Abstract

Visible-light-driven CdS loaded flower-like Bi2WO6 (Bi2WO6/CdS) heterostructured photocatalyst with surface-enrich CdS nanoparticles were prepared successfully by using a facile two-step method. The as-prepared photocatalyst was characterized by X-ray diffraction, scanning electron microscopy, and UV–Vis diffuse reflectance spectrum. The band gaps of the samples were estimated based on diffuse reflectance spectrum results. The as-prepared Bi2WO6/CdS heterostructured photocatalyst was used as catalysts in reduction of Cr(VI) to Cr(III) under visible light irradiation, and enhanced photocatalytic activities were observed as compared to pure flower-like Bi2WO6 and CdS nanoparticles. The origin of the excellent performance of the catalyst as well as the mechanism of photoreduction was discussed. Effective electron–hole separation and variation of band gap due to the formation of type II heterostructure is believed to be responsible to the much improved reaction rate.

Graphical Abstract

Flower-like Bi2WO6/CdS heterostructures was used to photoreduce toxic Cr(VI) to Cr(III) under visible light irradiation. 99% reduction of Cr(VI) could be reached within 10 min. It is found that the heterogenization favors the facilitated interfacial charge transfer and inhibited electron–hole recombination.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Increasing environmental problems, especially the water pollution, have been a heavy threaten to our daily life. Hexavalent chromium Cr(VI), a heavy metal ion in the aquatic environment, is well known for being highly toxic and mutagenic and carcinogenic when assimilated, stored, and accumulated by living organisms. Furthermore, hexavalent chromium is readily soluble in number of solvents and is thus difficult to remove from stream effluent. One way to resolve this problem is to reduce hexavalent chromium to its trivalent form, which is less toxic and easily precipitated, and separated from wastewater [1]. Compared with the traditional chemical reduction method, semiconductor-based photocatalysis targeting on the reduction of Cr(VI) represent a promising area of research because it is a facile and environmentally friendly way to take advantage of solar energy [1, 2]. Among the various studied photocatalysts, visible-light-active Bi2WO6 has aroused increasing concern due to facile preparation and easily adjustable band gap. Researches show that Bi2WO6 has potential in splitting water and decomposing organic contaminations under visible light [3,4,5]. However, there still remain two formidable challenges [6, 7]. One centers on the difficult migration and high recombination of photo-generated electron–hole pairs, which will greatly reduce the photocatalytic activity of Bi2WO6. A second entails its wide band gap, which severely precludes the employment of visible light with wavelength longer than ~450 nm. To overcome these drawbacks of Bi2WO6 and meet the requirement of future environmental application and for better utilization of solar energy, it is indispensable to develop more efficient Bi2WO6-based photocatalysts. Up to now, an enormous amount of research effort has been focused on coupling Bi2WO6 with other semiconductors to extent the absorption range, such as Bi2S3 [8], Bi2O3 [9], ZnS [10], Ag2O [11,12,13], TiO2 [14] etc. Cadmium sulfide (CdS) as an important II–VI semiconductor with a narrow band gap of 2.40 eV, corresponding well with the spectrum of visible sunlight, is considered as a promising candidate [15]. Based on previous studies [10, 16,17,18,19,20,21,22,23], it can be found that the as-formed heterostructured photocatalyst by coupling various semiconductors with CdS show enhanced photocatalytic activity compared with pure semiconductors because the formation of well-defined interfaces between different semiconductors can promote facilitates charge transfer and restrains the recombination of photogenerated electrons and holes, resulting in extremely high activity and stability. Therefore, it could be inferred that Bi2WO6 modified with CdS to form Bi2WO6/CdS heterostructure will exhibit excellent visible light photocatalytic activity for Cr(VI) reduction.

In this study, we have prepared a flower-like Bi2WO6/CdS heterostructured photocatalyst with a much narrower band gap than that of pure Bi2WO6, and highly enhanced photocatalytic activity (reaction constant k Cr(VI) increases by ca. 8.1–37.1 times) was achieved with respect to Cr(VI) ion reduction under visible light irradiation. The outstanding performance of the heterostructured photocatalyst may find other use in wastewater disposal.

2 Experimental

All reagents were of analytical grade and were used without further purification.

2.1 Preparation of flower-like Bi2WO6

Flower-like Bi2WO6 were prepared via a hydrothermal method: the starting materials of Na2WO4 and Bi(NO3)3 were mixed together with the molar ratio of 1:2, deionized water was added, then white slurries appeared immediately, and the mixture was transferred into a 50 mL Teflon lined autoclave and kept at 160 °C for 12 h. The Teflon lined autoclave was then naturally cooled down to room temperature. The products were isolated by centrifugation and washed and dried.

2.2 Preparation of Bi2WO6/CdS heterostructures

Bi2WO6/CdS heterostructures were prepared by two steps which are the preparation of seed solution and solution growth, respectively. In a detail procedure, firstly 0.0697 g Bi2WO6 was immersed in 10 mL of Cd(CH3COO)2·2H2O (0.0627 g) solution for 6 h. And then the Bi2WO6 sample was taken out and added into the growth solution (30 mL of H2O, 0.03806 g thiourea and 0.0925 g Cd(NO3)2·4H2O) under stirring for 1 h. Later, the obtained mixture was transferred into a Teflon-lined autoclave and heated at 150 °C for 15 h. After naturally cooled to room temperature, yellow suspension was collected by filtration, washing with plenty of H2O and drying at room temperature overnight.

As a comparison, high-purity CdS powder was prepared by using the above-mentioned solution growth method.

2.3 Characterization of samples

The crystal structure of the samples was characterized by a powder X-ray diffractometer (XRD, Rigaku, Dmax-2600/pc) equipped with Cu Kα radiation (1.542 Å) in a 2θ range of 10°–80° at a scan rate of 0.05° s−1. Field emission scanning electron microscopy (SEM, Hitachi SU-70) was used to observe particle sizes and morphologies of the samples. The element composition and distribution were examined by a SEM equipped with an energy dispersive spectrometer (EDS, EDAX-TEAM Octane Plus). UV–Vis diffuse reflectance spectra (DRS) were recorded on a UV–Vis spectrometer (Shimadzu UV-2550) by using BaSO4 as a reference and were converted from reflection to absorbance by the Kubelka-Munk method. Transmission electron microscope (TEM) images and high-resolution transmission electron microscopy (HRTEM) images were taken on a JEOL-2010 transmission electron microscope with an accelerating voltage of 200kV.

2.4 Photocatalytic experiment

In a typical experiment, 50 mg of the as-synthesized sample was dispersed in 100 mL 50 ppm chromium (Cr(VI)) solution and then magnetically stirred in the dark for 30 min to reach the adsorption-desorption equilibrium. Then 0.5% (volume ratio) methanol was added to the Cr(VI) solution, followed by adjusting the pH value to be 3 constantly using a 1 M H2SO4 solution. The suspension was then exposed to a 300 W Xe lamp with a 420 nm cutoff filter, and the working distance from the Xe lamp to the beaker is kept to be 20 cm. At given irradiation time intervals, adequate aliquots of the suspension were extracted and centrifuged to remove the residual photocatalyst for analysis. The concentration of Cr(VI) was measured with a spectrophotometer at λ = 540 nm (UV-3600, Shimadzu, Japan) using the diphenylcarbazide (DPZ) method.

3 Results and discussion

Figure 1 shows the XRD patterns of the as-prepared samples. All the diffraction peaks in Fig. 1a can be indexed to the orthorhombic phase of Bi2WO6 and are consistent with the reported data (JCPDS No. 73-1126). All diffraction peaks in Fig. 1b can be indexed to the hexagonal phase of CdS (JCPDS No.80-0006). In Fig. 1c, peaks at 2θ of 24.94°, 26.48°, 28.24°, 43.78°, and 51.9° are indexed as (100), (002), (101), (110), and (112) planes of hexagonal CdS, respectively. These peaks unambiguously indicate the presence of CdS on the heterostructures.

The morphologies and microstructures of the as-prepared samples were further investigated by SEM (Fig. 2). The pure Bi2WO6 crystals present flower-like microstructure with an average diameter of about 2.0 μm, and consist of many stacked nanosheets in a hierarchical structure (Fig. 2a, b). This self-organization process was generally accompanied by the formation of porous structures. The morphology of Bi2WO6/CdS composites (Fig. 2c, d) is similar to that of the pure Bi2WO6, just with the deposition of many small CdS nanoparticles on the surface.

To gain further insight into the detailed microstructure of the obtained samples, TEM was employed (Fig. 3). Figure 3a, b show the TEM images of the whole and a part of flower-like Bi2WO6, respectively. As expected, loosely assembled and pore-incorporated internal regions were captured by TEM. The HRTEM image (Fig. 3c) of Bi2WO6 taken on two overlapped nanosheets shows that the lattice spacing, being determined to be 0.315 nm, is consistent with the (113) planes of orthorhombic Bi2WO6. Figure 3d presents an individual Bi2WO6/CdS with a circle shape, in accordance with the SEM image. It can be found that the contrast of Bi2WO6/CdS composites is deeper than that of Bi2WO6 due to the deposition of CdS nanoparticles. As shown in Fig. 4e, some CdS nanoparticles with the fairly uniform shape and size below 40 nm are coated on the surface of Bi2WO6 nanosheets, confirming the combination of CdS and Bi2WO6. Especially, it can be seen from the HRTEM image in Fig. 3f, the lattice spacing taken on the tiny nanocrystals is about 0.330 nm, which is consistent with the (002) planes of hexagonal CdS. The interplanar spacing of the substance on the bottom is measured to be 0.377 nm, which agrees with the (111) planes of orthorhombic Bi2WO6. These results signify that the relatively small CdS nanoparticles with high crystallinity spread uniformly on the Bi2WO6 surface, indicating that Bi2WO6 is essentially interacting with CdS nanoparticles and thus creating tight Bi2WO6/CdS heterojunction. On the basis of previous studies [8, 10, 12, 13, 17, 19, 23], it can be inferred that Bi2WO6/CdS heterojunction can enhance charge transfer and inhibit the recombination of electron-hole pairs, which is very important for the improvement of photocatalytic activity and must lead to better photocatalytic activity than pure Bi2WO6 and pure CdS.

a EDS elemental spectrum of the as-prepared Bi2WO6/CdS heterostruture; b SEM image of a single Bi2WO6/CdS heterostructure; c EDS mapping of all elements in the Bi2WO6/CdS heterostruture; maps of the distribution of each element: d Bi element, e O element, f W element, g Cd element and h S element

Furthermore, EDS analysis was also employed to test and verify the real existence and uniform distribution of CdS nanoparticles in Bi2WO6/CdS heterostructures. The presence of C, S, Bi, and Cd elements in the composites can be proved evidently by the EDS elemental spectrum of Bi2WO6/CdS (Fig. 4a). The content of CdS was estimated to be ca. 27 wt%. The EDS elemental mapping of the Bi2WO6/CdS composites (Fig. 4c–h) displays that the elements of Cd and S are distributed uniformly on the surface of the Bi2WO6 nanosheets. The elements of Cd and S are from CdS. The results further indicate that the CdS nanocrystals have been successfully and firmly grown on the surface of the Bi2WO6.

The optical properties are vital to the photocatalytic performance of a photocatalyst. Therefore, the optical properties of the as-prepared photocatalysts are investigated by using the UV-Vis DRS, and the results are presented in Fig. 5a. It can be seen that the pure Bi2WO6 sample can only absorb UV light and visible light with wavelength less than 440 nm. However, the Bi2WO6/CdS composites exhibited stronger light absorption and wider optical response range compared with pure Bi2WO6, which can be ascribed to the deposition of CdS nanoparticles on the surface of the Bi2WO6 microflowers. Decoration of Bi2WO6 with CdS nanoparticles is beneficial to the improvement of light absorbing capacity, thus enhances the photocatalytic activity.

The optical band gap energy of the as-formed samples can be calculated using the Tauc plot, which is described as follows [24]:

where h is the Planck’s constant, ν is the frequency of vibration, α is the absorption coefficient, E g is the band gap energy of the semiconductor. Among them, n is determined from the type of optical transition of a semiconductor, and the value of n for the direct semiconductor is 1/2, while for indirect transition, n = 2 [25]. By calculation, n is determined to be 1/2 for the as-formed samples. Based on the plotting graph (Fig. 5b), the band gap energy of Bi2WO6, CdS, and Bi2WO6/CdS were estimated to be 3.00, 2.18, and 2.25 eV, respectively. The results illustrate that the Bi2WO6/CdS composites can be excited by visible light with longer wavelength due to the deposition of CdS nanoparticles.

Based on the results of DRS, the band edge positions of the as-prepared semiconductors can be theoretically predicted using the electronegativity concept [26, 27]. The conduction band (CB) and valence band (VB) potentials of the semiconductor at the point of zero charge can be calculated by the following equation:

and

where E g represents the band gap energy of the semiconductor, E CB is the CB potential, E VB is the VB potential, E 0 is scale factor relating to the reference electrode redox level to the absolute vacuum scale (E 0 = −4.5 eV for normal hydrogen electrode), and X is the electronegativity of the semiconductor, which is defined as the geometric average of the absolute electronegativity of the constituent atoms. The calculated CB and VB potential of Bi2WO6, CdS and Bi2WO6/CdS are shown in Table 1. The E CB and E VB of pure Bi2WO6 are calculated to be 0.36 and 3.36 eV, respectively. For CdS nanoparticles, both the values of E CB (−0.505 eV) and E VB (1.675 eV) are lower than the corresponding values of Bi2WO6, corresponding to the type-II band gap alignment. Importantly, the difference of chemical potential between semiconductor Bi2WO6 and CdS can cause band bending at the interface of junction. The band bending induces a built-in field, which drives the photogenerated electrons and holes to move in opposite directions, leading to a spatial separation of the electrons and holes on different sides of heterojunction [28]. Thus, the formation of Bi2WO6/CdS heterojunction will be in favor of the improvement of photocatalytic activity.

The synthesized Bi2WO6, CdS, and Bi2WO6/CdS nanocomposites were used to remove toxic Cr(VI) ions via reduction to water insoluble Cr(III) utilizing visible-light irradiation. Figure 6a shows the photoreduction curves of Cr(VI) in the presence of different catalysts after exposure for different times under visible light at room temperature and ambient pressure, where C 0 is the concentration of Cr(VI) after achieving equilibrium in the dark, and C t is the concentrations of Cr(VI) in solution at desired time. Notably, among all the tested samples, Bi2WO6/CdS exhibits the highest photocatalytic activity for Cr(VI) reduction in that 99% reduction of Cr(VI) was achieved within 10 min. On pure Bi2WO6, only 25.8% reduction was detected in 10 min and 87.8% reduction was reached until 90 min. The reduction degree increased to 58.9% in 10 min and 96.8% in 50 min on CdS. However, blank test without any catalyst exhibited a photoreduction degree of 3.7% in 10 min and 34.7% in 90 min, which suggests a partial contribution of methanol for the Cr(VI) reduction reaction even in the absence of catalysts. The reaction may be ascribed in part to a spontaneous photoexcitation of methanol upon irradiation, which generates electrons and facilitates their transport to Cr(VI) ions for reducing into Cr(III). In view of rapid reaction rate of the Bi2WO6/CdS heterostructure for the Cr(VI) reduction, the effect of methanol on the Cr(VI) reduction could be negligible.

To quantitatively understand the reaction kinetics of Cr(VI) reduction in our experiments, Langmuir–Hinshelwood model was employed. This model is well-established for photocatalytic experiments when the concentration of the pollutant is in the millimolar range [29], which is expressed as follows:

where C 0 is the concentration of Cr(VI) after achieving equilibrium in the dark, and C t is the concentrations of Cr(VI) in solution at desired time, and k is the apparent first-order rate constant, t is the irradiation time. The calculated photocatalytic reaction rate constants in this study are shown in Fig. 6b. The estimated pseudo-first order kinetic constant (k) for Cr(VI) reduction decreased in the following order: 0.3696 min−1 (Bi2WO6/CdS) > 0.0456 min−1 (CdS) > 0.009965 min−1 (Bi2WO6) > 0.001995 min−1 (blank). Compared to pure Bi2WO6 and CdS, the estimated k Cr(VI) on Bi2WO6/CdS increases by ca. 37.1 and 8.1 times, respectively. Clearly, the photocatalytic activity of the Bi2WO6/CdS heterostructure boosts with the addition of CdS compared to pure Bi2WO6. The difference in photocatalytic activity may relate to visible light absorption properties, separation efficiency of photogenerated electrons and holes and efficient charge transfer. Flower-like Bi2WO6 exhibits the lowest photocatalytic activity, which may result from its relatively large band gap. According to the band gap calculated above, the band gap of Bi2WO6 is 3.0 eV, indicating the poor absorbance of light in the visible region. CdS nanoparticles showing relatively high photocatalytic activity may be ascribed to its narrow band gap. However, the recombination rate of electrons and holes in CdS nanoparticles is higher than that in the composite Bi2WO6/CdS heterostructure. For the Bi2WO6/CdS heterostructure, the as-formed Bi2WO6/CdS heterojunctions, confirmed by the HRTEM image, play an important role in the enhancement of photocatalytic activity. Indeed, the Bi2WO6/CdS heterojunction acts as a separation barrier to effectively hinder recombination of electrons and holes and then improves charge transfer efficiency. All in all, the Bi2WO6/CdS heterojunctions can make more electrons and holes transfer to the reaction sites and generate more reactive species, which leads to better photocatalytic activity than pure Bi2WO6 and pure CdS.

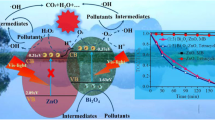

Based on the above experimental results, the schematic diagram for the photocatalytic process in the presence of Bi2WO6/CdS heterostructures is presented in Scheme 1. When Bi2WO6/CdS is irradiated by visible light, electrons are excited from the VB of CdS to its CB. Then, the CB-electrons of CdS could easily transfer to the CB of Bi2WO6 through the formed heterojunctions, driven by the decrease in potential energy. This process could facilitate their participation in three electron reduction reaction of Cr2O7 2− to Cr(III). At the same time, the holes in the VB are consumed by methanol, which minimizes the rate of electron–hole recombination. As a result, the recombination of electron–hole pairs is efficiently inhibited and the lifetime of charge carriers is prolonged, leading to the enhanced photocatalytic performances of the as-formed Bi2WO6/CdS heterostructures.

4 Conclusions

Flower-like Bi2WO6/CdS heterostructures was successfully prepared by using a two-step method. The photoreduction efficiency of the heterostructures for Cr(VI) was approximately 8.1 and 37.1 times of pure CdS and Bi2WO6, respectively. The enhanced photocatalytic activities of the as-obtained heterostructures could be attributed to the facilitated interfacial charge transfer and inhibited electron–hole recombination. Based on the experimental results, the photocatalytic mechanism on Bi2WO6/CdS heterostructures is proposed. All of these results clearly indicate that the formation of these type II heterostructure by coupling of another semiconductor is proved to be an effective approach to improve the photocatalytic performance of the Bi2WO6.

References

Hu EL, Gao XH, Etogo A, Xie YL, Zhong YJ, Hu Y (2014) Controllable one-pot synthesis of various one-dimensional Bi2S3 nanostructures and their enhanced visible-light-driven photocatalytic reduction of Cr(VI). J Alloys Compd 611:335–340

Li H, Wu T, Cai B, Ma WG, Sun YJ, Gangstar SY, Han DX, Niu L (2015) Efficiently photocatalytic reduction of carcinogenic contaminant Cr (VI) upon robust AgCl:Ag hollow nanocrystals. Appl Catal B 164:344–351

Zhang L, Bahnemann D (2013) Synthesis of nanovoid Bi2WO6 2D ordered arrays as photoanodes for photoelectrochemical water splitting. ChemSusChem 6:283–290

Wu J, Duan F, Zheng Y, Xie Y (2007) Synthesis of Bi2WO6 nanoplate-built hierarchical nest-like structures with visible-light-induced photocatalytic activity. J Phys Chem C 111:12866–12871

Deng WY, Li H, Li L, Qin B, Fan Z, Zhao YB (2014) Photocatalytic reduction of Cr(VI) under visible light over Bi2WO6 with different morphologies. Chem Lett 43:729–731

Zhang ZJ, Wang WZ, Shang M, Yin WZ (2010) Low-temperature combustion synthesis of Bi2WO6 nanoparticles as a visible-light-driven photocatalyst. J Hazard Mater 177:1013–1018

Zhu SB, Xu TG, Fu HB, Zhao JC, Zhu YF (2007) Synergetic effect of Bi2WO6 photocatalyst with C60 and enhanced photoactivity under visible irradiation. Environ Sci Technol 41:6234–6239

Rauf A, Shah SAS, Choi GH, Humayoun UB, Yoon DH, Bae JW, Park J, Kin WJ, Yoo PJ (2015) Facile synthesis of hierarchically structured Bi2S3/Bi2WO6 hotocatalysts for highly efficient reduction of Cr(VI). ACS Sustain Chem Eng 3:2847–2855

Li XN, Huang RK, Hu YH, Chen YJ, Liu WJ, Yuan RS, Li ZH (2012) A templated method to Bi2WO6 hollow microspheres and their conversion to double-shell Bi2O3/Bi2WO6 hollow microspheres with improved photocatalytic performance. Inorg Chem 51:6245–6250

Tang RF, Su HF, Duan SX, Sun YW, Li L, Zhang XX, Zeng SY, Sun DZ (2015) Enhanced visible-light-driven photocatalytic performances using Bi2WO6/ MS (M = Cd, Zn) heterostructures: Facile synthesis and their photocatalytic mechanisms. RSC Adv 5:41949–41960

Chen L, Hua H, Yang Q, Hu CG (2015) Visible-light photocatalytic activity of Ag2O coated Bi2WO6 hierarchical microspheres assembled by nanosheets. Appl Surf Sci 327:62–67

Yu HG, Liu R, Wang XF, Wang P, Yu JG (2012) Enhanced visible-light photocatalytic activity of Bi2WO6 nanoparticles by Ag2O cocatalyst. Appl Catal B 111–113:326–333

Liu CM, Liu JW, Zhang GY, Zhang JB, Wu QS, Xu YY, Sun YQ (2015) Facile room-temperature precipitation strategy for Ag2O/Bi2WO6 heterojunction with high simulated sunlight photocatalytic performance via bi-directed electron migration mechanism. RSC Adv 5:32333–32342

López SM, Hidalgo MC, Navío JA, Colón G (2011) Novel Bi2WO6–TiO2 heterostructures for rhodamine B degradation under sunlike irradiation. J Hazard Mater 185:1425–1434

Jang JS, Joshi UA, Lee JS (2007) Solvothermal synthesis of CdS nanowires for photocatalytic hydrogen and electricity production. J Phys Chem C 111:13280–13287

Ge L, Liu J (2011) Efficient visible light-induced photocatalytic degradation of methyl orange by QDs sensitized CdS-Bi2WO6. Appl Catal B 105:289–297

Ao YH, Xu LY, Wang PF, Wang C, Hou J, Qian J (2015) Preparation of CdS nanoparticles loaded flower-like Bi2O2CO3 heterojunction photocatalyst with enhanced visible light photocatalystic activity. Dalton Trans 44:11321–11330

Zong X, Yan HJ, Wu GP, Ma GJ, Wen FY, Wang L, Li C (2008) Enhancement of photocatalytic H2 evolution on CdS by loading MoS2 as cocatalyst under visible light irradiation. J Am Chem Soc 130:7176–7177

Cui WQ, An WJ, Liu L, Hu JS, Liang YH (2014) Synthesis of CdS/BiOBr composite and its enhanced photocatalystic degradation for phodamine B. Appl Surf Sci 319:298–305

Li X, Chen JT, Li HL, Li JT, Xu YT, Liu YJ, Zhou JR (2011) Photoreduction of CO2 to methanol over Bi2S3/CdS photocatalyst under visible light irradiation. J Nat Gas Chem 20:413–417

Zhang Q, Wang L, Feng JT, Xu H, Yan W (2014) Enhanced photoelectrochemical performance by synthesizing CdS decorated reduced TiO2 nanotube arrays. Phys Chem Chem Phys 16:23431–23439

Wang R, Xu D, Liu JB, Li KW, Wang H (2011) Preparation and photocatalytic properties CdS/La2Ti2O7 nanocomposites under visible light. Chem Eng J 168:455–460

Hao LX, Chen G, Yu YG, Zhou YS, Han ZH, Liu Y (2014) Sonochemistry synthesis of Bi2S3/CdS heterostructure with enhanced performance for photocatalytic hydrogen evolution. Int J Hydrog Energ 39:14479–14486

Sippel P, Denysenko D, Loidl A, Lunkenheimer P, Sastre G, Volkmer D (2014) Dielectric relaxation processes, electronic structure, and band gap engineering of MFU-4-type metal-organic frameworks: towards a rational design of semiconducting microporous materials. Adv Funct Mater 24:3885–3896

Kim MR, Kang AY, Jang DJ (2007) Synthesis and characterization of highly luminescent CdS@ZnS core–shell nanorods. J Phys Chem C 111:18507–18511

Ke DN, Peng TY, Ma L, Cai P, Jiang P (2008) Photocatalytic water splitting for O2 production under visible-light irradiation on BiVO4 nanoparticles in different sacrificial reagent solutions. Appl Catal A 350:111–117

Ren L, Lei J, Wang JB, Qiu M, Yu Y (2009) Template-free synthesis of BiVO4 nanostructures:II. Relationship between various microstructures for monoclinic BiVO4 and their photocatalytic activity for the degradation of rhodamine B under visible light. Nanotechnology 20:17579–17584

McDaniel H, Heil PE, Tsai CL, Kim KK, Shim M (2011) Integration of type II nanorod heterostructures into photovoltaics. ACS Nano 5:7677–7683

Sakkas VA, Arabatzis IM, Konstantinou IK, Dimou AD, Albanis TA, Falaras P (2004) Metolachlor photocatalytic degradation using TiO photocatalysts. Appl Catal B 49:195–205

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 21571045).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Liu, Y., Liu, S., Wu, T. et al. Facile preparation of flower-like Bi2WO6/CdS heterostructured photocatalyst with enhanced visible-light-driven photocatalytic activity for Cr(VI) reduction. J Sol-Gel Sci Technol 83, 315–323 (2017). https://doi.org/10.1007/s10971-017-4416-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-017-4416-x