Abstract

This paper presents the results of a study of the formation of the structure and properties of the 40Au–25.4Pd–34.6Cu alloy (wt %) in the course of its atomic ordering. A number of literature sources have been analyzed, and possible reasons for the deviation between experimental data of different authors are discussed here. Earlier field ionic microscopy (FIM) results have been confirmed: ordered В2-phase nuclei in a matrix with an L10-superstructure were observed in this alloy after prolonged annealings. It has been shown that the kinetic of atomic ordering is abruptly accelerated in a field of external tensile stresses. The results of this work demonstrate the possibility to control the structure in the course of “disorder ↔ order” transitions and can be used for the creation of new approaches to the treatment of orderable alloys.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 INTRODUCTION

Gold-based alloys are applied in a number of ways and, for this reason, have been studied in sufficient detail [1]. Nevertheless, a number of earlier results do not fit well into the overall picture, thus necessitating a deeper insight into the nature of observed phenomena.

Gold–palladium–copper alloys form a basis for most contemporary “white-gold” jewelry alloys and are used in technology, e.g., as contact materials. The most detailed study of Au–Pd–Cu alloys was performed by E. Raub et al. [2], who constructed several polythermal sections in the phase diagram of this ternary system at different ratios of components. The methods used by E. Raub et al. [2] were the following: optical microscopy, X-ray diffraction analysis, and electrical resistivity and microhardness measurements. One of the results of these studies is the constructed CuPd–CuAu quasi-binary section of the phase diagram (Fig. 1).

Quasi-binary CuAu–CuPd section of the phase diagram [2] with schemes of corresponding crystal lattices and composition of the 40Au–25.4Pd–Cu alloy (wt %) studied in this work (dashed line).

From Fig. 1 we can clearly see that the processes of atomic ordering occur in all the alloys of the CuAu–CuPd quasi-binary section upon cooling to a temperature below a certain critical temperature Тс. When palladium predominates in ternary Au–Pd–Cu alloys, the initial disordered ffc lattice is transformed into a В2-ordered BCC lattice (such a lattice is schematized in the left part of Fig. 1). An increased content of gold atoms in these alloys induces L10-ordering (such a crystal lattice is schematized in the lower right part of Fig. 1). A mixture of ordered phases (B2 + L10) is formed in the central part of the quasi-binary section. Researchers repeatedly referred to the study of the structure and properties of Au–Pd–Cu alloys in subsequent works [3–6]. The obtained results confirm conclusions [2] about the temperature ranges of phase transitions in the alloys of different compositions from this ternary system alongside with the types of ordered phases formed in them.

However, some nuclei with a B2-ordered bcc structure were observed in work [7] in the 40Au–25.4Pd–Cu alloy (wt %) alongside the ordered L10-phase. It is noted that the revealed phase is rather stable and persists after annealing at 250°C for 100 h. The conclusions [7] were made on the basis of the single method, i.e., the study of atomic crystal structure of thin wire specimens on a field ion microscope (FIM) via the controllable removal of surface atoms from the top of a spike with an electrical field. The magnification in such an instrument provides the sharp visualization of antiphase boundaries and dislocations of different types alongside the recognition of atom grades (due to different contrast) [7, 8].

In Fig. 1, we can clearly see that the 40Au–25.4Pd–Cu alloy (wt %) corresponds to the single-phase L10-superstructure region. The two-phase (B2 + L10) region lies to the left from the discussed composition. No studies have detected a В2-phase in the alloy. Let us note that the authors of [7] detected the formation of a В2-phase in the 40Au–25.4Pd–Cu alloy (wt %) only in the low-temperature region (250–300°C). Other researchers did not study the structure of Au–Pd–Cu alloys within this temperature range. The minimum disordering temperature used in work [2] to construct the CuAu–CuPd section was 350°C. This raises the problem of studying the process of atomic ordering in the 40Au–25.4Pd–Cu alloy (wt %) in the temperature region of 250–300°C.

A so-called lamellar structure composed of twin-like c-domains of 90°-misorientation is formed in most alloys (CuAu, FePd, etc.) in the course of atomic L10-ordering [6]. It has been established that the application of an external load provides the possibility to control such a domain structure, orienting the growth of c-domain by means of compressive or tensile stresses [9]. However, earlier microstructural studies have shown that the atomic ordering process in the ternary 40Au–25.4Pd–Cu alloy (wt %) occurs in a manner quite different from the equiatomic CuAu alloy. It has been reliably established [10, 11] that a granular structure, in which every grain is a c-domain, is formed in the ternary alloy. The effect of external stresses on such a structure is unknown.

The objective of this work is to study the formation of an ordered structure in the 40Au–25.4Pd–Cu alloy (wt %) at temperatures below 350°C, including the formation of such a structure in a field of external tensile stresses.

2 MATERIAL AND EXPERIMENTAL METHOD

The study was performed on the alloy 40Au–25.4Pd–34.6Cu (wt %) or 20.6Au–24.2Pd–55.2Cu (at %). The following methods were used in our work: X‑ray diffraction analysis and the study of the temperature dependences of the alloy electrical resistivity after different treatments.

An ingot of 5 mm in diameter for 3 h was homogenized at a temperature of 850°C. A wire of 0.22 mm in diameter for the measurement of electrical properties and X-ray diffraction analysis was manufactured by drawing with intermediate annealings at 800°C for 1 h and quenching by water. Plates of 0.3 mm in thickness for X-ray diffraction analysis were manufactured using rolling and intermediate annealings. All thermal treatments were performed in evacuated quartz ampoules.

The electrical resistivity of specimens on heating at a rate of 120 K/h was measured by the standard four-probe method in an evacuated quartz ampoule [12]. Several resistometric experiments were performed on a special holder, which allowed us to stretch a specimen in the course of heating.

X-ray diffraction analysis was performed on a Rigaku DMAX 2200 diffractometer using the method of continuous recording at a speed of 4°/min. Cu Kα radiation was monochromitized with a graphite single crystal.

3 EXPERIMENTAL RESULTS AND DISCUSSION

3.1 Structural Rearrangement in the Process of Ordering

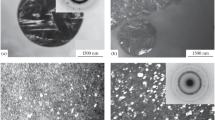

The results of X-ray diffraction analysis for the lamellar 40Au–25.4Pd–Cu specimens (wt %) in different structural states are shown in Fig. 2. The quenching of the alloy from 800°C fixes its disordered state. The quenched alloy has a FCC lattice with a unit cell parameter а = 0.3801 nm (lower X-ray diffraction pattern in Fig. 2). The peaks from the disordered phase alone persist in X-ray diffraction pattern 2 after the quenched alloy was annealed at 250°C for 1 h.

The X-ray diffraction study of atomic ordering in the equiatomic CuAu alloy was performed in work [9]. When comparing these results with the X-ray diffraction patterns in Fig. 2, it is clear that the initial stages of L10-ordering occur in the studied alloy after annealing for 1 h.

When analyzing X-ray diffraction pattern 2, we can see that annealing has induced the appearance of a kind of “shoulder” on the left side of peak (200)А1. This “shoulder” is a sign for the appearance of peak (200)fct. The intensity of peak (002)fct is two times lower (in comparison with (200)fct), and this peak is formed later [9]. Both these peaks can clearly be seen after annealing for 75 h (X-ray diffraction pattern 3 in Fig. 2). The presence of a disordered ffc-phase in the specimen is confirmed by the reflection (200)А1 in X‑ray diffraction pattern 3. Hence, annealing for 75 h at a temperature of 250°C leads to the formation of the two-phase (L10 + A1) state in the studied alloy.

X-ray diffraction pattern 4 in Fig. 2 corresponds to the ordered alloy state, which we attained by cooling from 800°C at a rate of 240 K/h. Such thermal treatment (slow cooling from a temperature above Тс) provides the formation of an equilibrium structure with a high degree of atomic order [6]. In the case of L10‑ordering, each kind of atom alternatively occupies one of planes (100) in the initial fcc lattice [6, 9]. It has been reliably established [2, 7, 10] that gold and palladium atoms in the ordered ternary Au–Pd–Cu alloys occupy the same sublattice. The existence of a preferred direction in the arrangement of atoms leads to the appearance of tetragonality in the crystal lattice in the case of L1о-ordering [6, 9].

The attained 40Au–25.4Pd–Cu alloy (wt %) in the ordered state has the following unit cell parameters: a = 0.3948 nm and c = 0.3494 nm (X-ray diffraction pattern 4 in Fig. 2). Hence, the lattice tetragonality degree is c/a = 0.89. This value slightly differs from c/a = 0.87 given in work [2]. We can hypothesize that the cooling rate from the disordered region was very high in our case to attain a high degree of long-range atomic order in the studied alloy.

The temperature dependence measured for the electrical resistivity of the quenched 40Au–25.4Pd–Cu alloy (wt %) upon heating is shown in Fig. 3.

The structural state of this specimen corresponds to X-ray diffraction pattern 1 in Fig. 2. The specific electrical resistivity of the quenched alloy at room temperature is ρ = 23.1 × 10–8 Ω m and decreases by nearly two times in the course of atomic ordering. The change in electrical resistivity upon heating allows us to confidently judge the kinetics of phase transitions in different alloys [13].

In Fig. 3 we can see that the electrical resistivity of the specimen begins to slowly decrease upon heating above 200°C. Such a low temperature for the beginning of a phase transition is due to the presence of ordered nanodomains in the quenched alloy. It has been established by means of FIM studies that the size of such domains in the quenched CuAu alloy is 20–30 Å [14]. When the quenching temperature approaches Тс, the volumetric density of these domains decreases, thus producing a strong effect on the kinetics of ordering [6]. For this reason, the kinetics of atomic ordering in the 40Au–25.4Pd–Cu alloy (wt %) after quenching from 600°C is completely different (see below).

The result of the resistometric experiment (see Fig. 3) confirms the above conclusions made on the basis of X-ray diffraction analysis (see Fig. 2): the quenched alloy sustains atomic ordering at a temperature of 250°C, but at a very low speed. This corresponds to the results seen in [7]. However, we did not observe the В2-phase in the studied alloy even after prolonged annealings at 250°C.

The X-ray diffraction data obtained at different stages of atomic ordering in the 40Au–25.4Pd–Cu alloy (wt %) can be compared with the results of studying the formation of an ordered structure in the equiatomic CuAu alloy [9]. We can make the firm conclusion from this comparison that the rearrangement of a fcc disordered structure into a fct L10-ordered structure occurs in these alloys by similar mechanisms.

3.2 Effect of Tensile Stresses on the Formation of an Ordered Structure

The effect of external tensile and compressive stresses on the formation of an L10-superstructure in the equiatomic CuAu alloy has already been studied by X-ray diffraction in an earlier work [9]. It has been shown that all c-axes in the tetragonal lattice of the ordered alloy are arranged along the force-application direction under compressive stresses. In turn, tension leads to the rearrangement of c-axes perpendicularly to the acting force.

The X-ray diffraction patterns taken from the specimens, which were simultaneously ordered for 75 h at a temperature of 250°C, are shown in Fig. 4. Specimen 1 was in a free state, while specimen 2 was subjected to tension at P ≈ 50 MPa. We can clearly see that all the peaks in X-ray diffraction pattern 2 are narrower and have a much higher intensity. We can conclude that the speed of atomic ordering in the studied alloy abruptly grows under tensile stresses. We did not observe any reflections from the В2-phase in these X‑ray diffraction patterns.

As mentioned above, ordering under a tensile load induces the reorientation of tetragonal с-domains in the copper–gold alloy [9]. This can be easily detected by X-ray diffraction: peaks (200)fct and (002)fct become comparable by their intensities. However, we cannot see this in Fig. 4: ordering under tension has led to an increase in the intensities of all peaks. The ratio between the intensities of peaks (200)fct and (002)fct is nearly the same in all the X-ray diffraction patterns presented in this work (see Figs. 2 and 4) and equal to 2 : 1.

Different researchers with different purposes studied the effect of external stresses on the formation of an L10-ordered structure on various alloys [9, 15]. However, none of them reported an appreciable acceleration of the “disorder → order” phase transition in a field of external forces. We can conclude that the formation of an ordered structure in the studied alloy differs from the ordering process, which is repeatedly described in the literature for the equiatomic CuAu alloy [1, 9]. The study of the formation of a microstructure in the 40Au–25.4Pd–Cu alloy (wt %) in the process of ordering in a field of external forces is a problem that requires further attention.

We should note that X-ray diffraction analysis in Fig. 4 was performed on thin wires with ∅0.22 mm. The appearance of strong interferences at small angles is caused by a small transversal dimension of specimens. Experiments on thin specimens are convenient because they allow us to vary the tensile load within a broad range (up to the yield stress). Moreover, such wires are used in this work to measure the electrical properties. However, we did not observe any differences between the electrical resistivity when studying specimens 1 and 2 in Fig. 4.

To study the dependence of the electrical resistivity of a specimen under tension on its temperature, the structure of a measuring cell was appreciably improved. The temperature dependence of the electrical resistivity of the 40Au–25.4Pd–Cu alloy (wt %) quenched from 600°C is shown in Fig. 5. In the course of this experiment, the specimen was under the tensile stress P ≈ 50 MPa.

It can clearly be seen from the plot that the electrical resistivity of this specimen nonmonotonically changes at ~515°C. Such an effect cannot be produced by creep processes: the elongation of the specimen with a simultaneous decrease in its diameter can lead only to an increase in the electrical resistivity. Slipping in pinches would also lead to an increase in the electrical resistivity of the specimen (due to its elongation).

The temperature at which a decrease in the electrical resistivity was detected in Fig. 5, almost coincides with the temperature boundary of the transition from the ordered alloy state to the two-phase (L10 + A1) state in the phase diagram (see Fig. 1). However, no similar phenomenon is observed in the high-temperature region of the specimen electrical resistivity–temperature dependence without loading (see Fig. 3). Based on the obtained result (see Fig. 5), we can hypothesize that the application of a tensile force initiates structure-rearrangement processes in the material.

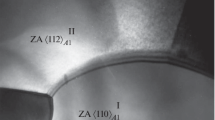

To confirm this hypothesis, we decided to increase the tensile stress applied to the specimen. The X-ray diffraction pattern taken from the quenched specimen held at 250°C for 250 h is shown in Fig. 6. The specimen was under the tensile load P ≈ 100 MPa throughout the entire period of annealing. No reflections from the disordered ffc phase were seen in the X-ray diffraction pattern. However, a weak peak identified by us as peak (110) from the В2-phase can be distinguished against the background of the more intense peaks from the ordered L10-superstructure.

4 RESULTS AND DISCUSSION

The main result of our study is the X-ray diffraction detection of the possibility of the formation of a two-phase (L10 + B2)-ordered structure in the studied alloy (see Fig. 6). This confirms the results of the work [7], in which nuclei of the ordered В2-phase were observed in the FIM structural study of the 40Au–25.4Pd–Cu alloy (wt %). However, the obtained result does not agree with the data of other researchers who studied this alloy using different methods [2–6].

We should note that we have not detected the В2‑phase in the specimens annealed in a free state at 250–300°C. With regard to the interpretation for the X-ray diffraction results in Fig. 2, the structure rearrangement in the studied alloy upon the “disorder → order” phase transition completely corresponds to the formation of an ordered L10-structure in the equiatomic CuAu alloy, which was described earlier.

The two-phase (L10 + B2)-ordered structure in the studied alloy was obtained only after prolonged annealing at 250°C, during which we subjected the specimen to the negative pressure P ≈ 100 MPa. In turn, we performed the experiments in the work [7] as follows: we first annealed alloy specimens (in a free state) and they were further studied by field ion microscopy at a liquid nitrogen temperature. The specimens before the FIM study were in the states investigated by us above (X-ray diffraction patterns 2 and 3 in Fig. 2). After annealing at 250°C for 1h, the alloy has a two-phase (A1 + L10) structure, i.e., is at the initial state of atomic ordering. After exposure at this temperature for 75 h, the alloy is also in a two-phase (A1 + L10) state, but the ordered phase predominates. No В2-phase was seen in the initial specimens. Nevertheless, this phase was seen in both specimens in the FIM study of their structure [7].

Despite the fact that our research methods and treatment techniques differ from those used in the work [7], their common feature is that a specimen in a field ion microscope is also in a field of strong tensile stresses. The FIM image is formed via the field evaporation of atoms from the surface of a specimen due to the application of a strong electrical field to this specimen. As a result of such an effect, the specimen is subjected to appreciable tensile stresses (so-called ponderomotive forces) [16]. This specific feature of such an instrument is known and was used, e.g., for the tensile tests of needle specimens manufactured of high-temperature superconducting ceramics [17].

The effect of a strong electrical field on a specimen located in a field ion microscope at a cryogenic temperature has been repeatedly discussed in earlier works. For example, it is noted in the work [18] that mechanical stresses approaching the theoretical strength of the material appear on the apex of a spike specimen in the FIM studies. As noted by E.W. Muller et al. [19], the application of a strong negative pressure to a specimen in a field ion microscope in-situ induces the volumetric expansion of the crystal by 5–10%, thus leading to the nucleation of dislocation loops and dislocation sliding, and the possibility of rearrangement in its structure cannot be excluded. It was shown in work [16] that the non-equilibrium state of a specimen during its FIM study may lead to the deviations of the temperature ranges of transitions in comparison with the corresponding ranges in the generally accepted phase diagram.

The formation of a network of α2-phase twins (with an ordered D019 structure) during the FIM study of the TiAl based alloy with an L10-ordered structure is described in [20]. It is pointed out that such in-situ transitions result from instability in the geometry of a specimen in a field ion microscope. It was established in work [15] that the FePd alloy sustains the consecutive phase transitions fcc → fct → bct with decreasing temperature. The fct → bct transition [21] undesirable for the ferromagnetic FePd alloy begins at temperatures below –20°C and pressures above 8 MPa.

We can hypothesize from these results that the 40Au–25.4Pd–Cu alloy (wt %) residing in a field of strong stresses transits to a metastable state, in which the formation of a B2-ordered bcc phase becomes more energetically advantageous. The closeness of this alloy to the two-phase (L10 + B2) region boundary (Fig. 1) agrees with this hypothesis.

We can conclude that the existence of the B2-phase in the studied alloy is a non-equilibrium state, and its formation is induced by the field of external negative pressure.

5 CONCLUSIONS

We have obtained several interesting experimental results in the course of this study. We have confirmed the conclusion [7] about the possibility of the formation of a B2-phase in the studied alloy. We have shown that the nuclei of this phase are formed in the low-temperature region (at 250°C), and this also confirms the results of the work [7]. We should note that we only detected the formation of the B2-phase in experiments where a specimen was under negative pressures (P ≈ 100 MPa) during its thermal treatment. Based on the analysis of obtained experimental data and their comparison with the literature data, we have concluded that the two-phase (L10 + B2) state of the studied alloy in the low-temperature region is non-equilibrium, and the formation of the B2-phase is induced by the field of external forces.

Moreover, we have shown that the application of strong tensile stresses does not produce any effect on the formation of a c-domain structure in the 40Au–25.4Pd–Cu alloy (wt %) in contrast to most of the alloys with an L10-superstruture. At the same time, we have seen an appreciable acceleration of atomic ordering in the field of external forces. This may be used in practice for the production of functional materials with specified properties.

REFERENCES

V. M. Malyshev and D. V. Rumyantsev, Gold (Metallurgiya, Moscow, 1979) [in Russian].

E. Raub and G. Worwag, “Uber Gold–Palladium–Kupfer-Legierungen,“ Zs. Metallkd. Bd. 46, 119–128 (1955).

T. Shiraishi, M. Ohta, and M. Yamane, “Ordering process and age-hardening mechanism of CuPd–AuCu pseudo-binary alloys,” Dent. Mater. J. 3, 193–204 (1984).

T. Shiraishi and M. Ohta, “Low temperature ageing in equiatomic CuAu and Cu–Au–Pd ternary alloys,” J. Mater. Sci. 24, 1049–1052 (1989).

H. Winn, Y. Tanaka, T. Shiraishi, K. Udoh, E. Miura, R. I. Hernandez, Y. Takuma, and K. Hisatsune, “Two types checkerboard-like microstructures in Au–Cu–Pd ternary alloys,” J. Alloys Compd. 306, 262–269 (2000).

A. Yu. Volkov, “Structure and mechanical properties of CuAu and CuAuPd ordered alloys,” Gold Bull. 37, 208–215 (2004).

V. A. Ivchenko, E. V. Popova, and T. S. Gorskikh, “Effect of palladium on the phase transformations in gold–copper–palladium alloys,” Phys. Met. Metallogr. 97, 207–211 (2004).

N. N. Syutkin, V. A. Ivchenko, A. B. Telegin, and A. Yu. Volkov, “Field ion microscopy of early stages of ordering and decay of palladium–copper–silver alloy,” Fiz. Met. Metalloved. 62, 965–969 (1986).

A. Yu. Volkov, B. D. Antonov, and A. M. Patselov, “Effect of external force fields on the domain structure of equiatomic CuAu alloy,” Phys. Met. Metallogr. 110, 250–259 (2010).

A. Yu. Volkov, M. L. Kotik, B. P. Adrianovskii, and V. I. Syutkina, “Effect of palladium on the structure of gold–copper alloy,” Fiz. Met. Metalloved., No. 10, 147–154 (1990).

A. Yu. Volkov, and V. I. Syutkina, “Structure formation in gold–copper–palladium alloys upon atomic ordering: I. High-temperature ordering,” Phys. Met. Metallogr. 79, 643–648 (1995).

A. Yu. Volkov, A. E. Kostina, E. G. Volkova, O. S. Novikova and B. D. Antonov, “Microstructure and physicomechanical properties of a Cu–8 at % Pd alloy,” Phys. Met. Metallogr. 118, 1236–1246 (2017).

P. Kirbiš, I. Anžel, and M. Brunčko, “Application of in-situ electrical resistance measurements to the study of phase transformations in ferrous alloys,” Phys. Met. Metallogr. 117, 1092–1100 (2016).

V. A. Ivchenko and N. N. Syutkin, “Atomic structure CuAu in field ion microscope,” Fiz. Tverd. Tela 25, 3049–3054 (1983).

J. Cui, T. W. Shield, and R. D. James, “Phase transformation and magnetic anisotropy of an iron-palladium ferromagnetic shape-memory alloy,” Acta Mater. 52, 35–47 (2004).

E. F. Talantsev, V. A. Ivchenko, and N. N. Syutkin, “Temperature of phase transition of superconductor to the state of field emission catode,” Zh. Tekh. Fiz. 63, 199–203 (1993).

E. F. Talantsev, “The tensile strength of perfect LuBa2Cu3O7 – x single crystals of submicrometre cross-sectional dimensions,” Supercond. Sci. Technol. 7, 491–494 (1994).

C. K. S. Moy, G. Ranzi, T. C. Petersen, and S. P. Ringer, “Macroscopic electrical field distribution and field-induced surface stresses of needle-shaped field emitters,” Ultramicroscopy 111, 397–404 (2011).

E. W. Muller, “Field ion microscopy,” Science 149, 591–601 (1965).

D. J. Larson and M. K. Miller, “In-situ micro-twinning of TiAl in the field ion microscope,” Mater. Sci. Eng., A 250, 72–76 (1998).

L. V. Redel, Yu. Ya. Gafner, S. L. Gafner, I. S. Zamulin, and Zh. V. Goloven’ko, “Estimate of the applicability of Pd–Pt nanoalloy for data recording by the method of phase change,” Phys. Met. Metallogr. 118, 452–458 (2017).

ACKNOWLEDGMENTS

This work was performed within the subject “Pressure” (budget project no. AAAA-A18-118020190104-3) and financially supported in part by the Ural Branch of the Russian Academy of Sciences (project no. 18‑10-2-24), the Russian Foundation for Basic Research (project no. 17-33-50076) and by Act 211 Government of the Russian Federation, contract no. 02.A03.21.0006.

X-ray diffraction studies were performed in the Shared Facilities Center of the Institute of High-Temperature Electrochemistry of the Ural Branch of the Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Glushachenkova

Rights and permissions

About this article

Cite this article

Volkov, A.Y., Talantsev, E.F., Novikova, O.S. et al. Formation of an Ordered Structure in the 40Au–25.4Pd–34.6Cu Alloy (wt %). Phys. Metals Metallogr. 119, 1222–1228 (2018). https://doi.org/10.1134/S0031918X18120220

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X18120220