Abstract

The paper discusses the influence of retained austenite formed in a structure after the phase transition in the bainitic temperature range on the properties of structural low-alloy steels. It is shown that the bainite transformation proceeds through two stages. The first stage is characterized by the formation of completely carbide-free bainite containing up to 45% retained austenite, which is stable under deep cooling. The second stage develops with increasing holding time and is accompanied by the release of carbides and a reduction in the amount of retained austenite. The mechanical properties of steels are given in terms of the morphology and chemical composition of the phases forming in the course of isothermal transformation in the bainitic temperature range.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The bainitic transformation in structural steels remains the least studied phase transition [1] and, therefore, is the subject of many scientific works. The bainitic structure has a complex nature and, depending on the carbon content, alloying elements, and cooling conditions, can substantially change its morphology. In recent years, extensive material has been accumulated on the intermediate transformation of overcooled austenite [2–5] and the properties of bainitic structural steels [6–11]. The specific features of the bainitic transformation are due to its temperature range, in which there is no diffusion of iron and alloying atoms but intensive diffusion of carbon takes place. This, first, causes a large variety of morphological forms of the phases and, second, various chemical compositions of these phases are obtained that differ in carbon content. The degree of carbon redistribution determines the structural features and properties of steel after transformation in the bainitic range.

The structure and properties of hardened steels are largely controlled by the cooling conditions, which have a strong effect on the amount of retained austenite present in hardened steel, since, depending on the cooling rate, in steels, either the martensitic (upon rapid cooling) or bainitic transformation (upon slow cooling or isothermal holding) takes place. In both cases, the transformation, as a rule, does not proceed to the end; therefore, some austenite remains in the structure of steels. However, the properties and behavior of retained austenite can vary significantly because, upon treatment of steels to create the bainitic structure, retained austenite can be substantially enriched in carbon. It will have a lower martensitic point than that of retained austenite obtained after quenching of steels to create martensite.

Retained austenite in steels with the bainitic structure can significantly differ in carbon content from the average composition of steel. The bainitic transformation proceeds with time; therefore, at temperatures for the bainitic transformation (300–450°C), in steels there forms a two-phase austenite–bainite structure in which the α- and γ-phases coexist. In this case, untransformed austenite can be enriched in carbon. This process is especially noticeable in steels alloyed with elements preventing carbide formation, e.g., silicon.

The alloying of steel significantly affects the bainitic transformation and stability of retained austenite. Most alloying elements have a greater affinity to carbon and form carbides more easily than iron. The basic alloying elements can be arranged in decreasing order of affinity to carbon and their resistance to decomposition with the carbide formation as follows: Zr, Ti, Ta, Nb, V, W, Mo, Cr, Mn, and Fe. All these elements, except for manganese, form special carbides in steels. Chrome, with its low content in steels, usually enters the composition of cementite, as well as manganese. Special carbides also form at high temperatures and do not participate in the bainitic transformation. Among the basic alloying elements, nickel and silicon are not carbide-forming, but their influence on the stability of austenite is very strong.

The effect of carbon redistribution in the course of the bainitic transformation can be made noticeable by introducing an increased amount of silicon into carbon steel. Aluminum plays the same role. It has been noted that, in alloyed steels with an increased silicon or aluminum content, the amount of retained austenite can be increased by cooling under conditions that allow partial bainitic transformation. When the silicon content is increased, retained austenite is found in low-carbon industrial steels after cooling in air as a result of its significant local enrichment in carbon. This redistribution of carbon becomes possible if, upon the release of excess ferrite or the α-phase in the course of the bainitic transformation, carbon remains free, not bound in carbides. This is promoted, apparently, by silicon and aluminum; they inhibit carbide formation upon tempering of hardened steel.

In some cases, after transformation in the bainitic range in steels, a structure called carbide-free bainite is formed. As a rule, such a structure is formed in steels alloyed with silicon and aluminum [12–18], but it was also observed in low-carbon alloy steels that do not contain these elements after continuous cooling [19, 20].

PROPERTIES OF RETAINED AUSTENITE IN CARBIDE-FREE BAINITE

Let us consider the regularities in the development of the bainitic transformation and the role of retained austenite in the formation of structure and properties of structural steels using as an example low-alloy steels 38KhS and 70S2, which are widely used in various branches of engineering. Table 1 shows the results of measuring the amount of retained austenite (RA), hardness, and impact strength after various regimes of isothermal quenching of the 38KhS steel with subsequent treatment in liquid nitrogen (for 1 h). The holding time was chosen to allow the bainitic transformation to proceed and to obtain a significant amount of retained austenite after cooling. It can be seen that its maximum amount (28–29%) is observed after quenching in the upper bainitic range of 425–400°C. However, after cold treatment, this retained austenite mostly decomposes. The thermal stability of retained austenite is conveniently characterized by the ratio of its amount remaining in the steel after cooling to liquid nitrogen temperature (\({\text{A}}_{{{\text{ret}}}}^{{ - 196^\circ {\text{C}}}}\)), to the amount of retained austenite obtained in the steel after isothermal holding and cooling to room temperature (\({\text{A}}_{{{\text{ret}}}}^{{20^\circ {\text{C}}}}\)), i.e., by the quantity (\({\text{A}}_{{{\text{ret}}}}^{{ - 196^\circ {\text{C}}}}\)/\({\text{A}}_{{{\text{ret}}}}^{{20^\circ {\text{C}}}}\)) × 100, %, (Table 1). The relative stability of the retained austenite obtained in the upper temperature range 425–400°C varies from 29 to 64%; i.e., this austenite is thermally unstable. Upon treatment in the lower part of the bainitic range 350–375°C, the amount of \({\text{A}}_{{{\text{ret}}}}^{{20^\circ {\text{C}}}}\) is slightly smaller (16–23%), but its thermal stability is high, up to 100%. This means that the martensitic point of such retained austenite is below liquid nitrogen temperature and indicates significant oversaturation of retained austenite with carbon.

Electron microscopic analysis of the 38KhS steel structure showed that, in all isothermal treatment regimes studied above, no release of carbide in either bainitic ferrite or retained austenite is observed in the structure (Fig. 1). Thus, in the 38KhS steel, the product of transformation of austenite in the temperature range 425–350°C is carbide-free bainite, which is a purely ferrite–austenite structure. The formation of such carbide-free bainite in a fairly wide temperature range is due to the presence in the steel of a significant amount of silicon, which suppresses the release of the carbide phase. It should be noted that the relative stability of retained austenite at the liquid nitrogen temperature correlates well with the change in the impact strength of steel with the structure of carbide-free bainite (see Table 1). The higher the stability, especially after treatment in the lower bainitic transformation range 350–375°C, the higher the impact strength in combination with a rather high hardness.

The amount of carbon in retained austenite was determined by X-ray diffraction. It turned out that retained austenite in all the considered regimes was substantially enriched in carbon; e.g., after the treatment at 425°C for 10 min (28% RA), the carbon content was 1.21 wt % (with a carbon content in steel of 0.36 wt %) and, in the lower bainitic range after the treatment at 375°C for 20 min (23% RA), the carbon content in austenite was 1.42 wt %, which means oversaturation with carbon in comparison with the initial one increased by more than 1.0%. Thus, for a short time, during the austenite–bainite phase transition, the steel becomes strongly differentiated in composition: along with ferrite crystals containing a small amount of carbon, austenite regions highly enriched in carbon appeared. The further state of these regions of untransformed austenite depends on the peculiarities of the subsequent heat treatment. Cooling to room temperature after the isothermal holdings presented in Table 1 fixes the structure of carbide-free bainite with stable retained austenite up to liquid nitrogen temperature (in the case of transformation in the lower bainitic range).

Therefore, the bainitic transformation upon isothermal holding of silicon steel is carried out as follows: during the incubation period, carbon atoms in austenite undergo chaotic thermal motion, which leads to depletion of some regions. When the size of such regions reaches the critical value, ferrite-crystal nuclei begin to form in them, the carbon content in which roughly corresponds to the P–Q line of the iron–carbon state diagram. From the newly formed ferrite crystals, carbon diffuses to austenite, the crystals grow, and untransformed austenite is increasingly enriched in carbon. Due to the presence of silicon in the first stage of the bainitic transformation, cementite does not form and ferrite is released from the solid solution (austenite), forming completely biphasic carbide-free bainite. If the isothermal holding time increases, untransformed austenite, which is oversaturated with carbon, decomposes with the formation of a considerable amount of cementite-type carbides.

Table 2 presents the results illustrating how the holding time in the lower bainitic range affects the mechanical properties and variation in the amount of retained austenite in steel. It can be seen that, with increasing isothermal holding time, its amount continuously decreases and the retained austenite almost completely disappears at holding times of more than 5 h. In this case, the impact strength decreases on the background of the decrease in the amount of retained austenite and, at long holding times, becomes three to four times lower that when the structure of carbide-free bainite is obtained. It should be noted that, with increasing isothermal holding time, the carbon content in retained austenite remains virtually unchanged. The fraction of carbon in retained austenite with respect to its content in steel also continuously decreases (from 91% after holding at 375°C for 20 min to 32% after holding for 3 h), which is undoubtedly related to the release of carbides from the retained austenite oversaturated with carbon.

Thus, in the 38KhS steel, we observe two clearly pronounced stages of bainitic transformation, the first of which (disintegration) is the formation of bainitic ferrite depleted in carbon and the preservation of a significant amount of retained austenite in the steel structure. At this stage, no carbide is released either in ferrite or austenite. The second stage develops with increased isothermal holding time and includes an appreciable release of carbides and a gradual decrease in the amount of retained austenite after cooling.

Study of the mechanical properties shows (see Tables 1, 2) that, at the first stage of the transformation, when the structure comprises a carbide-free complex of packet-rack bainitic ferrite and thin interrack layers of retained austenite, the combination of high strength and impact strength is ensured. The decomposition of austenite with the release of the carbide phase preserves the strength but dramatically reduces the impact strength of isothermally hardened steel; thus, the development of the second stage of the transformation significantly deteriorates the mechanical properties under impact loading. It should be noted that a very long holding (more than 10 h) leads to the complete disappearance of retained austenite in the steel structure and the bainitic transformation in this case can proceed to the end. It should also be emphasized that, according to Table 2, the fraction of carbon contained in retained austenite can characterize the morphological features of the structural components in the phase transformations in the intermediate temperature range (carbide-free bainite or bainite with carbides) and the impact strength of steel.

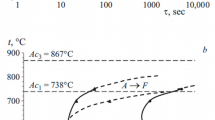

The two-stage character of the bainitic transformation is also observed in the 70S2 steel (0.72 wt % C and 1.54 wt % Si) after various isothermal holding regimes in the temperature range 300–400°C. At the first stage of the bainitic transformation, the amount of retained austenite increases, reaching 29% (T = 300°C, 10 min), 34% (T = 350°C, 10 min), and even 45% (T = 400°C, 5 min); then, with the development of the second stage, it smoothly decreases.

The thermal stability of retained austenite gradually increases as the transformation develops, and it reaches the complete (100%) resistance to decomposition in liquid nitrogen at the beginning of the second stage, when the amount of retained austenite begins to decrease with increasing isothermal holding time. It is interesting to note that, in a low-alloy steel, after sufficiently simple treatment in the bainitic transformation range, it is possible to obtain a significant amount (more than 40%) of retained austenite thermally stable not only at room temperature but also after long (for 1 h) holding in liquid nitrogen.

This stability of the retained austenite is undoubtedly associated with its enrichment in carbon in the course of the phase transformation. Table 3 summarizes the influence of the temperature–time parameters of isothermal holding on the amount of RA and its relative stability upon cooling.

With the development of the bainitic transformation, at the first stage, carbon diffuses intensively from the α/γ interphase boundary, which leads to sharp differentiation of the steel in chemical composition: along with ferrite, virtually carbon-free, in steel with 0.72 wt % C, areas of austenite containing more than 1.5 wt % C appear (see Table 3). The higher the enrichment of the retained austenite in carbon, the higher its relative stability upon cooling in liquid nitrogen. After the treatment at T = 400°C for 10 min, the stability of a considerable amount of retained austenite (42%) is observed, which is related to its very high enrichment in carbon up to 1.71 wt %. The fraction of carbon contained in the retained austenite relative to the average carbon content in the steel (last column in Table 3) correlates well with the thermal stability of RA and reaches 99% in the case of the complete stability in the deep cold treatment.

Thus, after the isothermal treatment at 400°C for 10 minutes, practically all carbon is in the retained austenite, and the structure comprises a biphasic ferrite–austenite complex without a carbide release. Electron microscopic studies confirmed this assumption and showed that the structure consists of completely carbide-free ferrite crystals and layers of retained austenite, i.e., a carbide-free bainitic structure is observed (Fig. 1).

Formation of carbide-free bainite in low-alloy steels with silicon is possible only upon isothermal holding in special thermal equipment: salt and alkaline bath furnaces, and in rather small articles with a cross section of no more than 25–30 mm. However, in [19–21], it was shown that, in steels not containing elements such as silicon or aluminum, which effectively suppress the carbide release from untransformed austenite at the temperatures for the bainitic transformation, completely carbide-free bainite can form even under slow continuous cooling. For this, it is necessary to reduce the carbon content to 0.10–0.15 wt % and ensure via alloying effective suppression of the transformation of overcooled austenite at the first stage. For example, Table 4 presents the results of analyzing the bainitic structure of chromium–nickel–molybdenum steels after slow continuous cooling with a furnace (V = 5°C/min). Electron microscope studies have shown that a distinctive feature of the bainitic structure is the complete absence of carbides (Fig. 2). In this case, the retained austenite contains 0.8–1.0 wt % C. Steels after such treatment have a good combination of strength and impact strength. Therefore, for massive articles in whose cores bainite formation is inevitable under continuous cooling, it is necessary to use steels with a limited carbon content, which ensures bainitic hardenability with the formation of carbide-free bainite.

CONCLUSIONS

In structural silicon steels, the bainite transformation in a wide temperature range proceeds through two stages. At the first stage, a carbide-free bainitic structure is formed consisting of a mixture of bainitic ferrite with 15–40% retained austenite. As the isothermal holding time increases, the second stage of bainitic transformation develops: the decomposition of untransformed austenite with the release of carbide.

The structure of the carbide-free bainite formed at the first stage ensures high impact strength of the steel. The development of the second stage of bainitic transformation and the appearance of carbides in the structure lead to a significant reduction in the impact strength.

The retained austenite in carbide-free bainite is enriched in carbon and contains a significant fraction of the total carbon content in steel. The carbon fraction in the retained austenite can characterize the morphological features of the structural components in the bainitic transformation (carbide-free bainite or bainite with carbides) and the impact strength of steel.

The thermal stability of retained austenite depends on the heat treatment regimes and is related to its enrichment in carbon. In the case of the formation of carbide-free bainite, high thermal stability of the retained austenite is observed (the absence of its transformation up to liquid nitrogen temperature).

In the development of the compositions of steels for massive articles in the central sections of which the formation of a bainitic structure upon heat treatment is inevitable, alloying should be directed at the production of carbide-free bainite. A reduction in the carbon content in chromium–nickel–molybdenum steels to 0.10–0.15 wt % makes it possible to exclude carbide formation in the course of the intermediate transformation upon continuous cooling, resulting in the formation of carbide-free bainite.

REFERENCES

C. Hofer, H. Leitner, F. Winkenhofer, H. Clemens, and S. Primig, “Structural characterization of “carbide-free” bainite in a Fe–0.2C–1.5Si–2.5Mn steel,” Mater. Charact. 102, 85–91 (2015).

H. K. D. H. Bhadeshia, Bainite in Steels: Theory and Practice, Third Edition (CRC Press, London, 2015).

F. G. Caballero and H. K. D. H. Bhadeshia, “Very strong bainite,” Curr. Opin. Solid State Mater. Sci. 8, 251–257 (2004).

C. Garcia-Mateo, F. G. Caballero, and H. K. D. H. Bha-deshia, “Mechanical properties of low-temperature bainite,” Mater. Sci. Forum 500–501, 495–502 (2005).

Yu. M. Kaletin, A. G. Ryzhkov, and A. Yu. Kaletin, “Effect of silicon and aluminum on the properties of structural chromium–nickel steels with a bainitic structure,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 6, 96–99 (1989).

A. Yu. Kaletin, V. M. Schastlivtsev, N. T. Kareva, and M. A. Smirnov, “Embrittlement of structural steel with a bainitic structure during tempering,” Fiz. Met. Metalloved. 56, 366–371 (1983).

M. N. Georgiev, A. Yu. Kaletin, Yu. N. Simonov, and V. M. Schastlivtsev, “Influence of stability of retained austenite on the crack resistance of engineering steel,” Phys. Met. Metallogr. 69, 110–118 (1990).

N. A. Tereshchenko, T. I. Tabatchikova, I. L. Yakovleva, A. N. Makovetskii, and S. V. Shander, “ Influence of structure on the static cracking resistance and fracture of welded joints of pipe steels of strength class K60,” Phys. Met. Metallogr. 118, 707–715 (2017).

T. I. Tabatchikova, I. L. Yakovleva, S. Yu. Del’gado Reina, A. I. Plokhikh, O. G. Ospennikova, and V. I. Gromov, “Influence of warm deformation on the formation of a fragmented structure in low-carbon martensitic steels,” Phys. Met. Metallogr. 117, 61–73 (2016).

T. I. Tabatchikova, I. L. Yakovleva, S. Yu. Del’gado Reina, and A. I. Plokhikh, “Effect of cyclic treatment on the formation of a fragmented structure in a sparingly alloyed martensitic steel,” Phys. Met. Metallogr. 117, 1123–1128 (2016).

O. V. Sych, A. A. Kruglova, V. M. Schastlivtsev, T. I. Tabatchikova, and I. L. Yakovleva, “ Effect of vanadium on the precipitation strengthening upon tempering of a high-strength pipe steel with different initial structure,” Phys. Met. Metallogr. 117, 1270–1280 (2016).

Z. Bojarski and T. Bold, “Structure and properties of carbide-free-bainite,” Acta Metall. 22, 1223–1234 (1974).

J. C. Hell, M. Dehmas, S. Allain, and J. M. Prado, “Microstructure–properties relationships in carbide-free bainitic steels,” ISIJ Int. 51, 1724–1732 (2011).

D. A. Mirzaev, A. A. Mirzoev, I. V. Buldashev, and K. Yu. Okishev, “Thermodynamic analysis of the formation of tetragonal bainite in steels,” Phys. Met. Metallogr. 118, 517–523 (2017).

V. M. Schastlivtsev, Yu. V. Kaletina, E. A. Fokina, and A. Yu. Kaletin, “On the role of retained austenite in the structure of alloyed steels and the effect of external factors,” Phys. Met. Metallogr. 115, 904–917 (2014).

V. M. Schastlivtsev, Yu. V. Kaletina, E. A. Fokina, and A. Yu. Kaletin, “Effect of cooling rate on the amount of retained austenite upon bainitic transformations,” Phys. Met. Metallogr. 115, 990–1000 (2014).

A. Yu. Kaletin and Yu. V. Kaletina, “Evolution of the structure and properties of silicon steels in the austenite–bainite phase transition,” Phys. Solid State 57, 59–64 (2015).

D. O. Panov, Yu. N. Simonov, P. A. Leont’ev, and A. Yu. Kaletin, “Formation of structure and properties of carbide-free bainite in steel 30KhGSA,” Metalloved. Term. Obrab. Met., No. 2, 13–24 (2016).

A. Yu. Kaletin, A. G. Ryzhkov, and Yu. V. Kaletina, “Enhancement of impact toughness of structural steels upon formation of carbide-free bainite,” Phys. Met. Metallogr. 116, 109–114 (2015).

Yu. N. Simonov, M. Yu. Simonov, D. O. Panov, V. P. Vylezhnev, and A. Yu. Kaletin, “Obtaining the structure of noncarbide bainite as a result of isothermal treatment of steels of the Kh3G3MFS and KhN3MFS types,” Metalloved. Term. Obrab. Met., No. 2, 4–13 (2016).

A. Yu. Kaletin and Yu. V. Kaletina, “Increase in the viscosity of structural steels in the formation of non-carbide bainite,” Vestn. PNIPU 16, 22–30 (2014).

ACKNOWLEDGMENTS

This work was carried out within the state task “Pressure” (state registration no. AAAA-A18-118020190104-3) and was supported in part by the Russian Foundation for Basic Research (project no. 16-03-00043).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Chernokozhin

Rights and permissions

About this article

Cite this article

Kaletin, A.Y., Kaletina, Y.V. The Role of Retained Austenite in the Structure of Carbide-Free Bainite of Construction Steels. Phys. Metals Metallogr. 119, 893–898 (2018). https://doi.org/10.1134/S0031918X18090053

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X18090053