinate˗ammonium herbicide, and acetonitrile as a solvent for carbofuran insecticide.

Effect of carbon disulfide variation. The effect of different CS2 concentrations has been studied, and it has been found that with an increase in the concentration of CS2 the color intensity increases. When the concentration is increased beyond 10%, the solution becomes turbid (Fig. 4).

Quantification. Under the optimized experimental conditions, the proposed spectrophotometric method obeys Beer’s law in the range of 0.4–8 and 0.4–9 µg/mL for glufosinate˗ammonium and carbofuran, respectively. The complex formed is stable for 3 h for both the pesticides. The method is quite sensitive with molar absorptivity (ε) and Sandell’s sensitivity values of 10.53 × 103 L/(mol cm) and 0.0188 µg/cm2 for glufosinate˗ammonium at 380 nm and 8.83 × 103 L/(mol cm) and 0.0250 µg/cm2 for carbofuran at 365 nm. The limit of detection (LOD) and limit of quantification (LOQ) are 0.4 and 1.4 µg/mL for glufosinate˗ammonium and 0.6 and 1.8 µg/mL for carbofuran.

To find the validity of the above method, it has subsequently been applied to the determination of glufosinate˗ammonium herbicide and carbofuran insecticide in commercial formulation, grains, vegetables and spiked water samples. The recoveries of glufosinate˗ammonium herbicide from commercial formulation were 98.0–99.0% of the nominal content with relative standard deviations (RSDs) in the range of 0.4–0.8 and 96.8–98.1% with relative standard deviations in the range of 0.7–1.7% for carbofuran (Table 3). The recoveries of glufosinate˗ammonium herbicide from grains, vegetables and spiked water samples were good, ranging from 89.4 to 96.7% with RSDs in the range of 0.5–1.5 and 89.0–94.8% for carbofuran with RSDs of 0.7–1.7%. The recoveries of glufosinate˗ammonium and carbofuran from vegetable and water samples are given in Tables 4 and 5.

Proposed mechanism for the spectrophotometric method for glufosinate-ammonium and carbofuran. The proposed spectrophotometric method is based on the color reaction of the amino function of glufosinate˗ammonium and carbofuran with carbon disulfide to form corresponding dithiocarbamate which reacts with nickel(II) acetate in an aqueous medium to form yellow˗colored nickel dithiocarbamate [Ni(DTC)2] complex (Scheme 2). The colored complex is measured under optimized conditions at 380 and 365 nm for glufosinate˗ammonium and carbofuran, respectively (Fig. 1). That amino function of glufosinate˗ammonium and methyl amine formed from the alkaline hydrolysis of carbofuran [28] reacts smoothly and quantitatively with carbon disulfide and nickel-(II) acetate (in a 2 : 1 molar ratio) forming metallic complex nickel(II) dithiocarbamate, [Ni(DTC)2] is quite well known and thoroughly established in our laboratory [33, 34]. The reaction proceeding in a 2 : 1 molar ratio has also been established by photometric titration of glufosinate˗ammonium and carbofuran with nickel(II) acetate in aqueous acetonitrile medium. In this titration performed at 380 and 365 nm for glufosinate˗ammonium and carbofuran (λmax of colored complex, Fig. 1), the absorbance increases till glufosinate-ammonium and carbofuran to nickel(II) molar ratio of 2 : 1 is achieved indicating the formation of yellow˗colored complex, and thereafter it attains almost constant values indicating no more formation of the colored complex (Fig. 5).

Scheme 2 . Proposed mechanism for the spectrophotometric method.

Interference studies. To assess the validity of the proposed spectrophotometric method, the effect of various amines, common ions and pesticides was studied. Known aliquots of diverse ions, amines (5 mM) and various pesticides (0.5 mM) were added to the standard solution containing 5 μg of glufosinate˗ammonium and carbofuran separately and were analyzed by the proposed method. The method was found to be free from interferences due to added organic nitrogen compounds including tertiary amines, aromatic amines, pesticides and common ions. These compounds did not affect the accuracy of the determination of the above pesticides. The proposed method can also be applied for the determination of primary and secondary amines in other systems and, hence, their interference in absorbance is possible. The tolerance limit of added foreign species is given in Table 8.

Comparison of the proposed spectrophotometric method with other reported methods. The parameters obtained from the proposed spectrophotometric method have been compared with other reported spectrophotometric methods, and details are given in Table 9. The current method is more sensitive than the reported methods in terms of its simplicity, rapidity and the instantaneous development of the color with nickel (II) acetate reagent.

Standardization of the reaction conditions for the spectrofluorimetric method. The proposed spectrofluorimetric method was standardized under optimized experimental conditions of heating time, hydrolysis time, pH, solvents and reagent concentration.

Effect of heating time. The optimum time required for the complete reaction was calculated by varying heating time from 20 to 60 min at 55°C. The results indicate that maximum fluorescence intensity was obtained corresponding to 45 min of heating (Fig. 6). Heating time less than 45 min gives less fluorescence intensity of the complex thus indicating non-completion of reaction, and after 45 min the fluorescence intensity slightly decreases.

Effect of time of hydrolysis. The optimum time required for complete hydrolysis (in the microwave) of carbofuran to methylamine was obtained by varying the time of hydrolysis from 30 to 140 s. The results indicate that maximum fluorescence intensity was obtained corresponding to hydrolysis time of 90 s (Fig. 7).

Effect of pH. The effect of pH on the sensitivity and stability of the complex was determined by varying pH from 3.8 to 6.3. Different acetic˗acetate buffers were prepared by mixing certain volumes of 1 N acetic acid and 1 N sodium hydroxide and diluting the mixture with distilled water [31]. It was observed that maximum yellow color and sensitivity were achieved by a buffer of pH ~5.5 (Fig. 8).

Effect of diluting solvents. The effect of different diluting solvents as water, ethanol, acetonitrile, dimethyl formamide, dimethyl sulfoxide and acetone on the stability of colored product was studied. Acetonitrile is the solvent of choice for carbofuran and water for glufosinate-ammonium, as they clear and stabilize the colored product quantitatively.

Effect of reagent concentration. Different volumes of mixture of acetylacetone and formaldehyde solutions were investigated for maximum fluorescence intensity. The maximum fluorescence intensities were observed upon using 5 mL of reagent solution (prepared by mixing 0.8 mL of acetylacetone and 2 mL of formaldehyde in 27.2 mL of distilled water).

Quantification. The proposed spectrofluorimetric method obeys the linearity range of 0.13–5 and 0.14–6 µg/ mL for glufosinate˗ammonium and carbofuran, respectively, under the standardized experimental conditions. The complex formed is stable for 5 h for both the pesticides. The limit of detection and limit of quantification for glufosinate˗ammonium are 0.18 and 0.6, and 0.4 and 1.1 µg/mL for carbofuran. The method has been subsequently applied to the determination of glufosinate˗ammonium herbicide and carbofuran insecticide in commercial formulations, vegetables and spiked water samples. The recoveries from the commercial formulation were 97.0–98.7% of the nominal content with RSDs in the range of 0.4–1.0 and 97.0–98.6% with RSDs in the range of 0.6–1.5% for carbofuran (Table 3). The high recoveries of glufosinate˗ammonium and carbofuran from spiked water, grain and vegetable samples in the range of 90.0–98.6% with RSDs of 0.3–1.8% for glufosinate˗ammonium and 89.0–94.1% with RSD’s of 0.7–1.8% for carbofuran indicate good accuracy and precision of the method (Tables 6 and 7).

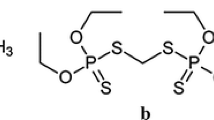

Proposed mechanism for the spectrofluorimetric method. The proposed spectrofluorimetric method is based on Hantzsch reaction which is a known condensation reaction for the synthesis of dihydropyridine and pyridine [35, 36]. Therefore, the advantage of Hantzsch condensation reaction has been utilized using acetylacetone as β-diketone and formaldehyde as an aldehyde which forms a colored condensation product (Scheme 3) with the primary amino function of glufosinate˗ammonium and methyl amine of carbofuran. The reaction product dihydropyridine derivative formed exhibited strong fluorescence at λemission of 470 nm after excitation at λexcitation of 380 nm for glufosinate˗ammonium and at λexcitation of 388 nm for carbofuran (Fig. 2).

Scheme 3 . Proposed mechanism for the spectrofluorimetric method for glufosinate˗ammonium and carbofuran.

Interference studies. To assess the validity of the proposed spectrofluorimetric method, effect of various amines and pesticides was studied. Known aliquots of the diverse foreign species amines (5 mM) and pesticides (0.5 mM) were added to the standard solution containing 5 μg of glufosinate˗ammonium and carbofuran separately and were analyzed by the proposed method. The method was found to be free from interferences due to various organic nitrogen compounds including secondary and tertiary amines. It was found that these compounds did not affect the accuracy of the determination of the above pesticides indicating that the method is selective for the determination of compounds containing the primary amino group. The method can also be applied for the determination of primary amino group in other systems. The tolerance limit of these added foreign species is given in Table 10.

Comparison of the proposed spectrofluorimetric method with other reported methods. A comparison of some parameters obtained from the proposed spectrofluorimetric method for the determination of glufosinate-ammonium and carbofuran with some reported spectrofluorimetric methods has been done and described in Table 11. The proposed spectrofluorimetric method has superior sensitivity to other reported methods with the use of low-cost reagents. The spectrofluorimetric method is more sensitive than spectrophotometric analysis so can be applied at a lower concentration range.

CONCLUSIONS

The proposed spectrophotometric and spectrofluorimetric methods are simple, sensitive, reliable and economical, allowing the determination of glufosinate-ammonium herbicide and carbofuran insecticide in bulk as well as in commercial formulations without any interference from inert carriers commonly present in their formulations. The instantaneous development of color, stability of the colored products, with the omission of an extraction step are some added advantages of the proposed methods. The high recoveries of glufosinate˗ammonium herbicide and carbofuran insecticide in formulation and residue analysis, with low relative standard deviation values show good accuracy and precision of the methods.

REFERENCES

Gupta, R.C., Malik J.K., and Milatovic, D., in Reproductive and Developmental Toxicology, Gupta, R.C., Ed., Amsterdam: Elsevier, 2011, p. 471. https://doi.org/10.1016/B978-0-12-382032-7.10037-2

Omwenga, I., Kanja, L., Zomer, P., Louisse, J., Rietjens, I., and Mol, H., Food Addit. Contam., Part B, 2020, vol. 14, p. 48. https://doi.org/10.1080/19393210.2020.1861661

Vale, A. and Lotti, M., in Occupational Neurology, Lotti, M. and Bleecker, M.L., Eds., Handbook of Clinical Neurology, vol. 131, Amsterdam: Elsevier, 2015, p. 149.

Halim, N. and Kuntom, A., J. Oil Palm Res., 2013, vol. 25, p. 84.

Wang, Y., Gao, W., Li, Y., Xiao, Y., Song, W., Yao, T., Cheng, M., Wang, W., and Hou, R., J. Agric. Food Chem., 2021, vol. 69, p. 7969. https://doi.org/10.1021/acs.jafc.1c01757

Hsiao, J.T., Pan, H.Y., Kung, C.T., Cheng, F.J., and Chuang, P.C., Am. J. Emerg. Med., 2021, vol. 50, p. 232. https://doi.org/10.1016/j.ajem.2021.08.017

Zhang, Y., Wang, K., Wu, J., and Zhang H., Int. J. Anal. Chem., 2014, vol. 2014, p. 256091. https://doi.org/10.1155/2014/256091

Nguyen, M.H., Nguyen, T.D., Vu, M.T., Duong, H.A., and Pham, H.V., J. Anal. Methods Chem., 2022, vol. 2022, p. 5687025. https://doi.org/10.1155/2022/5687025

Mariyappan, V., Murugan, K., and Shen-Ming, C., J. Agric. Food Chem., 2021, vol. 69, p. 2679. https://doi.org/10.1021/acs.jafc.0c07522

Khan, A., Zaman, T., Fahad, T. M., Akhter, T., Hasan, M.F., Naz, T., and Kishi, S., J. Cell. Mol. Med., 2022, vol. 26, p. 35. https://doi.org/10.1111/jcmm.16774

Saquib, Q., Siddiqui, M.A., Ansari, S.M., Alwathnani, H.A., and Al-Khedhairy, A.A., J. Appl. Toxicol., 2021, vol. 41, p. 847. https://doi.org/10.1002/jat.4150

Mishra, S., Zhang, W., Lin, Z., Pang, S., Huang, Y., Bhatt, P., and Chen, S., Chemosphere, 2020, vol. 259, p. 127419. https://doi.org/10.1016/j.chemosphere.2020.127419

Ariffin, F. and Rahman, S.A., J. Environ. Microbiol. Toxicol., 2020, vol. 8, p. 50. https://doi.org/10.54987/jemat.v8i1.523

Pimmata, P., Alissara, R., and Pensri, P., Int. Biodeterior. Biodegrad., 2013, vol. 85, p. 196. https://doi.org/10.1016/j.ibiod.2013.07.009

Małysiak, M. and Kiljanek, T., Molecules, 2022, vol. 27, p. 5741. https://doi.org/10.3390/molecules27175741

Jing, Y., Liu, C., and Xu, S.Z., J. Food Saf. Qual., 2018, vol. 9, p. 1395.

Chen, S., Yu, Y., and Ma, J., Acta Chromatogr., 2021, vol. 33, p. 354. https://doi.org/10.1556/1326.2020.00827

Ahn, S., Lee, J.Y., and Kim, B., Chromatographia, 2021, vol. 84, p. 27. https://doi.org/10.1007/s10337-020-03976-y

Khadem, M., Faridbod, F., Norouzi, P., Foroushani, A.R., Ganjali, M.R., Yarahmadi, R., and Shahtaheri, S.J., J. Anal. Chem., 2020, vol. 75, p. 669. https://doi.org/10.1134/S1061934820050068

Sharma, D.K., Kumar, N., Chaudhary, A., and Raj, P., Bull. Environ. Contam. Toxicol., 2020, vol. 105, p. 95. https://doi.org/10.1007/s00128-020-02901-1j

Asghar, M., Mohammed, Y., and Abdul, N., Int. J. Environ. Anal. Chem., 2019, vol. 99, p. 692. https://doi.org/10.1080/03067319.2019.1609460

Baksh, H., Buledi, J. A., and Khand, N. H., Chem. Mon., 2020, vol. 151, p. 1689. https://doi.org/10.1007/s00706-020-02704-4

Pacioni, N.L. and Veglia, A.V., Anal. Chim. Acta, 2003, vol. 488, p. 193.

Shen, S., Long, Z., Lu, Y., and Chen, J., Luminiscence, 2022, vol. 37, p. 348. https://doi.org/10.1002/bio.4177

Ni, Y. and Cao, D., Spectrosc. Lett., 2006, vol. 39, p. 431. https://doi.org/10.1080/00387010600812640

Sahu, D.K., Banjare, M.K., and Banjare, R.K., J. Indian Chem. Soc., 2021, vol. 98, p. 100261. https://doi.org/10.1016/j.jics.2021.100261

Dhahir, S.A., Mohammed, N.J., and Shetha, F.N., Baghdad Sci. J., 2016, vol. 13, p. 498. https://doi.org/10.21123/bsj.2016.13.3.0894

Jan, M.R., Shah, J., and Khan, H., Chemosphere, 2003, vol. 52, p. 1623. https://doi.org/10.1016/S0045-6535(03)00480-6

Dhahir, S.A., Mohammed, N.J., and Khalaf, K.D., Int. J. Chem. Sci., 2015, vol. 13, p. 213.

Harikrishna, V. and Naidu, N.V.S., J. Chem., 2005, vol. 2, p. 218. https://doi.org/10.1155/2005/172909

Lurie, Yu., Handbook of Analytical Chemistry, Moscow: Mir, 1975.

Schenck, F.J., Lehotay, S.J., and Vega, V., J. Sep. Sci., 2002, vol. 25, p. 883.

Verma, B.C., Chauhan, S., Sharma, N., Sharma, U., Sharma, D.K., and Sood, A., Talanta, 1986, vol. 33, p. 703.

Sharma, D.K., Dharmani, T., and Sharma, N., Bull. Chem. Soc. Ethiop., 2015, vol. 29, p. 173. https://doi.org/10.4314/bcse.v29i2.2

Barton, D.H., Haslam, E., and Ollis, W.D., Comprehensive Organic Chemistry: The Synthesis and Reactions of Organic Compounds, London: Pergamon, 1979.

Clayden, J., Greeves, N., and Warren, S., Organic Chemistry, Oxford: Oxford Univ. Press, 2016.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharma, N., Kaura, A. & Chaudhary, A. Development and Validation of Spectrophotometric and Spectrofluorimetric Methods for Glufosinate-Ammonium Herbicide and Carbofuran Insecticide Contamination in Environmental Samples. J Anal Chem 78, 1511–1524 (2023). https://doi.org/10.1134/S1061934823110059

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061934823110059