Abstract

The problem of ensuring the continuously growing needs of people for freshwater is becoming more acute in Iran. In order to resolve the serious water crisis in arid regions of the country near the Gulf, several desalination units have been used. However, most of the installed units of seawater desalination are based on fossil fuels consumption, which suffers from several disadvantages. According to the demand for clean energy to provide water and electricity, nuclear technology is gaining higher attention as compared to other energy sources. Bushehr NPP as the first commercial nuclear reactor in the country can be included the establishment of a large-scale desalination plant. In this study, after reviewing pertinent aspects of commercial desalination technologies, the history of seawater desalination in Iran is presented. This paper is focused on economic assessment of coupling the Bushehr NPP with different types of desalination systems, namely, Multiple Effect Desalination (MED), Multi-Stage Desalination (MSF), Reverse Osmosis (RO), and RO + MSF, RO + MED (hybrid methods) by using the Desalination Economic Evaluation Program (DEEP) package. By considering the obtained results and advantages of hybrid methods, RO + MED process with thermal/RO ratio of 0.7 and the total capacity of 150 000 m3/day is suggested.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Water is a limited valuable resource, which is the basis of human existence and the essential aspect of developing productions and economy. The demographic statistics have predicted that the population growth in the world between 2011 and 2050 will increase by 33% from 7.0 billion to 9.3 billion while the natural water resources remain constant. Consequently, by 2030 the global water demand is expected to grow from 4500 to 6900 billion m3/year portraying a 53% increase [1]. If it is not possible to significantly reduce (and even better eliminate) this deficit, then many countries of the world will be threatened by growing food shortages, rising social tensions and other difficulties, including war for water [2]. The residential areas, which are extremely in the face of water shortage and drought danger in future, are mostly located around the Mediterranean, the Middle East, western North America, eastern Australia, western Asia, northern China, and Chile.

Currently, there is an effective way to solve this problem, namely, large-scale (in amounts of about one hundred thousandths of cubic meters per day or more) seawater desalination, which can be implemented in countries with territories, which are located near the seas and oceans.

Developing the desalination technologies has started since the mid-20th and principally, the countries located at the highest risk regions, such as the Middle East and South Africa, expressed their interest to use them. A number of countries in the Middle East, which have great economic opportunities, already utilize large and high-technology desalination plants for producing freshwater. During the last two decades, the rate of installing new desalination units has increased quickly. Currently, more than 150 countries are trying to solve their freshwater shortages using desalination options. Globally, at the end of 2015, around 80 million m3 of potable water is being produced daily by more than 18 000 desalination plants and of these, 50% (40 million m3/day) are utilizing seawater as the source [3]. Around half of this capacity (37.32 million m3/day) is located in the Middle East and North Africa [4]. Moreover, it is expected that the global capacity of desalination plants constantly grows and from 21 million m3/day of desalinated water in 2007 reach 110 million m3/day by 2030 [5].

However, desalination is an energy-intensive process. Most of the existing water desalination plants use non-renewable fuels as their primary energy sources, which is the major source of CO2 emission [6].

As stated in many reports, though solar energy is often labelled as free energy and is environmentally friendly, it’s not so simple to evaluate feasibility and cost for solar desalination. The major disadvantages of the solar water distiller are weather dependent, high cost and requiring a large space [7].

Between all types of energy sources, nuclear power has the indisputable advantages over the others and in this case can be quite competitive. The possibility of developing the units of nuclear desalination depends on the economic factors of the region. Technically, any reactor type can be used for nuclear desalination, although several types are identified as the most practical, beneficial and probable for this application.

In the literature, there are various types of nuclear desalination systems in different countries, for example, LMFR in Kazakhstan, PWR in Korea, Argentina, Russia and India and BWR in Japan [8].

Similar to many countries in the west and west south of Asia, Iran is also experiencing extreme water shortages. Iran has a noticeable amount of gas turbine plants and in their majority have been established in the south, near the seashore region. By virtue of the freshwater insufficiency in arid parts of Iran, these power plants are used for supplying freshwater, which generally uses an enormous amount of energy. However, the energy produced from fossil fuels is the dominant source of CO2 emission and also the resources of them are limited. Therefore, nuclear energy applications have a great role in Iran’s future energy strategies.

Numerous studies have been carried out on combining nuclear reactors with desalination plants, including technical aspects [9, 10], safety consideration [11], and economic evaluation [12–14] of nuclear desalination. Recently, Khalid et al. [15] developed and analyzed two nuclear power station (CANDU 6 and SFR) for the purpose of generating electricity and freshwater. Park and Kim [16] considered a high-temperature reactor coupled with the forward osmosis plant. They arrived at the conclusion that the combination of a high-temperature reactor with the forward osmosis unit is more profitable compared to coupling with an MSF system.

Yong Hun Jung et al. [17] analyzed various aspects of using nuclear desalination in the UAE (United Arab Emirates). They believed that the most optimal choice for generating the freshwater is linking a small nuclear heat-only plant (SNHP) and a MED (Multiple Effect Desalination) system. Nissan and Dadour [18] compared economic aspects of four different nuclear desalination systems with the purpose of supplying freshwater. In their investigation suggests that reverse osmosis is the most profitable compared to the other three options. Alonso et al. [19] have explored five various ways of nuclear desalination. They fathomed out that each method has its own merits and demerits.

The basic motivation of our research is to compare the five different types of desalination systems namely MED, RO, MSF, RO + MSF, and RO + MED, coupling with Bushehr nuclear power plant located at the northern east coast of Gulf in Iran, which could be sustainable and at the same time economically viable. The economic calculations presented at this paper are based on the utilization of the Desalination economic evaluation program (DEEP 5) software, developed by the IAEA (International atomic energy agency).

A General Overview of Commercial Desalination Technologies

Basically, the commercial desalination units are classified into two major categories, which are called thermal and membrane types. The thermal type is split into two groups (MSF and MED) based on heating and evaporating seawater, condensing the produced steam and subsequently, obtaining freshwater. MSF method was dominating from the 1980s to 1990s because of the high quality operating and maximum availability during the whole year [20]. In this method, although the main type of energy required is thermal, electrical energy is also used. The requirement thermal energy for MSF varies from 191 to 290 MJ/m3 that is equivalent to 15–25 KWelec/m3 at 30% power plant efficiency [21]. These types of plants can treat very salty water (to 70 000 mg/L) to produce practically pure water having about 5–25 ppm TDS. In 1928 the first MSF plant was installed in Saudi Arabian with a total capacity of 227 m3/day.

The first multiple effect desalination plant in the world with the capability of producing about 500 m3/day were constructed around the early 1960s. Multi-effect distillation is based on evaporation and condensation with decreasing ambient pressure, which takes place in a sequence of equipment called ‘effects’ [22]. Analogous to MSF, the MED plants also need electrical and thermal energy to produce potable water. However, their consumption energy has a considerable difference and commonly, MED is lower than MSF (because of operating at lower top brine) [23].

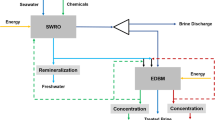

The primary techniques of membrane processes are reverse osmosis and electrodialysis, however, reverse osmosis is more commercial on the industrial scale.

In this method, freshwater permeates under high pressure through semi-permeable membranes leaving behind highly concentrated brine solution. The needed energy for high-pressure pumps of RO units is influenced by total dissolved solids and a part of this energy can be supplied by recovering energy of brine water. RO specific energy usage and the value of CO2 emission has a minimum volume among all desalination methods. RO units easily adapt to environmental conditions and the plant size can be expanded as needed [24].

According to the reports [9, 10] in 2016, 65% of the total world capacity was constituted by membrane desalination and 27% by thermal (the remaining 8% belongs to other desalination methods). Furthermore, by the year to 2017 greater than 90% of total capacity in new contracts is based on membrane process. For selecting among desalination processes, especially in countries with moderate technology, should be taken consideration several mainly factors such as; total capacity, design, material, feed water quality, energy consumption and gain output ratio. Estimating the energy consumption of various desalination methods is a function of numerous parameters, such as temperature, the flow rate of desalination and salinity of seawater. The feed concentration does not influence thermal energy usage, but it impresses the energy consumption of membrane systems. Table 1 summaries the operational and performance parameters of various desalination schemes [24–30].

Seawater Desalination in Iran

Iran is a wide country, which is covering an area of 1 648 195 square kilometers of the Middle East with an estimated population of about 82 million. With regard to the significance of water in Iran, producing freshwater has become an important issue for the government of Iran and gave a strong motivation to install desalination units [30, 31]. The total border of Iran is equal to 8 731 kilometers, which about 30% of this, constitutes water border (Gulf and Sea of Oman). Hence the seawater desalination can be easily considered as a safe and permanent water supply for coastal communities. Already several desalination units have been built in the south of the country, near the seashore region where there is located sources of oil and gas. But, nevertheless, Iran is not a country with a large number of installed desalination plants in comparison to other countries in the Middle East. In association with the technology, the desalination plants which have been installed in Iran, mostly use hybrid processes while the RO method has become dominate the thermal technologies.

The major source of the supplying required energy for desalination units in the world are fossil power plants. However, the combustion of fossil fuels emits a considerable amount of greenhouse gas and raises environmental concerns, including the threat of a gradual climate change. In addition to environmental emissions, fossil fuels resources are limited and their use in other industries have remarkably increased the price of fossil fuels. Therefore, as a consequence of these concerns over fossil fuel, other alternative energy sources have been developed for future desalination needs, including nuclear energy.

The possibility of using nuclear reactors as a thermal or electrical energy source in desalination plants was studied by IAEA in the 1950s. Iran is a country with a huge number of underground reserves, such as coal, natural gas, oil, and heavy oil. In the last decade, an increase (about 50%) in primary total energy consumption has appeared in Iran, and it’s clear that fossil resources are the main source of supplying this amount of energy. The enormous toll exacted by using fossil fuels as well as a high increase in the demand for energy led the government to consider alternative resources energy. Currently, Iran is the member state of International Atomic Energy Agency and has expressed his interest in nuclear desalination resulting from increasing population and a growing economy.

Iran’s original Bushehr-I facility has introduced as the first profitable power reactor in the Middle East. This power plant is based on a VVER 1000 MWe light-water reactor, which is designed by the Russian Federation and started to add the nuclear electricity to the capacity of power grid at the year of 2013. Currently, the plant is operating by Iranian staff with the assistance of Russian specialists.

The possibility of coupling large-scale desalination units was predicted during building the first phase. On the grounds of this feasibility, the Atomic Energy Organization of Iran (AEOI) has planned to generate about 200 thousand m3 of potable water per day. However, to supply the internal demands of freshwater in the Bushehr nuclear power plant, already producing 5000 m3 per day is achievable.

Economic Evaluation

Recently, various attempts have been made to decrease the cost of nuclear desalination in both industrial and developed country. For example, in the eighties, the cost of a 1 m3 of distilled water with the MSF process varied between 6 and 7 $/m3. But currently, the international cost is between 0.52 and 1.75 $/m3. Especially in Iran, as a developed country the economic aspects of installing a nuclear desalination unit is rather more important than the other parameters. Hence before designing a desalination unit in the country, it seems to be necessary to consider all possible options of nuclear desalination and compare them in the case of the economic, to select the best case. The main factors, which are affecting the cost of the desalination unit’s productions are the total water capacity, the salinity and quality of sea water and energy consumption. Moreover, by increasing the temperature of the RO inlet with preheating or increasing the recovery ratio, the total cost of the desalination will decreases. The IAEA DEEP is a comprehensive software in the field of analyzing the economic aspects of desalination units which, has become an acceptable tool to evaluate and estimate the price of different desalination technologies (thermal or electrical), based on various energy sources (nuclear, fossil-fueled or renewable).

Main factors affecting the total cost of the desalinated water are discussed below.

Interest rate. The time value of money is one of the most important parameters in the economic evaluation during a period of time. This concept is that the money available at the present time is worth more than the identical sum in the future due to its potential earning capacity and. Generally, inflation and interest rates affect the time of money. The interest rate is the rate of return of investment banking across a time period. The interest rate is a specific value for each country, which can be changed by the economic conditions and policy. For example, in Iran, the interest rate of the country increased between the years of 2009 to 2015 and after that, this value is decreased, sharply. The maximum and minimum value of the interest rate in the past 20 years is about 22 and 6% respectively. Furthermore, the average value of interest rate in 10 years ago and 20 years ago is about 15 and 10%, respectively. The economic evaluation of the produced freshwater with respect to changing the interest rate is indicated in the result section.

Preheating the feed water for RO unit. The preheating of feed-water of RO systems is a useful and possible method to reduce the specific power consumption of desalination and consequently, decrease the total cost of the freshwater. The permeability of seawater in the membranes is inversely proportional to feed water viscosity. In the other hand, by increasing the temperature, the viscosity decreases and as a result, the RO membrane becomes more permeable [32]. The best way to preheating of feed water is to use the waste heat generated in the nuclear power plant. By mixing the treated water from the UF unit with the hot stream from the outlet of the condenser, or outlet stream from the thermal desalination unit, the preheating of inlet water for RO unit can be implemented.

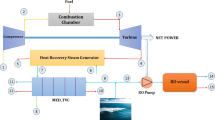

In Fig. 1 the simple scheme of the second cycle of Bushehr nuclear power plant is drawn. In this scheme, three possible streams are suggested to use as the preheating the feed water. The first pipeline, which is indicated by L2 is the basic case and the feed water from the sea is pumped to the RO unit with out of preheating. The second possible pipeline of RO feed water, which can be considered in the Bushehr nuclear power plant is marked by L5. The inlet feed water of the RO unit, in this case, is a hot stream from the condenser. The temperature of the outlet stream from the low-pressure turbine in the Bushehr NPP is about 40°C. Hence, removing waste heat from the condenser in order to use for preheating the inlet feed water of the RO unit can be carried out, easily. The last scheme of preheating is using the heated water from the last effect of the MED unit, which is considered as the waste heat (removing the waste heat from both MED and MSF units are possible. But in the drawn scheme just the MED unit is indicated). The effect of increasing the temperature of the RO inlet is indicated in the results section.

The schematic view of the Bushehr NPP coupling a hybrid desalination unit (RO + MED). 1—Steam generator; 2—high pressure turbine; 3—low pressure turbine; 4—generator; 5—condenser; 6—med unit; 7—ro unit; 8—pump; 9—preheater; L1 and L2—intake sea water; L3—the line of produced freshwater; L4—the line of the brine water; L5—the feedwater of RO plant from condenser; L6—line of water between MED unit and RO unit.

Feed water quality. One of the main factors to choose desalination technology is the salinity of inlet water to the desalination equipment. The salinity of feed water of RO units depends on the regional location and the type of water source. The Persian Gulf is among the most saline locations on Earth. The salinity of this gulf is different from one part to another part. For example, the average salinity of the Arabic parts is about 45 000, while this parameter for the north part of the gulf, which ends to coasts of Iran, is about 40 000 ppm. This high value has forced the Gulf countries to develop the desalination units based on the thermal methods.

Energy consumption. As discussed in the last sections, each desalination method has a certain value of energy consumption. However, by applying the high-technologies methods, which are recently developed such as pre-heating, energy recovery devices (ERD) and using the waste water from condenser can be decreased the energy consumption, considerably. On the other hand, the type of energy source can affect the total cost of freshwater. The energy cost is different for various countries. For example in GCC countries, due to the fact that they are the main oil-exporting governments in the world, the cost of fossil fuels in these countries is less. One of the common difficulties in conducting economic calculations is the comparison of economic parameters and fossil energy. Nuclear power plants usually have a low capital cost with longer construction times and relatively low fuel cycle cost. About the Bushehr nuclear power plant, it is necessary to note that the first block of this plant already has been constructed and is operating.

Wastewater reuse. Recently, the environmental concerns of the desalination plants such as emission of pollutants into the atmosphere, noise, and produced pollution by the discharge of concentrates have been considered as one of the major issues of using the water plant, which should be investigated before designing the desalination options. In regard to this matter, the environmental impact assessment (EIA) should be developed to consider all the critical environmental parameters and estimate potential impacts on air, land, and marine environments. The main four aspects to the impact of water plants on the environment and the economic effects are listed by following:

1. Turning the tourist areas into the industrial centers and desalination plants: Most of the desalination plants in the world have been established close to the seas and oceans, which are the main tourist areas, and consequently, the rejected water from desalination plants impresses the environmental of these regions. Hence, the economic benefits of installing a water plant instead of recreation centers should be taken into account before the detailed study of a water plant project.

2. Leakage from the pipes and consequently, penetration of saltwater to the environmental: to prevent this difficulty, the additional coasts of the sealing and insulation the main pipelines passing through the earth should be considered.

3. Destructive impacts on the marine environment. In the result of the high concentrated water evacuation to the sea, the specific weight of the marine ingredients leads to produce the deposited materials on the seabed. The cost of eliminating the produced layers should be added to the calculated total cost.

4. Noise effects. The produced noise from the various equipment of the power plant and the coupled water plant such as high pressure pump of the RO units, should be considered. The desalination plants located near to the residential areas or animal locations should spend extra money to decrease the impacts of the noise.

The technologies of concentrate disposal such as deep well injection, land application, evaporation ponds, brine concentrators, and zero liquid discharge (ZLD) technologies have been developed to reduce the environmental impact of the desalination plant. The economic assessment of applying these options should be carried out in the calculation of the produced water. In this study, the economic aspects of considering the concentrate disposal have been assumed in the terms of the pre-post treatment.

RESULTS AND DISCUSSION

The purpose of our work is to analyze and compare the possible desalination options for Bushehr nuclear power plant using the DEEP under the specific conditions in terms of cost. In this section, firstly, the coupling of Bushehr NPP with 5 possible scenarios of seawater desalination, which has been described in previews sections is presented. The initial total capacity of the desalination unit (for all methods) is suggested being 150 000 m3/day. Notwithstanding, the optimum total capacity in terms of cost can be estimated within the range of 50 000 to 200 000 m3/day. In the same way, several parameters such as discount rate and the ratio of the flow rate obtained by the thermal method of desalinated water to the total capacity of the desalination plant (thermal/RO ratio) are considered as variable parameters in order to demonstrate the behavior of outputs. With the purpose of making analyze simpler, except for the particular properties of Bushehr NPP, all other technical and economic input parameters were assumed to be the same as the default of DEEP database. The main desalination parameters at the Bushehr nuclear power plant considered in this study are as follows:

Total dissolved solids, ppm | 40 000 |

Feed water inlet temperature for reverse osmosis, °С | 25 |

The lifetime of the desalination system, year | 20 |

Interest rate, % | 4 |

Discount rate, % | 5 |

Electricity selling price, $/(MW h) | 100 |

Water selling price, $/m3 | 1.9 |

Results of Desalination Cost Calculations

Table 2 is listed all the important economic output parameters for different desalination methods by coupling of the Bushehr nuclear power plant. The summaries of tabulated numerical values about the cost parameters for each scenario are visualized in Fig. 2. The obtained results are based on the total capacity of 150 000 m3/day. Output economic parameters include:

• The capital costs of the desalination unit

• Energy costs

• Operating and maintenance costs

One of the most remarkable results to emerge from Fig. 2 is that the MSF method is the highest-priced option. According to the given details, the main cost differences between the possible scenarios are total energy costs, which include heat costs and electricity costs. It is apparent from data that the heat cost covers almost more than half of the MSF water production cost, while RO has zero heat cost because it does not require any heat. On the other hand, the total water cost of MSF is approximately 0.44% more than the MED price. As it was expected the RO technology has the lowest total cost. However, according to different reports, it seems that the most usable method in nuclear desalination units, which are coupled with PWR reactors is the hybrid method. There are several logical and economic reasons to implement a hybrid complex for a dual-purpose unit such as:

• the intake seawater of the desalination plant is typically smaller than the single technology and can be shared in different units;

• it’s possible to use the seasonal surplus of idle power and diversify steam/power allocations;

• by using the RO plant with one of the thermal methods, because of the less energy consuming RO, the fuel costs will be decreased compared with using just thermal methods;

• the cost of concentrate and cooling water discharge will be reduced;

• it’s possible to combine the higher-salinity RO product with the better quality product of a thermal desalination unit in order to eliminate the problem of high-quality water requirement in the first cycle of the nuclear reactor.

In the hybrid case of this study, the amount of total capacity has been divided into two parts, in which the thermal/RO ratio is considered 30%. The thermal method could be either MED or MSF, contingent upon the economic aspects. By considering the obtained outputs of DEEP for Bushehr nuclear desalination plant, and the advantages of using hybrid methods, it seems that the RO + MEDprocess can be selected as the best choice in terms of costs, among the suggested scenarios. Nonetheless, it is conceivable that our suggested scheme faces a number of industrial limitations of the country, which analyzing them are beyond the scope of this study.

According to Iranian standards and the lifestyle of residents, the average daily consumption of water varies in different cities from 150 to more than 300 liters. The total water consumption of Bushehr city extremely depends upon climate conditions. Bushehr is one of the warmest cities in Iran. The average daily high temperature is about 30°С and consequently, the demand water of the region is relatively more than other cities of the country. Initially, the total capacity of producing freshwater can be considered up to 150 000 m3/day. By considering the population of city in 2020 (about 350 000), average daily consumption (about 300 liters per person) and the industrial consumption of power plant, this amount of water, as a safe water source, not only is sufficient for demand of potable water in Bushehr city, but also it can be transferred to neighbor villages of the city in order to work out the dilemma of water deficit. It can be predicted that the potable water demand in Bushehr and neighboring villages of the city will increase to reach around 250 000 m3/day in future, which can be supplied by means of the second unit of Bushehr nuclear power plant. In Fig. 3 the varying of total water cost with different total capacities for each scenario is demonstrated.

In a recent studyFootnote 1 of the best hybrid plant combination (RO + MED and RO + MSF), a ratio of 2 : 1 in RO plant to thermal plant product capacity was found to be optimal in terms of overall system cost. Thereby in our suggested process (RO + MED), the MED portion is considered to comprise 30% of the total capacity for supplying the demands of high-quality water in plant and future development of the site.

In our study, the effect of changes in input values and assumptions made in DEEP and justifying the weight of importance of parameters during the computation of the water cost has been evaluated. The main approach of the sensitivity analysisFootnote 2 is to choose a base case scenario of input values and to perturb each input variable by a given percentage away from the base value while keeping all other input variables constant. In Fig. 4 some of the input variables for RO, MED, RO + MED and RO + MSF methods are adjusted by ±10% and are sorted by their influence on the results. According to Fig. 4, the costs have high sensitivity to the interest rate, power plant availability, lifetime and power plant cost rate.

The comparison between the water cost of nuclear energy and fossil fuels for Bushehr desalination unit is carried out. The considered energy sources for this analysis are Oil-steam cycle, Coal-steam cycle, Gas turbine, Combined Cycle (Steam Turbine) and the VVER-1000 power plant. The calculations have been carried out for various total capacity and interest rate and are listed in Table 3.

From Table 3 you can see the following conclusions.

1. The best case of the thermal scenario is corresponding to MED method with total capacity of 150 000 m3/day and interest rate of 5%, which is obtained by the nuclear energy and is always better than the best case of thermal desalination with fossil fuels (Coal power plant–MED method with total capacity of 150 000 m3/day and interest rate of 5%). Furthermore, it is obvious that the MSF method generally, is not a suitable process, compared to all the thermal, electrical and hybrids systems.

2. In the RO method, the best case again is obtained by nuclear energy. However, the total costs of the produced water with the coal power plant and the combined cycle is approximately close to the VVER case. But results show that the oil power plant absolutely is not a beneficent case to produce freshwater by the RO method in the case of the cost.

3. The best variant within the nuclear options is always better than the best variant within the fossil fuel options for hybrid systems. The worth case of the MED-RO for VVER [0.89 $/(m3 day)] is better than the best case of fossil fuels with the hybrid process [0.90 $/(m3 day)].

The economic evaluation is repeated with considering the changing of the interest rate for 5 possible options of desalination and the details are indicated in the Fig. 5. As can be seen, the maximum effect of changing the interest rate belongs to the thermal method and the RO method has the minimum sensitivity among all processes.

The effects of changing the feedwater temperature on the total costs are reported for the Bushehr nuclear power plant. Calculations are repeated for several values of feed temperature and the results are indicated in Fig. 6 for processes with RO technology.

CONCLUSIONS

(1) It was evident that using nuclear energy to supply the required freshwater of the Bushehr city is more beneficial than the utilization of fossil fuels such as oil and coal.

(2) Due to the several advantages of using the pre-heat systems for the inlet of feed water for the RO unit, the effects of this option on the total cost of produced freshwater evaluated. This analysis showed that by using the waste heat released from different parts of the power plant and using them as the pre-heater, the total cost of the produced water can be decreased.

(3) The general desalination schemes with the total capacity of the 150 000 m3/day, various desalination methods and standards input parameters presented. According to the obtained results, the MSF method is the highest-priced option, while the RO method is the lowest-priced. By comparison of their total costs, finally, the hybrid scheme of RO+MED with thermal/RO ration of 0.7 suggested.

(4) The effects of the exact value of interest rate on the total costs for Iran assessed and it was obvious that the maximum effect of changing the interest rate belongs to the thermal method, MSF and MED and the RO method has the minimum sensitivity among all processes.

(5) The produced freshwater in the Busher plant can be increased in the next years by installing the second and third blocks of Bushehr NPP, which already are under the contract. We propose that further research should be undertaken in the optimizing the new desalination units for second and third blocks of Bushehr NPP, in case of the cost. In addition, future work should focus on analyzing and optimizing of thermodynamic aspects of Bushehr nuclear power plant desalination, analyzing the possible options of reusing brine water and also considering the safety aspects of coupling the water plant to the nuclear power plant in the case of the Bushehr NPP.

Notes

IAEA, Economics of Nuclear Desalination: New Developments and Site-Specific Studies. IAEA, Vienna, 2007.

Sensitive analysis—analysis of the sensitivity of models to changes in their parameters.

REFERENCES

M. Shatat, M. Worrall, and S. Riffat, “Opportunities for solar water desalination worldwide: Review,” Sustainable Cities Soc. 9, 67–80 (2013). https://doi.org/10.1016/j.scs.2013.03.004

World Economic and Social Survey 2011 (UN DESA, New York, 2011).

Desalination by the Numbers (Int. Desalin. Assoc., 2013).

E. Jones, M. Qadir, M. T. H. van Vliet, V. Smakhtin, and S.-M. Kang, “The state of desalination and brine production: A global outlook,” Sci. Total Environ. 657, 1343–1356 (2019). https://doi.org/10.1016/j.scitotenv.2018.12.076

K. Zotalis, E. G. Dialynas, N. Mamassis, and A. N. Angelakis, “Desalination technologies: Hellenic experience,” Water 6, 1134–1150 (2014). https://doi.org/10.3390/w6051134

Nuclear Power in the World Today (World Nucl. Assoc., London, 2014).

P. Compain, “Solar energy for water desalination,” Procedia Eng. 46, 220–227 (2012). https://doi.org/10.1016/j.proeng.2012.09.468

Introduction of Nuclear Desalination (IAEA, Vienna, 2000).

Floating Nuclear Energy Plants for Seawater Desalination (Proc. Technical Committee Meeting, Obninsk, Russia, May 29–31,1995) (IAEA, Vienna, 1995). https://www-pub.iaea.org/MTCD/Publications/PDF/te_0940_scr.pdf.

Advanced Applications of Water Cooled Nuclear Power Plants (IAEA, Vienna, 2008), IAEA-TECDOC-1584. https://pub.iaea.org/MTCD/Publications/PDF/te_1584_ web.pdf.

Safety Aspects of Nuclear Plants Coupled with Seawater Desalination Units (IAEA, Vienna, 2001), IAEA-TECDOC-1235. https://pub.iaea.org/MTCD/publications/ PDF/te_1235_prn.pdf

Economics of Nuclear Power (World Nucl. Assoc., 2017). http://www.worldnuclear.org/information-library/economic-aspects/economicsof-nuclear power.aspx

Technical and Economic Evaluation of Potable Water Production Through Desalination of Seawater by Using Nuclear Energy and Other Means (IAEA, Vienna, 1992), IA-EA‑TECDOC-666. http://iaea.org/inis/co-llection/ NC-LCollectionStore/_Public/24/007/24007848.pdf

Examining the Economics of Seawater Desalination Using the Deep Code (IAEA, Vienna, 2000), IAEA-TECDOC-1186. http://pub.iaea.org/MTCD/publications/ PDF/te_1186_prn.pdf

F. Khalid, I. Dincer, and M. A. Rosen, “Comparative assessment of CANDU 6 and sodium-cooled fast reactors for nuclear desalination,” Desalination 379, 182–192 (2016). https://doi.org/10.1016/j.desal.2015.10.009

M. Y. Park and E. S. Kim, “Thermodynamic evaluation on the integrated system of VHTR and forward osmosis desalination process,” Desalination 337, 117–126 (2014). https://doi.org/10.1016/j.desal.2013.11.023

Y. H. Jung, Y. H. Jeong, J. Choi, A. F. Wibisono, J. I. Lee, and H. C. No, “Feasibility study of a small-sized nuclear heat-only plant dedicated to desalination in the UAE,” Desalination 337, 83–97 (2014). https://doi.org/10.1016/j.desal.2013.11.003

S. Nisan and S. Dardour, “Economic evaluation of nuclear desalination systems,” Desalination 205, 231–242 (2007). https://doi.org/10.1016/j.desal.2006.05.014

G. Alonso, S. Vargas, E. del Valle, and R. Ramirez, “Alternatives of seawater desn usalinatioing nuclear power,” Nucl. Eng. Des. 245, 39–48 (2012). https://doi.org/10.1016/j.nucengdes.2012.01.018

T. Mezher, H. Fath, Z. Abbas, and A. Khaled, “Techno-economic assessment and environmental impacts of desalination technologies,” Desalination 266, 263–273 (2011). https://doi.org/10.1016/j.desal.2010.08.035

M. W. Shahzad, M. Burhan, Li Ang, and Kim Choon Ng, “Energy-water-environment nexus underpinning future,” Desalination 413, 52–64 (2017). https://doi.org/10.1016/j.desal.2017.03.009

A. Cipollina, G. Micale, and L. Rizzuti, Seawater Desalination: Conventional and Renewable Energy Processes (Springer-Verlag, Berlin, 2009). https://doi.org/10.1007/978-3-642-01150-4

B. R. Hughes, F. Reza Zadeh, and H. N. Chaudhry, “Economic viability of incorporating multi-effect distillation with district cooling systems in the United Arab Emirates,” Sustainable Cities Soc. 7, 37–43 (2013).https://doi.org/10.1016/j.scs.2012.10.002

A. Rezaei, A. Naserbeagi, Gh. Alahyarizadeh, and M. Aghaie, “Economic evaluation of Qeshm island MED-desalination plant coupling with different energy sources including fossils and nuclear power plants,” Desalination 422, 101–112 (2017). https://doi.org/10.1016/j.desal.2017.08.016

Renewable Energy in the Water, Energy and Food Nexus: Report (Int. Renewable Energy Agency, 2015). http:// www.irena.org/DocumentDownloads/Publications/ IRENA_Water_Energy_Food_Nexus_2015.pdf

C. Sommariva, Desalination and Advance Water Treatment: Economics and Financing (Balaban, Hopkinton, MA, 2010).

K. Z. Al-Subaie, “Precise way to select a desalination technology,” Desalination 206, 29–35 (2007). https://doi.org/10.1016/j.desal.2006.04.049

M. A. Shannon, P. W. Bohn, M. Elimelech, J. G. Georgiadis, B. J. Mariñas, and A. M. Mayes, “Science and technology for water purification in the coming decades,” Nature 452, 301–310 (2008). https://doi.org/10.1038/nature06599

I. C. Karagiannis and P. G. Soldatos, “Water desalination cost literature: Review and assessment,” Desalination 223, 448–456 (2008). https://doi.org/10.1016/j.desal.2007.02.071

H. Malekinezhad, “Study on the water availability in Iran, using the international water indicators,” in Proc. 8th Int. Congr. on Civil Engineering, Shiraz, Iran, May 11–13,2009 (Dānišgāh Dep. Civil Environ. Eng., Shiraz, 2009). http://iwra.org/member/congress/resource/abs353_article.pdf

N. A. Tir, F. Momeni, and G. T. Boboevich, “Exploring the effects of water sector investment in economic development in Iran,” Procedia - Soc. Behav. Sci. 131, 396–405 (2014).

I. Al-Mutaz, “Hybrid RO MSF: A practical option for nuclear desalination,” Int. J. Nucl. Desalin. 1, 47–57 (2003). https://doi.org/10.1504/IJND.2003.003442

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sadeghi, K., Ghazaie, S.H., Fedorovich, E.D. et al. Economic Assessment of the Possible Desalination Processes for the First Unit of Bushehr Nuclear Power Plant. Therm. Eng. 67, 271–281 (2020). https://doi.org/10.1134/S0040601520050080

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601520050080