Abstract

The electrochemical behavior of m-nitrosulphonic acid of benzene was studied by polarography, voltammetry at glassy carbon electrode, electrolysis at the controlled potential, and electrolysis in galvanostatic mode. A distinguishing feature of the m-nitrosulphonic acid of benzene electroreduction, as compared with that of aromatic nitro-compounds, both on mercury dropping electrode and glassy carbon electrode, is shown to be a strong dependence of parameters and shape of the polarization curve on the supporting electrolyte solution composition and рН in neutral and alkaline solutions. The two waves observed are bound to the reduction of undissociated m-nitrosulphonic acid of benzene molecule and its anion; the reduction intermediately product is hydroxylaminesulphonic acid of benzene. The wave of its further reduction to m-aminosulfonic acid of benzene is camouflaged by the supporting-electrolyte discharge. Ammoniac-buffered solutions can be recommended for preparative electrosynthesis of m-aminosulfonic acid of benzene because its yield in the electrolysis at nickel cathode in galvanostatic mode in these solutions is as high as 92.8%, with current efficiency of 82.0%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

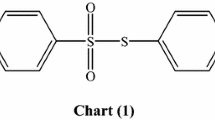

The benzene m-aminosulfonic acid (m-ASAB) is used in the manufacturing of azo-dyes [1]. The starting material in the m-ASAB industrial synthesis is nitrobenzene, which is sulphonated with oleum; thus obtained corresponding benzene m-nitrosulfonic acid (m-NSAB) is neutralized with powder chalk in the presence of sodium carbonate, then reduced, as a sodium salt in concentration of 140–180 g/L, with cast-iron turnings ammoniac-alkaline solution at the boiling temperature [2]. Upon the reduction, the reaction mass is neutralized with caustic ash up to рН 7.5–8.0, filtered, and boiled-down to the m-ASAB concentration of 225–250 g/L. The target product is worked up from the solution by acidifying of the amine solution with concentrated sulfuric acid down to рН 1.5–2.0. The m-ASAB final yield for the reduction and product isolation from the solution came to 76.0%. The lack of the chemical method of m-ASAB preparation is its multistage and labor-consuming nature, a great deal of solid waste in the form of nonrecyclable iron spent slurry, and low purity of the target product.

To improve and simplify the stage of the aromatic nitrosulfonic acid reduction, the progress is sought for by using two methods: catalytic hydrogenation and electroreduction. In patent literature [3] a method is described how to manufacture aromatic aminosulfonic acids by catalytic hydrogenation of alkali salts of the corresponding nitrosulfonic acids in water or water-alcohol solutions at temperatures of 50–100°С and elevated pressure, preferably 50–200 atm. When m-NSAB sodium salt is hydrogenated in this way, the m-ASAB yield comes to 94%. In addition, platinum, palladium, and ruthenium sulfides can be used as catalysts in the m-NSAB (Na-salt) reduction [4]. Also, m-ASAB can be prepared by m-NSAB catalytic reduction at Raney nickel as catalyst in 85% yield [5].

The data on the m-NSAB electrochemical reduction are few and do not give clear vision of optimal conditions of the process, which allow obtaining high yield of the target product. The effects of temperature, current density, the nitro-compound and sulfuric acid concentrations on the m-NSAB reduction at copper cathode were studied [6]. High yields in m-ASAB and current efficiencies (nearly 100%) are achieved in sulfuric acid solutions at low concentrations of the primary nitro-compound (0.02–0.2 М) at a current density of 0.25 А/dm2 and temperature of 80°С. With the increasing of current density, sulfuric acid concentration, and that of the primary nitro-compound in catholyte, the efficiency decreased. Such a process is of no interest for the development of m-ASAB manufacturing technology by using the m-NSAB electroreduction method, indeed, because of its low productiveness and large energy consumption, caused by the aminic solution boiling down at the stage of the target product work up. Meanwhile, we have shown recently [7] that the preparative electrosynthesis of the 1,6- and 1,7-naphthaleneaminosulfonic acids (Cleves-acids) isomeric mixture from the corresponding nitrosulfonic acids can be successively carried out in ammoniac buffer medium at a nickel or stainless steel cathode, in 88–93% yield and 58–60% current efficiency. Therefore, it is of interest to study m-NSAB electrochemical behavior in ammoniac buffer solutions in more details. Results of the study can be used in the developing of the m-ASAB electrosynthesis conditions acceptable for industrial applications.

EXPERIMENTAL

Polarograms were taken by using a PU-1 polarograph. A dropping mercury electrode with forced droplet detachment (using a spatula) in 0.1 N КСl solution at open circuit potential and a mercury column height of 50 cm has the following characteristics: m = 1.0 mg/s, t = 0.65 s. Potentials are given against saturated calomel electrode (SCE).

Supporting electrolytes were Britton–Robinson buffer solutions with рН 2.0–11.0 and constant ionic strength 0.5 М, НС1, Н2SO4, and NaOH solutions with concentration 0.1–1.0 N and ammoniac buffer solutions (рН 5.0–9.0), as well as ammonium chloride solutions concentration 0.01–1.0 N.

Polarization curves were recorded at glassy carbon (SU-2000) using a PU-1 polarograph in differential mode. A steady-state electrode we used was end-face of glassy carbon rod, 2 mm in diameter, pasted in glass envelope [8].

Cell for the polarization curve registration is a conical glass with a volume of 20 сm3 with jacket for thermostatic control. Saturated calomel half-cell was the reference electrode; all potential values are given with respect to this electrode. Another saturated calomel half-cell served as auxiliary electrode.

To obtain reproducible results, glassy carbon was treated with fine polishing paper, then polished to high finish at a felt impregnated with glycerol and alumina. Upon being washed with distilled water, the electrode was exposed to concentrated sulfuric acid, then washed again thoroughly. Right prior to the voltammogram recording, the electrode was washed with water and dried with filter-paper. The electrode was then dipped to electrolyte pre-deaerated with inert gas, to remove dissolved oxygen.

To identify the m-NSAB reduction products, as well as evaluate its efficiency, we carried out electrolysis at controlled potentials by using a P-5848 electronic potentiostat. The electrolysis with different metal-cathodes was performed in a cylindrical glass cell with jacket for thermostatic control; the anodic and cathodic compartments were separated with a МК-40 cation-exchange membrane. The electrochemical cell has ground-in cover provide with joints for current collectors and sleeves for sampling, connecting Luggin capillary, and nitrogen supply. A cathode made of the studied metal was mounted at the cell bottom. The current collector was a stem sealed-in to a glass tube. To agitate the catholyte, a magnet stirrer was used. A platinum plate served as anode; sulfuric acid 10%-solution, the anolyte. The catholyte volume was 70 mL.

Potentials were set in accordance with the data obtained in polarization measurements at solid electrodes.

During the electrolysis, changes in the initial nitro-compound and reaction products were monitored by using polarography and voltammetry therefor [8].

The m-NSAB reduction in galvanostatic mode was carried out in the same electrochemical glass cell as the electrolysis at fixed potentials.

For polarographic and voltammetric studies, both substances, m-NSAB and m-ASAB, were purified by twice-repeated crystallization from deionized water.

Concentration of intermediate, benzene hydroxylaminosulfonic acid, was determined by voltammetry in differential mode in 1 М NaOH as a supporting solution [8]; that of m-ASAB, by diazotization, counting per diazotized products with molecular mass 173.

The target product, m-ASAB, was separated from post-electrolysis solution by its acidifying with sulfuric acid until the reaction mass рН of 1.5–2.0 at temperature of 75–80°С, with subsequent cooling at 50°С, then down to 20–22°С.

RESULTS AND DISCUSSION

The m-NSAB Polarographic Reduction

Polarograms of the m-NSAB sodium salt in 0.1 N sulfuric or hydrochloric acid solutions as supporting electrolytes, as well as buffer solutions with рН 1.96–3.5 we see two waves (Fig. 1) characteristic of the aromatic nitro-compound reduction [9]. In acid buffer solutions, the second wave is weakly pronounced, its height is one half as high as that of the first one. With the increasing of the supporting electrolyte рН the second wave height drops down; at рН 4.6 the wave disappears completely.

The height of the first wave of m-NSAB reduction keeps its nearly constant value over the entire studied рН range (Fig. 1).

With the increasing of рН the value of Е1/2 for the first wave of m-NSAB reduction becomes more negative. Over the рН range from 1.0 to 8.0 the ratio ∆Е1/2/∆рН is 55.8 mV/рН. In solutions with рН exceeding 8.0 the value of Е1/2 for the first wave remains constant; from –0.74 to –0.76 V.

The limiting current Id of the first wave of m-NSAB reduction in 0.1 N Н2SO4 solution depends linearly on the m-NSAB concentration; also, Id is a linear function of the square root from the mercury column height, the dependence crossing the origin. The temperature coefficient is 1.69%/degree. These data points to the diffusion nature of the limiting current.

The number of electrons involved to the electrode process was estimated by the comparing of the reduction wave height for nitrobenzene (that is reduced in strongly acidic medium in two stages to amino-compound with total consuming of six electrons; in alkaline medium, to hydroxylamino-compound with total consuming of four electrons [9]) with that for m‑NSAB under identical conditions. At that, the reduction wave height for m-NSAB both in strongly acidic and alkaline media is equal to that for nitrobenzene. Therefore, it is believed that the m-NSAB polarographic reduction in strongly acidic medium proceeds with total consuming of six electrons: first, the corresponding hydroxylamine is formed, with consuming of four electrons (the first wave), following by a two-electron reduction stage with the forming of m-ASAB (the second wave). In alkaline medium, the reduction reaction consumes four electrons, producing the corresponding benzene m-hydroxylaminesulfonic acid.

In ammoniac buffer solutions (0.1 N NH4Cl + NH4OH) with рН 5.0–9.0 the m-NSAB polarograms show a single wave. At that, the limiting current and Е1/2 practically do not change over the studied рН range; the wave height decreased but insignificantly (Table 1).

The limiting current Id of the first wave of m-NSAB reduction in ammoniac buffer solutions with рН 9.0 depends linearly on the m-NSAB concentration, the dependence crossing the origin. At the same time, the Id dependence on the square root from the mercury column height intercepts the abscissa axis; the temperature coefficient is 0.65–0.97%/degree. The data is likely to evidences the effect of adsorption of the initial nitro-compound or its reduction products on the m‑NSAB electroreduction wave limiting current.

The effect of the solution ionic strength on the m‑NSAB electroreduction electrode in ammoniac buffer solutions with рН 8.8–8.9 (Fig. 2) and NH4Cl solution with рН 4.9–5.0 (Fig. 3) was studied on the dropping mercury electrode. At the NH4Cl low concentration (0.01 N) m-NSAB polarograms contain two waves both in weakly acidic and weakly alkaline media. The waves are not characteristic of aromatic nitro-compounds [9], Their heights ratio depends on the supporting electrolyte concentration and рН. From Figs. 2 and 3 we see that with the increasing of the solution рН up to 8.8–8.9 in 0.01 N NH4Cl supporting electrolyte solution the height of the first wave decreased; of the second one, increased. As the electrolyte concentration increased, the waves merged, and the summary wave shifts markedly toward less negative potentials. In particular, with the increasing of NH4Cl solution concentration from 0.01 to 1.0 N Е1/2 in weakly acid solutions moved by 190 mV; in weakly acidic, by 230 mV toward anodic potentials. The height of the summary wave increased but insignificantly.

Voltammetric Measurements at Glassy Carbon

In the cathodic branch of cyclic differential polarization curves taken at glassy carbon electrode in 0.1 N sulfuric acid solution, as well as in Britton–Robinson buffer solutions with рН 1.96–7.02, we observed a single irreversible peak of m-NSAB electroreduction (Table 2). From Table 2 we see that the m-NSAB reduction first peak potential shifts to more negative potentials, whereas at рН 7.02–14.0 it no longer depends on рН and is from –0.91 to –0.92 V. At the same time, the second cathodic peak potential also shifts to more negative potentials (from –1.2 to –1.46 V) with the increasing of the supporting solution рН from 8.1 to 14.0.

With the increasing of the solution рН the height of the m-NSAB reduction peak decreased; in the buffer solutions with рН 8.1–9.6, as well as in 0.1 N NaOH solution, the peak becomes splitted into two peaks with different height ratio. Note that with the increasing of the background solution рН the height of the first cathodic peak continued decreasing; that of the second one, increased.

When the potential scanning direction is reversed from the potential of –1.5 V we observed an anodic current peak at potentials from –0.04 to +0.14 V, depending on the supporting solution рН. To elucidate the anodic peak nature, we studied the m-ASAB electrooxidation at glassy carbon electrode in different supporting solutions. From Fig. 4 we see that m‑ASAB is subject to anodic oxidation at more positive potentials as compared with the oxidation peaks given in Table 2. In particular, in 0.1 N НСl, 0.1 N NH4Cl, and ammoniac buffer solutions with рН 7.3 and 9.0 the m-ASAB oxidation peak is observed at Еp = 0.81 V, Еp = 0.69 V, and Еp = 0.64 V and Еp = 0.57 V, respectively. As the supporting solution рН increased, the peak shifts to less positive potentials (Fig. 4). Therefore, the anodic peak potentials given in Table 2 are likely to correspond to the reduction of an intermediate hydroxylamine derivative to the corresponding nitroso compound. Aromatic hydroxylamine compounds, in particular hydroxylaminesulfonic acids, are known to be reduced easily at anodes [7–10].

It follows from Table 3 that in ammoniac buffer solutions with рН 5.0–9.0 at cathodic potentials we also observed an irreversible peak (wave) of the m‑NSAB reduction, whose height and Еp varied but insignificantly over the studied рН range.

However, with the increasing of supporting solution рН up to 9.0 the m-NSAB reduction peak (wave) becomes splitted into two peaks (waves). A similar effect is observed in the Britton–Robinson alkaline buffer solutions with рН 8.1–9.6 (Table 2), as well as at dropping mercury electrode over this рН range (Fig. 2).

The supporting solution ionic strength effect on the m-NSAB electroreduction at glassy carbon electrode is illustrated by Fig. 5, from which we see that the voltammogram cathodic branch comprised two peaks (two waves in the classical mode: Fig. 5а).

From Fig. 5 we see that for the first cathodic peak (Fig. 5b, curve 3) Еp equals –0.83 V; for the second, ‒1.05 V. With the increasing of the solution ionic strength the m-NSAB cathodic peaks (waves) moves toward less negative potential values. For example, with the increasing of the NH4Cl concentration from 0.01 to 1.0 N the Еp value for the first and the second peaks (waves) are shifted toward anodic potentials by 170 and 470 mV, respectively. At that, the first cathodic peak becomes significantly higher; the second one, lower. However, the height of the summary wave increased but insignificantly (Fig. 5а). When the potential is scanned in the anodic direction from ‒1.65 V, the voltammograms contain two oxidation peaks (in the curve 3, Fig. 5b, these are: peak А1 with ЕP = –0.83 V and peak А2 with Еp = –0.25 V). The anodic peak А2, like in the Britton–Robinson buffer solutions (Table 2), is likely to correspond to reduction of the hydroxylaminesulphonic acid of benzene, which is produced in the course of the m-NSAB electroreduction to the corresponding nitroso compound [7–10]. Note that the first anodic peaks А1 (curves 2 and 3) and the first cathodic peaks (curves 2 and 3) are observed at the same potential Еp equal to –0.83 V and the height of the anodic peaks А1 is approximately by factor of 4 less than that of the first cathodic peaks, which points to the reversible and one-electron character of the oxidation process. Hence, one may suggest that the anodic peak А1 relates to the radical-anion reversible oxidation to the initial compound. The cathodic wave related to the radical-anion formation is likely to be camouflaged by the summary four-electron wave of the hydroxylamine derivative synthesis.

The changes in the relation between the cathodic peak (wave) height and the supporting solution composition are unrelated to the nitro-group electroreduction selectivity; the m-NSAB electroreduction product is hydroxylaminesulphonic acid of benzene, which is readily oxidizable. It produced the anodic peak А2 in the voltammograms, which is characteristic of the aromatic nitro-compound electroreduction, including aromatic nitrosulphonic acids [7–10]. In addition, when cyclic voltammograms are taken in these supporting electrolyte solutions, no target m‑ASAB formation is observed (Fig. 5b), which is evidenced by the absence of its anodic peak, which must manifest itself at Еp = 0.57 V, as shown in Fig. 4.

At the same time, both in strongly acidic (0.1 N Н2SO4) and in ammoniac buffer solution (0.7 N NH4Cl + NH4OH, рН 8.4) in the microelectrolysis at glassy carbon electrode at the electrode potentials from –1.2 to –1.4 V and from –1.4 to –1.6 V, respectively, for 10–30 min and subsequent potential scanning in anodic direction voltammograms show not only two anodic peaks А1 and А2 at the electrode potentials from –0.65 to –0.85 V and from –0.25 to +0.15 V, respectively, but also a peak of the target m‑ASAB oxidation at the electrode potential of 0.6–0.75 V. This is confirmed by the spiking of the latter (peak А3 in Fig. 6, peak А3 in Fig. 7).

Classic voltammogram of m-NSAB reduction (1), cyclic differential voltammogram of m-NSAB reduction (2) in 0.1 N Н2SO4 solution, and differential voltammograms of oxidation of the m-NSAB reduction products formed at different potentials for 30 min: Е = –1.2 V (3); Е = –1.4 V (4), and differential voltammogram of m-ASAB oxidation (5). The m-NSAB concentration 1.96 × 10–4 М, the m-ASAB concentration 1.9 × 10–4 М, the potential scanning rate: 20 mV/s.

Classic voltammogram of m-NSAB reduction (1), cyclic differential voltammogram of m-NSAB reduction (2) in ammoniac buffer solution (0.7 N NH4Cl + NH4OH, рН 8.4), and differential voltammograms of of oxidation of the m-NSAB reduction products formed at different potentials for 30 min: Е = –1.4 V (3); Е = –1.6 V (4), and differential voltammogram of m‑ASAB oxidation (5). The m-NSAB concentration 1.9 × 10–4 М, the m-ASAB concentration 1.9 × 10–4 М, potential scanning rate: 20 mV/s.

We see from Figs. 6 and 7 that the anodic limiting currents ratio, hence, that of the final products formed, depends on the electrode potential applied, as well as the supporting electrolyte nature and concentration. In particular, during the microelectrolysis for 30–60 min at glassy carbon electrode in the ammoniac buffer solution (рН 9.0) and low NH4Cl concentration (0.01 N) at the electrode potentials of –1.2 V and –1.6 V, which correspond to the limiting currents of the waves in the voltammogram no m-ASAB formation occurs. Instead, it is the hydroxylaminesulphonic acid of benzene that appeared the microelectrolysis product (Table 4).

It follows from the above-given results that in both strongly acidic (0.1 N Н2SO4) solution (Table 2; Fig. 6, curves 2 and 3) and in neutral and alkaline media (Britton–Robinson buffer solutions, Table 2), as well as in ammoniac buffer solutions (Fig. 7, curves 2 and 3) the m-NSAB is reduced at glassy carbon electrode in a single-stage four-electron reaction, producing hydroxylamine derivative. The latter is confirmed by the registration of cyclic voltammograms during its reduction and the microelectrolysis at the electrode potentials corresponding to limiting currents of the registered waves (peaks) (Figs. 6 and 7), as well as the data on the target m-ASAB anodic behavior (Fig. 4). The subsequent two-electron stage resulting in the m‑ASAB formation is camouflaged by the supporting electrolyte discharge, which was shown by the microelectrolysis carried out at the electrode potentials –1.4 and –1.6 V (Fig. 6, curve 4; Fig. 7, curve 4) and the m‑ASAB spiking into the supporting solution (Fig. 6, curve 5; Fig. 7, curve 5).

Dependence the m-NSAB electroreduction involves protons, we studied its reduction at glassy carbon electrode in solutions of different acidity in the presence of proton donors of different chemical nature. In Table 4 we summarized data on the m‑NSAB electroreduction at glassy carbon electrode in the galvanostatic mode of microelectrolysis at potentials of limiting currents in different supporting electrolytes.

It follows from the data of Table 4 that the product of the m-NSAB electroreduction at glassy carbon electrode in the studied supporting solutions at the potentials corresponding to limiting currents of the first and second waves is the corresponding hydroxylamine derivative. At the electrode potentials approaching those of the supporting electrolyte discharge (from –1.6 to –1.7 V) m-ASAB is also produced, along with the hydroxylamine derivative. Similar results were obtained in 0.1 N H2SO4 solution. However, in 1 N КСl solution and ammoniac buffer solution with 0.01 N NH4Cl, рН 9.0 even at the electrode potential of –1.6 V no further reduction of the hydroxylamine derivative to the corresponding m‑ASAB was observed. It is likely to be due to the difficulties in the protonation of the hydroxylamine-derivative intermediate in these supporting solutions.

In NH4Cl solution and ammoniac buffer solution with рН 7.5–8.4 the m-NSAB electroreduction process not only is shifted toward more positive potentials, as compared with KCl solution, but also further reduction of the derivative to amine is facilitated (Table 4). This is likely to be caused by the \({\text{NH}}_{4}^{ + }\) ready proton availability as compared with water (in KCl solutions water molecules are the proton donors). Water protonates nitro- and hydroxylamine groups, favors the m-NSAB anions recombination with proton donors and possibly involves \({\text{NH}}_{4}^{ + }\) to the formation of electroactive species (ion pairs) with the m-NSAB anions [11].

The distinguishing feature of m-NSAB electroreduction, as compared with the aromatic nitro-compound electroreduction [9] both at mercury dropping electrode and glassy carbon one is strong dependence of the polarization curve parameters and shape on the supporting solution concentration and рН.

Observed differences in the m-NSAB electrochemical behavior in neutral and weakly alkaline solutions, as compared with nitrobenzene and its derivatives [9], are apparently due to the presence of sulfo group in its molecule. It is known that aromatic sulfonic acids are among strong acids (they approach hydrochloric and sulfuric acids in its strength [12]) and are present in the solution bulk in their dissociated state. Taking this into account, it can believed that m‑NSAB is subject to the electroreduction as anion and neutral molecules, whose ratio depends on the solution рН. With the increasing of the supporting solution рН the m-NSAB anion concentration increased, and two waves appear in polarographic curves, of which the first one relates to the m-NSAB neutral molecules’ electroreduction; the other one (observed at more negative potentials), to the m-NSAB anions. In weakly acidic solutions, the m-NSAB anion concentration decreased, probably, because of the anions’ recombination with proton donors. This results in the change of the discharging species nature; the second wave is weakly pronounced, as we see from Fig. 3. By contrast, in weakly alkaline solutions the m‑NSAB anion fraction is likely to increase, and the second wave in polarograms is well pronounced (Fig. 2). At that, the height of the summary wave increased but insignificantly (Fig. 2).

The rate of irreversible electrochemical processes involving anions depends significantly on the electrical double layer structure that depends, in its turn, on the solution ionic strength [13, 14]. The increasing of the ionic strength results in the decreasing of ψ1‑potential and the electrode negative charge and increase of the supporting electrolyte cation adsorption. The latter facilitates the ion pair formation between the discharging anions and the supporting electrolyte cations, which all in all leads to the polarogram shift toward positive potentials. All that must bring forward the m-NSAB anion near-electrode concentration and accelerate their reduction. In addition, the change in the ψ1-potential can bring about changes in the рН of the near-cathode solution layer as compared with that in the solution bulk [10].

Indeed, the increase in the supporting electrolyte concentration from 0.01 to 1.0 N both in weakly acidic (рН 4.9–5.0, Fig. 3) and alkaline solution (рН 8.7–8.9, Fig. 2) shifts polarographic curve toward positive potential values and accelerates the m-NSAB electroreduction. This shift is maximal in alkaline solutions in which the m-NSAB anion concentration is high and the electrical double layer effect is most pronounced.

Similar regularities in the changes of the parameters and shape of the m-NSAB electroreduction wave in weakly acidic and weakly alkaline solution, depending on the supporting electrolyte concentration and рН were observed at glassy carbon electrode as well (Table 2, Fig. 5).

The m-NSAB Electroreduction at Metal Electrodes

Strictly speaking, the results of polarographic studies cannot be extend to solid electrodes; moreover, the voltammetric measurements at glassy carbon electrode do not allow evaluating to the full extent the m‑NSAB synthesis efficiency. Therefore, to obtain additional information on the m-NSAB electroreduction we used electrolysis at controlled potential at metal electrodes. Preliminarily, we took polarization curves of m-NSAB reduction in the ammoniac buffer solution (0.7 N NH4Cl + NH4ОН, рН 8.4) at electrodes of nickel and the Kh18N10Т stainless steel (Fig. 8). This choice of the cathode materials and of the ammoniac buffer solution as supporting electrolyte is caused by the results of the polarization measurements at glassy carbon electrode (Fig. 7), as well as the data presented in work [7], which demonstrated the possibility of the aminesulfonic acids of naphthalene (the Clevet-acids) electrosynthesis in the ammoniac buffer solution (рН 6.1–9.1) at nickel and stainless steel cathodes.

Polarization curves of m-NSAB reduction at the Kh18N10Т stainless steel and nickel cathodes contain only one wave at more negative potentials, as compared with the glassy carbon electrode; the half-wave potentials fort the electrodes are –0.90 and –0.87 V, respectively (Fig. 8).

In Table 5 we give data on the m-NSAB electroreduction at controlled potential.

The obtained results on the m-NSAB solution electrolysis under controlled potential at the nickel and stainless-steel cathodes allow qualitatively evaluating the m-NSAB electroreduction efficiency in the ammoniac buffer media (Table 5). We see from Table 5 that the products of m-NSAB reduction at the Kh18N10Т steel and nickel cathodes are the corresponding hydroxylamine- and amino compounds, whose yield depends on the potential applied. For example, at the electrode potentials approaching the half-wave potential (–0.85 V), m-NSAB is reduced at the nickel or Kh18N10Т steel cathodes predominantly yielding m‑ASAB (77.0–83.2%) and small amount of m‑hydroxylaminesulfonic acid of benzene (8.3–12.5%). At the electrode potential of –1.0 V corresponding to the limiting current in the polarization curves the target m-ASAB yield increased up to 93.7–94.5%, due to fuller hydroxylaminesulfonic acid of benzene conversion to m-ASAB. However, at the electrode potential of –1.3 V both at the Kh18N10Т steel and nickel cathodes the m-ASAB yield and current efficiency decreased down to 77.2–87.8% and 27–34%, respectively, most probably due to the occurring of a side-reaction, namely, reductive desulphonation starting compound. The decrease in the current efficiency is caused by both by the decrease in the m-ASAB yield and increase of the current fraction consumed for the hydrogen evolution. At that, metal sulfide films are formed at the cathodes’ surface.

Data on the m-NSAB reduction in the galvanostatic mode are also given in Table 5. It follows from the data that m-NSAB dilute solution in galvanostatic mode in the ammoniac buffer medium with рН 8.4 at a current density of 1.0 А/dm2 and temperature of 25°С occurs with high efficiency, like in the electrolysis at the controlled electrode potential of –1.0 V. For example, at the nickel cathode at a current density of 1.0 А/dm2 the m-ASAB yield is 92.8%; the current efficiency, 82.0%. At the stainless-steel cathode we obtained m-ASAB at lower yield and current efficiency. Therefore, it is the nickel cathode and ammoniac buffer solutions that can be recommended for the developing of technology of the m-ASAB preparative electrosynthesis. Moreover, the ammoniac buffer solutions are preferable, when compared with acidic media [6], because they are more corrosion-stable, which facilitates the choice of both the electrode and construction materials for the electrolyzer, circulating pumps, and communications.

CONCLUSIONS

The obtained results allow deriving the following conclusions:

(1) The laws governing the m-NSAB electrochemical reduction in strongly acidic, ammonium-chloride, and ammoniac buffer solutions are established by using methods of polarography, voltammetry at glassy carbon electrode, microelectrolysis in potentiostatic mode at glassy carbon electrode, electrolysis at controlled potential and in galvanostatic mode.

(2) Anodic oxidation of the target product, m‑ASAB, is studied by voltammetry at glassy carbon electrode.

(3) The nature of separate stages of the cathodic and anodic processes involving m-NSAB is established; intermediate and final products of the reaction are identified as radical-anions, hydroxylamine- and aminosulfonic acids of benzene, and the cathode metal sulfides.

(4) The m-NSAB polarographic reduction in strongly acidic solution (0.1 N H2SO4) is shown to proceed in two stages with total consumption of six electrons: first, the corresponding hydroxylamine is formed with consumption of four electrons, then a two-electron stage of reduction to m-ASAB occurs; in alkaline medium, four electrons are consumed with the producing of the corresponding m-hydroxylaminesulfonic acid of benzene.

(5) It has been established that the m-NSAB reduction at glassy carbon electrode both in strongly acidic (0.1 N Н2SO4) and in neutral and alkaline media (in Britton–Robinson and ammoniac buffer solutions) proceeds in a single four-electron stage producing the corresponding hydroxylamine derivative. The subsequent two-electron stage resulting in the m-ASAB formation is camouflaged by the supporting electrolyte discharge.

(6) The distinguishing feature of the m-NSAB electroreduction in neutral and weakly alkaline solutions both at mercury dropping electrode and glassy carbon electrode, as compared with aromatic nitro-compounds, is strong dependence of the polarization curves’ parameters and shape on the supporting electrolyte nature, concentration, and рН. The two waves observed in these electrolytes are attributable to the reduction of the m-NSAB non-dissociated molecules and anions.

(7) The ammoniac buffer solutions with рН 7.5–8.4 and nickel cathode are recommended for the developing of the m-ASAB electrosynthesis technology, because in these solutions the electrolysis in the galvanostatic mode at the nickel cathode at a current density of 1.0 А/dm2 produced m-ASAB at a yield of 92.8%, with current efficiency of 82.0%.

REFERENCES

Vorozhtsov, N.N., The Fundamentals of Synthesis of Intermediate Products and Dyes (in Russian), Moscow: Goskhimizdat, 1955.

Venkataraman, K., Chemistry of Synthetic Dyes (in Russian), Leningrad: Goskhimizdat, 1956.

Ehrmann, K., VerfahrenzurHerstellung von aromatischen Aminosulfonsӓuren, Pat. 1233408 (BRD), 1967.

Svidchenko, V.F., Nikolaev, Yu.T., and Sokolsky, D.V., Sulfides of platinum metals as catalysts for reduction of nitrocompounds, Russ. J. Phys. Chem., 1973, vol. 47, p. 725.

Gait, R.J., Catalytic reduction of nitrobenzene sulphonic Acids. Pat. 1499589 (UK), 1978.

Khomutov, N.E. and Kasatonova, I.V., Studies of electrical reduction of sodium salt of nitrobenzene-m-sulfonic acid on the copper cathode, Russ. J. Appl. Chem., 1961, vol. 34, p. 860.

Konarev, A.A., Electrochemical synthesis of Cleves-acids, Russ. J. Electrochem., 1998, vol. 34, p. 1160.

Konarev, A.A., Method for detection of aromatic nitrocompounds and products of their reduction, Pat. 2159424, Russia, 2000.

Stradins, J., Polarography of Organic Nitrocompounds, Riga: Latvian Akad. Nauk, 1961.

Konarev, A.A., Studies of Intermediate Forms under the Conditions of Preparative Electroreduction of Naphthalene 1-Nitro-3,6,8-Trisulfo Acid, Russ. J. Electrochem., 2012, vol. 48, p. 922.

Kvaratskheliya, R.K. and Kvaratskheliya, E.R., On peculiarities of electrochemical behavior of I(5+) and I(7+) compounds in ammonium salt solutions, Russ. J. Electrochem., 1996, vol. 32, p. 868.

Fierz, H.E. and Weissenbuch, P., Uber die Reduktion von Nitronaphtalinssulfosauren, Helv. Chim. Acta, 1920, vol. 3, p. 305.

Mayranovsky, S.G., Double Layer and Its Effects in Polarography (in Russian), Moscow: Nauka, 1971. 87 p.

Mayranovsky, S.G., Stradins, J., and Bezugliy, V.D., Polarography in Organic Chemistry (in Russian), Leningrad: Khimiya, 1975, 351 p.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by Yu. Pleskov

Rights and permissions

About this article

Cite this article

Konarev, A.A. Electrochemical Behavior of m-Nitrosulfonic Acid of Benzene in Aqueous Solutions of Different Composition. Russ J Electrochem 56, 733–743 (2020). https://doi.org/10.1134/S1023193520090074

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193520090074