Abstract

Ion imprinted polymer (IIP) for copper was synthesized for selective extraction of copper from different samples for analysis using flame atomic absorption spectrophotometry. In the synthesis of ion-imprinted polymer Cu(II) ion (template), 2,2'-bibyridine (ligand) and 4-vinylpyridine (functional monomer) which formed a complex through coordination with Cu(II) ion, ethylene glycol dimethacrylate (cross-linker) and 2,2'-azobisisobutyronitrile (initiator) were used. The ion-imprinted polymer and non-imprinted polymer (NIP) were synthesized via precipitation polymerization process. The synthesized polymers were characterized using Fourier transform infrared spectroscopy and scanning electron microscopy. Variables affecting the solid phase extraction of Cu(II) such as pH, initial Cu(II) concentration and time were studied in batch experiments. Quantitative retention of Cu(II) on IIP was achieved at pH 7. The IIP selectivity for copper ion extraction was higher as compared to NIP in the presence of other competing metal ions. The method was successfully applied to the determination of copper in multivitamin tablet, various natural water samples and industrial effluent.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Copper is a biogenic element playing an important role in many biological processes such as blood formation, function of enzymes, photosynthesis and metabolism etc., but high levels of copper may cause problems like mucosal irritation, gastrointestinal disorders, capillary damage, and necrotic changes in liver and kidney [1‒3]. The acceptable concentration of copper in coastal and estuarine water is 0.005 mg/L, as suggested in European Community (EU) legislation. The adult daily dose of copper for human beings is 2 mg, but ecological effects are observed when it exceeds 0.2 mg/L [4]. Therefore, it is necessary to monitor copper in environmental and biological samples up to a microgram level. Important sources of copper in sewage water are households (tap water systems and food). Copper metal is used for drinking water pipes which corrode and contribute to copper concentration in wastewater from industries and residences [5].

The most widely used procedure for removal of analytes of interest is solid phase extraction (SPE) because of the advantages that it offers such as enrichment of analytes, removal of components of matrix, low consumption of reagents, simplicity and environmental friendliness [6]. The main drawback of SPE adsorbents is the lack of selectivity for metal ions, i.e. interferences of other species. In order to alleviate this effect, molecularly imprinted polymers (MIP) were reported which possess high selectivity and affinity for the template because of the synthetic recognition sites [7, 8]. Based on the idea of MIP, Nishide et al. in 1976 introduced ion imprinted polymers which possess selective sites for inorganic metal ions [9, 10]. Because of the removal of template, binding cavities are formed in the polymer material due to which IIP show high selectivity, high adsorption capacity, low detection limit and high sensitivity, stability, durability, low-cost synthesis and high sample clean-up in complex matrices [11‒13].

Generally, three steps are followed in the synthesis of IIP. In the first step template is formed by complexation of metal ion with ligand, in the second step copolymerization reaction occurs between the monomers in the presence of cross-linker and initiator around the template, and finally, template is removed from the polymer leaving behind imprinted cavities that are of specific size and shape to the target metal ion, which increases selectivity of the polymer for target metal ion over other interfering ions [14‒16].

The ligand, 2,2'-bipyridine (bipy), is a relatively selective ligand for Cu(II) determination by spectrophotometric method. The aim of the present study is to prepare bipy-based imprinted polymer sorbent for selective separation and preconcentration of Cu(II) from different matrices before its determination by flame atomic absorption spectrometry (FAAS). In the present work, copper-ion imprinted and non-imprinted polymers were synthesized with precipitation polymerization technique using Cu(II) as a metal ion, bipy as ligand, 4-vinyl pyridine (4-VP) as a monomer with a cross linker (ethylene glycol dimethacrylate) and initiator (2,2'-azobisisobutyronitrile). Recognition activity and binding ability of the imprinted material towards copper ion was investigated in batch experiments.

EXPERIMENTAL

Reagents and materials. All reagents used were of analytical grade or similar purity; Cu(NO3)2· 3H2O, 2,2'-azobisisobutyronitrile (AIBN), ethylene glycol dimethacrylate (EGDMA), 4-vinyl pyridine and 2,2'-bipyridine were purchased from Merck (Darmstadt, Germany) and used without further purification. The standard solutions of metal ions for selectivity study were prepared from their nitrate salts (Merck, Darmstadt, Germany). Standard solution (1000 µg/mL) of Cu(II) was also purchased from Merck. HPLC grade acetonitrile was purchased from BioM Laboratories (Cerritos, USA).

Instrumentation. Flame atomic absorption spectrophotometer (Perkin Elmer model AA200, USA) equipped with hollow cathode lamp (single element), deuterium background correction at 324.7 nm and air-acetylene flame was used for determination of Cu(II). For the analysis of samples, parameters recommended by the manufacturer were used; pH meter (Model-422 WTW, Weilheim, Germany) was used for pH measurements.

Synthesis of Cu(II) ion imprinted polymer. The precipitation polymerization method was used for preparation of Cu(II)-imprinted polymer. Synthesis of imprinted polymer was achieved in two steps. In the first step, 4-VP (4 mmol) and bipy (1 mmol) as a functional monomer and ligand, respectively, were dissolved in acetonitrile (40 mL) as a porogen solvent followed by the addition of Cu(NO3)2· 3H2O (0.5 mmol) as template metal ion to the solution, and the mixture was stirred for 5 h at room temperature. In the second step of polymerization, crosslinker EGDMA (20 mmol) and initiator AIBN (0.4 mmol) were added to the first-step mixture [16]. The polymerization mixture was purged with nitrogen for 10 min to remove oxygen (as it retards polymerization by trapping free radicles). The reaction tube was sealed and heated using water bath at 70°C for 12 h to complete thermal polymerization process. The synthesized polymer was washed for removal of unreacted materials with methanol‒water (1 : 4, v/v). The imprint ion, Cu(II), was leached with 0.5 M HNO3 solution and determined by FAAS in the leachate. Leaching of copper from the polymer was carried out till no Cu(II) ions were detected in the solution. After that the polymer particles were washed with distilled water until the pH of wash solution became neutral. The resulting imprinted polymer was dried at 70°C under vacuum in oven. Non-imprinted polymer was prepared by following the same procedure without addition of Cu(II) salt. The schematic presentation of the Cu(II)-imprinted polymer synthesis is shown in Fig. 1.

Characterization of polymers (IIP and NIP). The morphological features of IIP and NIP were observed by scanning electron microscopy (SEM) using JSM-5910, JEOL microscope Japan. The specimens for SEM analysis were prepared by coating the samples as a thin layer using double adhesive carbon tape over aluminum stubs. The functional groups in the IIP and NIP were confirmed from the infrared spectrum taken from IR Prestigue–21, Shimadzu, Japan.

Batch solid phase extraction of Cu(II). In batch experiments for extraction of Cu(II) from aqueous solutions the synthesized ion imprinted polymer was used as a sorbent. Ion imprinted polymer (10 mg) was added into 10 mL flask containing 5 mg/L of Cu(II) ion solution and pH was adjusted with Britton-Robinson buffer to 7 [17]. For binding/loading process it was stirred for 15 min and then filtered. After that the loaded polymer was suspended in 10 mL of 0.5 M HNO3 as an eluent, stirred for 15 min and filtered. The amount of Cu(II) ion was determined by FAAS in the filtrate.

Extraction percent of copper was calculated by the following equation:

where ci and cf are the copper ion concentrations before and after extraction in the solution.

The sorption capacity (qe) was calculated as:

where m is the mass of IIP (mg) and V is volume of solution (mL).

Sample preparation. Water samples such as well water (Karak, Khyber Pakhtunkhwa, Pakistan), river water (Kund Park, Khyber Pakhtunkhwa, Pakistan), tap water (University of Peshawar Campus, Khyber Pakhtunkhwa, Pakistan) and industrial effluent water (Hayatabad Industrial Estate, Khyber Pakhtunkhwa, Pakistan) were filtered for removal of insoluble particles through 0.2 µm cellulose acetate membrane. The pH of all water samples was adjusted to 7 and copper was determined according to the given extraction procedure.

Multivitamin supplement tablets (Alive-Plus) were purchased from local market. One tablet was digested on a hot plate with 10 mL of concentrated HNO3. After digestion the solution was diluted to 25 mL with deionized water and filtered. One mL of the sample solution was taken, pH was adjusted to 7 and copper was determined according to the extraction procedure.

Selectivity study. Competitive binding of divalent metal ions such as Ca(II), Mg(II), Ni(II), Co(II), Cd(II), Pb(II), Fe(II) and Zn(II) along with Cu(II) was studied in batch experiments for IIP. A binary mixture (pH 7) of Cu(II) with selected divalent metal ions of 5 mg/L concentration. IIP (10 mg) was added to the binary mixture of metal ions solution and stirred for 15 min. After binding, the IIP was separated and eluted with 10 mL of 0.5 M HNO3 and metal ion concentration in the elute was determined by FAAS.

The selectivity of Cu(II)−IIP for Cu(II) over other metal ions was investigated from the results obtained by calculating distribution ratio, selectivity and relative selectivity coefficient for IIP and NIP as described in literature [8, 14, 18, 19].

Distribution coefficient was calculated from the following equation:

where Kd is the distribution coefficient/ratio, ci and cf refer to initial and final concentrations of the solution, respectively. While m is the mass of polymer and V is the volume of solution. Selectivity coefficient (k) and relative selectivity coefficient (k') for copper ion relative to the competing metal ion in solution were calculated from the equations as:

where Kd Cu(II) and KdM(II) are distribution ratio of Cu and divalent competitor ion, respectively. The larger k' value indicates the enhancement of Cu(II) sorption affinity and more selective IIP for Cu(II) extraction with respect to NIP.

RESULTS AND DISCUSSION

Characterization of Cu(II)-ion imprinted polymerand non-imprinted polymer. The synthesis of Cu−IIP involved precipitation polymerization; therefore, polymer in the form of precipitate, with Cu(II) ions leached and unleached, was studied for morphological features using SEM. The SEM images obtained at ×6000 magnification is shown in Fig. 2. It can be seen that there is no significant difference in the appearance of IIP in the leached and unleached form, which indicates that the morphology of IIP remains the same after leaching.

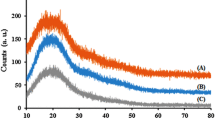

Fourier transform infrared spectroscopy (FTIR) was used to identify the complexation between Cu(II) ions and IIP; therefore, the leached and unleached IIP were characterized. The IR spectra are shown in Fig. 3a for leached IIP and in Fig. 3b for unleached IIP. A band located at 1250 cm–1 in leached IIP is shifted to 1254 cm–1 on complexation with Cu(II) ion indicating that C=N group in vinyl pyridine is involved in complexation. The intensity of the band due to pyridine at 1597 cm–1 in the unleached IIP is decreased after leaching process as compared to leached IIP. Decrease in the band intensity indicates that in 2,2'-bipyridine on nitrogen the non-bonding electron pair is involved in coordination with Cu(II) ions, which confirms the complexation of Cu(II) in IIP as well as supports the evidence of Fig. 1. Additionally, a strong vibration band was observed at 1730 cm–1 due to the carbonyl group of EGDMA, and another distinct vibration at 1155 cm–1 (leached IIP) and 1152 cm–1 (unleached IIP) attributed to C‒O of EGDMA. The absorption band at 1454 cm–1 is due to –CH2 and –CH3 deformations. A branched peak at 2951 and 2954 cm–1 was assigned to C‒H stretching of the –CH2 and –CH3 groups.

Optimization of solid phase extraction conditions.Effect of pH. Metal ion complexation with ligand and sorption of metal ions is pH dependent. Therefore, the effect of pH on the sorption of Cu(II), 2 mg/L standard solution of Cu(II) were prepared in the pH range of 3‒8 and loaded with 10 mg of IIP in batch was studied. The results for the sorption of Cu(II) on IIP at different pHs are presented in Fig. 4. The percent sorption of Cu(II) on IIP increased from pH 3 to 7 and then decreased from pH 7 to 8. Maximum sorption (100%) of Cu(II) on IIP was achieved at pH 7. As the presence of nitrogen in ligand (2,2'-bipyridine) and functional monomer (4-VP) involved in the complex formation with Cu(II) ion is strongly dependent on pH of the solution. At low pH, the nitrogen as a donor in the 2,2'-bipyridine -4-VP network becomes protonated and lower concentration of Cu(II) sorbed on the IIP. While with increase in pH, the protonation of 2,2'-bipyridine – 4-VP decreased and the conditions became suitable for complexation reaction and sorption of Cu(II) on IIP. Further, at pH higher than 7, the percent sorption decreased due to copper hydroxide formation in the solution. Therefore, further study was performed with pH 7 as an optimum pH for sorption of Cu(II) on IIP.

Effect of sorption time. The effect of time was studied on percent sorption of Cu(II) ions in aqueous solution using IIP in a batch system. For binding of Cu(II) ions, 10 mg of IIP (sorbent) was added to 10 mL of Cu(II) solution (2 mg/L) at pH 7 and agitated for 5‒35 min on orbital shaker. After filtration, Cu(II) ions were analyzed by FAAS. The results revealed that 100% sorption/binding of Cu(II) ion on IIP was achieved in 15 min (Fig. 5a). As indicated in the figure that Cu(II) ions sorption is rapid in the initial period of time and then reached at a constant value (100%) in 15 min. The initial rapid rate may be due to the availability of sites on ligand in IIP and after coverage of sites with Cu(II) ions the sorption remained constant.

To investigate the rate of sorption of copper ions on ion-imprinted and non-imprinted polymer, the kinetic data were fitted to the two most common kinetic models, namely pseudo-first-order and pseudo-second-order [20]. The sorption kinetic constants and correlation coefficients were calculated and presented in Table 1. The calculated sorption capacity (qe = 2.4 mg/g) with a correlation coefficient (R2 = 0.9973) from pseudo-second-order kinetic model is close to the experimental sorption capacity value (qe = 2.0 mg/g). The results are also given in Fig. 5b and show that using IIP for the sorption of Cu(II) fitted well to the pseudo-second-order kinetic model which prevails that the rate limiting step is chemosorption.

Sorption capacity. The sorption capacity of Cu(II) ion on IIP was studied using the proposed procedure in a batch system at room temperature. To measure the sorption capacity (qe), 10 mg of IIP was equilibrated with 10 mL of Cu(II) solution in the range of 2‒18 mg/L at pH 7. The sorption value increased with the increase in concentration of Cu(II) from 2‒18 mg/L. The sorption capacity of IIP was calculated and found to be 7.4 mg/g. The sorption capacity of IIP is greater than the NIP (not shown), which indicates that IIP plays an important role in the sorption behavior. In the synthesis of IIP sorbent, Cu(II) gave an arrangement of ligand in order, and after removal of Cu(II) ions the imprinted cavities and specific binding sites of ligand and functional monomer groups are formed in a predetermined orientation. In NIP no such specificity is present. Due to the specific template, imprinted polymer (IIP) allows metal ions to be sorbed in a shorter time with higher sorption capacity.

The proposed method was used to study the sorption isotherm and sorption capacity of IIP at room temperature. The sorption capacity of the imprinted polymer was calculated using the following Langmuir equation:

where ce is the equilibrium concentration, qe refers to amount of solute sorbed per gram of sorbent, KL and aL are the Langmuir sorption isotherm constants and are related to the maximum capacity (L/g) and bonding strength (Lg/mg), respectively. Q° is the maximum sorption capacity and is numerically equal to KLaL. The values of KL, aL, and Q° were calculated from linear plot of ce/qe versus ce (Figs. 6a, 6b). The sorption capacity of the IIP was calculated to be 22.17 mg/g.

Effect of interfering ions and selectivity study. The effect of interfering ions including Na, K, Ca and Mg as matrix ions while Zn(II), Co(II), Ni(II), Cd(II), Pb(II) and Fe(II) as matrix and interfering ions were studied on the sorption of Cu(II) in a binary solution. The recoveries (97.0‒99.8%) show that the IIP was unaffected by the presence of common matrix ions and divalent competitive transition metal ions (Table 2). The data suggests that the cavities present in IIP are selective for Cu(II) ions.

The cavity formed after removal of the metal ion (template) in IIP is specific in size and coordination geometries to the metal ion. In case of NIP, the distribution of ligand functionalities in the polymeric network is random and results in nonspecific rebinding affinities. The selectivity of IIP for Cu(II) was also evaluated by comparing with the competitive divalent transition metal ions like Ni(II), Zn(II), Co(II), Cd(II), Pb(II) and Fe(II) because of formation of coordination complexes. Binary aqueous solution, 10 mL, of pH 7 containing 5 mg/L of each metal ion [Cu(II)/Pb(II) and Cu(II)/Ni(II), Cu(II)/Co(II), Cu(II)/Cd(II), Cu(II)/Pb(II) and Cu(II)/Fe(II)] were studied in batch experiments at optimum conditions of sorption using IIP and NIP. The concentration of metal ions in the elute was determined with FAAS. The results are summarized in Table 3 for distribution coefficient (Kd), selectivity coefficient (k) and relative selectivity coefficient (k'). The results of distribution coefficient values of IIP sorbent for Cu(II) were greater than the other metal ions. The selectivity coefficients of Cu(II)−IIP for Cu(II) with respect to other interfering transition metal ions were very high. The relative selectivity coefficient values for the binary mixture of metal ions are greater than 1 and suggest that IIP show great selectivity to Cu(II) ions in the presence of metal ions from the same transition metal ions group. The value of relative selectivity coefficients also indicates high binding affinity and selectivity of ion imprinted polymer, for the template (Cu(II)) with respect to non-imprinted polymer.

Reusability of ion imprinted polymer. The stability and reusability of Cu(II)−IIP polymeric material was studied by using repeated cycles of sorption‒elution with same polymeric material at optimum conditions (10 mg IIP, pH 7, initial Cu(II) concentration 5 mg/L, sorption and extraction time 15 min). After each use 10 mL of 0.5 M HNO3 was used for elution of the sorbed Cu(II) ions and regeneration of IIP. Results of reusability of IIP are shown in Fig. 7. After seven cycles of sorption‒elution, the change in percent sorption was insignificant and the mean sorption was 99% at 5% confidence level. This indicated that the loss in the binding affinity of IIP is not significant and could be repeatedly used for sorption of Cu(II) ions.

Applications. In order to examine precision and accuracy of the proposed method, the method was applied to water samples including well water (Karak, Khyber Pakhtunkhwa, Pakistan), industrial effluent water (Hayatabad Industrial Estate, Khyber Pakhtunkhwa, Pakistan), tap water (Peshawar University Campus, Khyber Pakhtunkhwa, Pakistan) and river water (Kund Park, Khyber Pakhtunkhwa, Pakistan). As no Cu(II) was found in water samples, they were spiked with known concentration of Cu(II) and treated according to optimal experimental conditions. Accuracy of the method was verified by extraction recovery experiments using spiked samples. Extraction recoveries were found in the range of 97.5 to 99.5% (Table 4). The precision of the method was verified by analyzing multivitamin supplement (Alive Plus) tablets. Known amount of multivitamin tablet containing known concentration of Cu(II) was analyzed by the proposed method. The extraction recovery was found to be 97.9%, which shows good precision of the method (Table 4). The results suggest that the proposed method is precise, accurate and suitable for quantitative determination of Cu(II) ion in different matrices.

CONCLUSIONS

In this study, Cu(II) ion imprinted polymer was synthesized by incorporating 2,2'-bipyridine as a chelating agent for Cu(II). Cu(II)−IIP was found highly selective as compared to NIP in the presence of common transition and heavy metal ions. The synthesized IIP showed high affinity for binding Cu(II) ion in complex matrices of samples, found highly stable and could be repeatedly used for sorption‒elution without any significant change in binding properties. Based on the performance of Cu(II)−IIP in the present study, it is visualized that Cu(II)−IIP is a promising sorbent for selective extraction of Cu(II) from different samples.

REFERENCES

Ashkenani, H. and Taher, M.A., J. Electroanal. Chem., 2012, vol. 683, p. 80.

Khajeh, M. and Sanchooli, E., Environ. Chem. Lett., 2011, vol. 9, p. 177.

Lu, S. and Gibb, S.W., Bioresour. Technol., 2008, vol. 99, p. 1509.

Sörme, L. and Lagerkvist, R., Sci. Total Environ., 2002, vol. 298, p. 131.

Godlewska-Żyłkiewicz, B., Spectrochim. Acta, Part B, 2003, vol. 58, p. 1531.

Cabral de Lima, G., Campos do Lago, A., Alves Chaves, A., Fadini, P.S., and Luccas, P.O., Anal. Chim. Acta, 2013, vol. 768, p. 35.

Alizadeh, T., Ganjali, M.R., and Zare, M., Anal. Chim. Acta, 2011, vol. 689, p. 52.

Liu, Y., Liu, Z., Gao, J., Dai, J., Han, J., Wang, Y., Xie, J., and Yan, Y., J. Hazard. Mater., 2011, vol. 186, p. 197.

Singh, D.K. and Mishra, S., Chromatographia, 2009, vol. 70, p. 1539.

Hoai, N.T. and Kim, D., AIChE J., 2009, vol. 55, p. 3248.

Branger, C., Meouche, W., and Margaillan, A., React. Funct. Polym., 2013, vol. 73, p. 859.

Bahrami, A., Besharati-Seidani, A., and Abbaspour, A., Electrochim. Acta, 2014, vol. 118, p. 92.

Azevedo Lemos, V., Sena Gomes Teixeira, L., de Almeida Bezzera, M., Spínola Costa, A.C., Teixeira Castro, J., Martins Cardoso, L.A., et al., Appl. Spectrosc. Rev., 2008, vol. 43, p. 303.

Yilmaz, V., Hazer, O., and Kartal, Ş., Talanta, 2013, vol. 116, p. 322.

Abedi, H. and Ebrahimzadeh, H., React. Funct. Polym., 2013, vol. 73, p. 634.

Ebrahimzadeh, H., Behbahani, M., Yamini, Y., and Adlnasab, L., React. Funct. Polym., 2013, vol. 73, p. 23.

Britton, H.T.S., Hydrogen Ions, Ser.: Monographs on Applied Chemistry, vol. 3, Tripp, E.H., Ed., New York, 1943.

Jo, S.H., Park, C., Yi, S.C., Kim, D., and Mun, S., J. Chromatogr. A, 2011, vol. 1218, p. 5664.

Luo, X., Luo, S., Zhan, Y., Shu, H., Huang, Y., and Tu, X., J. Hazard. Mater., 2011, vol. 192, p. 949.

Shah, J., Jan, M.R., Haq, A.U., and Zeeshan, M., J. Saudi Chem. Soc., 2015, vol. 19, p. 301.

ACKNOWLEDGMENTS

The analysis in the Centralized Resource Laboratory, University of Peshawar is highly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Jasmin Shah, Jan, M.R. & Anjum Selective Solid Phase Extraction of Copper from Different Samples using Copper Ion-Imprinted Polymer. J Anal Chem 73, 1146–1153 (2018). https://doi.org/10.1134/S1061934818120055

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061934818120055