Abstract

The molar heat capacity of lanthanum hafnate of the pyrochlore structure type was measured by differential scanning calorimetry in the temperature range 310–1380 K. The temperature dependence of the unit cell parameter a in the range 303–1273 K was characterized. The absence of structural transformations was demonstrated, and the thermal expansion coefficients in this temperature range were estimated.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Thermal and corrosion protection of gas-fired power plants and aircraft engines has been a challenge over the last decades [1–5]. One of the candidates for a protective material is lanthanum hafnate of the pyrochlore structure type [6]. Among its advantages are high temperature of congruent melting, low thermal conductivity, low vapor pressure, and relatively wide homogeneity region [7–10]. The high-temperature chemical resistance of lanthanum hafnate to gaseous and solid substances contained in air, particularly to CMAS (calcia-magnesia-alumina-silica) [11], requires thorough experimental investigation, the extent of which can be significantly reduced by preliminary thermodynamic modeling [12]. The model calculations were based on the temperature dependence of the Gibbs free energy, which was calculated using the enthalpy of formation of lanthanum hafnate, and on the temperature dependence of the heat capacity over a wide temperature range. The enthalpy of formation of La2Hf2O7 of the pyrochlore structure type (Fd3m) was found earlier [13, 14]. The low-temperature (0–346 K) heat capacity and the calculated thermodynamic functions were determined in our previous work [15] from the results of adiabatic calorimetry of a synthesized and characterized La2Hf2O7 sample (pyrochlore). The molar heat capacity at higher temperatures is also available in the literature [6, 10, 16]. However, these data disagree with each other; therefore, the purpose of this work was to measure the temperature dependences of the heat capacity in the range 310–1380 K. The second purpose of this study was to investigate the thermal expansion by exploring the temperature dependence of the unit cell parameter a of lanthanum hafnate of the pyrochlore structure type in the range 303–1273 K.

EXPERIMENTAL

In our previous work [5], the reverse precipitation synthesis and subsequent step annealing of a lanthanum hafnate sample were described in detail, and so was its identification by X-ray powder diffraction analysis, chemical analysis, X-ray fluorescence analysis, scanning electron microscopy, and differential thermal analysis. The molecular weight of a sample (746.78933 g/mol) was determined from the atomic weights of the elements [17]. The molar heat capacity of lanthanum hafnate was measured by differential scanning calorimetry with a Netzsch STA 449 F1 Jupiter simultaneous thermal analyzer in an atmosphere of high-purity (99.999%) gaseous argon. The temperature dependence of the unit cell parameter was studied by high-temperature X-ray diffraction with a Shimadzu X-ray diffractometer (CuKα radiation, λ = 1.5418 Å) and an HA-1001 sample heating attachment in the temperature range 303–1273 K at an interval of 100 K with preliminary holding for 20 min at each measurement temperature [18].

RESULTS AND DISCUSSION

The final annealing of a lanthanum hafnate sample was performed at 1773 K for 4 h. This procedure is necessary for the complete interaction of the initial components and the formation of the pyrochlore crystal structure, which is not nanosized [14, 19]. According to the elemental analysis data, the obtained sample has the composition La1.992Hf2.008O7.004. As we showed previously [20], such a deviation from stoichiometry cannot significantly distort the calculation of the molar heat capacity for a rational composition from experimental data.

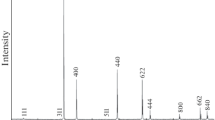

The molar heat capacity was measured by differential scanning calorimetry in the temperature range 310–1380 K, and the results of these measurements are illustrated in Fig. 1 (curve 1) with the uncertainty interval of the differential scanning calorimetry method (~2.5%). The obtained results are well described by the Maier–Kelley equation [21]

Figure 1 makes an estimate of the heat capacity of La2Hf2O7 by the Neumann–Kopp rule from the heat capacities of individual oxides La2O3 [22] and HfO2 [23] (curve 2),

and gives the results of the calculation from the experimentally measured increment in the enthalpy in the range 988–1773 K [16] (curve 3),

and also the results of the differential scanning calorimetry of the heat capacity (curve 4) [10],

Liang et al. [6] also measured the temperature dependence of the heat capacity by differential scanning calorimetry; however, the analytical expression that they presented [6] contains outright misprints, contradicts with the graphic image, and cannot be compared with other data.

As Fig. 1 shows, the curve calculated by the Neumann–Kopp rule (curve 2) is virtually parallel and above the confidence interval for the experimental heat capacity, beginning with the value 229.3 J/(mol K) at 298 K, which differs from the experimental value Cp (J/(mol K), 298.15 K) = 221.8 J/(mol K) that we found by adiabatic calorimetry [15]. The heat capacity calculated by the Neumann–Kopp rule was used [16] to calculate the heat capacity from the enthalpy increment \(H_{T}^{^\circ }\) – \(H_{{298.15}}^{^\circ }\) (Eq. (3)). As we noted previously [24], the differentiation of the enthalpy increment does not always give a satisfactory result. Note that, although curve 3 (Eq. (3)) to 1000 K is within the confidence interval of our data, it is steeper, which may significantly distort the calculations in the extrapolation toward higher temperatures.

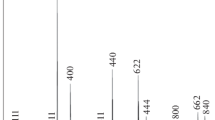

The thermal expansion of lanthanum hafnate with the pyrochlore structure was studied by high-temperature X-ray diffraction. The temperature dependence of the parameter a is illustrated in Fig. 2 and is near-linear, but can be more accurately described by the quadratic dependence

From this dependence, the thermal expansion coefficients can be estimated, namely, the instantaneous coefficient αT = (da/dT)/aT, the relative coefficient α298 = (da/dT)/a298, and the linear relative coefficient TE, % = 100 × (aT – a298)/a298.

Table 1 presents the calculated thermal expansion coefficients and unit cell parameter at temperatures of 303–1273 K at an interval of 100 K. The thermal expansion is positive: (da/dT) > 0, and the structure type Fd3m is preserved throughout the temperature range.

As Fig. 2 shows, both the temperature dependences of the lattice parameter of lanthanum hafnate and the previously characterized curves for neodymium hafnate (curve 2) [24] and gadolinium hafnate (curve 3) [25] are virtually parallel; hence, the thermal expansion coefficients calculated using the derivative (da/dT) have similar dependences on temperature. Here, the dependence a(T) (curve 4) taken from the published article [26] is also shown, with the difference that the variable T in the equation presented in the article is replaced by (T – 273 K). After this replacement, the temperature dependence takes the meaning and virtually coincides with that we obtained.

CONCLUSIONS

A polycrystalline sample of La2Hf2O7 of the pyrochlore structure type was synthesized and identified, and its heat capacity in the temperature range 310–1380 K was measured by differential scanning calorimetry. The thus measured heat capacity agrees with that determined previously by adiabatic calorimetry. The temperature dependence of the molar heat capacity was represented as the Maier–Kelley equation. At temperatures of 303–1273 K, by high-temperature X-ray diffraction, the change in the unit cell parameter of lanthanum hafnate was calculated, the thermal expansion was shown to be positive, the absence of structural transformations was demonstrated, and the thermal expansion coefficients were estimated. The results of this work can be used to make thermodynamic calculations of phase equilibria with the participation of lanthanum hafnate, determine its chemical resistance to aggressive media, а also develop technologies of synthesis and application of protective coatings.

REFERENCES

M. A. Subramanian, G. Aravamudan, and G. V. Subba Rao, Prog. Solid State Chem. 15, 55 (1983). https://doi.org/10.1016/0079-6786(83)90001-8

R. Vaßen, M. O. Jarligo, T. Steinke, et al., Surf. Coat. Technol. 205, 938 (2010). https://doi.org/10.1016/j.surfcoat.2010.08.151

N. P. Padture, M. Gell, and E. H. Jordan, Science 296, 280 (2002). https://doi.org/10.1126/science.1068609

D. Tejero-Martin, C. Bennett, and T. Hussain, J. Eur. Ceram. Soc. 41, 1747 (2021). https://doi.org/10.1016/j.jeurceramsoc.2020.10.057

H.-F. Chen, C. Zhang, Y.-C. Liu, et al., Rare Met. (2019). https://doi.org/10.1007/s12598-019-01307-1

P. Liang, S. Dong, J. Zeng, et al., Ceram. Int. 45, 22432 (2019). https://doi.org/10.1016/j.ceramint.2019.07.235

P. A. Arsen’ev, V. B. Glushkova, A. A. Evdokimov, et al., Compounds of Rare Earth Elements. Zirconates, Hafnates, Niobates, Tantalates, Antimonates (Nauka, Moscow, 1985) [in Russian].

E. R. Andrievskaya, J. Eur. Ceram. Soc. 28, 2363 (2008). https://doi.org/10.1016/jeurceramsoc.2008.01.009

S. V. Ushakov, P. M. Saradhi, A. Navrotsky, et al., ECS Meet. Abstr. 2329 (2012). https://doi.org/10.1149/MA2012-02/24/2329

V. A. Vorozhtcov, V. L. Stolyarova, M. Chislov, et al., J. Mater. Res. 34, 3326 (2019). https://doi.org/10.1557/jmr.2019.206

G. Costa, B. J. Harder, V. L. Wiesner, et al., J. Am. Ceram. Soc. 102, 2948 (2019). https://doi.org/10.1111/jace.16113

W. D. Summers, D. L. Poerschke, M. R. Begley, et al., J. Am. Ceram. Soc. 103, 5196 (2020). https://doi.org/10.1111/jace.17187

V. P. Glushko, Thermodynamic Properties of Individual Substances. Directory (AN SSSR, Moscow, 1978) [in Russian].

S. V. Ushakov and A. Navrotsky, J. Am. Ceram. Soc. 90, 1171 (2007). https://doi.org/10.1111/j.1551-2916.2007.01592.x

V. N. Guskov, P. G. Gagarin, A. N. Guskov, et al., Russ. J. Inorg. Chem. 64, 1436 (2019). https://doi.org/10.1134/S0036023619110068

R. Babu and K. Nagarajan, J. Alloys Compd. 265, 137 (1998). https://doi.org/10.1016/s0925-8388(97)00430-1

M. E. Wieser, Pure Appl. Chem. 78, 2051 (2006). https://doi.org/10.1351/pac200678112051

T. Yu. Kolomiets, G. B. Tel’nova, A. A. Ashmarin, et al., Inorg. Mater. 53, 874 (2017). https://doi.org/10.1134/s0020168517080076

V. V. Popov, A. P. Menushenkov, A. A. Yaroslavtsev, et al., J. Alloys Compd. 689, 669 (2016). https://doi.org/10.1016j.jallcom.2016.08.019

P. G. Gagarin, A. V. Guskov, V. N. Guskov, et al., Ceram. Int. 47, 2892 (2021). https://doi.org/10.1016/j.ceramint.2020.09072

C. G. Maier and K. K. Kelley, J. Am. Chem. Soc. 54, 3243 (1932). https://doi.org/10.1021/ja01347a029

R. J. M. Konings, O. Beneš, A. Kovács, et al., J. Phys. Chem. Ref. Data 43, 013101 (2014). https://doi.org/10.1063/1.4825256

L. B. Pankratz, U.S. Bur. Mines Bull. 672, 188 (1982).

V. N. Guskov, P. G. Gagarin, A. V. Guskov, et al., Ceram. Int. 45, 20733 (2019). https://doi.org/10.1016/j.ceramint.2019.07.057

V. N. Guskov, A. V. Tyurin, A. V. Guskov, et al., Ceram. Int. 46, 128229 (2020). https://doi.org/10.1016/j.ceramint.2020.02.052

Kutti Govindan, S. Rajagopaian, C. K. Mathews, and U. V. Varadaraju, Mater. Res. Bull. 29, 759 (1994). https://doi.org/10.1016/0025-5408(94)90201-1

ACKNOWLEDGMENTS

This work was performed using equipment of the Center for Common Use of Physical Methods of Investigation of Substances and Materials, Kurnakov Institute of General and Inorganic Chemistry, Russian Academy of Sciences, Moscow, Russia.

We thank A. A. Ashmarin, Candidate of Chemical Sciences, for help in performing high-temperature X-ray diffraction studies.

Funding

This work was supported by the Russian Science Foundation (project no. 18-13-00025).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by V. Glyanchenko

Rights and permissions

About this article

Cite this article

Guskov, A.V., Gagarin, P.G., Guskov, V.N. et al. Heat Capacity and Thermal Expansion of Lanthanum Hafnate. Russ. J. Inorg. Chem. 66, 1017–1020 (2021). https://doi.org/10.1134/S0036023621070056

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036023621070056