Abstract

Electrochemical behavior of naphthalene 1-nitro-6-sulfonic acid was studied by polarography, voltammetry on glassy carbon electrodes, and electrolysis at controlled potential and in galvanostatic mode. The 1-nitro-6-sulfonic acid, like α-nitronaphthalene and naphthalene 1-nitro-3,6,8-trisulphonic acid, was shown to be polarographically reduced in a strong acidic medium in the presence of 0.1 N H2SO4 to the corresponding naphthalene aminosulfonic acid in a single six-electron stage via an intermediate formation of hydroxylamine. Deceleration of the 1-nitro-6-sulfonic acid polarographic reduction manifesting itself as a decrease of the polarographic current, as well as strong dependence of the polarization curves’ parameters and shape on the neutral and alkaline supporting solution composition and pH, are related to anionic character of the species being reduced, which is caused by the presence of acidic sulfonic group in their molecules. The technological parameters for the naphthalene 1-amino-6-sulfonic acid preparative electrosynthesis are determined: the current density 5–10 A/dm2, temperature 30–32°C, and concentration of the initial nitro-compound 10–13%, which provide the target product yield of 87.0–93.5%, the current efficiency of 38.0–42.4%, and recovery of 69.0–80.0% (on the N3 grade nickel and Kh18N10Т-stainless-steel cathodes in ammonia buffer solutions with pH 7.0–8.2). To increase the electroreduction efficiency of the nitro-Cleve’s acids’ technical isomeric mixture reduction, the mixture preliminary purification and the using of inert atmosphere are recommended in the processes of both electrolysis and the target Cleve’s-acid extraction from the solution.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Isomeric mixture of 1,6- and 1,7-naphthalene 1‑aminosulfonic acids (Cleve’s-acids) has widespread application in the dyes manufacturing [1]. The Cleve’s-acids are produced by the electroreduction of the corresponding naphthalene nitrosulfonic acids by the using of various chemical reagents:

In the industry, the Cleve’s-acids are produced by the reducing of naphthalene nitrosulfonic acid mixture with the using of pig iron cutting [2]. This manufacturing is loaded with great amount of waste-waters and non-recyclable solid waste products as coal-iron slack (4.0–4.5 t of solid waste is formed per 1 t of the target product). In addition, the Cleve’s-acids’ yield is nonstable, it is determined by the pig-iron cutting quality and its pretreatment prior to the reduction.

Literature data concerning the electrochemical reduction of the naphthyl nitrosulphonic acid isomeric mixture are very scarce [3]. The 1,6- and 1,7-naphthyl nitrosulphonic acids’ electrochemical reduction at lead cathode in acidic solution was shown [3] to proceed no further than to the formation of naphthyl hydroxylaminosulphonic acids. The increase in temperature and the lead electrode activity (by the zinc or copper coating thereon) allowed accelerating the reaction; however, it did nor promote transformation of the hydroxylamino-derivatives to amines.

The electrochemical reduction of the 1,6- and 1,7-naphthyl nitrosulphonic acids’ technical mixture to the corresponding 1,6- and 1,7-naphthalene aminosulfonic acids (the Cleve’s-acids) in strong acidic and buffer ammonium solutions at various cathodic materials was studied in work [4]. At nickel cathode in the ammonium buffer solution under the conditions of preparative electrolysis the Cleve’s-acids’ yield is 88–93%; the current efficiency, 58–60%. However, the Cleve’s-acids’ recovery yield calculated by the disengagement from solutions obtained after the electrolysis is 39.0–43.0%, as compared with that of 52.0–60.0% in the chemical reduction. In addition, the Cleve’s-acids isolated from reaction mass after the current industrial procedure, unlike those obtained by the chemical reaction, are enriched with the 1,7-Cleve’s-acid isomer. In particular, the isomeric naphthalene aminosulfonic acids content in the spread is: the 1,6‑Cleve’s-acid, 8–9%; the 1,7-Cleve’s-acid, 80–90%; the 1,8-peri-acid, 6–8%. Therefore, the development of the technology for the 1,6- and 1,7-naphthyl nitrosulphonic acids’ technical isomeric mixture electroreduction into the corresponding naphthalene aminosulfonic acids required pre-examination of electrochemical behavior of the naphthalene 1-nitro-6-sulfonic acid as a model compound, in order to elucidate the reason for the lower Cleve’s-acids’ recovery yield from solutions obtained after the electrolysis, as well as to lower the naphthalene 1-nitro-6-sulfonic acid concentration in the isolated product as compared with the chemical reduction of 1,6- and 1,7-naphthyl nitrosulphonic acids’ isomeric mixture.

EXPERIMENTAL

Polarograms were taken using a PU-1 polarograph. A dropping mercury electrode with forced droplet detachment (by using an applicator) had the following characteristics (determined in 0.1 N КС1 solution under open circuit conditions and the mercury column height of 50 сm): m = 1.0 mg/s, t = 0.65 s. The potentials are given against saturated calomel electrode.

The indifferent electrolytes were Britton–Robinson buffer solutions with рН values from 2.0 to 11.0 and constant ionic strength of 0.5 М, 0.1–1.0 N НС1, Н2SO4, and NaOH solutions, and the buffer ammonium solutions with рН 5.0–9.0, as well as 0.1–1.0 N ammonium chloride solutions.

Cyclic voltammograms at glassy carbon (SU-2000) electrode were recorded using the PU-1 polarograph in differential mode. The stationary electrode we used was end-face of a glassy carbon rod (2 mm in diameter) [8].

The cell was a conical glass vessel with a volume of 20 сm3 provided with a jacket for thermostating. A saturated calomel half-cell was the reference electrode; the potential values below are given against this electrode. Another saturated calomel half-cell was the auxiliary electrode.

To obtain reproducible results, the glassy carbon electrode was grinded with a fine emery paper, polished to mirror-smooth surface with felt impregnated with glycerol with alumina. After washing with distilled water, the electrode was exposed to concentrated sulfuric acid, them washed again thoroughly. Immediately prior to the recording of current–voltage curves, the electrode was washed with water and wiped with filter paper. The electrolyte was deoxygenated by the bubbling with inert gas.

To identify the naphthalene 1-nitro-6-sulfonic acid reduction products and evaluate the reduction effectiveness, we carried out controlled-potential electrolysis using a P-5848 electronic potentiostat. The electrolysis was performed at electrodes made of various materials in cylindrical glass cell provided with jacket for thermostating; the anodic and cathodic compartments were separated with an МК-40 cation-exchange membrane. Platinum plate was anode; 10%-solution of sulfuric acid, the anolyte. The catholyte volume was 70 mL. The thermostated cell has ground cap provided with connecting pipes for current collectors, sampling, mounting the Luggin capillary, and nitrogen supply. The cathode made of the studied metal, with the surface area of 0.15 dm2, was mounted at the cell bottom. The current collector was a stem sealed in glass tube. The catholyte was agitated with a magnetic stirrer.

The potentials were set in conformity with the data obtained from the polarization measurements at the solid electrodes.

During the electrolysis, the changes in the concentration of the raw nitro-compound and the reaction products were controlled by using the polarography and voltammetry [8].

The naphthalene 1-nitro-6-sulfonic acid reduction in galvanostatic mode was carried out in a cylindrical glass cell similar to that used for the controlled-potential electrolysis.

To the polarographic and voltammetric studies, the naphthalene 1-nitro-6-sulfonic acid and naphthalene 1-amino-6-sulfonic acid were purified by double-crystallization from deionized water. The naphthalene 1-nitro-6-sulfonic acid ammonium salt was isolated from technical isomeric mixture of naphthyl nitrosulphonic acids with the concentration of 0.5–0.7 М, containing 40.5% of the naphthalene 1-nitro-6-sulfonic acid, 51.0% of naphthalene 1-nitro-7-sulfonic acid, and 3.5% of naphthalene 1-nitro-8-sulfonic acid, obtained from existing industry. The isolated naphthalene 1-nitro-6-sulfonic acid purity was evaluated by thin-layer chromatography, using the acetic acid : butanol : distilled water (1 : 4 : 5) mixture as eluent. In addition, the naphthalene aminosulfonic acids’ isomeric ratio in the solution and in the isolated product was analyzed by using high performance liquid chromatography as described in work [4].

α-Nitronaphthalene to be used in polarographic studies was re-crystallized twice from ethanol.

The concentration of the intermediate product, naphthalene hydroxylamine sulphonic acid, was determined by voltammetry in the 1 М NaOH supporting electrolyte solution in differential mode [5]; that of naphthalene 1-amino-6-sulfonic acid, by the diazotization method, reckoning to diazotized products with molecular mass 223.

The target naphthalene 1-amino-6-sulfonic acid was isolated from the post-electrolysis solution upon its acidifying with sulfuric acid down to the reaction-mass рН of 3.9–4.1 at 50–55°С, with subsequent cooling down to 20–25°С and acidifying down to рН of 2.0 under agitation; then exposed to the same temperature for 18–20 h at a stopped stirrer, with periodical kneading of the reaction mass.

RESULTS AND DISCUSSION

Polarographic Reduction of Naphthalene 1-Nitro-6-Sulfonic Acid

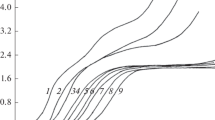

In strong acidic medium, with 0.1 N sulfuric or hydrochloric acid as a supporting electrolyte we observed a single polarographic wave with weakly pronounced current decay (Fig. 1) characteristic of the naphthalene 1‑nitro-3,6,8-trisulfonic acid, which is due to anionic character of the reducible nitro-compound [6]. At рН > 1.96, the current decay disappeared, and the polarograms recorded in solutions with рН 1.96–5.3 demonstrate two waves; at that, the height of the 2nd wave comes to 1/3 of the summary limiting current. With the increasing of the indifferent electrolyte рН, the height of the 2nd wave decreased; at рН 6.2, the wave disappeared completely, so, a single wave is registered in the polarogram. The рН dependence of the 1st wave limiting current in the 1.96–4.5 pH range is rather complicated; at pH > 4.5 the current appears being рН-independent (Fig. 1).

With the increasing of pH, the half-wave potential Е1/2 of the 1st wave shifts to more negative values (Fig. 1); that of the 2nd wave does not change, it equals –1.0 to –1.05 V. The рН-dependence of Е1/2 is S-shaped. In the 3.0–8.0 рН range, ∆Е1/2/∆рН equals 70 mV/рН. In the solutions with the рН exceeding 8.0, the Е1/2 value of the 1st wave remains unchanged; it equals –0.80 V.

The dependence of the 1st wave current Id in the 0.1 N sulfuric acid solution on the square root from the mercury column height and the nitro-compound concentration are represented by lines crossing the origin; the temperature coefficient of the 1st wave limiting current in acid solutions is 1.3–1.6%/degree, which points to a diffusion nature of the 1st wave current.

In the ammonia buffer solutions with рН 4.95–8.6, the naphthalene 1-nitro-6-sulfonic acid is reduced forming a single wave in polarograms. At that, the limiting current and Е1/2 value do not vary over the studied рН range (Table 1).

The limiting current of the naphthalene 1-nitro-6-sulfonic acid reduction wave in the ammonia buffer solution with рН 8.6 depends in linear fashion on the concentration, the line crossing the origin. The dependence of Id on the square root from the mercury column height intercepts the abscissa axis; the temperature coefficient is 0.7–0.8%/degree. The data evidence the presence of adsorption component in the naphthalene 1-nitro-6-sulfonic acid reduction current.

The number of electrons participating in the electrode process was estimated by the comparing, under identical conditions, of the wave heights for the naphthalene 1-nitro-6-sulfonic acid and α-nitronaphthalene that is also reduced, similarly to other naphthalene nitrosulfonic derivatives [6, 7], in strong acidic medium to the corresponding amino-compound in a single six-electron stage via hydroxylamine intermediate; in alkaline medium, in a four-electron stage to hydroxylamine compound. At that, the naphthalene 1-nitro-6-sulfonic acid wave height, both in strong acidic and alkaline medium, equals that of the α‑nitronaphthalene. Therefore, it is believed that the naphthalene 1-nitro-6-sulfonic acid polarographic reduction in the strong acidic medium also proceeds in a single six-electron stage to the corresponding naphthalene 1-amino-6-sulfonic acid; in alkaline medium, in a four-electron stage to the corresponding naphthalene hydroxylaminosulfonic acid.

The very presence of the nonseparated six-electron reduction wave for the α-nitronaphthalene [7], naphthalene 1-nitro-3,6,8-trisulfonic acid [6], and naphthalene 1-nitro-6-sulfonic acid is likely to be explained by the formation in the strong acidic solution of an active electrophilic intermediate, a carbonium ion mesomere that is produced in the naphthyl sulphonic hydroxylamine surface protonation and subsequent dehydration (bearing in mind the quinone imine structure):

The naphthyl sulphonic hydroxylamine is reduced at the same potentials as the initial nitro-compound.

Similar intermediate used to be produced in the N‑hydroxylamine phenol dehydration; it is easier reduced as compared with the initial compound [8]. On this reason, the о- and p-nitrophenols are polarographically reduced right to amine, showing a single six-electron reduction wave. And yet, we showed that the polarographic reduction of the naphthalene 2‑nitro-4,8-disulfonic acid in 0.1 N sulfuric or hydrochloric acid solution proceeds in two stages, similarly to nitrobenzene and its derivatives [9], with the summary consuming of six electrons. Here, first a four-electron wave is observed, which produced naphthyl sulphonic hydroxylamine; then, a two-electron wave of its further reduction to the corresponding nitro-compound is registered at more negative potentials. The observed difference in the polarographic behavior of the naphthalene 2-nitro-4,8-disulfonic acid and α‑nitronaphthalene and its sulfonic derivatives in strongly acidic medium is likely to be explained by the impossibility of formation of the carbonium ion mesomere, which is caused by the specifics in the naphthalene nitrodisulfonic acid molecule structure.

The Naphthalene 1-Nitro-6-Sulfonic Acid Electroreduction at Glassy Carbon Electrode

Cyclic polarization curves taken in 0.1 N solution of sulfuric acid or Britton–Robinson buffer solutions with рН 1.96–11.0 show a single irreversible peak of the naphthalene 1-nitro-6-sulfonic acid reduction current (Table 2), like the curves recorded at dropping mercury electrode. With the increasing of the solution рН the peak height decreased; at a 0.1 N NaOH solution, the peak is split into two approximately equally high peaks.

When the potential sweeping is reversed from the potential of –1.3 V, the anodic peak is registered at potentials from –0.35 to +0.24 V, depending on the supporting electrolyte solution рН. The peak is due to the oxidation of intermediate product, the naphthalene 1-hydroxylamino-6-sulfonic acid formed during the naphthalene 1-nitro-6-sulfonic acid reduction. Moreover, the nitro-compound reduction final product, the naphthalene 1-amino-6-sulfonic acid, is oxidized in 0.1 N Н2SO4 solution at more positive potential: +0.65 V; with the increasing of the supporting solution рН the value of Еp shifts to cathodic direction, which points to the facilitation of the naphthalene 1-amino-6-sulfonic acid oxidation in alkaline medium (Fig. 2).

Differential voltammograms of the naphthalene 1‑amino-6-sulfonic acid oxidation at glassy carbon electrode in different supporting electrolyte solutions: (1) 0.1 N H2SO4; (2) Britton–Robinson buffer solution with рН 5.2; (3) 0.1 N NaOH. The naphthalene 1-amino-6-sulfonic acid concentration 3.8 × 10–4 М.

We see from Table 2 that the potential of the naphthalene 1-nitro-6-sulfonic acid reduction peak shifts to more negative values with pH; over the 8.3–14.0 pH range it depends but scarcely on рН and comes to ‒0.71…–0.80 V. Such a dependence is observed at the dropping mercury electrode as well (Fig. 1). At that, both at the dropping mercury and glassy carbon electrodes the naphthalene 1-nitro-6-sulfonic acid electroreduction proceeds nearly at the same potentials.

In Table 3 we give results of our studies in the рН effects on the naphthalene 1-nitro-6-sulfonic acid electroreduction at the glassy carbon electrode in ammonia buffer solutions with рН 7.45–10.30 and constant ionic strength.

It follows from the data presented in Tables 2 and 3 that the naphthalene 1-nitro-6-sulfonic acid electroreduction in weakly alkaline ammonia buffer solutions proceeds at the potentials approaching those observed in the Britton–Robinson buffer solutions. However, the reduction current peak height in the latter is markedly lower than in the ammonia buffer solutions; the difference increased with the increasing of the supporting solution рН. For example, the naphthalene 1-nitro-6-sulfonic acid reduction limiting current in the Britton–Robinson buffer solution with рН 10.3 is 57 mm, whereas in the ammonia buffer solution of the same рН it equals 70 mm.

Aromatic sulfonic acids are strong acids (in their strength, the sulfonic acids approach sulfuric and hydrochloric acids [3]), in the solution bulk they exist as dissociated acids. Therefore, we studied the effect of the solution ionic strength on the naphthalene 1‑nitro-6-sulfonic acid electroreduction in 0.1 N NH4OH solution added with NH4Cl (Fig. 3).

We see from Fig. 3 that with the increasing of ionic strength the irreversible current peak of the naphthalene 1-nitro-6-sulfonic acid reduction shifts toward less negative potentials. In particular, with the increasing of the electrolyte concentration from 0.01 to 1.0 N the value of Еp becomes by 100 mV more positive. At that, the cathodic current peak height increased significantly; the products of the naphthalene 1-nitro-6-sulfonic acid reduction are likely to be the corresponding naphthyl sulphonic hydroxylamine, which is evidenced by the anodic current peaks of its oxidation to the corresponding nitroso-compound [4, 5] at the potentials of –0.14…–0.25 V (the А2 peaks), and the radical-anion (the А1 peaks) that is oxidized reversibly to the initial compound at the potentials approaching the Ер value for the naphthalene 1-nitro-6-sulfonic acid; the peaks are observed during the potential sweeping in the anodic direction from –1.4 V. Note that the naphthalene 1-amino-6-sulfonic acid formation is not recorded here.

However, voltammograms taken both in strong acidic 0.1 N Н2SO4 solution (Fig. 4) and ammonia buffer solution (0.7 N NH4Cl + NH4OH) with рН 8.4 (Fig. 5) after the microelectrolysis at the glassy carbon electrode for 10–30 min at potentials –1.0…–1.2 and –1.2…–1.4 V, respectively, with subsequent potential sweeping in the anodic direction, show not only the oxidation peaks of the naphthyl sulphonic hydroxylamine derivative (peak А2) and radical-anion (peaks А1), but also the naphthalene 1-amino-6-sulfonic acid oxidation peak. The latter was confirmed by the spiking of the naphthalene 1-amino-6-sulfonic acid to the solution (Fig. 4, curve 6 and Fig. 5, curve 5). We see from Figs. 4 and 5 that the ratio of the formed hydroxylamino- and amino-compounds depends on the potential applied for the naphthalene 1-nitro-6-sulfonic acid reduction. At the potentials of limiting currents both in acidic and ammonia buffer solution the naphthalene 1-nitro-6-sulfonic acid reduction occurs with the formation of naphthyl sulphonic hydroxylamine; at the potentials approaching the indifferent electrolyte discharge potential, of the naphthyl sulphonic hydroxylamine and the naphthalene 1-amino-6-sulfonic acid. At that, with the increasing of the cathodic potential the naphthyl sulphonic hydroxylamine concentration decreased, that of naphthalene 1-amino-6-sulfonic acid increased. Because the naphthalene 1-nitro-6-sulfonic acid reduction involves protons, we studied its reduction at the glassy carbon electrode in solutions with different acidity in the presence of proton donors of different chemical nature. In Table 4 we show results of the naphthalene 1-nitro-6-sulfonic acid electroreduction in various supporting electrolytes at the glassy carbon electrode and the potentiostatic-mode microelectrolysis at the limiting-current potentials.

Classic voltammogram of the naphthalene 1-nitro-6-sulfonic acid reduction (1), cyclic differential voltammogram of the naphthalene 1-nitro-6-sulfonic acid reduction (2), as well as differential voltammograms of oxidation of the naphthalene 1-nitro-6-sulfonic acid reduction products formed at different potentials for 30 min: Е = –0.7 V (3); Е = –1.0 V (4); Е = –1.2 V (5), and differential voltammogram of naphthalene 1-amino-6-sulfonic acid (6) in 0.1 N Н2SO4 solution. The naphthalene 1-nitro-6-sulfonic acid concentration 2.5 × 10–4 М, the naphthalene 1-amino-6-sulfonic acid concentration 1.9 × 10–4 М, the potential scanning rate 20 mV/s.

Classic voltammogram of the naphthalene 1-nitro-6-sulfonic acid reduction (1), cyclic differential voltammogram of the naphthalene 1-nitro-6-sulfonic acid reduction (2), as well as differential voltammograms of oxidation of the naphthalene 1-nitro-6-sulfonic acid reduction products formed at different potentials for 30 min: Е = –1.2 V (3); Е = –1.6 V (4), and differential voltammogram of naphthalene 1-amino-6-sulfonic acid (5) in ammonia buffer solution (0.7 N NH4Cl + NH4OH) with рH 8.4. The naphthalene 1-nitro-6-sulfonic acid concentration 2.5 × 10–4 М, the naphthalene 1-amino-6-sulfonic acid concentration 1.9 × 10–4 М, the potential scanning rate 20 mV/s.

It follows from the data of Table 4 that in the studied indifferent electrolyte solutions the product of the naphthalene 1-nitro-6-sulfonic acid reduction on the glassy carbon electrode at the potentials corresponding to the limiting current of the recorded wave is the corresponding hydroxylamino-derivative. Along with the latter compound, at the potentials approaching that of the supporting electrolyte discharge (from ‒1.6 to –1.7 V) we observed the naphthalene 1‑amino-6-sulfonic acid formation. Similar results were obtained in 0.1 N H2SO4 solution as a supporting electrolyte. However, in 1 N КСl solution even at the potential of –1.6 V we did not observe any further reduction of the naphthalene hydroxylaminosulfonic acid to the corresponding amino-compound.

In NH4Cl solutions and the ammonia buffer solutions with рН 7.5–8.6 the process of the naphthalene m-1-nitro-6-sulfonic acid electroreduction not only is shifted to more positive potentials as compared with those for KCl solutions, but also further reduction of the hydroxylamino-derivative to amine is facilitated. This is likely to be caused by the high proton-donating ability of \({\text{NH}}_{4}^{ + }\) as compared with water (in the KCl solution the role of proton-donating groups is player by water molecules), which makes possible the protonation of nitro- and hydroxylamino-groups, recombination of the naphthalene 1-nitro-6-sulfonic acid anions with the proton-donors, as well as possible \({\text{NH}}_{4}^{ + }\) participation in the formation of electroactive species (ionic pairs) with the naphthalene 1-nitro-6-sulfonic acid anions [9].

In the presence of ammonium chloride, nitrobenzene is chemically reduced to aniline with higher yield than in the presence of other electrolytes (MgCl2, CaCl2, Na2SO4, KCl); the positive effect is even stronger in the case of α-nitronaphthalene reduction [10]. Under these conditions, in the presence of ammonium chloride the solution рН falls within 7.6–8.4; with calcium chloride, within 11.0–11.75.

As shown earlier [4], the preparative electroreduction of the nitro-Cleve’s acids’ technical mixture proceeds more efficiently at cathodes made of lead, copper, titanium, and nickel. Therefore, we used these metals as cathodes for the naphthalene 1-nitro-6-sulfonic acid electroreduction in potentiostatic mode. Preliminarily, we measured polarization curves of the naphthalene 1-nitro-6-sulfonic acid reduction at these cathodes in ammonia buffer solution (0.22 N NH4Cl + NH4ОН) with рН 8.3 (Fig. 6).

We see from Fig. 6 that the naphthalene 1-nitro-6-sulfonic acid reduction polarization curves measured at titanium, copper, nickel, and lead electrodes show a single reduction current wave with Е1/2 –0.93, –0.72, –0.48, and –0.45 V, respectively. The naphthalene 1‑nitro-6-sulfonic acid reduction wave heights are approximately similar.

The naphthalene 1-nitro-6-sulfonic acid potentiostatic reduction was carried out in ammonia buffer solution with рН 8.3 at a nickel cathode because the naphthalene 1-nitro-6-sulfonic acid reduction proceeds with a smaller polarization thereon. Also, the nitro-Cleve’s acids’ technical mixture is electroreduced most effectively in this medium [4]. Results of the studies are summarized in Table 5. Depending on the applied potential, the potentiostatic electrolysis at the nickel cathode produced in the post-electrolysis solutions, along with the naphthalene 1-amino-6-sulfonic acid, also a corresponding naphthyl sulphonic hydroxylamine. The latter, as we see from Table 5 and Fig. 7, is formed with a high yield (84.0–84.7%) at the electrode potentials–0.5…–0.70 V, approaching the half-wave potential.

Dependences of changes in the naphthalene 1‑nitro-6-sulfonic acid (1–4), naphthalene 1-hydroxylamino-6-sulfonic acid (11, 21, 31, 41), and naphthalene 1‑amino-6-sulfonic acid (311, 411) concentrations on the duration of electrolysis in ammonia buffer solution (0.22 N NH4Cl + NH4ОН) with рН 8.3 at different potentials of nickel cathode: (1) –0.50; (2) –0.70; (3) –1.1; (4) ‒1.3 V. The naphthalene 1-nitro-6-sulfonic acid concentration 4 × 10–2 М.

At more negative cathode potentials (–1.1…–1.3 V), first, hydroxylamino-derivative accumulates in the solution, reaching a maximum at a naphthalene 1‑nitro-6-sulfonic acid full conversion into naphthalene 1-amino-6-sulfonic acid. At that, the more negative the electrode potential, the less is the naphthalene hydroxylamine sulfonic acid concentration in the solution during the electrolysis: the naphthalene 1‑amino-6-sulfonic acid forms starting right from the process onset.

In Table 6 we give results of the reduction of the studied naphthalene nitrosulfonic acids in galvanostatic mode. It follows therefrom that the naphthalene 1-nitro-6-sulfonic acid dilute solution reduction in galvanostatic mode in ammonia buffer solution with рН 8.3 at a current density of 1.0 А/dm2 and temperature 25°С occurs with a naphthalene 1-amino-6-sulfonic acid yield of 93.3% and current efficiency of 71%, like in the case of the controlled-potential electrolysis. However, the reduction of the nitro-Cleve’s acids’ isomeric technical mixture gives lower naphthalene aminosulfonic acid yield (77.8%) and current efficiency (58.2%). In addition, the post-electrolysis solution contains nonconverted intermediate naphthyl sulphonic hydroxylamine (with a yield of 11.2%).

The Naphthalene 1-Nitro-6-Sulfonic Acid Preparative Electroreduction

The results presented in Table 6 gave occasion to the more detailed studying in the effects of different technological parameters on the process of the naphthalene 1-nitro-6-sulfonic acid reduction; these factors are the cathode material, solution рН, current density, and temperature.

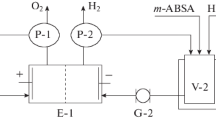

The cathode materials used were: copper, nickel, lead, and the Kh18N10Т stainless steel. Results of the study are given in Table 7 and Figs. 8 and 9.

Dependence of cathode potential on the consumed charge for different cathodic materials: (1) lead; (2) nickel; (3) copper; (4) Kh18N10Т stainless steel. The naphthalene 1-nitro-6-sulfonic acid concentration 4 × 10–2 М, current density 1.0 A/dm2, temperature 25°С, indifferent electrolyte—ammonia buffer solution (0.2 N NH4Cl + NH4ОН) with рН 8.2.

Dependences of changes in the naphthalene 1‑nitro-6-sulfonic acid (1), naphthyl sulphonic hydroxylamine (2), naphthalene 1-amino-6-sulfonic acid (3) concentrations and electrode potential (4) on the passed charge. The naphthalene 1-nitro-6-sulfonic acid concentration 4 × 10–2 М, current density 1.0 A/dm2, temperature 25°С, cathode—N3 grade nickel, indifferent electrolyte—ammonia buffer solution (0.2 N NH4Cl + NH4ОН) with рН 8.3.

We see from the data of Table 7 that the naphthalene 1-amino-6-sulfonic acid yield and current efficiency do depend on the cathode material nature. The lowest yield of the target product and its current efficiency are observed at the lead cathode. The low effectiveness of the naphthalene 1-nitro-6-sulfonic acid reduction at this cathode is likely to be due to the decrease in the actual current density because of the lead electrode corrosion in the alkaline solution, which leads to increase in the cathode surface area. The decrease in the current density leads to the cathode potential shift toward less negative values, as seen from Fig. 8. And this potential shift hampers further reduction of the intermediately formed hydroxylamino-derivative to the naphthalene 1-amino-6-sulfonic acid. Here the naphthalene hydroxylamine sulfonic acid yield comes to about 41.0%.

For all electrode materials, as seen from Fig. 8, we observed gradual potential shift to more negative values as the initial naphthalene 1-nitro-6-sulfonic acid has been consumed. However, when the charge passed approached the theoretical value (~0.3 А h), the potential of the studied cathodic materials differed insignificantly (by 50–100 mV) and came to –0.50…‒0.75 V. Moreover, the initial naphthalene 1-nitro-6-sulfonic acid conversion is 75–80%; the reduction product is naphthalene 1-hydroxylamino-6-sulfonic acid whose yield reached 82–88% (Fig. 9). Further reduction of the formed naphthyl sulphonic hydroxylamine to naphthalene 1-amino-6-sulfonic acid occurs at more negative potentials: –1.1…–1.3 V.

It follows from the obtained results that the most effective naphthalene 1-nitro-6-sulfonic acid reduction to the corresponding amine occurs at the nickel electrode, and this gave occasion to accept this electrode for further studies.

The α-naphthyl hydroxylamine instability in acidic and alkaline media [11] involves the Gattermann rearrangement in acidic medium; formation of dimeric products, in alkaline one. Bearing in mind the instability, we studied рН effects in ammonia buffer solutions (0.2 N NH4Cl + NH4ОН) and in 0.2 N NH4Cl solution, added with hydrochloric acid down to a preset рН value, on the yield of naphthalene 1-amino-6-sulfonic acid. We give results of the study in Table 8 and Fig. 10.

Dependences of changes in the naphthalene 1‑nitro-6-sulfonic acid (1–4), naphthyl sulphonic hydroxylamine (11, 21, 31 and 41), and naphthalene 1‑amino-6-sulfonic acid (111, 211, 311 and 411) concentrations on the passed charge at different solution рН: (1, 11, 111) 1.5; (2, 21, 211) 5.0; (3, 31, 311) 8.2; (4, 41, 411) 10.0. The naphthalene 1-nitro-6-sulfonic acid concentration 4 × 10–2 М, current density 1.0 A/dm2, temperature 25°С, cathode—N3 grade nickel.

We see from the data given in Table 8 that with the increasing of the solution рН from 1.5 to 8.2 the target naphthalene 1-amino-6-sulfonic acid yield and the current efficiency increased from 61.2 to 86.5% and from 26.7 to 56.2%, respectively. Further increase of the solution рН leads to the decreasing of both naphthalene 1-amino-6-sulfonic acid yield and current efficiency.

The naphthalene 1-nitro-6-sulfonic acid conversion rate, as we see from Fig. 10, is practically рН-independent over the studied pH range; upon the passing of theoretical charge (0.3 А h), the naphthalene 1-nitro-6-sulfonic acid conversion degree is about 85.0–90.0%.

At the same time, the concentration of the formed intermediate product (naphthyl sulphonic hydroxylamine) depends on the solution рН; it is maximal in the рН range 5.0–8.2. We obtained the maximal naphthalene 1-amino-6-sulfonic acid yield over this catholyte рН range.

The naphthyl sulphonic hydroxylamine concentration decreased drastically both in the acidic (рН 1.5) and alkaline (рН 10.0) media, its yield does not exceed 30%, which leads to the decreasing of the naphthalene 1-amino-6-sulfonic acid yield. The observed naphthyl sulphonic hydroxylamine instability in acidic and alkaline solutions, like that of α-naphthyl hydroxylamine [11], is likely to be due to the proceeding of the Gattermann rearrangement in acidic medium; to the formation of dimeric side products, in the alkaline one.

Thus, in the ammonia buffer solutions with рН 7.0–8.2 the naphthyl sulphonic hydroxylamine is stable, therefore, the naphthalene 1-amino-6-sulfonic acid, the product of the naphthyl sulphonic hydroxylamine further reduction, is produced with higher yield.

In Table 9 we give results of the studying of the current-density effects on the naphthalene 1-nitro-6-sulfonic acid reduction process.

We see from Table 9 that with the increasing of the current density from 1.0 to 5.0 А/dm2 the naphthalene 1-amino-6-sulfonic acid yield increased from 86.5 to 93.5%; the current efficiency decreased from 56.2 to 39.0%. With the increasing of the current density the electrode potential is shifted sharply to –1.4…–1.5 V, which increased the current fraction consumed in the hydrogen evolution. Additionally, at the current density of 5.0 А/dm2 the electrolysis produced α-naphthylamine. Evidently, at still more negative electrode potentials electrolytic desulphonation occurs, which lowers the naphthalene aminosulfonic acid yield in long-term electrolysis.

In Table 10 we present result of the studying of temperature effects on the naphthalene 1-nitro-6-sulfonic acid reduction process.

We see from Table 10 that with the increasing of temperature from 25 to 60°С the naphthalene 1‑amino-6-sulfonic acid yield and current efficiency decreased from 86.5 to 57.3% and from 56.2 to 29.0%, respectively. With the increasing of temperature the electrode potential becomes less negative, which hampers further reduction of the naphthyl sulphonic hydroxylamine to the naphthalene 1-amino-6-sulfonic acid and brings into being optimum conditions for the side-reactions of condensation involving the initial reagents and intermediate products (Fig. 11) [12, 13]. The dimeric condensation products’ formation is revealed by the solution coloration observed after its electrolyzing at elevated temperatures, as well as in the ammonia buffer solution with рН 10.0.

Dependence of cathode potential on the passed charge at different temperatures, °С: (1) 25; (2) 40; (3) 60. The naphthalene 1-nitro-6-sulfonic acid concentration 4 × 10–2 М, current density 1.0 A/dm2, cathode—N3 grade nickel, indifferent electrolyte—ammonia buffer solution (0.2 N NH4Cl + NH4ОН) with рН 8.2.

In Fig. 12 we give data on the distribution of products of the naphthalene 1-nitro-6-sulfonic acid in the course of its electroreduction at different temperatures. We see from the figure that the initial nitro-compound concentration to high conversion degree decreased proportionally to the electrolysis duration; it depends on the temperature but insignificantly. At the same time, the concentration of the naphthyl sulphonic hydroxylamine intermediate, first, increased linearly, reached its maximum, then, decreased readily after the reaction mass has been exhausted in the nitro-compound.

Dependences of changes in the naphthalene 1‑nitro-6-sulfonic acid (1, 2), naphthyl sulphonic hydroxylamine (11, 21), and naphthalene 1-amino-6-sulfonic acid (111, 211) concentrations on the passed charge at different temperatures: (1, 11, 111) 25°С, (2, 21, 211) 60°С. The naphthalene 1-nitro-6-sulfonic acid concentration 4 × 10–2 М, current density 1.0 A/dm2, cathode—N3 grade nickel, indifferent electrolyte—ammonia buffer solution (0.2 N NH4Cl + NH4ОН) with рН 8.2.

The naphthyl sulphonic hydroxylamine concentration depends significantly on the temperature; it decreased readily upon its increasing up to 60°С. At that, the naphthyl sulphonic hydroxylamine yield does not exceed 25.0%; that of the naphthalene 1-amino-6-sulfonic acid comes to 57.3%. Seemingly, at elevated temperatures, as well as in ammonia buffer solutions with рН 10.0, we have simultaneous nitro-compound electroreduction and the corresponding naphthyl sulphonic hydroxylamine conversion to the naphthalene 1-amino-6-sulfonic acid, which is confirmed by the latter’s formation starting with the electrolysis onset (Figs. 10, 12). The simultaneity of the transformations may be explained by the occurring of the naphthyl sulphonic hydroxylamine disproportionation reaction, which produced nitroso-compounds and amines. This reaction discovered by Bamberger is characteristic of aromatic hydroxylamino-derivatives and depends on reaction medium (it is catalyzed by both acid and base), the substituents nature, and temperature [14–16]; also, it can be initiated by oxygen traces and iron compounds [17].

Thus, the reduction of the naphthalene 1-nitro-6-sulfonic acid dilute solutions in the galvanostatic mode produced the same final compounds as the controlled-potential electrolysis. The naphthalene 1-nitro-6-sulfonic acid is reduced most effectively at nickel and Kh18N10Т-steel electrodes in the ammonia buffer solution with рН 7.0–8.2 at temperature of 25–30°С and current density of 5.0 A/dm2.

The discovered conditions of the naphthalene 1‑nitro-6-sulfonic acid and Cleve’s acids’ isomeric mixture [4] electrosynthesis were approbated by using an enlarged laboratory setup with a filter-press cell (Table 11).

The data presented in Table 11 shows that the naphthalene 1-nitro-6-sulfonic acid is reduced under the preparative electrolysis conditions, giving the naphthalene 1-amino-6-sulfonic acid with a yield of 87.0–92.0% and current efficiency of 38.0–42.0%. With the increasing of temperature from 30 to 55°С the naphthalene 1-amino-6-sulfonic acid yield decreased down to 72.8%. The yield of the naphthalene 1-amino-6-sulfonic acid isolated from post-electrolysis solution does not depend on the reduction conditions; it comes to 69.0–80.0%.

The preparative reduction of the nitro-Cleve’s acids’ mixture produced Cleve’s acids with a yield of 85.0–94.0%. A lower yield of naphthalene aminosulfonic acids is reached at temperature 50–60°С. However, at the nitro-Cleve’s acids’ portion loading during the reduction process, the Cleve’s acids’ yield increased up to 93.6–93.8% (at the temperature of 60–62°С), as is sometimes the case during the chemical reduction [1, 18, 19]. In the post-electrolysis solution the ratio of the isomeric naphthalene aminosulfonic acids (measured by the high performance liquid chromatography on a per the amine sum basis) is: 1,6‑Cleve’s acid 44–45%, 1,7-Cleve’s acid 40–45%, 1,8-Peri-acid 8–10%. After the chemical reduction of nitro-Cleve’s acids the reaction mixtures have the same isomeric composition.

However, the Cleve’s acids’ yield upon their recovery from the post-electrolysis solutions (Table 11) is 39.0–43.7% (cf. with 52.0–56.0% at the chemical reduction [19]); in addition, the Cleve’s acid spread isolated from the reaction masses after the existing industry procedure is enriched with the 1,7-Cleve’s acid isomer (80–90% of the amines’ summary amount). The relatively low yield of the Cleve’s acids’ recovery from solutions, as well as the changes in the naphthalene aminosulfonic acids’ isomeric composition in the isolated product, are likely to be due to the side-products formed in the course of the electrolysis and registered in the cyclic voltammograms taken in the post-electrolysis solutions [4], as well as those formed in the preceding stages of the naphthalene sulphonation and nitration, in particular, to α-nitronaphthalene reduced to α-naphthylamine during the electrolysis. This is confirmed by the reduction of naphthalene 1-nitro-6-sulfonic acid isolated from the nitro-Cleve’s acids’ isomeric mixture and purified by re-crystallization from water, which gives a yield of 69.0–80.0% for the naphthalene 1-amino-6-sulfonic acid recovery from solution. In addition, the lowering of the Cleve’s acids’ recovery from solution can be related to their oxidation products, as well as side-products. A post-electrolysis amino-derivative-containing solution darkens instantly in air producing resinous substances. Our studies of the naphthalene aminosulfonic acids’ oxidation at glassy carbon electrode showed that the naphthalene 1-amino-6-sulfonic acid is much readily oxidizable than naphthalene 2-amino-4,8-disulfonic acid and 1-amino-3,6,8-trisulfonic acid, which can be recovered from solutions with a yield of 88–90% [20] and 70–80% [21], respectively. In particular, in a Britton–Robinson buffer solution with рН 5.2 Еp for the naphthalene 1-amino-6-sulfonic acid oxidation at glassy carbon electrode is +0.50 V; for the naphthalene 2-amino-4,8-disulfonic acid, +0.83 V; for the naphthalene 1-amino-3,6,8-trisulfonic acid, +0.77 V. Additionally, the intermediately formed naphthyl sulphonic hydroxylamine, a nonstable product, which is accumulated in the course of the electrolysis depending on its conditions (Figs. 10 and 12), can remain in the electrolysis reaction products (Table 6) [4]. We see from Figs. 3–5 that the naphthyl sulphonic hydroxylamine is oxidized to the corresponding nitroso-compound even easier than the naphthalene 1-amino-6-sulfonic acid both in acidic and weakly alkaline media. At that, dimeric side-products can also be formed [12], which are likely to hinder the recovery of target isomeric naphthalene aminosulfonic acids from solutions.

At the same time, the α-naphthyl amine, one of the side-products, containing in the technical isomeric mixture, is more readily oxidizable then the naphthalene 1-amino-6-sulfonic acid. For example, in ammonia buffer solutions (0.4 N NH4Cl + NH4OH) with рН 8.4 the values of Еp for the 1-amino-6-sulfonic acid and α-naphthyl amine oxidation at the glassy carbon electrode are +0.23 and +0.10 V, respectively.

The obtained results allow concluding that important factors for the nitro-Cleve’s acids’ technical isomeric mixture effective electrochemical reduction and the Cleve’s acids’ isolation from reaction solutions are: the preliminary cleaning of the nitro-Cleve’s acid initial solution and arrangement of conditions excluding oxidation of the produced naphthalene aminosulfonic acids, the intermediate and side products during the electrolysis and at the stage of the Cleve’s acid ex-solution, in particular, the realization of these technological stages under nitrogen atmosphere.

CONCLUSIONS

The obtained results allow deriving the principal conclusions:

(1) General features of the naphthalene 1-nitro-6-sulfonic acid electrochemical reduction in acidic, as well as ammonium-chloride and in ammonia buffer solutions were found by the methods of polarography and voltammetry at glassy carbon electrodes, microelectrolysis in potentiostatic mode at glassy carbon, and electrolysis at controlled potential and in galvanostatic mode.

(2) It has been established that the naphthalene 1‑nitro-6-sulfonic acid, like the α-nitronaphthalene and naphthalene 1-nitro-3,6,8-trisulphonic acid, is polarographically reduced in a strong acidic medium to the corresponding naphthalene 1-amino-6-sulfonic acid in a single six-electron stage via an intermediately formed hydroxylamine. The very presence of the single six-electron wave is likely to be explained by the easiness of reduction of the carbonium ion produced in the dehydration of protonated hydroxylamine-derivative with iminoquinoid structure.

(3) The polarographic reduction of the naphthalene 1-nitro-6-sulfonic acid nitro-group in strongly acidic medium includes a preceding surface protonization; it starts at positively charged dropping mercury electrode surface. Deceleration of the process at negatively charged dropping mercury electrode surface manifesting itself as a decrease of the polarographic current is related to anionic character of the species being reduced, which is caused by the presence of acidic sulfonic group in the molecules.

(4) The naphthalene 1-nitro-6-sulfonic acid anionic nature in neutral and alkaline solutions manifests itself as complicated form of polarization curves recorded both at a dropping mercury and glassy carbon electrodes and their changing characteristics depending on the supporting electrolyte concentration, nature, and рН.

(5) The nature of separate stages of the naphthalene 1-nitro-6-sulfonic acid reduction is established using the methods of microelectrolysis in potentiostatic mode at glassy carbon electrode and electrolysis at controlled potential and in galvanostatic mode, as well as aminoacid electroreduction at glassy carbon. The intermediate and final reaction products are found and identified, namely: the naphthalene 1‑nitro-6-sulfonic acid radical-anions, naphthalene hydroxylamino- and aminosulfonic acids.

(6) The parameters recommended for the naphthalene 1-amino-6-sulfonic acid preparative electrosynthesis are: ammonia buffer solutions with pH 7.0–8.2, the current density 5–10 A/dm2, temperature 30–32°C, and the concentration of naphthalene 1-nitro-6-sulfonic acid 10–13%. They provide the target product yield of 87.0–93.5% and the current efficiency of 38.0–42.4% on the N3 grade nickel and Kh18N10Т stainless steel cathodes. At that, the naphthalene 1‑amino-6-sulfonic acid recovery from post-electrolysis solution is 69.0–80.0%, independently of the reduction conditions.

(7) To increase the Cleve’s acid recovery from the post-electrolysis solutions, preliminary cleaning of the initial nitro-Cleve’s acid technical isomeric mixture is required, as well as arrangement of conditions excluding the oxidation of the produced intermediate and side products during the electrolysis and at the stage of the target Cleve’s acid ex-solution.

REFERENCES

Vorozhtsov, N.N., The Fundamentals of Synthesis of Intermediate Products and Dyes (in Russian), Moscow: Goskhimizdat, 1955.

The Chemistry of Synthetic Dyes, Venkataraman, K. (Ed.), Academic, 1974.

Fierz, H.E. and Weissenbuch, P., Uber die Reduktion von Nitronaphtalinssulfosauren, Helv. Chim. Acta, 1920, vol. 3, p. 305.

Konarev, A.A., Electrochemical synthesis of Cleves-acids, Russ. J. Electrochem., 1998, vol. 34, p. 1160.

Konarev, A.A., RF Patent 2159424, 2000.

Konarev, A.A. and Avrutskaya, I.A., Features of electrochemical reduction of 1-nitro-3,6,8-trisulfonic acid of naphthalene, Russ. J. Electrochem., 1988. vol. 24. p. 1548.

Jubault, M. and Peltier, D., Reduction electrochimique a potentiel controle des nitronaphtalenes substitues. Etudes preliminaries, Bull. Soc. Chem. France, 1972, no. 4, p. 1544.

Stradins, J., Polarography of Organic Nitrocompounds (in Russian), Riga: Latvian Akad. Nauk, 1961.

Kvaratskheliya, R.K. and Kvaratskheliya, E.R., On peculiarities of electrochemical behavior of I(5+) and I(7+) compounds in ammonium salt solutions, Russ. J. Electrochem., 1996, vol. 32, p. 868.

Lukashevich, V.O., Organic Semiproducts and Dyes (in Russian), Moscow: Goskhimizdat, 1959.

Jubault, M. and Peltier, D., Reduction electrochimique a potentiel controle des nitronaphtalenes substitues. Influence des substituents, Bull. Soc. Chim. France, 1972, no. 4, p. 1551.

Tomilov, A.P., Mayranovsky, S.G., Fioshin, M.Ya., and Smirnov, V.A., Electrochemistry of Organic Compounds (in Russian), Leningrad: Chemistry, 1968.

Bamberger, E., Arylhydroxylamine und Arylazideeine Parallele, Ann., 1921, vol. 424, p. 233.

Heller, H.E., Hughes, E.D., and Ingold, C.K., A New View of the Arylhydroxylamine Rearrangement, Nature, 1951, vol. 168, p. 909.

Bamberger, E. and Lagutt, G., Uber das Verhalten des Phenylhudroxylamins gegen alkoholische Schwefelsaure und gegen Anilin, Ber. Bunsengesellschaft, 1898, vol. 31, p. 1500.

Simonov, V.D., Denisenko, T.V., and Savchenko, V.I., Study of decomposition reaction of phenylhydroxylamine and its derivatives in presence of hydrogenation catalysts, Russ. J. Organic Chem., 1976. vol. 12. p. 1036.

Mizuch, K.G., Collateral oxidation processes in reduction of aromatic nitrocompounds, Dokl. Phys. Chem., 1937, vol. 15, no. 1, p. 37.

Fierz-David, H.E. and Blangey, L., Grundlegende Operationen der Farbenchemie, Wien: Springer, 1952.

Donaldson, N., The Chemistry and Technology of Naphthalene Compounds, London: Edward Arnold, 1960.

Konarev, A.A., Pomogaeva, L.S., Vorotnikova, E.Yu., et al., RF Patent 2009125, 1994.

Konarev, A.A., Katunin, V.Kh., and Sukhinina, N.G., USSR Inventor’s Certificate no. 1369232, 1987.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author declares the absence of conflict of interest.

Additional information

Translated by Yu. Pleskov

Rights and permissions

About this article

Cite this article

Konarev, A.A. Electrochemical Behavior of Naphthalene 1-Nitro-6-Sulfonic Acid. Russ J Electrochem 57, 1–15 (2021). https://doi.org/10.1134/S1023193521010055

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193521010055