Abstract

Electron microscopic study of the structure evolution of the equiatomic Cu–50Pd alloy in the course of transformation of the А1 disordered phase into the ordered B2 phase is carried out. The disordered state in the initial samples was formed by two ways, namely, by severe plastic deformation by rolling (е ≈ 3.8) and quenching from 700°С. The ordering was realized by annealing of initial samples at 350°С for 2 weeks. Literature data on the fact that the rate of atomic ordering with the formation of the В2 structure in the preliminarily deformed Cu–Pd alloy is substantially higher than that of the alloy quenched from a high temperature are confirmed. The annealing of the preliminary deformed Cu–50Pd alloy leads to the formation of recrystallized ordered structure with a grain size of less than 1 µm. It was found that, at 350°С, B2-phase particles in the form of rods precipitate and grow in the disordered matrix of the quenched alloy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

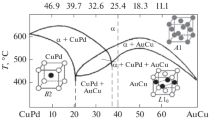

The near-equiatomic Cu–Pd alloys are characterized by high corrosion resistance and catalytic capacity, which allow the alloys to be used in energy-saving technologies [1]. Moreover, membranes fabricated from copper–palladium alloys with the ordered В2 structure are characterized by high stability to the formation of sulfides on the surface and exceed the analogous characteristics of membranes prepared from pure palladium (in this case, the substantially lower cost of products fabricated from the alloy plays the key role) [1, 2]. According to the phase diagram [3], the single-phase ordered state with the В2 structure can form in the Cu–Pd alloys containing 36 to 47 at % Pd. It was reliably determined that the maximum rate of atomic ordering is observed for the Cu–40 at % Pd alloy; as the alloy composition approaches the equiatomic composition, the rate of formation of the ordered phase abruptly decreases [4, 5].

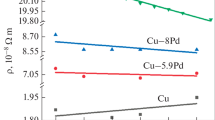

Earlier, we have shown [6, 7] that the severe plastic deformation (SPD) substantially accelerates the formation of В2 ordered structure in Cu–Pd alloys. X-ray diffraction (XRD) analysis allowed us to find that, after deformation (е ≈ 3.8) and subsequent long-term annealing at temperatures of 250–450°С, the almost single-phase state with the ordered В2 structure forms is the equiatomic Cu–50Pd alloy (further, the atomic percentage is omitted). This does not correspond to the copper–palladium phase diagram [3], in which this alloy is indicated in the two-phase (A1 + B2) region. Moreover, the electrical resistivity of the alloy in the obtained structural state is ρ = 5.48 × 10–8 Ω m [6], which is substantially lower than that available in the literature [8]. This study confirms conclusions inferred in [9]. According to the theoretical calculations [9], it was found that the formation of the single-phase state with the ordered B2 structure in the equiatomic CuPd alloy is energetically favorable. We did not find detailed electron microscopic studies performed for the Cu–50Pd alloy subjected to various thermomechanical treatments.

It is likely that the cause for the fact that the microstructure and properties of the ordered Cu–50Pd alloy have not been studied much is the very low rate of the А1 → В2 phase transformation. The kinetics of the atomic ordering of the alloy was considered in detail by us based on resistometry data [6]. However, to date changes in the physical-mechanical properties of the Cu–50Pd alloy have not been compared with the microstructure evolution upon atomic ordering of the alloy.

The aim of this study is to perform electron microscopic study of the equiatomic Cu–50Pd alloy in different structural states.

EXPERIMENTAL

The alloy was prepared by twofold melting in a vacuum of no less than 10–2 Pa and subsequent casting in graphite crucible using copper and palladium of 99.98% purity. According to electron microprobe analysis data (Superprobe JCXA-733), the composition of the prepared alloy is 49.8 at % Cu–50.2 at % Pd.

The ingot 8 mm in diameter was homogenized at 850°С for 3 h and subsequently subjected to water quenching. A foil 0.1 mm thick, which is intended for microstructural studies, is prepared by rolling at room temperature (the true deformation is е ≈ 3.8). After that, part of the samples were annealed at 700°С for 1 h and subsequently water cooled. Thus, in this study, we investigate two initial disordered states, which were obtained by preliminarily deformation and quenching. The ordered state was formed as a result of annealing of the initial samples at 350°С for 2 weeks (334 h). All heat treatments were performed in evacuated quartz and glass ampoules.

Electron microscopic study of the alloy microstructure were carried out using a JEM–200CX microscope and an accelerating voltage of 160 kV. Foils for the electron microscopic study were prepared by electrolytic polishing in a concentrated HNO3 nitric acid. The current density was 4 A/cm2; a platinum plate was used as a cathode. In the course of electrolytic polishing, the electrolyte was cooled with cold water in order to hold a temperature of less than 20°С.

RESULTS

In this work, we only report results of electron microscopic study. XRD and resistometry data obtained previously by us and published in [6, 7, 10] are given in Table 1. The presented data give sufficiently clear knowledge on the kinetics of atomic ordering of the Cu–50Pd alloy. The long-term (for several months) cooling from 350°С ensures the formation of the В2 superstructure in the initially deformed alloy, in which traces of the disordered А1 phase are found [6]. The properties of the alloy subjected to such a treatment will be used as standard properties of the adequately ordered state.

Microstructure of the Quenched Alloy

In accordance with the XRD data, the studied alloy in the quenched state is disordered and has the single-phase А1 structure with the fcc lattice parameter а = 0.3765 nm (Table 1). This corresponds to the literature data; i.e., according to data [3], the lattice parameter of the quenched Cu–49.9 at % Pd alloy is а = 0.3767 nm.

The majority of grains in the quenched alloy are characterized by curved boundaries; the average grain size is ~20 µm (Fig. 1). All electron diffraction patterns taken for the quenched alloy correspond to the disordered А1 phase. For example, for two grains denoted as I and II in Fig. 1, reciprocal lattice sections (RLSs) with the zone axes (ZA) 〈011〉 and 〈012〉 of the А1 phase are determined. The electron microscopic study allowed us to find elongated grains with straight boundaries. Since twins earlier were observed more than once in the quenched Cu–Pd alloys [11], we assume the twin origin of such boundaries. A tweed contrast is observed within many grains; this indicates the nonequilibrium structural state. In general, the tweed contrast was observed more than once in the electron microscopic study of the quenched copper–palladium alloys [11]; it is a typical feature for the formation of the short-range order [12].

It also can be noted that, for some RLSs, we fix interplanar spacings {hkl} that do not correspond to the tabulated data. This fact also confirms the formation of the pretransition state in the studied alloy after quenching.

Microstructure of the Alloy Ordered after Quenching

According to the XRD and resistometry data (Table 1), the holding of the quenched alloy at 350°С for 334 h (~2 weeks) transforms it into the two-phase (А1 + В2) state. In this case, the main volume of the material remains disordered. The lattice parameters of the disordered and ordered phases are а = 0.3766 nm and а = 0.2977 nm, respectively.

Using the resistometry data, we can approximately estimate the volume ratio of the new and old phases in the alloy after heat treatment. Indeed, taking into account the fact that the electrical resistivity of the completely disordered alloy (100% A1 phase) is ρ = 38.64 × 10–8 Ω m and that of the well-ordered state (~100% B2 phase) is ρ = 5.48 × 10–8 Ω m, and using the formula available in [5], we obtain that the sample having the electrical resistivity ρ = 35.50 × 10–8 Ω m is characterized by the presence of ~9.5% B2 phase formed in the sample.

Results of the performed electron microscopic study confirm the XRD and resistometry data; i.e., in the course of the annealing, at 350°С, of the preliminary quenched CuPd alloy, the two-phase (А1 + В2) structure forms. The transformation occurs very slowly, and, after 2-week heat treatment, the А1 phase is dominating.

The microstructure of the preliminarily quenched alloy subjected to the above treatment is characterized by a great amount of particles observed in the form of lenses and rods of different sizes (Figs. 2a, 2b). The majority of such particles give only individual reflections, the calculated interplanar spacings of which correspond to the B2 phase. Elongated particles (denoted as 1 and 2) shown in Fig. 2b are sufficiently large; this allowed us to obtain the RLSs that are typical of the В2 phase. This is confirmed by electron diffraction pattern (Fig. 2c) and the dark-field image of these particles (Fig. 2d), which was taken in the superlattice reflection g = [001]B2.

Microstructure of the initially quenched Cu–50Pd alloy ordered after 2-week annealing at 350°С: (a) typical bright-field image; (b) typical bright-field image and (c) associated electron diffraction pattern, RLSs with ZA 〈5-1-2〉 of А1 phase and 〈1-30〉 of В2 phase; and (d) dark-field image of particles taken in reflections of the B2 phase g = [001]B2.

The crystallography of the В2-phase precipitates present in the disordered matrix of the alloy under study calls for individual detailed studies, and, therefore, in this study, is considered largely insufficiently.

Microstructure of the Deformed Alloy

According to the XRD data, the equiatomic CuPd alloy in the deformed state (е ≈ 3.8) has a single-phase fcc structure (А1) (Table 1). The lattice parameter of the deformed alloy is а = 0.3770 nm and slightly exceeds that of the quenched alloy. The slight increase in the lattice parameter as a result of SPD earlier was observed by us in studying the Cu–40Pd [13] and Cu–55Pd [14] alloys. This is caused by a high volume of nonequilibrium boundaries in the nanostructured material. Indeed, as is followed from the estimation performed by us in using the Williamson–Hall method, the coherent domain size for the studied alloy subjected to plastic deformation is ~37 nm. No literature data on the lattice parameter of the highly-deformed Cu–50Pd alloy are available.

Figure 3 shows the most typical microstructure of the studied alloy in the deformed state. The dark-field image (Fig. 3a) is characterized by the absence of clear boundaries of any structural elements. The electron diffraction pattern taken for an area of ~0.5 µm in diameter exhibits the ring arrangement of reflections typical of the fcc lattice (А1 phase).

Microstructure of the CuPd alloy after deformation with е ≈ 3.8: (a) bright-field image taken in the foil plane (inset shows the electron-diffraction pattern associated with the central area of image); (b) dark-field image taken in reflections of the A1 phase g = 〈111〉 A1; and (c) bright-field image after tilting the surface (Fig. 3a) by 30° (an enlarged image of moire contrast is shown at the left corner).

The dark-field image was taken in the group of reflections g = 〈111〉; it shows an irregular band structure with the substructure differing in the morphology and sizes within each band (Fig. 3b). Figure 3c shows the bright-field image of the microstructure, which was taken after 30° tilting the foil; the greater amount of bands (as compared to that observed in Fig. 3a) characterized by weak contrast from boundaries is observed.

It should be noted that, in studying samples of highly deformed Cu–50Pd alloy, neither individual dislocations, nor complex dislocation configurations were found. However, it is necessary to note that a moire contrast often is observed in electron microscopic images. As an example, the inset in Fig. 3c demonstrates the formed moire contrast within one of bands. Such a phenomenon can be caused by concentration inhomogeneities in the material bulk and small differences in the interplanar spacing across the foil thickness [15], which result from crystal lattice distortions caused by severe deformation [16].

Change of the Microstructure of Deformed Alloy as a Result of Long-Term Annealing

The annealing at 350°С for 334 h leads to the formation of the two-phase (A1 + B2) state in the initially deformed Cu–50Pd alloy (Table 1). In accordance with the XRD data, after such a treatment, the ordered В2 phase dominates in the alloy. The lattice parameters of the disordered and ordered phases are а = 0.3767 nm and а = 0.2977 nm, respectively. According to the resistometry data, the alloy in such a state is characterized by the sufficiently low electrical resistivity, namely, ρ = 7.58 × 10–8 Ω m (Table 1). Using the resistometry data and a formula available in [5], the volume of the ordered В2 phase for the obtained structural state is estimated to be ~94%.

After preliminary deformation and 2-week holding at 350°С, the microstructure of the studied alloy is characterized by well-recrystallized grains 0.25 to 2 µm in size (Fig. 4a). In the electron diffraction pattern taken for the microstructure area in Fig. 4a, three RLSs with ZA \(\left[ {\bar {2}30} \right],\) \(\left[ {34\bar {4}} \right]\) and \(\left[ {\bar {3}84} \right]\) can be selected for the В2 phase (Fig. 4b). It should be noted that, for the RLS with ZA \(\left[ {\bar {2}30} \right]\), the interplanar spacings do not correspond to the tabulated data; however, in this case, angular relationships for the ordered bcc lattice (В2 phase) are satisfied. The two other RLSs correspond to the tabulated interplanar spacings and angular relationships. The coexistence of pure recrystallized grains and initial structure characterized by the higher density of dislocations is observed for some areas of the microstructure (i.e., areas in which recrystallization processes are not started yet). The analysis of electron diffraction patterns for such areas reveals the coexistence of the А1 and В2 phases.

Figure 4 (see inset) shows the grain-size distribution histogram for the alloy in the obtained structural state. The histogram was plotted using images of the microstructure and results of 300 measurements.

DISCUSSION

Peculiarities of the nucleation and growth of new phase particles in the initial matrix always are of interest for material scientists. For example, the beginning stages of the formation of the ordered phase in the disordered Cu–40Pd alloy were discussed in [11, 17]. However, this alloy is characterized by the highest rate of atomic ordering; because of this, it is extremely difficult to find beginning stages of the structure transformation in the alloy. In particular, nuclei of the ordered phase were observed in the preliminarily quenched Cu–40Pd alloy already after 3-min annealing at 400°С [17].

In this work, we performed the electron microscopic study of the microstructure of the equiatomic Cu–50Pd alloy, which is characterized by the very low rate of the А1 → В2 transformation. This allowed us to, for the first time, observe the formation of rodlike particles of the ordered B2 phase in the disordered matrix of the copper—palladium alloy. It should be noted that, this called for the 2-week annealing at 350°С. However, earlier, as a rule, the higher temperatures were used to form the ordered Cu–Pd alloys. For example, after long-term annealing of the Cu–55Pd alloy at 500°С, rounded nuclei of new phase were found [14]. The annealing of the disordered Cu–40Pd alloy at 400°С led to the formation of the ordered-phase grains the shape of which also is close to spherical [17].

Thus, the following interesting feature is observed for the Cu–Pd alloys ordered with the formation of the В2 structure. Ordered-phase nuclei formed at 350°С are present in the form of rods; as the annealing temperature increases, the grains become spherical. In this case, the feature is observed for a wide concentration range (therefore, is independent of the kinetics of the A1 → B2 transformation).

The kinetics of atomic ordering in various Cu–Pd alloys earlier was studied in [5–7, 18]. It was found that, in the case of annealings of the Cu—50Pd alloy in a temperature range of 250–350°С, the value of the thermodynamic parameter n in the Johnson–Mehl–Avarmi equation is n ≈ 0.8 [6]. As the annealing temperature increases, the parameter increases to n ≈ 2.5 at 450°С. As is known [19], the change in the value of the n parameter is caused by the change in the mechanism of diffusion-controlled transformation. For example, in the case of the formation of long cylinders (rods), n ≈ 1; in the case of growth of spheroids, n takes the value ~1.5 [19]. Thus, the experimental results obtained in the present study adequately agree with the thermodynamic calculations.

Certainly, the low rate of atomic ordering makes difficult the use of the equiatomic Cu–Pd alloy in practice as the membrane material in hydrogen engineering. At the same time, the preliminary plastic deformation substantially accelerates the atomic ordering as compared to the ordering of the quenched alloy. The use of preliminary cryodeformation is the next step towards further increasing the rate of the A1 → B2 phase transformation in the Cu–50Pd alloy. As was shown in our study [20], the disordered structure formed in the Cu–47Pd alloy as a result of cryorolling is extremely unstable and begins to order slowly even at room temperature.

In the whole, the obtained results are of evident interest for science and practice; therefore, these investigations need to be continued.

CONCLUSIONS

The electron microscopic study of the evolution of disordered microstructure of the equiatomic Cu–50Pd alloy in the course of atomic ordering with the formation of the В2 structure was performed. The disordered state was formed in two ways, namely, quenching from 700°С and severe deformation by rolling (е ≈ 3.8). It was found that the grain size of the quenched alloy is ~20 µm. The microstructure of the deformed CuPd alloy is observed to be nonuniform over the bulk and characterized by high density of various defects. It is shown that the 2-week annealing of initially quenched and preliminarily deformed samples of the alloy at 350°С leads to the formation of the two-phase (А1 + В2) structure. The earlier obtained XRD and resistometry data were confirmed, namely, the preliminarily deformation substantially accelerates the kinetics of the А1 → В2 phase transformation in the alloy under study. It was found that, in the course of annealing of the quenched equiatomic CuPd alloy, rodlike particles of ordered phase form in the alloy microstructure and grow. The comparison with the literature data shows that the annealing at the higher temperatures leads to the formation of spherical precipitates of the new phase in the Cu–Pd alloys. These results agree well with thermodynamic calculations, which earlier were performed by us and showed that the increase in the annealing temperature causes the change in the mechanism of diffusion-controlled nucleation and growth processes. It was found that the annealing of the preliminarily deformed equiatomic Cu–50Pd alloy at 350°С leads to the formation of recrystallized well-ordered phase with the В2 structure with an average grain size of ~0.5 µm.

REFERENCES

V. M. Ievlev, E. K. Belonogov, and A. A. Maksimenko, “Oriented crystallization of thin Pd-Cu films,” Phys. Met. Metallogr. 105, No. 6, 574–579 (2008).

O. V. Akimova, A. A. Veligzhanin, R. D. Svetogorov, S. V. Gorbunov, N. R. Roshan, and G. S. Burkhanov, “Kinetics of hydrogen absorption from a gas phase by diffusion filtering Pd–Y membranes,” Phys. Met. Metallogr. 121, No. 2,157–163 (2020).

P. R. Subramanian and D. E. Laughlin, “Cu–Pd (Copper–Palladium),” J. Phase Equilib. 12, No. 2, 231–243 (1991).

Yu. I. Beletskii, T. A. Dzigrashvili, V. V. Kokorin, V. M. Pan, K. V. Chuistov, and A. D. Shevchenko, “Features of physical properties and ordering in Cu–Pd alloys,” Fiz. Met. Metalloved. 45, 1200–1204 (1978).

E. A. Balina, P. V. Gel’d, L. P. Andreeva, and L. P. Zelenin, “Kinetics of ordering and disordering processes in binary Cu–Pd alloys,” Phys. Met. Metallogr., No. 12, 144–148 (1990).

A. Yu. Volkov, O. S. Novikova, and B. D. Antonov, “The kinetics of ordering in an equiatomic CuPd alloy: A resistometric study,” J. Alloys Compd. 581, 625–631 (2013).

O. S. Novikova and A. Yu. Volkov, “Kinetics of atomic ordering of Cu–49 at % Pd alloy after severe plastic deformation,” Phys. Met. Metallgr. 114, No. 2, 162–170 (2013).

E. M. Savitskii, V. P. Polyakova, and M. A. Tylkina, Palladium Alloys (Nauka, Moscow, 1967) [in Russian].

E. Bruno, B. Ginatempo, and E. S. Giuliano, “Fermi surface origin of non-stoichiometric ordering in CuPd alloys,” J. Phys.: Condens. Matter, No. 13, 711–716 (2001).

O. V. Antonova, O. S. Novokova, and A. Yu. Volkov, “Structure of an equiatomic CuPd alloy after severe plastic deformation and subsequent ordering,” Diag., Resour. Mech. Mater. Struct. 5,133–138 (2015).

O. V. Antonova and A. Yu. Volkov, “Microstructure of an ordered Cu–40 at % Pd alloy,” Phys. Met. Metallogr. 108, No. 4, 395–405 (2009).

K. Ohshima, D. Watanabe., “Electron diffraction study of short-range-order diffuse scattering from disordered Cu–Pd and Cu–Pt alloys,” Acta Crystallogr. A 29,520–525 (1973).

O. V. Antonova and A. Yu. Volkov, “Changes of microstructure and electrical resistivity of ordered Cu–40Pd (at %) alloy under severe plastic deformation,” Intermetallics 21, 1–9 (2012).

O. S. Novikova and A. Yu. Volkov, “Determining temperature boundary of A1–(A1 + B2) phase transformation in the copper–55 at % palladium alloy subjected to severe plastic deformation,” Johnson Matthey Technol. Rev. 58, No. 4,195–201 (2014).

P. Hirsh, A. Hovi, P. Nicolson, D. Peshli and M. Yelan, Electron Microscopy of Crystals, Ed. by L.M. Ytevski (Mir, Moscow, 1968) 574 p.

O. V. Mishin, A. Godfrey, D. Jensen Juul, and N. Hansen, “Recovery and recrystallization in commercial purity aluminum cold rolled to an ultrahigh strain,” Acta Mater. 61, 5354 (2013).

A. B. Telegin, N. N. Syutkin, and O. D. Shashkov, “Structure and mechanical properties of an ordered copper–palladium alloy,” Fiz. Met. Metalloved. 52, No. 3, 627–633 (1981).

A. Yu. Volkov, V. R. Baraz, O. S. Novikova, and E. I. Polovnikova, “Kinetics of disorder → order transformation in Cu–47 aт. % Pd alloy,” Izv. Vyssh. Uchebn. Zaved., Fiz. 55, No. 11, 17–23 (2012).

J. Christian, The Theory of Transformations in Metals and Alloys. Part 1: Equilibrium and General Kinetic Theory (Pergamon, Oxford, 1975), vol. 1.

O. S. Novikova, E. G. Volkova, A. V. Glukhov, O. V. Antonova, A. E. Kostina, B. D. Antonov, and A. Yu. Volkov, “Evolution of the microstructure, electrical resistivity and microhardness during atomic ordering of cryogenically deformed Cu–47 at %Pd alloy,” J. Alloys Compd. 838, 155591 (2020).

Funding

This study was supported by the Russian Foundation for Basic Research, project no. 18-03-00532. The electron microscopic study of samples was performed using equipment of the Center of the Collaborative Access at the Mikheev Institute of Metal Physics, Ural Branch, Russian Academy of Sciences, Yekaterinburg, Russia.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Kolchugina

Rights and permissions

About this article

Cite this article

Novikova, O.S., Antonova, O.V. & Volkov, A.Y. Formation of an Ordered Structure in the Cu–50 at % Pd Alloy. Phys. Metals Metallogr. 122, 651–656 (2021). https://doi.org/10.1134/S0031918X2107005X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X2107005X