Abstract—

Coals from the Ekibastuz, Maikuben, and Karazhyra deposits in Kazakhstan were subjected to thermal analysis for determining the temperature ranges suitable for producing high-calorific gaseous fuel with optimal characteristics. Thermal experiments were performed using the thermogravimetric (TG and DTG) and differential thermal analysis (DTA) methods in oxidizing (air) and inert (helium) media in the temperature range from room temperature to 700–900°С at a linear heating rate of approximately 10°С/min. The results obtained from the TG, DTA, and DTG analyses made it possible to identify three main thermal decomposition intervals of the studied coals in air and in oxygen-free medium: at a temperature below 120–140°С (in air) and below 130–160°С (in helium flow), the water adsorbed in the coal is removed from it; at 280–480°С, low-molecular volatile coal pyrolysis products release and burn (in oxygen-containing medium); the temperature range 340–530°С corresponds to the stage of primary or rapid pyrolysis of coal (in inert medium); the char derived from coal burns (in oxygen-containing medium) at temperatures higher than 480°С; and temperatures above 510°С correspond to the stage of secondary or slow pyrolysis of coals (in inert medium). The maximum yield of volatile products (16.2%) is obtained from the pyrolysis of coal from the Maikuben deposit, and their minimum yield (7.1%) is obtained from the pyrolysis of Ekibastuz coal. The reactions of intensive release of volatile products at the rapid pyrolysis stages of the studied coals end with exothermic (500–550°С) and endothermic (at approximately 650°С) condensation of emerging aromatic structures and formation of char residues. The data presented in the article can be used in searching for raw coal material most suitable for obtaining high-calorific fuel and for selecting the conditions for its industry-grade devolatization.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Coal devolatization or, more precisely, the stage of its partial pyrolysis for obtaining high-calorific fuel is the subject of the scientific investigations whose results are presented in this article. This is a topical scientific problem that is of undoubted practical interest. This problem is considered in quite a detailed manner in many literature sources, primarily for determining the thermal effects relating to thermal decomposition processes of coals, their technical characteristics, physicochemical properties, etc. The pyrolysis mechanism of coals as a heterogeneous system has been described on the examples of certain coal grades [1, 2]. In this study, we made an effort to study the behavior of some grades of Kazakhstan power plant coals when being heated in oxidizing and neutral media to determine the temperature intervals of their decomposition and estimate the effectiveness of using them in pyrolytic processes.

Table 1 summarizes the results from a technical analysis of coals from the Ekibastuz, Maikuben, and Karazhyra deposits that were selected as study subjects in this work.

Thermal analysis is one of the widely known methods for coal investigation [3–5]. Among its different versions, analytical techniques—which obtain the dependences of changes in the studied sample mass and temperature on the heating temperature in graphic form—yield the most informative results. They reflect the changes occurring in the composition and structure of the studied sample during its heating and indicate the breaking and/or formation of molecular bonds in it at each pyrolysis stage. The principle of plotting such dependences lies at the heart of the derivatographic method. By using this method, it is possible to trace the change in the sample mass and its variation rate during the experiment and simultaneously record the release and absorption of heat or, more exactly, the increase or decrease of the studied sample’s temperature in response to linear increase and decrease of temperature in the thermal reaction zone [4, 5]. Thus, it becomes possible to consider, in a sequential and detailed manner, different coal devolatization stages from its drying to full decomposition of burning out [1].

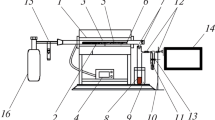

In this study, the thermal decomposition curves for the studied coals in air and in inert media were obtained using the Q-1500D derivatograph (Hungary), the design of which had been modified by adding the I-7018P analog-to-digital converter module (ICP DAS, Taiwan) for analog-to-digital conversion of the signals with subsequently recording them on a personal computer using the SIMP Light computer program (SIMP Light SCADA, Russia). The obtained results were subjected to final mathematical processing using the Origin Pro software package (OriginLab, United States). During the experiments, the samples were heated to 700–900°C at a rate of approximately 10°С/min. The sample’s weighed portion was 200–400 mg; α-oxide of aluminum calcinated at 1200°C was used as the comparison (reference) sample. In being subjected to devolatization in inert medium, the coal samples were placed in a flow of helium (with purity of 99.99%) moving with a flowrate of 300–450 cm3/min.

For any single-stage nonisothermal reaction, it is possible to select two characteristic points on its thermogravimetric curve: the initial decomposition temperature at which the total change of mass reaches the sensitivity of thermal scales, and the final temperature at which the total change of mass reaches its maximal value corresponding to completion of the reaction. By applying such approach, it is possible to determine the most optimal intervals of carrying out thermal processes in practice.

The results of experiments on firing the studied coals in air in the derivatograph furnace are shown in Fig. 1 as dependences of sample mass m (the TG curve), its variation rate dm/dt (the DTG curve), and the difference between the studied sample and reference sample temperatures Δt (the DTA curve) on the heating temperature t.

In subjecting coal from the Ekibastuz deposit to a thermal analysis (the initial mass was 196 mg, and the mass of residue was 64 mg), the sample heating process starts from the temperature equal to 18°С (see Fig. 1a). A decrease in its mass (the TG curve) is observed as the heating is started. In the temperature interval 18–115°С, adsorbed water is removed; i.e., the sample is dried. The small loss of sample mass (1.8 g) is almost identical with the data from technical analysis of the studied coal (according to which its moisture content is equal to 0.86%). However, a wide endoeffect is observed on the DTA curve in the temperature range 80–220°С, which is connected with heat absorption during the evaporation of water in all likelihood. After the drying is completed, the sample mass increases slightly at temperatures above 200°С; this increase reaches its maximum at 277°С, which, taking into account the sample heating medium (air), can be attributed to the occurrence of coal oxidation reactions, during which oxygen atoms penetrate into the coal structure. Such processes (increase of sample mass during its heating) are typical for low-temperature heating of high-molecular organic compounds (polymers, coals, bitumen, etc.) in oxidizing media.

In heating the Ekibastuz coal sample to a temperature above 277°С, fragments of its molecular structure begin to decompose, as a result of which low-molecular compounds separate from the carbon matrix and transform into the gas phase. This is accompanied by a decrease in sample mass, the rate of which increases drastically at a temperature above 394°С, which is clearly seen from the TG curve. The releasing gaseous products are ignited in air medium, causing a growth of temperature in the sample zone. This gives rise to exothermal processes, which accompany the release of heat in the temperature range 350–800°С with maximums occurring at 422, 500, and 532°С. The coal decomposition and combustion processes most intensely occur in the temperature range 424–608°С with the maximum at 503°С (see the DTG curve in Fig. 1a). At temperatures above 532°С, the exoeffects begin to weaken, which is due to the fact that the gas release slows down and the combustion of char residue prevails over the combustion of gaseous products. The combustion ends at temperatures above 933°С. The mass of residue from firing the Ekibastuz coal sample in the derivatograph furnace was equal to 64 mg, which corresponds to the ash content in this coal, as was obtained in carrying out its technical analysis.

In considering the results from thermal analysis of coal from the Maikuben deposit (the sample mass before and after the experiment was 234 and 34 mg, respectively), noticeable changes in its composition were already observed at the earliest coal heating stages, i.e., in the temperature range 14–139°С (see Fig. 1b). A loss of mass (by approximately 22 mg) with simultaneous heat absorption (as is seen from the DTG curve, the maximal mass loss rate is observed at 72°С) is mainly related to the removal of adsorbed water and, which is also possible, also with simultaneous release of low-molecular organic products, because, according to the technical analysis data, the source coal had a small moisture content (approximately 5%).

Unlike coal from the Ekibastuz deposit, the decomposition and combustion processes in coal from the Maikuben deposit begin already at temperatures above 250°С, i.e., in the interval of significantly lower temperatures. This is because this coal (grade 3B brown coal) is characterized by a lower degree of metamorphism and, accordingly, has a higher content of thermally less stable aliphatic and oxygen containing structures. It should be noted that, unlike Ekibastuz coal, an increase of mass in the Maikuben coal sample before its decomposition (due to the penetration of oxygen atoms) is not observed almost at all.

The intense decomposition processes of Maikuben coal with release and ignition of low-molecular products occur in the temperature range 280–480°С with the maximum on the DTG curve at 347°С, which is accompanied by the occurrence of a series of exothermal effects with maximums at 293, 327, 390, and 470°С (see Fig. 1b). The loss of mass in this temperature range (approximately 100 mg) is in good correlation with the data from the technical analysis of Maikuben coal regarding the yield of volatiles. At higher temperatures (above 470°С), Δt on the DTA shows hardly any increase, but exoeffects with loss of mass continue to manifest themselves up to the end of sample combustion (950°С). The mass of the residue after completion of the experiment was equal to 34 mg, which is fairly close to the ash content of Maikuben coal according to the data of its technical analysis.

In carrying out the thermal analysis of the coal sample from the Karazhyra deposit (its mass before and after the experiment was equal to 250 and 34 mg, respectively), the sample was dried taking the thermogravimetry data into account (the TG curve) in the temperature range from 18 to 118°С, during which the sample lost 13 mg of its mass (see Fig. 1c).

The maximal mass loss rate (see the DTG curve) is observed at 87°С. At temperatures above 200°С, a small growth is observed on the TG curve, which reaches its maximum at 235°С. Like for Ekibastuz coal, this is because oxygen atoms penetrate into the coal structure as a consequence of its oxidation. And like for Ekibastuz coal, the low-molecular volatile products obtained from devolatization of coal from the Karazhyra deposit in air begin to release and burn at temperatures above 270–300°С (which is reflected by the decrease in sample mass on the TG curve and by the increase in sample temperature with respect to the reference sample temperature on the DTA curve). But these processes occur most intensely in the temperature range 380–490°С (the loss of mass is 115 mg) with the maximum at 424°С (the DTG curve). It should be noted that the endothermal coal thermal destruction processes predominate in this temperature range over the combustion of its decomposition products, as a result of which the endoeffect emerges, which takes place in this region with the maximum at 434°С (the DTA curve). At temperatures above 490°С, with which the gas release reactions become less intense, the combustion processes again become prevailing, and exothermal effects are only observed in the wide temperature range from 490 to 665°C (see the DTA curve in Fig. 1c). The mass of ash residue remaining after devolatization of the Karazhyra coal sample in air under programmed temperature conditions to 665°С was approximately 30 mg, which is in quite satisfactory agreement with the ash content of this coal according to the technical analysis data.

The results obtained in this study for thermal decomposition of the studied Kazakhstan coals in air are in quite good agreement with the data known from the literature. Thus, the authors of [6] have shown that the coal devolatization process in oxidizing medium can be conditionally divided into three stages: preheating, release of volatiles, and coal substance combustion. It should be noted that the pattern of processes that occur at these stages in different coals depends on the degree of their metamorphism. During thermal decomposition of comparatively young and low-metamorphized coals (in particular, Maikuben coal), a large amount of readily ignited volatiles is released already at relatively low temperatures. This is why a two-peak combustion pattern with the first exothermal effect emerging at a temperature of approximately 300°C is clearly seen on the DTA curve for these coals [6]. For coals with a high degree of metamorphism (anthracite), which have a small content of volatiles, there is no exothermal peak at this stage, i.e., at temperatures near 300°C. Bituminous (black) coals with a moderate degree of metamorphism demonstrate a smooth exothermal oxidation curve (DTA) on the derivatograms without clear-cut separation of low- and high-temperature combustion regions. It should be pointed out that, for coals with a higher degree of metamorphism (bituminous coals and anthracites), a small increase of sample mass preceding their decomposition is noted on their TG curves in the temperature range 200–350°C [6].

In the opinion of the authors of [7], the increase in the mass of coals when being heated in air in the temperature range from 100 to 250°C is due to adsorption of oxygen on their surface with the generation of oxygen-containing complexes, a phenomenon that can serve as a clear indicator of coal’s proneness to self-oxidation. In particular, the authors of [7] have shown that the stability of these surface oxygen-containing complexes can be determined from the loss of mass observed in heating the sample.

High-reactive coals prone to self-ignition tend to produce unstable oxygen-containing complexes, which decompose at relatively low temperatures and release heat without a growth of mass. Low-reactive coals produce highly stable oxygen-containing complexes that decompose at much higher temperatures. These coals show a slower reaction with oxygen to cause a noticeable increase of mass in the range 100–250°C [7]. In their later studies, the authors of [7] revealed three low-temperature coal oxidation stages preceding their direct burning: slow, accelerated, and rapid oxidation. The activation energies obtained by the authors of [8] at the slow and accelerated oxidation stages increased with increasing the metamorphism degree of the studied coal, whereas the activation energies at the rapid oxidation stage hardly changed. In this connection, the authors of [8] believe that it is particularly the activation energy values at the first two oxidation stages that can be considered as the markers for revealing the solid fuel’s proneness to self-ignition.

The thermal decomposition curves of the studied coal samples obtained in the inert gas atmosphere (in a helium flow) are shown in Figs. 2a–2c, from which it follows that the thermal processes in inert medium become essentially different in nature. This can be attributed to the absence of oxygen, which participates in the coal oxidation reactions in the heating zone gas phase. Thus, in analyzing coal from the Ekibastuz deposit (the sample initial and final mass was 463 and 384 mg, respectively), the total loss of sample mass after its devolatization was no more than 17% (see Fig. 2a); that is, the major part of carbon remained in the sample and did not transfer into the gas phase, whereas the total loss of mass in analyzing the same sample in air medium was 67% (see Fig. 1a).

Adsorbed water leaves the sample in the temperature range 15–158°С. The increase in the sample mass at 200–280°С, which was due to penetration of oxygen into the coal matrix structure during devolatization in air medium (see Fig. 1a), is not observed in this case. The organic mass of Ekibastuz coal begins to decompose at temperatures above 400°С; this process takes place most intensely in the temperature range 407–534°С with the mass loss rate reaching its maximum (the DTG curve) at 453°С. Since the relative loss of mass determined in analyzing this coal had comparatively small values, the thermal effects corresponding to these changes of mass were also quite weak, and a certain total decrease of Δt values on the DTA curve in the range 50–600°С can be attributed to more intense cooling of the studied coal sample by the supplied helium flow (which is cooler than the medium’s temperature in the reaction zone).

During the investigations, the helium flowrate had to be kept quite high (no less than 300 cm3/min) for maximally full removal of oxygen from the atmosphere in the studied sample heating zone. This is because the heating zone in the derovatograph is not fully hermetic, and inert atmosphere in it is set up mainly by displacing air with helium (similar conditions were also observed in analyzing coals from the Maikuben and Karazhyra deposits). The exoeffect with the maximum on the DTA curve at 534°С observed after completion of the most intense pyrolysis stage of Ekibastuz coal is in all likelihood connected with condensation of aromatic structures and generation of char residue, which usually take place after removing the major part of volatile products during the pyrolysis of low-metamorphized coals [2, 9]. However, we should not fully exclude the possibility that oxidation of coal due to random ingress of air in the studied sample heating zone can also make a certain contribution to the occurrence of this effect.

The total loss of mass that occurred in subjecting the coal sample from the Maikuben deposit to pyrolytic decomposition in helium flow (its initial and final mass values were equal to 424 and 257 mg, respectively) is 40%, which is essentially more than the total loss of mass observed during the pyrolysis of Ekibastuz coal (17%). It should be pointed out that the loss of mass that occurred in decomposing the Maikuben coal sample in air was 86%, which is more than a factor of two higher than the similar indicator obtained in inert atmosphere. During the thermolysis of Maikuben coal in inert medium, the adsorbed water escapes from it in the temperature range 15–132°С (the maximum H2O removal rate is observed on the DTG curve at 67°С), i.e., approximately in the same manner as when analyzing this sample in air (see Fig. 1b). The escape of adsorbed moisture is accompanied by a small endoeffect at 86°С on the DTA curve (see Fig. 2b), and the most intense release of volatile pyrolysis products occurs in the temperature range 343–519°С with the maximal release rate reached at 415°С (see Fig. 2b). A similar process in the presence of air oxygen (see Fig. 1b) is observed at noticeably lower temperatures (300–416°С).

It should also be added that the intense decomposition stage corresponds to the endoeffect at 492°С on the DTA curve (see Fig. 2b). As for Ekibastuz coal, the completion of the intense volatile products’ releasing stage during the pyrolysis of coal from the Maikuben deposit at temperatures above 500°С is accompanied by exothermal condensation processes of the generating aromatic structures and formation of char residue (the exotherms at 522 and 545°С on the DTA curve). The endothermal effect occurring on the DTA curve at 651°С may be caused by the further dehydration and condensation processes of the produced char [9].

During pyrolytic decomposition of coal from the Karazhyra deposit in inert medium, adsorbed water is escaping in the temperature range 17–154°С, which is accompanied by the mass loss effect on the DTG curve with the maximum at 74°С (see Fig. 2c). As for Ekibastuz coal, during the devolatization of coal from the Karazhyra deposit in helium flow, no increase in sample mass was observed in the temperature range 200–280°С (see the TG curve), which was recorded during the thermal analysis of this coal in air (see Fig. 1c). In all likelihood, this is connected with the absence of oxygen in the reaction medium’s gas phase. The Karazhyra coal’s intense decomposition stage accompanied by the release of volatile compounds is observed in the range 349–507°С with the maximum at 423°С (the DTG curve). This pyrolysis stage corresponds to two endothermal effects on the DTA curve: at 468 and 496°С after the completion of which exothermal processes are started (the exoeffects at 521 and 554°С). In all likelihood, this is connected with the condensation of generating aromatic structures and the formation of char residue (see Fig. 2c). The endothermal effect that occurs at 655°С on the DTA curve of the considered coal can be related, as in the case of pyrolyzing Maikuben coal, to the dehydration and further condensation processes of the produced char. The total loss of mass in the experiment with the pyrolysis of coal from the Karazhyra deposit was 171 mg, i.e., 41%. A similar loss of mass occurred in decomposing this coal in air medium, i.e., in the presence of oxygen, and was equal to 86%, which is greater than a factor of two more than the loss of mass after subjecting this coal to devolatization in inert medium.

Summarizing what was said above, it should be emphasized that, for all studied coals that were subjected to devolatization in oxidizing medium (Table 2) and in inert medium (Table 3), three most pronounced thermal conversion regions are observed: removal of adsorbed water at a temperature below 140°С (in air) and below 160°С (in helium flow), release and burning of low-molecular volatile coal pyrolysis products (in air) at a temperature of 280–480°С, the primary or rapid coal pyrolysis stage at 340–530°С (in helium flow), and the burning of the char produced from coals at a temperature above 480°С (in air) and the secondary or slow coal pyrolysis stage at a temperature above 510°С (in helium flow).

Such a picture is generally typical for nonisothermal pyrolysis processes of solid fuel. It is believed [10, 11] that CO2, CO, H2O, methane СН4 and its homologues, as well as light unsaturated hydrocarbons, are the key components at the primary pyrolysis stage among the releasing gaseous products. These products are generated as a result of decomposition of aliphatic structures and separation of lateral substitutes from the carbon frame of the coal’s organic structure. At the secondary (high-temperature) pyrolysis stage, the bonds are broken, and the carbon matrix of coals themselves is transformed. Under such conditions, Н2 and CO, and also CS2 and HCN (in small amounts), are the main releasing gaseous products [11]. As is seen from the data given in Table 3, the maximal amount of volatile products (16.2%) is generated during the pyrolysis of coal from the Maikuben deposit, and their minimal amount is generated during the pyrolysis of Ekibastuz coal (7.1%).

Thus, it becomes possible using the obtained results to consider in detail the thermal decomposition processes of the investigated solid fuels in oxidizing (combustion) and inert (pyrolysis) media for each coal grade and at each stage of their devolatization starting from the drying stage and ending with complete combustion of coal substance. These data can be used in searching for the most suitable raw coal material for obtaining high-calorific fuel and selecting the conditions for its industrial devolatization.

CONCLUSIONS

(1) In subjecting coals from the Ekibastuz, Maikuben, and Karazhyra deposits to thermal decomposition in air, their organic mass begins to burn at temperatures of 250–300°С. In the range 300–500°С, the burning takes place concurrently with the coal substance pyrolysis (release of volatile products). In burning Ekibastuz and Karazhyra coals, their burning is preceded by oxidation without release of volatile products, which is accompanied by a growth in the mass of the studied samples. The mass of that remaining obtained after temperature-programmed heating of studied coals in air to 665–950°С is approximately consistent with the ash content of these coals according to their technical analysis data.

(2) In subjecting the studied coals to devolatization both in oxidizing (air) and inert (helium) media, three main regions of their thermal decomposition are observed: at temperatures below 140°С (in air) and below 160°С (in helium flow), the adsorbed water is removed; at 280–480°С, low-molecular volatile coal pyrolysis products release and burn (in air) and the primary or rapid coal pyrolysis stage (in helium flow) takes place at 340–530°С; at temperatures above 480°С, the char produced from coals burns (in air); and at temperatures above 510°С, the stage of secondary or slow pyrolysis (in helium flow) takes place.

(3) The maximal amount of volatile products released at the rapid pyrolysis stage (16.2%) is obtained during the pyrolysis of coal from the Maikuben deposit, and their minimal amount (7.1%) is obtained during the pyrolysis of Ekibastuz coal. The reactions of intense release of volatile products at the rapid pyrolysis stages for the studied coals are completed with exothermal (500–550°С) and endothermal (650°С) condensation of the generating aromatic structures and the formation of char residue.

REFERENCES

B. S. Belosel’skii and V. K. Solyakov, Fuel for Power Generation (Energiya, Moscow, 1980) [in Russian].

V. P. Ignashin, N. D. Rus’yanova, and A. V. Tenina, “Vicissitude of coal transformation during pyrolysis,” Khim. Tverd. Topl., No. 6, 7–12 (1991).

Principles of Thermal Analysis and Calorimetry, Ed. by P. J. Haines (The Royal Society of Chemistry, Cambridge, UK, 2002).

W. W. Wendlandt, Thermal Methods of Analysis (New York, Interscience, 1964; Mir, Moscow, 1978).

M. E. Brown, Introduction to Thermal Analysis. Techniques and Applications (Kluwer, New York, 2004).

Y. Chen, S. Mori, and W. P. Pan, “Estimating the combustibility of various coals by TG-DTA,” Energy Fuels 9, 71–74 (1995).

C. Avila, T. Wu, and E. Lester, “Estimating the spontaneous combustion potential of coals using thermogravimetric analysis,” Energy Fuels 28, 1765–1773 (2014).

Y. Zhang, J. Wang, S. Xue, Y. Wu, Z. Li, and L. Chang, “Evaluation of the susceptibility of coal to spontaneous combustion by a TG profile subtraction method,” Korean J. Chem. Eng. 33, 862–872 (2016).

N. D. Rus’yanova, Coal Chemistry (Nauka, Moscow, 2003) [in Russian].

S. K. Janikowski and V. I. Stenberg, “Thermal analysis of coals using differential scanning calorimetry and thermogravimetry,” Fuel 68, 95–99 (1989).

S. Ma, J. O. Hill, S. Heng, and A. Kinetic, “Analysis of the pyrolysis of some Australian coals by non-isothermal thermogravimetry,” J. Therm. Anal. 37, 1161–1177 (1991).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by V. Filatov

Rights and permissions

About this article

Cite this article

Bogomolov, A.R., Petrov, I.Y. & Zhalmagambetova, U.K. Thermal Analysis of Coals from Kazakhstan Deposits. Therm. Eng. 67, 165–172 (2020). https://doi.org/10.1134/S0040601520030015

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601520030015