Abstract

In China’s Pearl River Delta, numerous sinkholes caused by excessive groundwater pumping from a karst aquifer have opened. These sinkholes can cause wells and springs to dry up, dwellings to be damaged, and can facilitate the entry of pollutants into the aquifer. Controlling drawdown and pumpage to prevent sinkhole collapse is important for the aquifer’s protection and sustainability. This paper uses two approaches to obtain the critical drawdown and pumpage values to prevent sinkholes from opening: a field pumping experiment and hydraulic gradient tests. The results show that: (1) to prevent sinkhole collapse, the pumpage must be less than the allowable value determined by the seepage deformation method. (2) Water level decline is an important parameter that has to be considered to prevent sinkhole collapses. (3) Adjusting the intensity and mode of aquifer exploitation can increase allowable groundwater pumpage while preventing sinkhole development.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

In China, more than 70% of the sinkholes have been caused by groundwater exploitation [11]. This proportion has even reached more than 90% in some areas [13]. Solving this problem is an urgent matter for groundwater managers and scientists. They must determine how to regulate groundwater exploitation in ways that will allow the agricultural and other water needs to be met without causing sinkhole collapse and other environmental problems.

Sinkhole collapse caused by groundwater pumping has been widely studied. Erosion has been recognized in academic circles as one of the most important genetic mechanisms for sinkholes development [2]. It is believed that erosion changes the mechanical properties of the soil layers and this leads to deformation, failure, and finally to collapse [3]. The critical hydraulic gradient is commonly used as a criterion for sinkhole collapse by many scholars. The gradient can be determined by pinhole test in the laboratory, field monitoring, and other methods [10] and laboratory tests are widely used although their results are not always consistent with the results of tests conducted in the field [8]. Turning to the relationship between groundwater fluctuations and sinkhole collapse, variations in water level appear to be the main factor [1] but other factors including fluctuation frequency [9], flow velocity [12], and groundwater chemistry [5] can also be important.

In the Pearl River Delta region in China, sinkholes can be divided into four types according to the factors that trigger the collapse. These factors are pumping water from aquifers, underground engineering excavations, limestone mining, and constructing pile foundations [6]. Sinkholes induced by pumping from aquifers are mainly concentrated in six areas in the Guanghua basin, namely the Jiangcun, Xinhua, Lianglong, Chini, Tanbu, and Xiaogang areas. Since the 1970s, more than 230 sinkholes have opened because of groundwater pumping [4].

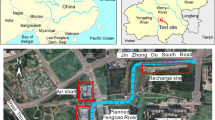

For this paper, typical sinkholes in the Jiangcun region are used as examples to demonstrate how to prevent sinkhole collapse by determining allowable groundwater withdrawals.

MATERIALS AND METHODS

Geological Background

Jiangcun is located in the Guanghua basin, an alluvial plain underlain by karst with a shallow cover. The water is Quaternary pore and confined water in an upper aquifer and underlying carbonate karst cave and fissure water. Karst water is mainly stored in Hutian Formation (C2+3ht) and Shidengzi Formation (C1ds) limestone caves and fissures. The natural water level is 1–5 m below the ground surface. The upper and lower aquifers are close to each other and they are hydraulically connected. The natural annual variation in groundwater level is around 1–5 m.

Since 1966, more than 150 sinkholes opened in the Jiangcun water supply region. The sinkholes are clustered within 1 km of the pumping wells and their collapse pits are oval or circular in plan view (Fig. 1) and shaped like vertical cylinders or funnels. They are 3–8 m in diameter, 0.3–4 m deep, and their floors are covered with collapsed loose soil or, commonly, water.

Pumping Test Drill-Holes Layout

The layout of the drill holes from which the data for this study were collected is shown in Fig. 2. The pumping holes are two large diameter boreholes 5.5 m apart each with a diameter of 0.8 m. The center observation hole, Zk0, is between those two holes and the other observation holes are distributed on four radial observation lines. Water from the limestone and Quaternary aquifers are observed simultaneously.

Critical Hydraulic Gradient

Thirty-one undisturbed soil samples from different depths in the test area were selected for critical hydraulic gradient tests. The critical hydraulic gradient is calculated from the equation for geological exploration criterion provided by the Institute of Water Conservancy and Hydropower Engineering [7]:

where icr—critical hydraulic gradient of soil, Gs—specific gravity of soil grain, n—porosity of soil, d5, d20—corresponding particle size when the soil particle content less than a certain particle size is 5 and 20% (mm).

The curve for withdrawal (Q) versus drawdown (S) can be calculated from a three-stage pumping test. From this curve, water yield can be obtained based on the drawdown:

where q—withdrawal, S—drawdown.

RESULTS

Pumping Test

The pumping test was carried out with a 400-type deep well electric pump for 17 days and 21 h. The aquifer in the pumping hole was 80.81 m thick and the interval pumped for the test was 77.26 m long. The pumping was divided into three stages. In the first stage, the static water level depth was 2.74 m, the maximum water level drop was 4.62 m, and the maximum flow was 72.21 L/s. In the second test, the static water level depth was 3.06 m, the maximum drop was 9.09 m, and the maximum flow was 131.52 L/s. The static water level depth in the third test was 3.34 m, the maximum drop was 13.05 m, and the maximum flow was 182.44 L/s. The water level recovery time was 11 days 18 h (Figs. 3 and 4).

Cross section A–B (Fig. 2) showing the monitoring wells and the pumping test water levels.

Some sinkholes collapsed around the pumping well when the water level in the well reached a depth of 12.986 m. These collapses were dish-shaped with diameters of 1–9 m. Other pumping wells in the study area were similar to Zk0 in that sinkholes collapsed around the well. Sinkholes opened when the water level reached 11.314 m in one well and when the water reached 13.168 m in another. The natural groundwater hydraulic gradient in the study area is generally less than 0.02%. Because of the prolonged precipitation during the pumping test, the natural state of the groundwater was altered, and the groundwater conditions changed. This resulted in deformation and failure of the soil and soil collapse. The pumping results from Zk0 showed that the hydraulic gradient reached 4.5% within 100 m of the pumping well and 0.016% within 1000 m. The distal sinkhole collapses occurred 450 to 712 m from the well.

Critical Hydraulic Gradient and Allowable Drawdown

To collect the data necessary to solve Eq. (1) for the soil’s critical hydraulic gradient, work on the 31 soil samples (Fig. 5) was carried out in four stages. (1) The 31 soil samples were accurately described, and their density, water content, and specific gravity measured. (2) The samples’ porosity index was calculated. (3) Soil particle size distributions were determined for each sample. These tests were carried out by sieving and the hydrometer method. For particles >0.075 mm in diameter, the sieving method was used; the hydrometer method was used for particles <0.075 mm. (4) A combined liquid-plastic limit test was also conducted on the soil samples in order to further understand their physical and mechanical properties. The values determined by these tests were used to calculate the critical hydraulic gradients for the 31 samples.

In the group of 31 samples, the minimum critical hydraulic gradient was 2%, the maximum was 164%, and the average was 56% (Fig. 6). A value of 2% was selected as the pumping test critical hydraulic gradient for safety. The sinkhole collapse that was closest to the pumping well was 450 m away, so the allowable groundwater withdrawal that will avoid sinkhole collapse is 9.0 m.

Allowable Groundwater Withdrawal

Figure 7 shows a plot of the data from the pumping test. The graph of groundwater withdrawals versus drawdowns shows a linear relationship and the correlation coefficient for the curve through those points is 0.99. The equation for that curve is:

When S (the allowable drawdown) is 9.0 m, Q (withdrawal) is 129.433 L/s and thus the allowable groundwater withdrawal is approximately 130 L/s.

DISCUSSION

The result from the lab test is basically consistent with the actual water levels in the sinkholes in the field. When the sinkholes in the study area were opened, the water level was 11.314 m.

For most of the soil samples, the calculations returned values for the critical hydraulic gradients that were greater than 2%. The maximum value was 164%. These results show that different allowable groundwater withdrawals should be expected in different regions. Enough groundwater can be obtained according to the pumping influence radius of a well and a map of critical hydraulic gradients.

Field pumping tests are idea for determining the critical indices for sinkhole collapse and safe groundwater withdrawal, but they are not commonly used because of geological conditions and economic factors. The critical hydraulic gradient is important in terms of predicting the locations where sinkholes might occur, and the gradient can be obtained from field tests. The results from these tests are better and more useful than laboratory tests and can provide a new method for monitoring and forecasting sinkhole collapse. A field study to produce a contour map of hydraulic gradients will be our next endeavor.

Pumpage is closely related to water level decline, pumping time, and flow velocity. Therefore, adjusting the intensity and mode of aquifer exploitation can increase allowable groundwater pumpage without causing sinkhole collapse. The required production can be achieved by prolonging the pumping time and reducing the pumping speed. If conditions permit, surface storage facilities can be built to achieve the desired volume of water supply at the appropriate times.

Because the processes that lead to a sinkhole collapse are very complex, a disaster plan should be in place during pumping to control any sudden unanticipated events. In addition, the existing real-time groundwater monitoring programs should be improved. These programs can be used to control dynamic groundwater changes, give warnings of extreme rainfall, and record the influence of blasting vibration and other disruptive events. Once an exception to normal conditions takes place, pumping should immediately stop, and the situation should be analyzed and action taken until the problem is resolved.

Field monitoring and laboratory test show that for the Jiangcun water source, the safest groundwater drawdown to prevent sinkhole collapse is less than 9.0 m and groundwater withdrawal should be less than about 130 L/s. This study shows that using the critical hydraulic gradient test to determine allowable groundwater withdrawal is effective and practical and this method can be used in other areas with similar hydrology.

REFERENCES

Anikeev, A.V. and Leonenko, M.V., Forecast of sinkhole development caused by changes in hydrodynamic regime: Case study of Dzerzhinsk Karst Area, Water Resour., 2014, vol. 41, pp. 819–832.

DeStephen R.A. and Benson, C.P., Groundwater withdrawal impacts in a karst area, Environ. Geol., 1993, vol. 22, pp. 314–320.

Gutiérrez, F., Cooper, A.H., and Johnson, K.S., Identification, prediction, and mitigation of sinkhole hazards in evaporite karst areas, Environ. Geol., 2008, vol. 53, pp. 1007–1022.

Jianglong, L., Huiping, L., and Xiangbin, W., Mechanism and Temporal-Spatial Distribution of Ground Collapse in Guangzhou, J. Catastroph., 2007, vol. 22, pp. 62–65. (In Chinese)

Junkang, L. and Sheng, G., The hydro-geochemical characteristics in the karst collapse zone in Guilin city, J. Guilin Inst. Technol., 1996, vol. 16, pp. 150–155. (In Chinese)

Minggui, X., Jieguang, W., and Baochen, L., Surface Collapse Mechanism Induced by Pile Foundation Construction and Prevention Method in Karst Region, Site Investig. Sci. Technol., 2004, vol. 1, pp. 52–55. (In Chinese)

Ministry of water resources of the People’s Republic of China., Specifications for Geological Investigation of Water Conservancy and Hydropower Projects(GB50487-2008), China, Beijing: China Planning Press, 2008, p. 230.

Qing-hua, W., Wei, Z., Yu, L., and Hao-dong, C., Quantifying the Process of Karst Collapse by a Physical Mode, J. Yangtze Riv. Sci. Res. Inst., 2018, vol. 35, pp. 52–58.

SiYi, H., ZongZhi, W., YinTang, W., and LingLing, Z., Total control-based unified allocation model for allowable basin water withdrawal and sewage discharge, Sci. China: Technol. Sci., 2010, vol. 53, pp. 1387–1397. (In Chinese)

Xin, Z., Ke-rui, C. and Fu-sheng, Z., Experiment Research of the Critical Water Level Fell of Covered Karst Collapse, Sci. Technol. Engineering, 2016, vol. 16, pp. 195–199. (In Chinese)

Yan, M., Ming-Tang, L., Yu-Shan, L., Jian-Ling, D., Zhen-De, G., Models and mechanisms of drilling-induced sinkhole in China, Environ. Earth Sci., 2012, vol. 67, pp. 1961–1969.

Ye-Shuang, X., Run-Qiu, H., Jie, H., and Shui-Long, S., Evaluation of allowable withdrawn volume of groundwater based on observed data, Nat. Hazards, 2013, vol. 67, pp. 513–522.

Yongjian, L., Yaheng, L., Xiangqiu, L., Ying W., Yimei, L., Study of Collapse Characteristics of Karst Ground in the Guanghua Basin and Its Formation Mechanism, J. Guangdong Univ. Technol., 2013, vol. 30, pp. 25–30. (In Chinese)

ACKNOWLEDGMENTS

This work was funded by the National Natural Science Foundation (nos. 41877300, 41302255) and The Project of the China Geological Survey (the survey and assessment of the karst collapse in Pearl River Delta, no. 1212011220192), and the comprehensive geological survey project of karst collapse area in south Hunan and central Chongqing, no. DD20190266. We thank David Frishman, PhD for editing the English text of a draft of this manuscript.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yan Meng, Li, Z. & Jia, L. An Analysis of Allowable Groundwater Drawdown and Pumpage from a Karst Aquifer to Prevent Sinkhole Collapses in the Pearl River Delta, China. Water Resour 47, 530–536 (2020). https://doi.org/10.1134/S0097807820040089

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0097807820040089