Abstract

Corrosion of low-carbon steel St3 in 2 M H2SO4 containing Fe2(SO4)3 was studied by measuring mass loss of the metal samples and using voltammetric measurements on a rotating disk electrode. Corrosion of steel in this medium involves anodic ionization of steel proceeding in the kinetic region and two cathodic partial reactions: hydrogen evolution and reduction of Fe(III) to Fe(II) cations characterized by kinetic and diffusion control, respectively. The potentiometric data measured on a platinum electrode in 2 M H2SO4 containing Fe2(SO4)3 and FeSO4 made it possible to establish that Fe(III) cations are bound in complexes with sulfate anions in these media. The oxidizing ability of a corrosive medium, characterized by the Fe(III)/Fe(II) redox pair potential, depends on the Fe(III) content in it and is well described by the Nernst equation. The diffusion coefficients of Fe(III) cations were determined by cyclic voltammetry on a platinum electrode in 2 M H2SO4 in the presence of Fe(III) and by evaluating the response of the cathodic current of a steel electrode to the convective factor in the same medium. The apparent diffusion coefficient of Fe(III) cations measured on a steel electrode in inhibited media may be significantly lower than that in uninhibited media because the penetration of Fe(III) cation through the protective layer of inhibitor to the metal surface is hindered. The weak inhibition of corrosion of low-carbon steel in H2SO4 solutions containing Fe2(SO4)3 by the composite inhibitors under study is the result of the accelerating action of Fe(III) cations on three partial electrode reactions on the metal surface: reduction of Fe(III) and H+ characterized by diffusion and kinetic control and anodic ionization of iron.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

When used under industrial conditions, mineral acid solutions contact with the steel parts of equipment or corrosion products covering them, and Fe(III) salts accumulated in them significantly lower the efficiency of metal protection by corrosion inhibitors in such media.

In simplified form, corrosion of low-carbon steels in mineral acid solutions (“non-oxidizing agents”) is described by the general reaction:

This reaction is the result of predominant partial reactions [1], namely, anodic dissolution of iron:

and cathodic release of hydrogen:

Reaction (3) [1] involves the supply of H+ from the bulk of acid to the metal surface (\({{({{{\text{H}}}^{ + }})}_{*}}\) is the hydrogen ion lying at the closest distance from the metal surface):

and the charge transfer stage (Vollmer reaction)

This is followed by the stage of chemical (Tafel reaction)

or electrochemical recombination (Heyrowsky reaction)

The set of stages (5) and (6) is called the Vollmer–Tafel mechanism; the set of (5) and (7) is the Vollmer–Heyrowsky mechanism. Both mechanisms are considered to take place on the steel surface during hydrogen liberation [2].

The known mechanisms of anodic dissolution of iron were proposed by Heusler and Bockris. Heusler considered [1] that the reaction of Fe atoms of the crystal lattice with adsorbed OH– formed the compound FeOHad:

It was assumed that the reaction of transition of Fe(II) ions through the double layer is catalyzed by this compound:

and the compound FeOH+ slowly decomposes:

Bockris [3] considered FeOH to be an intermediate during the reaction occurring in stages:

Kolotyrkin [4] and Nobe and Chin [5] admitted that the anodic reaction of iron involved not only OH–, but also the anions that formed during acid dissociation.

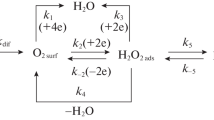

In acid solutions containing a Fe(III) salt as an additional strong oxidant, the process

also occurs, which involves the anode (2) and cathode

reactions. Our studies showed [6] that on low-carbon steel in these media, the cathodic reaction involves the parallel and independent reactions: kinetically controlled liberation of hydrogen and diffusion-controlled reduction of Fe(III) cations to Fe(II). Regretfully, the available literature gives no details on the mechanism of steel corrosion in these inhibitor-containing media, which restricts the development of approaches to metal protection in them.

In view of the foregoing, it seems important to determine the mechanism of corrosion of low-carbon steels in inhibited solutions of inorganic acids containing Fe(III) salts. As a corrosive medium we have chosen sulfuric acid, which has wide industrial applications. Binary mixtures of quaternary ammonium salts (QASs) and potassium iodide were studied as corrosion inhibitors. The composites of QASs and alkali halides, primarily, iodides, are known to be highly efficient inhibitors of steel corrosion in H2SO4 solutions [7]. Among QASs, we chose tribenzyl ethanolammonium chloride (TBEAC) and the commercially available product catamine AB (alkylbenzyldimethylammonium chloride [\({{{\text{C}}}_{n}}{{{\text{H}}}_{{2n + 1}}}\)N+(CH3)2CH2C6H5]Cl–, where n = 10–18). Important information necessary for understanding the details of the mechanism of steel corrosion in acidic solutions containing Fe(III) salts can be obtained by potentiometric [8] and voltammetric [9, 10] studies, which make it possible to quantify the oxidizing ability and mobility of Fe(III) cations in these solutions.

EXPERIMENTAL

Objects and Methods of Investigation

To prepare the solutions, we used H2SO4 (reagent grade), Fe2(SO4)3⋅9H2O (reagent grade), FeSO4⋅7H2O (reagent grade), and distilled water. The corrosion inhibitors under study included tribenzyl ethanolammonium chloride (high purity grade), catamine AB (specifications (TU) 9392-003-48482528-99) and potassium iodide (reagent grade) (State Standard (GOST) 4232-74).

The corrosion rate of St3 steel (composition, wt %: C 0.14–0.22, P 0.04, Si 0.15–0.33, Mn 0.40–0.65, S 0.05, Cr 0.3, Ni 0.3, N 0.008, Cu 0.3, As 0.08; the rest is Fe) in 2 M H2SO4 at temperatures t = 25 and 60°С was determined from the weight loss of the samples (≥3 per point) with dimensions 50 × 20 × 3.0 mm based on 50 mL of acid solution per sample:

where Δm is the change in the mass of the sample, g; S is the sample area, m2; and τ is the time of corrosion tests, h. The time of experiment is 2 h. The samples were cleaned before the experiment on an abrasive wheel (ISO 9001, grain size 60) and degreased with acetone.

The efficiency of inhibitors was evaluated from the degree of inhibition:

where k0 and kin are the corrosion rate in the supporting solution and in the solution with the addition under study. In calculations of Z, the supporting solution was taken to be a solution containing only Fe(III) cations as additives of appropriate concentration.

For quantitative characterization of the effect of Fe(III) cations on steel corrosion in acid solutions, the increment of corrosion losses expressed in percent was used, all other conditions being equal. It was determined as the difference in the steel corrosion rates in an aggressive medium in the presence and absence of a Fe(III) salt addition related to the steel corrosion rate in a medium without a Fe(III) salt.

The electrochemical measurements on St3 steel were performed on a rotating disk electrode (n = 460 rpm) in hydrogen-deaerated 2 M H2SO4 at t = 25°C. The potentials of steel were measured relative to the silver chloride electrode. The steel electrode was cleaned with M20 sandpaper and degreased with acetone. Polarization curves were recorded using an EL-02.061 potentiostat in the potentiodynamic mode at a polarization rate of 0.0005 V/s. Before polarization was applied, the electrode was kept in the test solution for 30 min to establish the free corrosion potential Ecor, and then the curves of the anodic and cathodic polarization of steel were recorded. After the recording, the dependence of the cathodic current at E = –0.30 V on the electrode rotation rate (460, 780, 1090, 1400 rpm) was studied. Thirty minutes before the study and in the course of the experiments, the investigated solutions were deaerated with hydrogen obtained in the electrolyzer from a NaOH solution. The effect of inhibitors on the electrode reactions was evaluated from the inhibition coefficient:

where i0 and iin are the current densities in the supporting solution and in the solution with the addition under study. In the calculations of γ, the supporting solution was taken to be a solution containing only Fe(III) cations in appropriate concentration as additives.

As the basic rotation rate of the steel disk electrode in electrochemical studies, we chose the lowest value, 460 rpm. At this rotation rate, the kinetic and diffusion current densities characterizing the cathodic reaction on the electrode under the experimental conditions are the closest. This situation makes us hope that the estimated effect of Fe2(SO4)3 additives and corrosion inhibitors on the partial cathodic reactions of steel will be more correct.

The potentiometric measurements in acid solutions containing Fe(III) and Fe(II) were performed in a thermostatted glass electrochemical cell with a separated space for the saturated silver chloride electrode. Smooth platinum (1.5 cm2) was used as a working electrode; a saturated silver chloride electrode served as a reference electrode. The potential difference between the working electrode and the reference electrode was determined using a PI-50 potentiostat.

Cyclic voltammetry (CV) on the platinum electrode in the media under study was performed using an EL-02.061 potentiostat in a thermostatted three-electrode glass cell with a divided electrode space. The working electrode was platinum wire (S = 15.9 mm2); the reference electrode was a silver chloride electrode; the auxiliary electrode was a platinum plate (S = 1.5 cm2). The potential scanning was performed from 1.4 to 0.0 V, and then from 0.0 to 1.4 V. The scan rate was 0.10 V/s.

The potentiometric and CV studies were performed in the solutions deaerated with argon preliminarily for 30 min and in the course of experiments. Before the experiment, the working Pt electrode was degreased with acetone, kept for 3 min in concentrated HNO3, and washed with distilled water.

The values of the electrode potentials are given here according to the standard hydrogen electrode scale.

RESULTS AND DISCUSSION

The addition of Fe2(SO4)3 to 2 M H2SO4 significantly increases the corrosion rate of low-carbon steel in it (Table 1). The addition of 0.20 M Fe(III) to 2 M H2SO4 (t = 25°C) provides 176% increment in corrosion losses. An increase in the solution temperature to 60°C enhances the effect of Fe(III) cations on steel corrosion. In this case, the proportion of the increment of corrosion losses due to the presence of Fe(III) decreases due to the high corrosion rate of the metal in the acid itself.

In 2 M H2SO4, the addition of 5 mM TBEAC + 5 mM KI significantly reduces St3 steel corrosion, making it 20 and 97 times slower at t = 25 and 60°C, respectively. The presence of Fe2(SO4)3 in the acid solution has a negative effect on steel corrosion inhibition by the composite of inhibitors. The higher the concentration CFe(III), the stronger the negative effect. At CFe(III) = 0.20 M, steel corrosion is only 2.3 and 5.5 times slower at t = 25 and 60°C, and the increment of corrosion losses is significant, 2300 and 2500%, respectively.

In 2 M H2SO4, the addition of 5 mM catamine AB + 5 mM KI inhibits steel corrosion better than the TBEAC + KI mixture, slowing it down 28 and 110 times at t = 25 and 60°C, respectively. The presence of Fe2(SO4)3 in solution also adversely affects the corrosion deceleration, especially when CFe(III) increases. At CFe(III) = 0.20 M, corrosion deceleration is 2.4 and 3.4 times at t = 25 and 60°C, and the increment of corrosion losses is even more significant, 3200 and 4600%, respectively.

The results indicate that steel protection by both composite inhibitors is unsatisfactory in 2 M H2SO4 if the Fe2(SO4)3 content in it is high. An analysis of the degrees of inhibition of total corrosion (Z) by these inhibitors and the corrosion loss increment due to the presence of Fe2(SO4)3 (ZFe(III)) in solution suggests that poor steel protection in such media is largely determined by weak inhibition of the reduction of Fe(III) cations to Fe(II) by the inhibitor. This assumption can be confirmed by studying the electrode reactions of steel in these media.

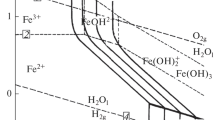

The study of the properties of the corrosive medium itself is an important step toward the understanding of processes in the corrosive medium–metal system. From a technical viewpoint, potentiometry is the simplest method for studying the properties of acid solutions containing oxidizing metal ions [11, 12]. In 2 M H2SO4 containing 0.10 M Fe(III) + Fe(II), the potential of the Pt electrode in solution is determined by the equilibrium reaction on its surface:

and the oxidizing capacity of the system increases with the Fe2(SO4)3 content in it (Fig. 1) and, as expected, is satisfactorily described by the Nernst equation:

where \(E_{{{\text{Fe(III)/Fe(II)}}}}^{^\circ }\) is the standard electrode potential of the Fe(III)/Fe(II) redox pair, and aFe(III) and aFe(II) are the active concentrations of Fe(III) and Fe(II) in solution. However, the potentials of the Pt electrode in 2 M H2SO4 + Fe(III) + Fe(II) are considerably lower than the reference values. For example, in the system under study, \(E_{{{\text{Fe(III)/Fe(II)}}}}^{^\circ }\) = 0.665 V, while the reference value is 0.771 V [13]. The reduced oxidative ability of Fe(III) cations in H2SO4 solution is the result of their binding into complex compounds by the \({\text{SO}}_{4}^{{2 - }}\) and \({\text{HSO}}_{4}^{ - }\) anions in the corrosive medium. The instability constants of these complexes reported in the literature are given in Table 2.

Potentials of a platinum electrode in argon-deaerated 2 M H2SO4 containing 0.10 M Fe(III) + Fe(II) depending on the ratio of Fe(III) and Fe(II) concentrations: (1) reference data [13] and (2) experimental dependence. Lines: theoretical dependence obtained from the Nernst equation. Dots: experimental data.

The potentiometry data qualitatively explain the effects observed in corrosion tests. The presence of Fe(III) salts in the corrosive medium significantly increases the redox potential of the latter and hence its aggressiveness toward steel. Despite the decrease in the oxidizing ability of Fe(III) cations as a result of their binding into complexes by sulfate anions, their oxidizing ability remains reasonably high. Even if СFe(III) is very low, 0.001 M, EFe(III)/Fe(II) = 0.560 V. The presence of a Fe(III) salt in the H2SO4 solution affects the thermodynamic property of the system, increasing its oxidizing ability. The higher the Fe(III) content, the higher this effect. At the same time, the Fe(III) cations as an oxidizing agent contained in the corrosive medium mainly exist in the form of sulfate complexes.

More complete information on the properties of the 2 M H2SO4 + Fe2(SO4)3 system can be obtained by CV studies. The voltammograms of the Pt electrode in these media (Fig. 2, Table 3) have two peaks. The first (cathodic) peak lying at higher negative potentials corresponds to the reduction of Fe(III) cations on the Pt electrode:

and the second (anodic) peak is due to the oxidation of the resulting Fe(II) cations:

The system under study is not equilibrium as it does not satisfy the criteria when the separation of the anodic and cathodic peak potentials is Epa – Epc ≤ 0.057 V and the ratio of anodic to cathodic peak currents is Ipa/Ipc = 1. However, the voltammograms contain both cathodic and anodic peaks, which allows us to interpret it as quasi-equilibrium [17].

The oxidizing ability of Fe(III) cations in a sulfuric acid medium is determined by the values of the half-wave potential:

which is often considered to be the redox potential of the system. The E1/2 values in the given media are close to \(E_{{{\text{Fe(III)/Fe(II)}}}}^{^\circ }\) determined potentiometrically, which also indicates that Fe(III) cations exist in an H2SO4 solution in the form of complex compounds with sulfate anions. An increase in СFe(III) in a corrosive medium causes an increase in Ipc and Ipa.

The maxima of the currents of voltammetric curves are characterized by the Randles–Ševčik equation [17]:

where z is the number of electrons involved in the redox process (z = 1 for the Fe(III)/Fe(II)) redox pair; F is the Faraday number (96 500 C/mol); S is the electrode surface area (m2); С is the concentration of the electrochemically active substance (mol/m3); D is the diffusion coefficient (m2/s); \({v}\) is the potential scan rate (V/s); R is the gas constant; and T is the absolute temperature. P is the parameter that is the function of zFvτ/RT, where τ is the time.

Equation (24) describes the redox processes occurring in equilibrium systems. However, it was noted that it can be used to describe quasi-reversible and even irreversible systems [17]. The applicability criterion of this equation for describing the cathodic process of a Pt electrode in 2 M H2SO4 + Fe2(SO4)3 are the linear dependences of Ipc on \({{{v}}^{{0.5}}}\) and СFe(III) (Fig. 3). The result allows us to conclude that it is correct to use Eq. (24) to calculate the diffusion coefficient of Fe(III) cations (DFe(III)) in the medium under study (Table 3). We have previously shown [6] that DFe(III) is an important quantity that largely determines the corrosion rate of low-carbon steel in acid solutions containing Fe(III) salts.

The most significant information on the mechanism of steel corrosion in acid solutions is provided by knowledge of how electrode reactions occur on it. In 2 M H2SO4, the shape of the polarization curves (PCs) of low-carbon steel is characteristic for corrosion occurring in the range of potentials of its active dissolution (Fig. 4, Table 4). In this medium, the slope of the cathodic polarization of steel (bc) agrees with the theoretically predicted value of 0.10 V, but the anodic polarization of the metal (ba) is higher than the theoretical value of 0.04 V [18]. The increased slope ba of steel is the result of the formation of a layer of sludge on its surface during metal dissolution, which is observed visually. The presence of Fe2(SO4)3 in solution shifts the potential of free corrosion of steel (Ecor) to the region of higher positive potentials, which is the result of the disinhibition of the cathodic reaction by this additive. The Fe(III) cations do not affect the anodic process, but the order of the cathodic reaction is positive with respect to the concentration of the cations. The initial section of the cathode PCs is characterized by the limiting current (ilim). In contrast, the slope of anodic polarization corresponds to background polarization.

The presence of Fe2(SO4)3 additives in the H2SO4 solution does not affect the character of the anodic reaction, which proceeds in accordance with Eq. (2) both in the presence and absence of Fe(III) sulfate. The character of cathodic PCs indicates that Fe(III) is involved in the cathodic reaction. In concentrated acid solutions (pH <2), the cathodic reaction corresponding to Eq. (3) occurs in the kinetic control region [19], which is confirmed by the nature of the cathodic PCs obtained by us. In the presence of Fe(III) sulfate, the PCs are complicated by the limiting current, which indicates a change in the mechanism of the cathodic reaction. The observed limiting current may be due to diffusion restrictions associated with the delivery of the H+ and Fe3+ oxidants, which are present in the acid solution, to the steel surface. As the H+ concentration is more than an order of magnitude higher than CFe(III), the limiting current will be the result of diffusion restrictions in the delivery of Fe(III) cations to the steel surface. To confirm this assumption, it is necessary to study the effect of the electrolyte flow on the cathodic reaction rate of steel; this study is performed using a disk electrode, regulating the liquid flow near the metal surface by varying the electrode rotation frequency [19].

We showed [6] that in the range of cathodic potentials on steel in solutions of inorganic acids containing Fe(III) salts, two independent reduction reactions of H+ and Fe3+ occur, which are described by reactions (3) and (15), and the cathodic current is the sum of two partial currents. For the cathodic process determined by kinetically controlled reaction (3) and diffusion-controlled reaction (15), the following equation is applicable:

where ik and id are the kinetic and diffusion current densities. In the case of the laminar liquid flow near the surface of the rotating metal disk, id is directly proportional to the square root of the rotation frequency of the disk electrode (n), and Eq. (25) takes the form

In 2 M H2SO4 + Fe2(SO4)3, the experimental dependence of ic on n1/2 is linear (Fig. 5, Table 5). In 2 M H2SO4, the response of cathodic current to the change in the disk frequency is absent, suggesting the kinetic character of reaction (3). In the presence of Fe2(SO4)3, the kinetic component of cathodic current is the same as in the absence of it, indicating that reactions (3) and (15) are independent. In addition, it is clear that reaction (3) occurs in the kinetic region, and reaction (15), in the diffusion region.

The diffusion current, which is due to the reduction of Fe(III) on the steel cathode during the laminar flow, is described by the equation [19]

where z is the number of electrons involved in the reaction occurring on the electrode, F is the Faraday number, C* is the Fe(III) concentration in the bulk of solution, D is the diffusion coefficient of an electroactive particle, η is the kinematic viscosity of liquid (0.011 cm2/s [20]), and n is the angular disk rate. Using Eq. (27), we can calculate DFe(III) in 2 M H2SO4 (Table 4). The obtained DFe(III) values are in good agreement with the data obtained by the CV method (Table 3). The difference between DFe(III) obtained by the CV method on the Pt electrode and the average value calculated from the results of measurements on a steel rotating disc does not exceed 18%. In our viewpoint, cyclic voltammetry gives more correct results on DFe(III). Determination of DFe(III) by measurements in a real corrosive medium is less accurate because of several parallel processes occurring in it. The lower DFe(III) values obtained by measurements on the rotating steel disk are largely due to the screening of the metal surface by hydrogen bubbles released at cathodic potentials. Unfortunately, the CV determination of DFe(III) on a Pt electrode is technically possible only in model acid solutions containing exclusively Fe(III) salts.

Acid solutions additionally containing corrosion inhibitors are less suitable for studying by this method. Therefore, in further studies of the effect of mixed corrosion inhibitors on the electrode reactions of steel in 2 M H2SO4 + Fe2(SO4)3, we use a more universal (though less accurate in the studied media) method for determining DFe(III) from the data obtained on a rotating disk.

A fundamentally important result which we obtained in the study of supporting H2SO4 solutions containing Fe2(SO4)3 is the conclusion that reactions (3) and (15) occurring during corrosion of low-carbon steel in these media are independent. Further discussion of the results related to steel corrosion inhibition in such media will proceed from the assumption that both these cathodic processes are also independent.

The introduction of the composite inhibitors 5 mM TBEAC + 5 mM KI and 5 mM catamine AB + 5 mM KI in 2 M H2SO4 significantly affects the parameters of the electrode reactions of St3 steel (Fig. 4, Table 4). In the presence of these inhibitors, both electrode reactions of low-carbon steel are inhibited, and the Ecor values are shifted toward positive potentials by 0.13 and 0.12 V, respectively, compared with the supporting medium, which indicates that these additions slow down the anodic reaction. In inhibited media, the slope of cathodic polarization compared with the supporting acid solution increases to the limiting current, indicating that a protective inhibitor film was formed on the steel surface by the mixtures of QAS with KI. In these media, there is no response of cathodic current to the disk frequency (Fig. 5, Table 5), and the cathodic process consists of kinetically controlled reaction (3), as it does in the absence of Fe2(SO4)3 in 2 M H2SO4. In inhibited media, especially in the presence of catamine AB + KI, the ik values are lower than in the supporting medium.

The presence of Fe2(SO4)3 in a corrosive medium significantly worsens the inhibition of the cathodic and anodic reactions of steel, and this effect is enhanced at increased Fe(III) content in solution (Fig. 4, Table 4). The response of cathodic current to the disk frequency is observed (Fig. 5, Table 5). In this system, the cathodic current is the sum of the kinetic current due to reaction (3) and diffusion current determined by reaction (15). An increase in the Fe2(SO4)3 content in the inhibited acid leads to an increase in both ik and id values. It turns out that in the inhibited acid, Fe(III) salts accelerate the cathodic reaction, in which they act not only as an additional depolarizer, but also as an agent reducing the inhibition of cathodic hydrogen evolution, adversely affecting steel protection.

Let us evaluate the effect of the given inhibitors on the kinetic and diffusion components of the cathodic process on steel. For this purpose, we calculate the ik and id of steel in 2 M H2SO4 at an electrode rate of 460 rpm (Table 6). At increased content of Fe(III) in solution, the fraction of the cathodic reaction increases due to its reduction. In an uninhibited solution containing 0.02 M Fe(III), it is 21.3%; in the presence of 0.20 M Fe(III), it is 77.8%. A similar picture is observed in inhibited solutions. In the acid containing 0.02 and 0.2 M Fe(III) in the presence of a TBEAC + KI mixture, the fraction of reduced Fe(III) cations is 40.5 and 86.7%; in a solution containing the catamine AB + KI mixture, 27.6 and 78.9%, respectively. The degrees of inhibition of partial cathodic currents show that, all other things being equal, the mixtures based on QAS predominantly inhibit the cathodic evolution of hydrogen. An increase in the concentration of Fe(III) cations simultaneously decreases the inhibition of the reduction of protons and Fe(III) cations by the mixtures of inhibitors.

It is important to understand how the presence of inhibitors in a corrosive medium will affect the DFe(III) value. The DFe(III) values observed in inhibited 2 M H2SO4, especially in the presence of catamine AB + KI, are lower than those characteristic of the supporting medium with the same parameters (Table 5). However, an increase in the content of Fe2(SO4)3 in the acid leads to increased DFe(III). In the presence of the TBEAC + KI composite, addition of 0.20 M Fe(III) increases DFe(III) to that of the supporting medium. For the catamine AB + KI composite, the increase in DFe(III) at increased CFe(III) is less pronounced. Let us say at the very outset that, in contrast to 2 M H2SO4 containing Fe2(SO4)3, in inhibited media, Eq. (27) allows us to calculate the effective values of DFe(III), but not the real ones. It is difficult to imagine that the introduction of a small amount of inhibitor (10 mM) in an acid solution can significantly change the true value of DFe(III) in it. The reason is different: the inhibitor molecules, adsorbing on the steel surface, form polymolecular protective layers. For reduction, the Fe(III) cation should pass through this layer to reach the steel surface. The rate of this process will be determined by the diffusion of Fe(III) cations in the protective layer formed by the corrosion inhibitor. The DFe(III) values in the protective surface layer of the inhibitor will largely determine the effective DFe(III) values obtained by Eq. (27). An increase in the Fe2(SO4)3 content in solution leads to degradation of the protective inhibitor layer on the steel surface, facilitating the diffusion of Fe(III) cations to the metal surface. The DFe(III) value will increase to the values typical for media without a corrosion inhibitor. In our case, this situation is typical for 2 M H2SO4 inhibited by TBEAC + KI. Thus, in supporting H2SO4 solutions containing Fe2(SO4)3, the diffusion current of the steel electrode caused by the reduction of Fe(III) cations is limited by the DFe(III) value in this medium. In similar media additionally containing an inhibitor, it is limited is the DFe(III) value in the protective inhibitor layer formed on the steel electrode.

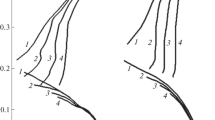

Another approach to obtaining the information about the effect of the convective factor on the rate of electrode reactions is analysis of the dependence of 1/i on 1/n0.5, which is described by the equation [19–22]

where i∞ is the real kinetic current, and K is the proportionality coefficient depending on η and D. Extrapolation of the linear dependence of 1/i on 1/n0.5 to n → ∞ (i.e., 1/n0.5 → 0) makes it possible to evaluate the real kinetic current, which expresses the reaction rate at reagent concentration which was not changed by the passage of electric current. Evaluation of the real kinetic current is used as a method for direct evaluation of the reaction rate constant. As depolarizers in the system are two particles, the solution of this problem is impossible. Despite this, analysis of the effect of the presence of Fe2(SO4)3 on this quantity seems important, especially in inhibited media (Fig. 6, Table 7). Both in the supporting and inhibited H2SO4 solutions in the absence of Fe(III) salts, the iс values correspond to i∞, which is typical for the kinetically controlled process. In contrast, in the presence of Fe(III) in these solutions, iс < i∞. The higher the Fe(III) content in solutions, the higher the observed i∞ values. The Fe(III) cations produce different effects on the i∞ values in the presence of composite inhibitors. For example, in the H2SO4 solution inhibited by TBEAC + KI in the presence of СFe(III) ≥ 0.05 M, i∞ is higher than in the uninhibited medium. All other conditions being equal, a mixture of catamine AB + KI provides i∞ that is significantly lower than in media without an inhibitor. The data obtained also clearly confirm the high efficiency of the catamine AB + KI composite in slowing down the cathodic reaction of steel in an acidic medium in the presence of Fe(III) salts.

Dependence of the reciprocal cathodic current density on the reciprocal square root of the rotation rate of the St3 steel disc electrode in (a) 2 M H2SO4 inhibited by (b) 5 mM TBEAC + 5 mM KI, and (c) 5 mM catamine AB + 5 mM KI in the presence of Fe(III) (M): (1) 0, (2) 0.02, (3) 0.05, (4) 0.10, and (5) 0.20; E = –0.30 V, t = 25°C. The presented lines correspond to the values of the ik and f constants given in Table 5; i, A /m2; n, rpm.

An apparent contradiction arises when we compare the results of electrochemical studies and corrosion tests (25°C). According to mass loss data for the steel samples in the presence of both inhibitor compositions at СFe(III) = 0.20 M, the corrosion rates are close; based on the electrochemical data, however, the catamine AB + KI mixture is more effective in slowing down the cathodic reaction. It should be understood that this composite of inhibitors significantly inhibits the diffusion-controlled reduction of Fe(III) rather than the kinetically controlled reduction of protons. Under the static conditions, corrosion occurs primarily due to the kinetically controlled process; the role of diffusion processes is minimum and determined only by the natural convection of solution.

Let us discuss some possible reasons for the decrease in the inhibitory effect of the inhibitor mixtures on the electrode reactions of steel in the presence of Fe2(SO4)3. The mechanism of action of organic inhibitors is based on their adsorption on the steel surface. When adsorbed on steel, organic molecules block its surface, which largely determines their inhibition of electrode reactions. Protection is more significant when the organic compound adsorbed on the metal surface forms a multilayer of inhibitor, but not a monolayer. In the given system, the organic compound is the QAS cation. In H2SO4 solutions, the steel surface is positively charged, which hinders the adsorption of organic cations on it [23]. The introduction of QAS together with I– cations in the H2SO4 solution leads to surface recharging by iodides adsorbed on steel, which facilitates the sorption of organic cations. In our case, the presence of Fe(III) in solution leads to partial oxidation of iodides to molecular iodine, weakening the adsorption of organic inhibitors and their protective effect. The higher the Fe2(SO4)3 content in a corrosive medium, the weaker the inhibitor adsorption and hence the slowdown of electrode reactions. An alternative and more general approach to the inhibition of the protective effect of QAS during steel corrosion in acid media in the presence of Fe(III) salts was proposed by Antropov [24]. The presence of a Fe(III) salt oxidant in the medium shifts the steel corrosion potential toward higher potentials at which the metal surface has a higher positive charge. As a consequence, the adsorption of organic cations on this surface is more difficult. In general, the two approaches do not conflict with each other.

Thus, we have established the reasons for the deterioration of the inhibitory protection of low-carbon steels in acid solutions in the presence of Fe(III) salts. The result is important from theoretical and practical viewpoints as it shows the ways for targeted search for compounds capable of slowing down steel corrosion in such media.

CONCLUSIONS

1. The presence of a Fe(III) salt in H2SO4 solutions accelerates steel corrosion in them in the absence and presence of corrosion inhibitors. At high Fe2(SO4)3 contents in solution, this leads to a complete loss of inhibitor’s protective properties, which is a consequence of increased aggressiveness of the corrosive medium due to the presence of an additional Fe(III) oxidizer in it. The oxidizing ability, characterized by the redox potential of the Fe(III)/Fe(II) pair, is lower than theoretical in this system because of the binding of Fe(III) into complexes by sulfate anions. The dependence of the redox potential of the system on the Fe(III) content in it is well described by the Nernst equation.

2. In H2SO4 solutions without an inhibitor, experimental determination of the diffusion coefficients of Fe(III) is possible by cyclic voltammetry of the Pt electrode or by measuring the dependence of the current of their reduction on the rotation rate of the disk electrode, which gives similar results. This suggests that the diffusion coefficients of Fe(III) in inhibited H2SO4 solutions can be determined by the second method.

3. In inhibited 2 M H2SO4 solution, the effective diffusion coefficients of Fe(III) can be significantly lower than the values observed in similar media without an inhibitor. This effect is the result of diffusion restrictions associated with the penetration of the medium through the inhibitor layer on the steel surface and is not a consequence of a change in the real diffusion coefficient of these cations in the most aggressive medium.

4. In 2 M H2SO4, the addition of Fe2(SO4)3 accelerates the cathodic diffusion current that is due to the reduction of Fe(III), but does not affect the kinetically controlled cathodic reduction of H+ and anodic ionization of iron. In contrast, in inhibited acid, the accelerating effect of Fe(III) cations affects the cathodic and anodic partial electrode reactions of steel. The adverse effect of Fe(III) cations on the inhibition of the total cathodic reaction of steel is confirmed by the values of real kinetic currents observed in the supporting and inhibited test media in the presence of Fe2(SO4)3. The weak corrosion inhibition of low-carbon steel in H2SO4 solutions containing Fe2(SO4)3 by the inhibitor composites under study is the result of the accelerating action of Fe(III) cations on the three partial electrode reactions of the metal.

REFERENCES

H. Kaesche, Die Korrosion der Metalle. Physikalisch-chemische Prinzipien und aktuelle Probleme (Springer, Berlin, 1979).

L. I. Antropov, Theoretical Electrochemistry (Vyssh. Shkola, Moscow, 1965), p. 348 [in Russian].

J. O’M. Bockris, D. Drazic, and A. R. Despic, Electrochim. Acta 4, 325 (1961). https://doi.org/10.1016/0013-4686(61)80026-1

G. M. Florianovich, L. A. Sokolova, and Ya. M. Kolotyrkin, Electrochim. Acta 12, 879 (1967). https://doi.org/10.1016/0013-4686(67)80124-5

R. J. Chin and K. Nobe, J. Electrochem. Soc. 119, 1457 (1972). https://doi.org/10.1149/1.2404023

Ya. G. Avdeev and T. E. Andreeva, Russ. J. Phys. Chem. A 95, 1128 (2021). https://doi.org/10.1134/S0036024421060029

S. A. Umoren and M. M. Solomon, J. Ind. Eng. Chem. 21, 81 (2015). https://doi.org/10.1016/j.jiec.2014.09.033

V. A. Zakharov, O. A. Songina, and G. B. Bekturova, Zh. Anal. Khim. 31, 2212 (1976).

Ya. G. Avdeev, T. E. Andreeva, A. V. Panova, and E. N. Yurasova, Int. J. Corros. Scale Inhib. 8, 411 (2019). https://doi.org/10.17675/2305-6894-2019-8-2-18

B. Belqat, A. Laghzizil, K. Elkacimi, et al., J. Fluorine Chem. 105, 1 (2000). https://doi.org/10.1016/S0022-1139(00)00256-6

M. M. Rakhimova, T. M. Nurmatov, N. Z. Yusupov, M. A. Ismailova, and E. Faizullaev, Russ. J. Inorg. Chem. 58, 719 (2013).

M. M. Rakhimova, N. Z. Yusupov, K. Dzh. Suyarov, K. G. Khasanova, and Sh. Bekbudova, Russ. J. Inorg. Chem. 58, 972 (2013).

Techniques of Electrochemistry: Electrode Processes, Ed. by E. Yeager and A. J. Salkind (Wiley, New York, 1972), Vol. 1.

Yu. Yu. Lur’e, Handbook on Analytical Chemistry (Khimiya, Moscow, 1971) [in Russian].

J. M. Casas, G. Crisostomo, and L. Cifuentes, Hydrometallurgy 80, 254 (2005).

G. Yue, L. Zhao, O. G. Olvera, and E. Asselin, Hydrometallurgy 147–148, 196 (2014).

J. A. Plambeck, Electroanalytical Chemistry: Basic Principles and Applications (Wiley, New York, 1982).

S. M. Reshetnikov, Inhibitors of Acidic Corrosion of Metals (Khimiya, Leningrad, 1986) [in Russian].

Yu. V. Pleskov and V. Yu. Filinovskii, The Rotating Disk Electrode (Consultants Bureau, New York, 1976).

Short Reference Book of Physicochemical Values, Ed. by K. P. Mishchenko and A. A. Ravdel’ (Khimiya, Leningrad, 1967), p. 103 [in Russian].

A. N. Frumkin and E. A. Aikazyan, Dokl. Akad. Nauk 100, 315 (1955).

A. N. Frumkin and G. A. Tedoradze, Dokl. Akad. Nauk 118, 530 (1958).

I. L. Rozenfel’d, Corrosion Inhibitors (Khimiya, Moscow, 1977) [in Russian].

L. I. Antropov and I. S. Pogrebova, Itogi Nauki Tekh., Ser. Korroz. Zashch. Korroz. 2, 27 (1973).

Funding

This study was performed under the Fundamental Research Program of the State Academies of Sciences for 2013–2020. The topic is “Development of the fundamentals of the protective action of metal corrosion inhibitors in gas and condensed media, nanocomposites, and paint-and-lacquer and conversion coatings” (state registration no. АААА-А18-118121090043-0).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by L. Smolina

Rights and permissions

About this article

Cite this article

Avdeev, Y.G., Andreeva, T.E. Mechanism of Steel Corrosion in Inhibited Acid Solutions Containing Iron(III) Salts. Russ. J. Phys. Chem. 96, 425–436 (2022). https://doi.org/10.1134/S0036024422020030

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024422020030