Abstract

Specificities of the theory of deformation interactions in polycrystalline alloys are discussed in this work. It is shown that, in the continuous approximation, these interactions are completely determined by the dilatation components of elastic and inelastic strain fields created by the systems of grain boundaries and the system of impurity atoms. Formulas and estimates for various types of deformation interactions are presented. Problems concerning the effect of the boundaries on the lattice parameters, the concentration expansion of the lattices of inhomogeneous alloys, and the interaction of grain boundaries are discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Deformation interactions between the structural elements of alloys significantly affect their behavior under many physicochemical and thermomechanical actions [1–5]. The theory of these interactions for chemically homogeneous single-crystal alloys has been developed in detail for quite a long time by various authors (see reviews [1–4]).

Polycrystalline alloys have structural features that significantly complicate the overall picture of interactions in the materials. One of the most important of these is the presence of an excess volume density field in polycrystals that appears due to the presence of grain boundaries. The excess volume significantly changes the atom and ion density distribution that in turn, completely determines all the properties of the electron-phonon subsystem of the alloy that affect the main channels of interparticle interactions [5–8].

In addition, grain boundaries always cause local segregations of impurity atoms [6], making the alloy chemically inhomogeneous. This means that when determining the physical parameters characterizing the deformation properties of polycrystalline alloys, certain refinements should be required. For example, the coefficients of impurity-concentration and vacancy-concentration expansion of the crystal lattice of an inhomogeneous alloy can become coordinate-dependent rather than constant as in a homogeneous alloy.

Of no less importance is the study of deformation interactions in polycrystals in connection with their effect on the structure of intercrystalline segregations [9] and a number of other surface phenomena that determine the kinetics of phase transformations with the participation of grain boundaries [10].

The aim of this work is a theoretical study of the dependence of deformation interactions on the excess volume density distribution within the microscopic theory of polycrystalline alloys.

1 FUNDAMENTALS OF THE THEORY

1.1 Hamiltonian of a Polycrystalline Alloy

The fundamental principle of applying the methods of statistical physics to the theory of alloys is that the results of theoretical calculations should always be represented as statistical averages over an ensemble of atomic systems that takes into account all significant random deviations of the structure of alloys from their average values. In thermodynamic equilibrium, the probability distribution of these deviations is completely determined by the Hamiltonian of the alloy.

For example, consider the Hamiltonian of a double substitution alloy A–B with a simple cubic lattice. The atoms of the basic element is denoted by symbol A, and the impurity atoms, by symbol B. A generalization of the theory to the case of complicated crystal lattices with an arbitrary basis does not cause fundamental difficulties [1]. In the approximation of central pair atomic interactions, this Hamiltonian is usually written in the following form [1–3]:

Here, \({{W}_{{IJ}}}({{{\mathbf{r}}}_{{\mathbf{n}}}}-{{{\mathbf{r}}}_{{{\mathbf{n}}{\kern 1pt} '}}})\) {I, J = A, B} are the interaction potentials of an atom of species I located at a point \({{{\mathbf{r}}}_{{\mathbf{n}}}}\) of a cell n of the crystal lattice with an atom of species J located at a point \({{{\mathbf{r}}}_{{{\mathbf{n}}{\kern 1pt} '}}}\) of a cell \({\mathbf{n}}{\kern 1pt} ',\) and H0 is a constant independent of the positions of the atoms, but including their proper energies. The summation in expression (1) is carried out over all lattice cells of the polycrystalline alloy. We have \({{\hat {c}}_{{I{\mathbf{n}}}}} = 1,\)if an atom of species I is at the point \({{{\mathbf{r}}}_{{\mathbf{n}}}}\) and \({{\hat {c}}_{{I{\mathbf{n}}}}} = 0\) otherwise. For a substitution alloy without vacancies, at each site, we have

The operators \({{\hat {c}}_{{I{\mathbf{n}}}}}\) at any m-th site of the lattice can take random values 0 and 1. The radius vector

depends on the function \({\mathbf{u}}({\mathbf{n}})\) that defines the displacement of the atom from the equilibrium position in the cell of the ideal lattice of the base metal. This displacement characterizes the elastic component of the strain field generated by all defects in the crystal structure of the alloy.

The presence of grain boundaries and dislocations in the alloy also suggests the presence of irreversible deformations associated with the displacement of the positions of the unit cells of the crystal lattice relative to their positions in the ideal lattice [8].

Expression (1) has several significant drawbacks. First, it does not correspond to the complete set of microscopic states of the atomic system of alloys and, therefore, cannot serve as the basis for a statistical description of their properties. The point is that the operators \({{\hat {c}}_{{I{\mathbf{n}}}}}\) determine the positions of atoms at the point \({{{\mathbf{r}}}_{{\mathbf{n}}}}\) with a probability equal to unity. However, in reality, the point \({{{\mathbf{r}}}_{{\mathbf{n}}}}\) corresponds only to the average position of the atom, in which it spends most time in thermal vibrations that always exist in the alloy at finite temperatures.

The statistical description assumes that the real positions of atoms should be determined by calculating the probability density \({{p}_{{J{\mathbf{n}}}}}({\mathbf{r}})\) of the position of an atom of species J in a cell number n. We define it as follows:

Here, \({{f}_{J}}({\mathbf{r}} - {{{\mathbf{r}}}_{{\mathbf{n}}}})\) is a continuous positive-definite function localized in a region \({{\Omega }_{n}}\) occupied by the atom in the cell n, with the normalization:

where V is the volume of the alloy.

Another drawback of expression (1) is that the operators \({{\hat {c}}_{{I{\mathbf{n}}}}}\) are not related to the impurity concentration distribution that is the main characteristic of the structure of any alloy. However, the use of the functions \({{p}_{{J{\mathbf{n}}}}}({\mathbf{r}})\) makes it possible to correctly pass in expression (1) from the operators \({{\hat {c}}_{{I{\mathbf{n}}}}}\) to physically well-defined continuous microscopic fields of atomic density and impurity concentration, describing fluctuations of the main structural parameters in the complete statistical ensemble of the alloy [11].

Thus, using expressions (4) and (5), we can define the microscopic density distribution of atoms of species J by the expression

In this notation, the Hamiltonian of the alloy is represented in the following form:

where

is the energy of effective chemical interaction of impurity atoms surrounded by atoms of the base metal,

is the density of nodes in the alloy lattice, and

is the microscopic impurity concentration.

The macroscopic distribution of the impurity concentration is defined as the statistical average of quantity (12) over the Gibbs ensemble with Hamiltonian (7) [11]:

The upper sign “~” in the potentials in (7)–(9) means that they coincide with the corresponding interatomic potentials at \({\mathbf{R}} \ne {\mathbf{R}}{\kern 1pt} '\) and are equal to zero at \({\mathbf{R}} = {\mathbf{R}}{\kern 1pt} '\) [1]. We neglect the dependence of atomic potentials on \(n({\mathbf{r}})\) and \(c({\mathbf{r}})\).

1.2 Continuous Approximation

The analysis of model (7)–(13) in the coordinate system S0 associated with the ideal lattice of the base metal encounters significant mathematical difficulties due to the fact that the crystallites of the polycrystal are randomly mutually misoriented. We will therefore consider a number of transformations that bring this expression to a form more convenient for calculations.

It is customary to study the structure of irreversible (plastic) strain fields in the continuum approximation [12]. A possible method for constructing a continuous model is as follows.

We replace the unknown function \({{f}_{J}}({\mathbf{r}} - {{{\mathbf{r}}}_{{\mathbf{n}}}})\) in formula (7) by the expression

As a result, we obtain a model of the alloy in which the matrix of the base metal is replaced with a continuum, the elastic properties of which coincide with the macroscopic elastic properties of the crystal lattice of the metal. The impurity atoms are randomly distributed over the entire volume of the polycrystal, as in the lattice version represented by formula (1).

In such a continuum, the chaotic misorientation of crystallites is quantitatively characterized only by changes in the density of the nodes \(n({\mathbf{r}})\) in the crystal lattice of the polycrystal in comparison with the density of the nodes \({{n}_{0}}\) in the ideal lattice of the base metal:

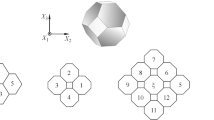

In the coordinate system S0, the density of nodes of the crystal lattice in the bulk of all crystallites is equal to the density of nodes n0 of the ideal lattice (see Fig. 1a). Thus, the quantity \(\Delta {{n}_{0}}({\mathbf{r}})\) is nonzero only at the points of mating of misoriented undeformed crystallites. Hence, \(\Delta {{n}_{0}}({\mathbf{r}})\) is uniquely determined by the excess volume density distribution \({{\varepsilon }_{{0V}}}({\mathbf{r}}),\) introduced into the polycrystal by unrelaxed grain boundaries (see Appendix):

Here, \(V({\mathbf{r}})\) is the volume of a polycrystal in a small neighborhood of the point r in the absence of an elastic field, and \({{V}_{0}}\) is the volume of an ideal lattice with the same number of atoms A. The effect of dislocations on \(\Delta n({\mathbf{r}})\) is negligibly small [7, 8] and is not considered further. From (15) and (16), we find

1.3 Elastic Strains in the Alloy

To determine the elastic displacements \({\mathbf{u}}({\mathbf{r}})\), we expand expression (7) in a Taylor series in \({\mathbf{u}}({\mathbf{r}})\) in the quadratic approximation. Taking into account expressions (15)–(17), we obtain

Here,

is the elastic energy of the ideal lattice of pure metal A, generated by the defect subsystem of the alloy, \({{\sigma }_{{ij}}}({\mathbf{r}})\) and \(\varepsilon _{{ij}}^{{{\text{el}}}}({\mathbf{r}})\) are the components of the stress and elastic strain tensors, respectively, (i, j = 1, 2, 3); the repeated subscripts in formula (19) and henceforward mean the summation;

is the energy of the unrelaxed system of boundaries (for compactness of formulas, the difference of arguments in the potentials is suppressed);

is the total energy of effective chemical interaction of impurity atoms;

is the energy of chemical interaction of the system of grain boundaries with the impurity subsystem of the alloy, caused by changes in the atomic density at the boundaries;

is the energy of the elastic field in the system of grain boundaries and impurity atoms. The subscript j in the potentials after a comma means the differentiation with respect to xj.

Formulas (18)–(23) were obtained within the linear theory of elastoplastic deformations, taking Vegard law [1] into account. The nonlinear version of the theory is more cumbersome, but does not cause any fundamental difficulties. Equating to zero the variation of expression (18) with respect to elastic displacements, we obtain the equation for the mechanical equilibrium of the alloy:

Relationships (18), (23), and (24) allow us to make a number of general statements that do not depend on the model of an elastic medium. Multiplying scalarly Eq. (24) by the displacement vector, after the integration over the volume, we obtain

With the help of the divergence theorem [4], expression (23) is transformed to

The functions \({\text{div}}{\kern 1pt} {\mathbf{u}}({\mathbf{r}})\) and \(\Delta {{n}_{0}}({\mathbf{r}})\) are related to the elastic and inelastic local variations in the volume of the alloy, respectively. Thus, expressions (15) and (26) imply that, in the continuum approximation, the interactions of the main types of defects in polycrystals occur only with the help of dilatation deformation fields.

Expressions (15)–(22), (25), and (26) and the solutions of Eq. (24) with the boundary conditions uniquely determine all types of deformation interactions within the continuous model of polycrystalline alloys.

2 ISOTROPIC MEDIUM MODEL

Despite the fact that many alloys in the single-crystal state exhibit the properties of elastic anisotropy, their polycrystalline analogs, as a rule, do not possess such properties [6]. It is therefore of considerable interest to study the features of deformation interactions within the model of an elastoplastic isotropic body. In this case, Eq. (24) is greatly simplified and allows exact analytical solutions.

Indeed, in an elastically isotropic medium,

Here, λ and μ are the Lamé coefficients [3, 7] and Δ is the Laplace operator. Under the condition (27), Eq. (24) has an exact solution for an elastic dilatation field in an unbounded medium:

\(\eta = {1 \mathord{\left/ {\vphantom {1 {(\lambda + 2\mu )}}} \right. \kern-0em} {(\lambda + 2\mu )}}.\) Substituting this quantity into formulas (18), (25), and (26), we obtain the exact expression for the Hamiltonian of a polycrystalline alloy in the isotropic approximation:

Here,

is the total energy of an elastically relaxed system of grain boundaries,

is the potential of elastic interaction of elementary fragments of grain boundaries,

is the elastic energy of interaction of the system of boundaries with the impurity subsystem of the alloy,

is the elastic interaction potential of an elementary fragment of the grain boundary with an impurity atom,

is the elastic energy of interaction of atoms in the impurity subsystem of the alloy, and

is the potential of elastic interaction of impurity atoms.

3 DISCUSSION OF THE RESULTS

3.1 Lattice Representation

Formulas (29)–(35) can be written in the lattice representation. Let us show this using expressions (34) and (35). Taking into account relationships (2)–(6), assuming in the summation that \(f({\mathbf{r}} - {\mathbf{n}}) = \delta ({\mathbf{r}} - {\mathbf{n}})\), we obtain

These representations make it possible to separate in the total elastic energy (36) of the impurity subsystem the terms associated with the elastic self-action of impurity atoms, \(W_{{0c}}^{{{\text{el}}}}{\text{:}}\)

The Fourier transform of the potential \(\tilde {w}_{{cc}}^{{{\text{el}}}}({\mathbf{n}})\) is

where \(w_{{cc,{\mathbf{k}}}}^{{{\text{el}}}}\) is the Fourier transform of the potential \(w_{{cc}}^{{{\text{el}}}}({\mathbf{n}}).\)

3.2 Concentration Expansion of Alloys

After statistical averaging of the second term in formula (28) over the Gibbs ensemble and using definition (13), we find the statistical averaged distribution of the dilatation created in the alloy by the impurity subsystem:

The volume average of this quantity is

Taking into account that the experimentally measured impurity expansion coefficient of a chemically homogeneous alloy is determined by the formula \({{\alpha }_{0}} = {{d{{{\left\langle {{\text{div}}{\mathbf{u}}({\mathbf{r}})} \right\rangle }}_{c}}} \mathord{\left/ {\vphantom {{d{{{\left\langle {{\text{div}}{\mathbf{u}}({\mathbf{r}})} \right\rangle }}_{c}}} {d{{c}_{0}}}}} \right. \kern-0em} {d{{c}_{0}}}}\) [1], we obtain

In the analysis of the deformed state in chemically inhomogeneous alloys, it should be taken into account that there is a spectrum of impurity expansion coefficients. Indeed, passing in formula (41) to the Fourier components of the corresponding functions, we obtain

Here, k is the wave vector, ck is the amplitude of the concentration wave [1, 2], and \({{\left\{ {{\text{div}}{{u}_{{\mathbf{k}}}}} \right\}}_{c}}\) and \(\Delta {{W}_{{AB,{\mathbf{k}}}}}\) are the Fourier transforms of the functions \({{\left\{ {{\text{div}}u({\mathbf{r}})} \right\}}_{c}}\) and \(\Delta {{W}_{{AB}}}({\mathbf{r}})\), respectively. Note that concentration waves are defined formally, only as terms of the Fourier series of the concentration field \(c({\mathbf{r}}).\) This definition is not related to any physical processes in alloys [2].

Formula (43) can be represented as \({{\alpha }_{0}} = {{\left\{ {\frac{d}{{d{{c}_{k}}}}{{{\left\{ {{\text{div}}{{u}_{{\mathbf{k}}}}} \right\}}}_{c}}} \right\}}_{{{\mathbf{k}} = 0}}}.\) This definition makes it possible to introduce for each concentration mode its own volume expansion coefficient by the formula

The physical meaning of the coefficient \({{\alpha }_{{\mathbf{k}}}}\) is that this coefficient, rather than the coefficient \({{\alpha }_{0}},\) determines the dilatation field distribution created by the concentration mode ck in the r-space: \({{\left\{ {{\text{div}}u({\mathbf{r}})} \right\}}_{{{{c}_{{\mathbf{k}}}}}}}\) = \({{\alpha }_{{\mathbf{k}}}}{{c}_{{\mathbf{k}}}}{{e}^{{i{\mathbf{kr}}}}}.\)

The quantities \({{\alpha }_{{\mathbf{k}}}}\) may be considered as Fourier transforms of the local concentration expansion coefficient of the lattice,

that depends on spatial coordinates.

A vacancy in a chemically pure metal can also be considered an impurity atom. In this case, formula (43) will determine the expression for the vacancy expansion coefficient of the lattice:

3.3 Volume Expansion of Polycrystals

The first term in formula (28) shows that grain boundaries can also affect the crystal lattice parameters due to the elastic deformation they generate in the bulk of the material:

The volume average of this quantity, taking into account formula (47), is equal to:

Here, \({{\bar {\varepsilon }}_{{0V}}} = {{\delta V} \mathord{\left/ {\vphantom {{\delta V} V}} \right. \kern-0em} V}\) and \(\delta V\) is the excess volume of the alloy with unrelaxed boundaries.

The total excess volume of the polycrystal consists of the unrelaxed and elastic parts:

For metals, \({{\beta }_{0}} \approx - 0.5\) [3]. In a unit volume of nanocrystalline Fe with a grain size D ≈ 10 nm, the total area of the grain boundaries per unit volume of the material is \(S \approx {3 \mathord{\left/ {\vphantom {3 D}} \right. \kern-0em} D}.\) The mean excess volume per unit surface area of the grain boundary is \({{\bar {\varepsilon }}_{0}}\) ≈ 0.064a [13]. Hence, we find \({{\bar {\varepsilon }}_{{0V}}} = {{\bar {\varepsilon }}_{0}}S\) ≈ 4.8 × 10–3 and \({{\left\langle {{\text{div}}{\mathbf{u}}({\mathbf{r}})} \right\rangle }_{g}}\) ≈ 2.4 × 10–3. This estimate is in good agreement with the experimental data on the change in the lattice parameter in nanocrystalline iron, given in [14]: \({{\Delta a} \mathord{\left/ {\vphantom {{\Delta a} a}} \right. \kern-0em} a}\) = 0.9 × 10–3 ≈ \({{{{{\left\langle {{\text{div}}{\mathbf{u}}({\mathbf{r}})} \right\rangle }}_{g}}} \mathord{\left/ {\vphantom {{{{{\left\langle {{\text{div}}{\mathbf{u}}({\mathbf{r}})} \right\rangle }}_{g}}} 3}} \right. \kern-0em} 3}\) = \(0.8 \times {{10}^{{ - 3}}}.\)

On the other hand, it is known that measurements of the impurity concentration in nanomaterials are mainly performed using X-ray data on variations in the crystal lattice parameter. For D ≤ 3–5 nm, the quantity \({{\bar {\varepsilon }}_{V}}\) can take the values \({{\bar {\varepsilon }}_{V}}\) ≈ (1–2) × 10–2 [8]. Since, for substitutional alloys, α ≈ 10–2 [1], this means that, for any value of impurity concentration c0, the changes in the lattice parameters of the alloy introduced into nanomaterials by the grain boundaries can be comparable to changes introduced by impurities. At unlike signs of the effects of impurities and the grain boundaries on the expansion of the lattice, the lattice parameter can have nonmonotonic behavior in the experimentally observed grain size reduction processes [15]. Similar effects can arise under the action of impurity on the structure and excess volume of the grain boundaries.

3.4 Estimating the Range of Elastic Interaction of Impurity Atoms

Formulas (35)–(40) show that the elastic interaction of point defects is determined by the nonlocal potential \(w_{{cc}}^{{{\text{el}}}}({\mathbf{r}},{\mathbf{r}}{\kern 1pt} ')\) = \(w_{{cc}}^{{{\text{el}}}}({\mathbf{r}} - {\mathbf{r}}{\kern 1pt} '),\) the value of which in an isotropic medium depends on the distance \(\left| {{\mathbf{r}} - {\mathbf{r}}{\kern 1pt} '} \right|.\) This potential is a convolution of the potentials \(\Delta {{W}_{{AB}}}({\mathbf{r}} - {\mathbf{r}}{\kern 1pt} '),\) entering in formula (35).

Using the Morse potentials as an example, it can be shown analytically that the radius of action of the convolution of potentials cannot be smaller than the minimum radius of the action of one of the potentials entering into it. This means that the radius of action of the elastic potential \(w_{{cc}}^{{{\text{el}}}}({\mathbf{r}} - {\mathbf{r}}{\kern 1pt} ')\) is the same as that of the potential \(\Delta {{W}_{{AB}}}({\mathbf{r}} - {\mathbf{r}}{\kern 1pt} ').\)

Let us therefore pay attention to the fact that inhomogeneous dilatation \({\text{div}}{\kern 1pt} {\mathbf{u}}({\mathbf{r}})\) created by a point defect always causes additional shear stresses, the range of which can be much larger than the range of atomic potentials [3]. However, shear stresses do not contribute to the interaction energy of impurity atoms and therefore do not affect the radius of their interaction.

3.5 Estimation of the Magnitude of the Elastic Interaction of Impurity Atoms

Estimating the elastic interaction energy of impurity atoms in interstitial alloys [1] is of greatest interest for researchers. It can be carried out in the long-wave approximation by setting \(\Delta {{W}_{{AB,{\mathbf{k}}}}} = {{W}_{{AB,{\mathbf{k}}}}}\) and \(c({\mathbf{r}}) \approx {{c}_{0}} = \operatorname{const} \) in formulas (34) and (35). Then \(W_{{cc,{\text{Int}}}}^{{el}}\) ≈ \( - n_{0}^{2}c_{0}^{2}\tilde {w}_{{cc,{\mathbf{k}}}}^{{el}}{{V}^{2}}.\)

From the inequality \(\tilde {W}_{{AB,{\mathbf{k}} = 0}}^{2} \gg \sum\nolimits_{\mathbf{k}} {{{\tilde {W}_{{AB,{\mathbf{k}}}}^{2}} \mathord{\left/ {\vphantom {{\tilde {W}_{{AB,{\mathbf{k}}}}^{2}} N}} \right. \kern-0em} N}} \) that is satisfied well for the Morse potentials, we find

Here, \({{n}_{{0B}}}\) and \({{L}_{B}}\) are the atomic density and the heat of vaporization of a unit volume of chemically pure substance B, respectively.

This expression should be compared with the energy of effective chemical interaction of impurity atoms in chemically homogeneous interstitial alloys. Replacing \(U({\mathbf{r}})\) with \({{\tilde {W}}_{{BB}}}({\mathbf{r}})\) in formula (21), we obtain

This result is in good agreement with the estimate given in [1].

In interstitial alloys, α0 ~ 1 [1] and \(\eta {{L}_{B}}\) ~ 1 [6], and it can be assumed that \({{n}_{0}} \approx {{n}_{{0B}}}.\) Hence, the quantity \(W_{{cc,Int}}^{{{\text{el}}}}\) can take equal and even greater values than \({{U}_{c}}\). This means that the elastic interaction of impurity atoms in interstitial alloys is not only comparable in magnitude with their direct chemical interaction, but can be stronger.

The same data on elastic and chemical interactions of impurities in real alloys are given in [1]. This allows us to conclude that the isotropic part of the elastic interaction of point defects, represented by formulas (34)–(40), makes the main contribution to the deformation interaction of impurities in real alloys.

3.6 Energy of Interaction of Boundaries

Let us consider the expression for the interaction energy of two plane-parallel grain boundaries. From formulas (20) and (30), we find:

Here, superscripts 1 and 2 mark the distributions of the specific excess volume at the first and second boundaries, respectively, the variable z is equal to the distance between the planes, the vectors \({\boldsymbol{\rho }}\) and \({\boldsymbol{\rho }}{\kern 1pt} '\) lie in the mismatched planes of boundaries 1 and 2, respectively, and Hi is the thickness of the ith boundary (see Figs. 1b and 1c) {i = 1, 2}.

The first term in (54) describes the direct chemical interaction of the boundaries, and it is always negative, since at distances \(r > a,\,\,{{\tilde {W}}_{{AA}}}({\mathbf{r}}) \leqslant 0.\) For the same reason, the potential \(\tilde {w}_{{gg}}^{{{\text{el}}}}({\mathbf{r}})\) is positive (see formula (31)). Since the mean values of \(\varepsilon _{V}^{{(j)}}({\mathbf{r}})\) (j = 1, 2) are also positive, w1, 2(z) < 0. Thus, the interaction of the boundaries reduces the total energy of the system of grain boundaries. As z → 0, the interaction of the boundaries becomes stronger; therefore, the total energy of the parallel boundaries will decrease with decreasing distance between them.

In conclusion, it should be noted that the main result of this work is that the potentials of deformation interactions of structural defects of polycrystalline alloys in it have been represented explicitly for the first time via simple functional dependences on the excess volume density distribution, the field of microscopic concentration of impurities, and real potentials of pair interatomic interactions.

This made it possible to reveal a number of important features characterizing deformation interactions within the isotropic continuous model that most adequately simulates the structure of polycrystalline alloys. They include the existence of nonlocal elastic and inelastic interactions in all elements of the defect subsystem of the alloy and the presence of functional dependences of the main parameters of volume expansion on the potentials of interatomic interactions of chemical components of the alloy.

The dependence of the results on the microscopic concentration field makes it possible to construct a complete statistical ensemble for an isotropic continuum and explicitly take into account the effect of fluctuations of strain fields and their interactions on most processes of structural and phase transformations in polycrystalline alloys without imposing significant restrictions on the smoothness of the distributions of the macroscopic impurity concentration \(c({\mathbf{r}}).\)

CONCLUSIONS

(1) Deformation interactions in polycrystalline alloys significantly depend on the distribution of excess volume in the system of grain boundaries.

(2) In polycrystalline alloys, the volume expansion coefficients of the crystal lattice can depend on the spatial coordinates.

(3) In nanocrystalline alloys, volumetric changes caused by the system of grain boundaries can be comparable with volumetric changes from impurities.

(4) The isotropic part of the elastic interaction of point defects makes the main contribution to the deformation interaction of impurities in real alloys.

REFERENCES

A. G. Khachaturyan, Theory of Phase Transformations and Structure of Solid Solutions (Nauka, Moscow, 1974) [in Russian].

M. A. Krivoglaz, Theory of Scattering of X-rays and Thermal Neutrons in Real Crystals (Nauka, Moscow, 1967) [in Russian].

A. A. Smirnov, Theory of Interstitial Alloys (Nauka, Moscow, 1979).

D. Eshelbi, Continual Theory of Dislocations (Inostrannaya Literatura, Moscow, 1963) [in Russian].

M. A. Shtremel’, Strength of Alloys. Chap. 2. Deformation (MISiS, Moscow, 1997) [in Russian].

J. P. Hirth and J. Lothe Theory of Dislocations (Cambridge University Press, Cambridge, 2017).

L. S. Vasil’ev and S. L. Lomaev, “Excess volume in materials with dislocations,” Phys. Met. Metallogr. 120, No. 7, 709–715 (2019).

L. S. Vasil’ev and S. L. Lomaev, “Influence of pressure on the processes of formation and evolution of the nanostructure in plastically deformed metals and alloys,” Phys. Met. Metallogr. 120, No. 6, 600–606 (2019).

L. E. Karkina, I. N. Karkin, A. R. Kuznetsov, I. K. Razumov, P. A. Korzhavyi, and Yu. N. Gornostyrev, “Solute–grain boundary interaction and segregation formation in Al: First principles calculations and molecular dynamics modeling,” Comput. Mater. Sci. 112, 18–26 (2016).

V. G. Pushin, V. V. Kondrat’ev, and V. N. Khachin, Pretransitional Phenomena and Martensitic Transformations (Ural Branch RAS, Yekaterinburg, 2020) [in Russian].

Yu. L. Klimontovich, Statistical Physics (Nauka, Moscow, 1982).

L. I. Sedov, Continuum Mechanics (Nauka, Moscow, 1970), Vol. 1 [in Russian].

L. S. Vasil’ev and S. L. Lomaev, “Excess volume formation in single-component nanocrystalline materials,” Fiz. Mezomekh. 20, No. 2, 50–60 (2017).

K. Lu and Y. H. Zhao, “Experimental evidences of lattice distortion in Nanocrystalline Materials: 1–4,” Nanostruct. Mater. 12, No. 1–4, 559–562 (1999).

J. Sheng, G. Rane, U. Welzel, and E. J. Mittemeijer, “The lattice parameter of nanocrystalline Ni as function of crystallite size,” Phys. E 43, No. 6, 1155–1161 (2011).

Funding

This work was carried out within research projects nos. АААА-А17-117022250038-7 and АААА-А18-118020190104-3.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Chernokozhin

APPENDIX

APPENDIX

EXCESS VOLUME OF BOUNDARIES

Let us consider the excess volume density distribution \({{\varepsilon }_{{0V}}}({\mathbf{r}})\) for a single unrelaxed plane special boundary with the tilt {n10}, \(\left| n \right| \geqslant 2\) (Fig. 1а) [13]. The boundary connects crystallites K1 and K2 along the planes A1 and A2. In Fig. 1b, the shaded square abcd shows the volume occupied by an atom in an ideal lattice. Therefore, the broken line \({{y}_{1}}(x)\) is the upper boundary of crystallite K1 and the line \({{y}_{2}}(x)\) is the lower boundary of crystallite K2 (Fig. 1c). Hence, the distribution of excess volume per 1 m2 of the boundary is determined by the difference

From definition (16), we find

Here, H is the width of the zone of irreversible volume changes. The form of functions \({{y}_{1}}(x)\) and \({{y}_{2}}(x)\) on the length of the period l for boundaries with an inclination angle θ and a relative displacement of crystallites by an arbitrary vector \({\mathbf{d}} = \{ {{x}_{0}},{{y}_{0}}\} \) (y0 is the distance between planes A1 and A2, Fig. 1a) is determined by the formulas (see Figs. 1b and 1c):

Here, \({{\varepsilon }_{0}} = h\) is the mean excess volume per 1 m2 of the unrelaxed boundary (see Fig. 1c) [13].

Rights and permissions

About this article

Cite this article

Vasil’ev, L.S., Lomaev, I.L. & Lomaev, S.L. Deformation Interactions in Polycrystalline Alloys. Phys. Metals Metallogr. 121, 1097–1104 (2020). https://doi.org/10.1134/S0031918X20110095

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20110095