Abstract

Methods for carrying out coupling reactions in the chemistry of alkynes to form C–C bonds (oxidative dehydrocondensation reactions, Cadiot–Chodkiewicz reaction, and Sonogashira reaction) are analyzed and generalized. Protocols of synthesis of products of these reactions are also presented, including homogeneous and heterogeneous catalytic systems. In all cases, emphasis is placed on the kinetics and mechanisms of reactions with the discussion of the results of kinetic and spectrometric studies of the mechanisms of coupling reactions involving Cu(I, II, III), Au(I, III), Pd(0, I, II), and Fe (0, I, II, III) complexes. Particular attention is paid to the heterogeneous catalysis of oxidation reactions of alkynes with the participation of nanoparticles and nanoclusters of Pd, Au, Ag, and other metals. The nature of the intermediates containing these metals and the relationships between various oxidative and nonoxidative transformations of alkynes are discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

In the previous review [1], advances in the theory and practice of alkyne dimerization reactions were considered. Over a century and a half of research on the processes of alkyne oxidation, a huge amount of information has appeared that allowed one to make interesting generalizations regarding the mechanisms of such reactions in various catalytic systems.

Problems associated with the attitude of specialists in synthetic organic chemistry to redox reactions (RRs), or to the so-called oxidative reactions, and to the application of the concept of oxidation state (OS) of atom were discussed in our review [2]. A common opinion among organic chemists is to deny the usefulness of the definition and use of OS in organic and organoelement chemistry (see, e.g., chapter 19 of March’s Advanced Organic Chemistry: Reactions, Mechanisms, and Structure, which discusses this problem; see also our review [2]). This point of view was refuted in our review [2], however, the specifics of this review require some additional explanations to facilitate the perception of the main body of the text. When studying ORR or when choosing the conditions for carrying out inorganic, organic, and organoelement syntheses, it is necessary to know the stoichiometry of reactions. This is important in evaluating the selectivity of reactions, checking the material balance, and determining the required amount of an oxidizing agent or a reducing agent. Although several methods are known for determining the stoichiometry of reactions, the use of OS of atom and the electron balance based on it is the most general approach for all types of chemical reactions; it is the approach that is demonstrated in this review.

When determining the OS of the A atom in A–X compound, it is necessary to know the sign and magnitude of the OS of the X atom (or a group of atoms). For this purpose, the fundamental concept of electronegativity (EN) of an element is used, specifically, the Pauling, Allred–Rochow, or Batsanov EN scale (averaged values [2]). For example, in the case of C–H, the electronegativities of the C and H atoms are very different (the EN of the H atom is 2.2, and the EN of the C atom is 2.6); therefore, it is assumed that, in the heterolysis of the polar A–X bond, the electron pair of this bond is completely transferred to the atom with higher EN, i.e., to the C atom in the C–H bond. Therefore, the OS of the H atom is +I, or simply I, and the OS of the C atom is –I. The same situation occurs in the case of X = N, Hal, and Te. Since OS is a formal tool, in case of equality or proximity of ENs (C–I, P–H, C–S), it is necessary to use the existing agreement that, in these cases, the heterolysis leads to C+ and I–, P–, and S–. These assumptions used on the left and right sides of the stoichiometric equations give correct information about the electronic balances and RR stoichiometry. For example, in the CH3X molecule, where X = Hal, OH, NR2, SR, or PR2, the OS of the X atom or group of atoms is –I, and that of the carbon atom is +II. Specifically, if it is assumed that, in the compound K3W(CH3)6, the OS of the CH3 group is –I, then the OS of tungsten is III, and the reduction of K3W(CH3)6 to W(0) requires three electrons (3 mol of one-electron reducing agents or 1 mol of three-electron ones).

In the electrophilic substitution of a hydrogen ion in benzene with metal cations in the oxidation states II, III, and IV, the OSs of the carbon atom and the Ph group, equal to –I, do not change, but after the interaction with the electrophile I+ (oxidizing agent I2), their OSs increase from –I to I, and the OS of iodine decreases from I to –I. For example, in ArI, the OS of iodine is –I. If we want to replace a hydrogen atom with a Cl– ion, then we need an oxidizing agent that can oxidize the C(–I) atom to C(I) in phenyl and make it an electrophile that adds the chloride ion. It is also possible to oxidize the chloride ion to a Cl2 molecule, which, as an electrophile, leads to the replacements of a proton, and therefore, e.g., in ArI, the OS of iodine is –I. Thus, the definition of OS of atom is applicable to any covalent compounds.

Let us show the usefulness of OS values for writing stoichiometric equations by two more examples. In the oxidation of an ammonium ion by sodium hypochlorite, six electrons should be withdrawn from the N(–III) atom to form a nitrite anion, in which the OS of the N atom is III:

Let us oxidize CH4 to CO2 by the oxidizing agent \({\text{Fe(CN)}}_{6}^{{3 - }}\). Because the OSs of the H, C (CO2), and O atoms are I, IV, and –II, respectively, it is obvious that eight electrons should be withdrawn from the C atom to oxidize methane; i.e., it is necessary to use, e.g., eight anions of the one-electron oxidizing agent \({\text{Fe(CN)}}_{6}^{{3 - }}\) or 4 mol of a two-electron oxidizing agent. As a result, according to the electronic, charge, and material balances, the following equation is obtained:

Obviously, at least two reagents (substrates) should participate in an RR: an oxidizing agent and a reducing agent. If the reducing agent is a substrate to be oxidized (ethylene) and the oxidizing agent is reduced, such an ORR is typically called an oxidation process. If the oxidizing agent is a substrate to be reduced (ethylene), which accepts electrons in the course of the RR, and the reducing agent is oxidized, this reaction is called a reduction process.

In the case of organic compounds being oxidized by an oxygen molecule, there are no doubts about the definition of reducing agent and oxidizing agent; however, it is not always easy to understand whether or not the reaction belongs to RRs. It is the calculation of the total OSs of carbon atoms (or other elements) in the reactants and products that makes it possible to identify which substrate is oxidized and which is reduced, and whether or not the process belongs to ORRs.

Let us briefly consider this issue. If an oxidizing agent and a reducing agent are within the same molecule that isomerizes with the redistribution of OSs between atoms, such reactions should hardly be considered ORRs. Among examples are the Meyer–Schuster rearrangement of alkynols:

the Rupe rearrangement; and the Favorskii isomerization of alkynes; however, the Meyer–Schuster reaction is for some reason called redox isomerization [3]. The reactions of addition of HX molecules to alkynes and olefins, in which the OSs of carbon atoms in the reactant and product are redistributed, are not considered RRs, and they are also not oxidation reactions because the total OS of carbon atoms does not change when passing from alkyne to the product in these processes:

In contrast to the reactions of addition of HX molecules to unsaturated molecules, the reaction of alkyne with methyl iodide,

has all the features of an RR: the total OSs of carbon atoms in alkyne increases from –II to –I and the OS of a carbon atom in the methyl group decreases from –II to –III; i.e., alkyne is oxidized, and methyl iodide as an external oxidizing agent and a substrate included in the product is reduced.

This reaction is no different from the reaction of iodination of acetylene:

In view of the above, all RRs can be divided into two large groups, A and B. Group A comprises ORRs in which an oxidizing agent is external to the substrates, i.e., is not a product of substrate oxidation:

The oxidizing agents in reaction (IV) are O2, benzoquinone (BQ), MXn, I2, R3NO, TEMPO, ClCH2COCH3, and other compounds [3–5]. For example, in reaction

the oxidizing agent accepts 2е and 2Н+, turning into HCl and acetone, and the total OS of carbon atoms in two alkynes increases from –II to zero.

Group B comprises reactions with an oxidizing agent that, according to stoichiometry, is completely or partially contained in the RR products:

In reaction (VI), the total OS of carbon atoms in acetylene molecules increases from –IV to IV, and in reaction (IX), this parameter in two substrates (RC2H and CO) increases from I to III. In reactions (VII)–(IX), the oxygen molecule is both an oxidizing agent and a substrate, which enters the oxidation product of the hydrocarbon molecule. In this case, the total OS of atoms in the substrates, of course, does not change when passing to the product due to the conservation of the electronic balance, but the total OS of carbon atoms in ethylene, CO, and RC2H + CO decreases.

To ORRs involving alkynes, we also assign processes in which the total OS of carbon atoms in the oxidized alkyne changes when passing to the product as a result of the breaking of one or two π-bonds or triple bonds, and the ≡С–Н bond with the formation of ≡С–X, ≡С‒С≡, and С–О bonds.

The Cadiot–Chodkiewicz coupling

and the Sonogashira coupling (acetylene condensation)

are usually not considered as oxidative processes [3–7], and only in chapter 8 of Lu and Zhou’s monograph [8], which considers the oxidation of the ≡C–H bond, they are discussed as alkyne oxidation reactions.

Indeed, the OS of the terminal carbon atom in the alkyne in reaction (XI) increases from –I to 0, whereas the haloalkyne acts as an oxidizing agent (and a substrate), and the OS of the carbon atom in the ≡C(I)X fragment decreases from I to 0. In reaction (XII), \({\text{R}'}{\kern 1pt} {\text{X}}\) is also both an oxidizing agent and a substrate, partly included in the reaction product of alkyne oxidation. Formally, the carbenium ions \({\text{R}'}{\kern 1pt} {\text{C}}{\equiv} {{{\text{C}}}^{{\text{ + }}}}\) and \({\text{R}'}{{{\kern 1pt} }^{ + }}\) accept one electron each from the carbon atom ≡C(‒I)H of the alkyne. Note that the famous Heck reaction

which is no different from the reaction

as well as reaction (XII), can be attributed to RRs. Reactions (X) and (XII) are similar in OS: R+ is used instead of I+. Note that the Heck reduction reaction is also known [9]. The OS of silicon (equal to IV) remains constant during the reaction, but the OS of the H atom changes from –I to I:

Features of the mechanisms of various reactions of alkyne oxidation, depending on the nature of the oxidizing agent and the catalyst and the type of reactions, are advisable to consider within the framework of individual types of processes. As a result, it is possible to identify the “genetic” relationship between the mechanisms of reactions of different types through the general structures of intermediates.

The review presents the reactions of dehydrocondensation (oxidative coupling, oxidative dimerization) (IV), Cadiot–Chodkiewicz C‒C coupling (XI), and Sonogashira C‒C coupling (XII). The role of Cu(I, II, III), Pd(0, I, II), Au(I, III), and Fe(0, I, II, III) complexes in the oxidative transformations of alkynes is analyzed in detail.

The reactions of oxidative halogenation, amination, and oxidative carbonylation of alkynes, triple bond oxidation to form oxygen-containing products, including some processes of oxidative cyclization, will probably be considered in the next review.

CHAPTER 1. OXIDATIVE DEHYDROCONDENSATION (OD) OF ALKYNES

This reaction, which is very useful for organic synthesis and has very complex and interesting mechanisms, is the subject of many reviews [3–8, 10–16]. The OD reaction is used for several purposes: the synthesis of symmetrical and unsymmetrical diynes, as well as cyclic diynes in the case of intramolecular OD of ethynyl substituents:

and the synthesis of macrocycles:

where Ox is an oxidizing agent and Red is a reducing agent.

In addition, linear oligomers H(C≡C–Z–C≡C)nH and, in the case of acetylene, polyynes H(C≡C)nH are also formed [10].

1.1. OD Involving Cu(I, II) Complexes

Let us consider very briefly the main stages in the history of this reaction, which began in 1869 with the research of Carl Glaser, a well-known German academic and industrial chemist. Working since 1864 in the laboratories of Adolph Strecker and August Kekulé at the University of Tübingen in the field of the chemistry of benzene and its derivatives, he, together with Kekulé, moved to Bonn (Friedrich Wilhelm Rhine University) in 1867 and continued research on synthesis of cinnamic acid (trans-PhCH=CHCOOH), during which he discovered the reaction for the synthesis of diacetylenic compounds by oxidation of ethynyl derivatives of Cu(I):

The oxidizing agents were O2, K3Fe(CN)6, etc. Already in 1882, Adolf von Baeyer (see the review [14]) showed the synthetic utility of this reaction, which later received the name of Glaser, in a three-step synthesis of the indigo dye from m-nitrophenylpropiolic acid.

In 1936, Zal’kind and Fundyler studied the Newland catalyst for the synthesis of vinylacetylene from acetylene (CuCl–NH4Cl–HCl (0.2%)–H2O) in order to carry out the dimerization of terminal alkynes. At the boiling point of the solution, phenylacetylene was introduced into the reactor in portions in a flow of CO2! Diphenyldiacetylene(!) C16H10 was isolated from the solid precipitate, the selectivity of the formation of which was about 50% [17]. The expected phenylacetylene dimer (C16H12) was also found in the solution, and so was a small amount of C16 hydrocarbons with a higher hydrogen content. Further, it was shown that tertiary alkynols also form diacetylenic alcohols under the same conditions [18]. Possibly, copper chloride was not purified to remove the CuCl2 impurity, the solution was not degassed, and the CO2 flow contained oxygen. Having made the wrong conclusion about the release of two atoms or a molecule of hydrogen during the reaction, Zal’kind and Fundyler decided to use oxygen as an oxidizing agent [5] and, when studying the reactions of substituted phenylacetylenes at 55–65°C, air was passed through the reaction mixture [19]. In this case, e.g., di(p-tolyl)diacetylene was obtained with a yield of 90% of the taken alkyne. Thus, these researchers discovered a new catalytic reaction of oxidative dimerization of alkynes without using ethynyl derivatives of Cu(I) as reagents.

A similar situation has already been encountered in the chemistry of alkynes. Studying the Glaser reaction with various oxidizing agents, Straus in 1905 determined that PhC≡CCu in boiling acetic acid in the absence of oxygen transforms into precipitate PhC≡CCu(CuOAc) and hydrocarbon C16H12 (1,4-diphenylbutenyne) by the stoichiometric equation [20]

Thus, phenylacetylene formed by the hydrolysis of copper phenylacetylide dimerizes in the reaction catalyzed by copper(I) acetate. This is how the catalytic dimerization of alkynes was discovered even before the research of Newland (1932). Later, in a 1959 article [21], Straus’ observation was confirmed, and alkyne dimerization products were obtained from RC≡CCu in hot acetic acid even when aerating the solution for the oxidation of metallic copper formed by the dismutation of CuOAc (with the formation of only 1% diacetylene derivative). This system was revisited in 1997 [22]: Z- and E-1,4-dialkylbutenynes were synthesized and the formation of RC≡CCu and Cu(OAc)2 (dismutation product) was also determined. Advances in catalytic chemistry concerning dimerization, cross-dimerization, and oligomerization of alkynes were discussed in the monograph [7] and the review [1].

Zal’kind et al.’s works [17–19, 23, 24] were followed by numerous studies of the discovered catalytic reaction in the CuCl–NH4Cl–H2O system, which were described in detail in Shvartsberg and Fisher’s review in the collective monograph [5]. Just note 1947–1957 works [25–33], in which the conditions, compositions of the catalytic system, pH values, and solvents (water, methanol, ethanol, acetone, dioxane) were varied. Mkryan and Papazyan [28] studied the effect of preliminary oxidation of CuCl by oxygen. When studying the reaction of oxidative dimerization of propargyl alcohol, the technology of which was brought to the level of a pilot plant [32, 33], Reppe showed that, at [CuCl] = const, an increase in the [alkyne] : [CuCl] ratio in the range of 1 to 7 leads to a drop in the reaction rate, and at a ratio of 4, the oxygen consumption versus time curve is S-shaped. These observations led to an important conclusion that the binding of CuCl to alkyne (to form an acetylide compound) inhibits the reaction by decreasing the concentration of Cu(II), which oxidizes the intermediate copper acetylide (RC≡CCu) more rapidly than O2. As the acetylide is formed, there is an increase in the concentration of the hydrogen ion, which also inhibits the process. The important role of pH in the process of oxidative dimerization of alkynes was noted by Zal’kind and Aizikovich [18], who showed that, in the Cu2O‒NH4OH‒H2O system, the reaction occurs rapidly during the oxidation by oxygen even at 20°C.

Various copper(I, II) complexes in catalytic and stoichiometric OD reactions. Apparently, the first use of amines in copper chloride catalytic systems was described by Klebanskii et al. (CuCl–Py–H2O) [30] and Cameron and Bennett (CuCl–amine–amine·HCl–H2O) [31]. Cameron and Bennett [31] used NH3, tBuNH2, Py, Et3N, and ethylenediamine (EDA), specifically, EDA in tetrahydrofuran (THF). In the same year of 1957, Franke and Meister’s patent (CuCl in pyridine (Py) and cyclohexylamine) was published [34], and a little later, Hay’s studies were published [35, 36], in which the amine was used as a solvent or as a ligand in the form of small amounts of CuCl·amine complex in an organic solvent (alcohols, acetone). The most popular was the CuCl complex with tetramethylethylenediamine (TMEDA) in methanol. This technique became most widely used in organic synthesis and is known as the Hay method (or catalytic system) (more precisely, the Franke–Meister–Hay method).

In 1957–1959, another system for the oxidative dimerization of alkynes was developed, in which Cu(II) complexes were used as a stoichiometric oxidizing agent. Eglinton and Galbraith showed [37, 38] that, in Cu(OAc)2–Py or Cu(OAc)2–Py–CH3OH solutions, various alkynes are oxidized under homogeneous conditions (without formation of insoluble ethynyl copper compounds RC≡CCu) at a high rate and very selectively. The use of terminal dialkynes at low concentrations makes it possible to carry out intramolecular and intermolecular reactions of oxidative cyclization and oxidative polycondensation to form cyclic polyynes and macrocyclic enynes [3, 11–15]. This is how the Eglinton oxidative dimerization method or the Eglinton system appeared. It should be noted that, in the Zal’kind catalytic system, Sondheimer et al. [39–41] also obtained polyyne macrocycles, but the product yields and oxidation selectivity were very low. In 1961 [42], they applied the Eglinton method and synthesized cyclic enediynes, and in 1962 [43], from 1,5-hexadiyne (HC≡CCH2CH2C≡CH) in solutions of Cu(OAc)2 in Py, they confidently synthesized macrocycles containing n-mers of this alkyne with n = 3, 4, 5, and 6, the hydrogenation of which gives saturated cycles C18, C24, C30, and C36 (Scheme 1)!

Scheme 1 . Unsaturated macrocycles.

Thus, copper(I, II) complexes participate in the reaction of oxidative dimerization (oxidative coupling, oxidative dehydrocondensation) of alkynes in various systems.

I. The catalytic oxidative dimerization of alkynes, discovered by Zal’kind et al., is performed in two systems:

Ia. Zal’kind (CuCl–NH4Cl–HCl–H2O) with variations;

Ib. Franke–Meister–Hay (CuCl–amine–organic solvent).

II. The stoichiometric reaction of OD of alkynes occurs in the Eglinton system (Cu(OAc)2–Py–organic solvent). Studies showed that, in this system, the dimerization reaction is autocatalytic in Cu(I), and the addition of Cu(I) compounds can significantly accelerate the oxidation reaction, depending on the conditions.

Specific conditions and results of oxidative dimerization in systems Ia, Ib, and II (with various variations) were in the 1967 monograph [5]. More than 360 syntheses were described, and in Shvartsberg and Fisher’s review in this collection, the catalytic reaction of oxidative dimerization of alkynes was proposed to be called the Glaser–Zal’kind reaction (at least for systems Ia and Ib).

Over the past 50 years, many studies have been made aimed at modifying the Glaser–Zal’kind and Eglinton methods for the synthesis of dialkynes and at expanding the scope of the OD reaction for the preparation of linear and cyclic diynes, oligomers, polymers, and macrocycles. For example, the review [16] presented tables describing 68 procedures for the synthesis of various diynes and 17 procedures for the preparation of oligomers and polymers in Hay systems with fantastically complex structures of products. Varying the nature of bases, ligands, oxidizing agents, solvents, and conditions made it possible to choose fairly universal systems efficient at room temperature for alkynes of various nature. Let us give several examples of such processes in copper-containing systems. OD reactions are carried out both in ionic liquids [44], and in polyethylene glycols [45], and even in amine alone (CuI–amine) [46] with the choice of optimal bases and ligands for Cu(I) [47]. The use of PhI(OAc)2 as an oxidizing agent in the CuCl–Et3N–AN (AN is acetonitrile) system enables one to perform the OD process with high yields at room temperature for 10 min for aromatic and aliphatic alkynes [48]. Variants of the Eglinton system are also used very efficiently in synthetic practice for the synthesis of diynes with substituents having many reactive functional groups, e.g., to obtain (bis-β-lactam)-1.3-diynes by of OD of N‑ and C-alkynyl-2-azetidinones [49]. In that work, Cu(OAc)2 in AN in the presence of Et3N or solid K2CO3 at room temperature was used. Interestingly, in oxygen or argon atmospheres with both bases, the yields of products reached 98–100% in the same time intervals (from 4 to 20 h). A comparison of the catalytic properties of various copper(I, II) compounds in CH2Cl2 in the synthesis of bis-β-lactam)-1,3-diynes in the presence of various bases and air at 25°C for 3 h showed [50] that the highest yields (93–98%) were obtained using pyrrolidine and piperidine with yields of 93–98% in CuCl, Cu2O, Cu(OAc)2∙H2O, Cu2SO4, CuCl2∙2H2O, and Cu(OTf)2 solutions. Cu(OAc)2∙H2O was recommended as the most available (!) salt that catalyzes the OD of various alkynes with the participation of oxygen as an oxidizing agent. In this system, the cross-coupling of alkynes also occurs successfully with yields of 75–99%.

Collins and colleagues [51–53] proposed an interesting variant of oxidative macrocyclization of diethynyl compounds in the synthesis of cycles containing conjugated 1,3-diynes in a two-phase system of CuCl or CuCl2 with the addition of Ni(II) salts. It was shown [51] that the presence of two phases—polar and nonpolar ones—gives rise to macrocycles with high yields at relatively high substrate concentrations. For example, the formation of a macrocycle from HC≡C(CH2)7OCO(CH2)3C≡CH in an amount of 0.36 mmol in a two-phase system (CuCl2–Ni(NO3)2–Et3N–Py, 60°C) requires only 15 mL of the 2 : 1 PEG400–methanol solvent, whereas in a homophase system, this requires as much as 1800 mL. An even more efficient system was that containing PEG1900 modified with tetramethylethylenediamine (TMEDA): (Т–PEG1900), or (Me2NCH2CH2N(Me)–(CH2CH2O)40), which ensures better solubility of Cu(I, II) and Ni(II) complexes in the polar phase. The two-phase strategy allows one to perform the catalytic cyclization reaction (with O2) at the interface between two phases (or in the polar phase) at a relatively small dilution and virtually without the formation of linear polymers. When T–PEG1900 is used, dialkyne cyclization with a concentration of 0.03 M is carried out in 5 mL of solution (instead of 600 mL of a solution with a substrate concentration of 0.0002 M). In this case, the product yield increases from 11 to 65%. This macrocyclization technique is called the Collins strategy. It was shown [52] that its efficiency noticeably increases when microwave radiation is used. The reaction time reduces by a factor of 4–24 at 100°C and 1 atm O2 with maintaining high yields of macrocycles of 61–81%, depending on the nature of the dialkyne. This Collins technique was successfully applied to the synthesis of a macrocyclic precursor in the production of the hepatitis C virus protease inhibitor vaniprevir [53].

OD reaction mechanisms. Let us consider the development of concepts of mechanisms of the OD reaction in various systems containing Cu(I) and Cu(II) complexes. In the pioneering works of Zal’kind et al. [23, 24, 27], Mkryan and Papazyan [28], and Reppe [33], it was determined that the OD reaction occurs over a wide pH range in CuCl solutions with oxygen as an oxidizing agent and is accelerated by the addition of copper(II) salts. Studying the kinetics of oxidative dimerization of alkynes in aqueous solutions of CuSO4 in a buffer system at pH 6, Baxendale and Westcott (see [11]) showed that the reaction rate is described by equations of the first order in the concentrations of Cu(II) and alkyne and depends on 1/[H+]. In this case, the reaction rate is determined by the stationary concentration of Cu+. Thus, the process is autocatalytic.

Klebanskii et al. [30] studied the OD reaction in CuCl–NH4Cl–H2O solutions with oxygen as an oxidizing agent. The role of oxygen, in their opinion, is the oxidation of CuCl to CuCl2; it is CuCl2 oxidizes the alkyne, but only in the presence of bases (NaOH, NH3, Py, Et3N). In the CuCl2–NH3–H2O system, the reaction rate is described by the equation

where k is the observed rate constant.

Klebanskii et al. [30] gave no explanation of the role of CuCl in acidic solutions in the presence of oxygen (conditions of Zal’kind, Reppe, and other authors). The presented scheme of the mechanism [30] includes the formation of RC≡C– anions and their oxidation by a copper(II) complex to RC≡C• radicals, the rapid recombination of which gives dialkyne.

The works of Eglinton and Galbraith [11, 37, 38] and Sondheimer [42] on the OD of alkynes in Cu(OAc)2–Py solutions stimulated kinetic studies of this and related systems [13, 54, 55]. Clifford and Waters [54] studied the oxidation of propargyl alcohol by Cu(II) acetate in pyridine in the presence of piperidine buffer (PiPy–AcOH). The process was determined to be autocatalytic in CuOAc, in excess of which the order of the reaction in [Cu(OAc)2] becomes zero. The reaction rate is described by an equation of fractional orders in alkyne and in [CuOAc] and increases with increasing [PiPy]. The derivation of the kinetic equation [54] ignored the material balances for the concentrations of alkyne and compounds of copper(I); the role of Cu(I) was reduced to the formation of RC≡CCu from the anion RC≡C– and Cu(I) (!).

Bohlmann et al. [55] compared the activities of two systems in the OD reaction: in acidic solutions at pH 3 in the system CuCl–CuCl2–HOCH2CH2NH∙HCl–HCl–CH3OH (80%) similar to those studied by Zal’kind, and in the Eglinton system Cu(OAc)2–Py–CH3OH–H2O. It was determined that an increase in the acidity of the alkyne with an increase in the number of conjugated triple bonds in R(C≡C)n–C≡CH leads to an increase in the OD rate in a basic medium and to a decrease in the rate in acidic media (pH 3). In Bohlmann et al.’s opinion [55], an increase in the degree of conjugation in alkyne is accompanied by a decrease in its ability to form Cu(I) π-complexes and, consequently, a decrease in the concentration of copper acetylide compound R(C≡C)nC≡CCu, which is oxidized by Cu(II) complexes in an acidic medium . In systems with a fivefold excess of the concentration of Cu(II) complexes over [RC≡СH], the second order in alkyne was obtained in the reaction rate equation, which contradicts the previous schemes of the reaction mechanism with the formation of RC≡CCu oxidized by Cu(II) complexes or other oxidizing agents up to RC≡C•. Bohlmann et al. [55] proposed a mechanism involving two molecules of ethynyl Cu(II) complexes with structure 1.

It is shown below that this mechanism can also occur without the participation of dimeric Cu(I) complexes.

In a series of papers by Fedenok, Berdnikov, and Shvartsberg [56–63], the concepts of the mechanisms and kinetic models of OD in Cu(I)- and Cu(II)-containing systems were significantly expanded. The “stoichiometric” and catalytic oxidation of alkynes in acidic (with amine–AcOH buffer) and basic (without acid) media were studied.

System (CuCl + O 2 )–Et 3 N–AcOH–Py (I)

The reaction of OD of PhC≡CH (A) was studied in an inert atmosphere (N2) with the preliminary oxidation of CuCl by oxygen [56]. The reaction rate was moni-tored by the change in the optical density D of a Cu(II)* solution at 680 nm (Cu(II)* are copper complexes obtained by the oxidation of CuCl, and [A]0 >> [CuCl]0, where [A]0 is the initial PhC≡CH concentration). Divalent copper formed by the complete oxidation of CuCl in the presence of acetic acid in pyridine is virtually indistinguishable spectrophotometrically from Cu(OAc)2. The studies determined the second order in [Cu(II)*]. The normalized quantity \(\left[ {{\text{A}'}} \right]\)0/[Py] was used as the concentration of phenylacetylene, and the second order in \(\left[ {{\text{A}'}} \right]\) was determined. The dependence of the reaction rate on [AcOH] is described by an equation of the minus second order (1/[AcOH]2). These results are described by the empirical kinetic equation

where a is an empirical parameter, B is a base, D is the optical density, and t is time.

The use of the normalized concentration of the alkyne was hardly necessary, since the concentrations of pyridine (0.5 M) and the alkyne (0.5–5.0 M) are much higher than the concentrations of CuCl and Cu(II)* (10–3 M), and [Py] remains almost constant after replacing Py by the alkyne in Cu(II) complexes in the formation of π-complexes. The order in [CuCl] turned out to be zero.

The second order in alkyne concentration, which was determined by Bohlmann [13] and by Fedenok and colleagues, excludes the appearance of RC≡C• radicals as intermediates of OD of alkynes: their recombination is an incomparably faster process in comparison with the steps of transformation of alkyne into this radical. Fedenok et al. [56] estimated the enthalpy of the formation of the RC≡C• radical from alkynes by the reaction

involving bases B and showed that \(\Delta H_{{298}}^{ \circ }\) of this reaction is ≥60 kcal/mol, which also excludes the formation of RC≡C• by OD of alkynes. Note that the oxidation of ethynyl carbanions in ethynyl compounds of alkali metals (MC≡CR) by strong oxidizing agents \(({\text{Cu(N}}{{{\text{H}}}_{{\text{3}}}}{\text{)}}_{4}^{{2 + }},\) KMnO4) can also give rise to the radical RC≡C• [7].

The zero order in Cu(I) in this system is probably due to the rapid formation of ethynyl Cu(II) complexes with the participation of the buffer, CuCl2, and other oxidized forms of Cu(II)*. The kinetic data suggest that the process in system I occurs with a rate-determining step, the transition state of which includes two RC≡C– anions and two Cu(II) ions (complexes). Therefore, the following reaction mechanism was proposed:

Taking into account the material balance of [Cu(II)]∑, an empirical kinetic equation with rate-determining step (XIX) and an expression for the effective rate constant keff (Eq. (3)) were obtained. From the dependence of this constant on temperature (20–50°C), the observed activation energy was determined to be 21 kcal/mol.

where l is the thickness of the solution layer, εs is the extinction coefficient, and \(\sum {{K}_{{i - 1}}}\left[ {{{L}_{{i - 1}}}} \right]\) characterizes Cu(II) complexes with other ligands (CH3COO–, Cl–, Et3N) and is a constant value at high concentrations of ligands and similar extinction coefficients for complexes with different ligands.

The observed facts of inhibition of the reaction by the chloride ion and acceleration by the acetate ion can be correctly explained after determining the forms of Cu(II)* and the compositions of the Cu(I) and Cu(II) complexes. It is known [64, 65] that such forms in a buffer system can be ClCuOOH, ClCuOH, CuCl2, and Cu(OAc)2. The main kinetic laws found in system I are also retained when passing to the 2 : 1 Py–H2O solvent, and the reaction rate in the aqueous system is an order of magnitude higher than that in the anhydrous one. The study of the kinetics of oxidation of 13 alkynes in the similar system CuCl–PiPy–AcOH–Py at 50°C confirmed the quadratic dependences of the rate on [Cu(II)*] and on the concentration of alkyne [62]. When passing to an aqueous ammonia solution of CuCl2 in the oxidation of propargyl alcohols, the kinetic laws described above for CuCl solutions and in the Py–H2O solvent are also retained [57]. It was also found that the values of keff in acidic media (BH+) are correlated for substituted phenylacetylenes with the Hammett σ-constant (ρ = 2.2) [58].

System (CuCl + O 2 )–Py (II)

Two systems were compared: one with buffer (I) and the other without buffer (II) [62]. After preliminary oxidation of CuCl by oxygen, phenylacetylene was introduced into the reactor. In this system, in the absence of additional amines and AcOH, an induction period appeared in the time curves of the formation of the reaction product, which was due to the formation of Cu(I) and, consequently, to autocatalysis. The addition of CuCl to the initial (oxidized) solution removed the induction period. These observations indicated the participation of Cu(I) complexes in the process with the formation of PhC≡CCu. In the oxidation of copper phenylacetylide in the same system with Cu(II)*, diyne was formed rapidly with a yield of approximately 50% [62]. Since of the two oxidized forms of copper, e.g., CuCl2 and Cu(II)*, chloride complexes oxidize copper acetylides rapidly at a rate of controlled diffusion, it can be concluded that the oxygen-containing forms of Cu(II)* are less active in this process. The addition of Et4NCl to the same system was accompanied by the rapid formation of 100% PhC4Ph. These observations confirmed that RC≡CCu intermediates can also participate in the catalytic process with oxygen as an oxidizing agent.

System CuCl–Et 3 N–AcOH–Py (III)

Let us now consider the results of the study of the kinetics of the catalytic syntheses of diynes with oxygen by Fedenok et al. [59, 62] under conditions close to those for studying the kinetics in systems I and II.

The oxygen consumption rate was monitored with a pressure-measuring setup, and the initial reaction rates were used to describe kinetic laws. It was found that the CuCl oxidation rate is quite high, and Cu(I) at \({{P}_{{{{{\text{O}}}_{2}}}}}\) > 450 mm Hg is completely converted into Cu(II). In the region of zero order in \({{P}_{{{{{\text{O}}}_{2}}}}}\), the same quadratic dependences in \(\left[ {{\text{A}'}} \right]\) and [Cu(II)]∑ were observed; i.e., the reaction mechanism is the same as that in system I (with preliminary oxidation of CuCl). The well-known Hay catalytic system (CuCl–amine–methanol) used no buffer; therefore, system IV in the catalytic version was also studied [61, 62].

System CuCl–Py (IV)

The study showed that the kinetics of phenylacetylene oxidation by oxygen without a buffer is much more complicated than that in system III:

– there is an extreme dependence of the initial reaction rate R0 on \({{P}_{{{{{\text{O}}}_{2}}}}}\);

– the reaction order in [A] is variable from zero in the region of increase in R0 with increasing \({{P}_{{{{{\text{O}}}_{2}}}}}\) to ~1.5 in the region of decrease in R0 with \({{P}_{{{{{\text{O}}}_{2}}}}}\);

– the order in [CuCl]0 is ~2 at low \({{P}_{{{{{\text{O}}}_{2}}}}}\).

Because the rate of oxidation of CuCl by oxygen without a buffer is much lower than that with it; an acid (BH+) is needed for the oxidation of CuCl. The rate of oxidation of phenylacetylene with Cu(II) complexes without AcOH is higher due to the 1/[ВН+]2 term in Eq. (2). When phenylacetylene is oxidized by oxygen under conditions of complete oxidation of CuCl, an induction period is observed, which disappears if CuCl is added at the beginning of the reaction. In system IV, a quasi-stationary concentration of Cu(I) is established during the reaction, which leads to catalysis of the process by copper(I) chloride to form acetylide complexes RC≡CCu [62]. The zero order in [Cu(II)] in the bufferless system is probably due to a change in the limiting step—slow formation of RC≡CCu because of the absence of an amine (PiPy, Et3N)—and to the rapid oxidation of acetylides by such strong oxidizing agents as CuCl2, ClCuOOH, or ClCu=O. Empirical kinetic equation

obtained in system IV for the initial reaction rates describes the entire set of experimental data (α1 and α2 are empirical parameters).

The high orders in \({{\left[ {{\text{A}}{\kern 1pt} '} \right]}_{0}}\) and [CuCl]0 may be due to the participation of dimeric ethynyl copper (I) complexes (RC≡CCu)2 in the OD reaction under these conditions. It was assumed [52] that the decrease in R0 at high \({{P}_{{{{{\text{O}}}_{2}}}}}\) is related to the appearance of the free chloride ion, which prevents the formation of dimeric Cu(I) acetylides. Indeed, in system IV, phenylacetylene is not oxidized catalytically after the addition of Et4NCl at a ratio to CuCl of 1 : 1. Thus, it was assumed that, in the formation of PhC≡CCu and its dimer, the oxidized forms of the Cu(II)* type are converted into \({\text{CuCl}}_{n}^{{2 - n}}\) due to the release of chloride ions with subsequent rapid oxidation of the dimer by this chloride complex to [RC≡CCu(II)]2 and rapid formation of PhC4Ph and \({\text{CuCl}}_{n}^{{1 - n}}.\) Within this hypothesis, it turns out that the chloride ion in this system has negative and positive effects. Experiments showed that the rate of oxidation of Cu(I) acetylides by copper chloride is so high that it is controlled by the diffusion rate. For example, when pyridine solutions of Cu(I) phenylacetylide and CuCl2 are poured together, the reaction of the formation of diphenylbutadiyne ends already during stirring. Just as rapid is the process when mixing pyridine solutions of Cu(I) phenylacetylide and oxygen-oxidized CuCl, with the difference that it occurs to 50% completion, which is due to the amount of CuCl2 in the composition of Cu(II)*. But if chlorine anions in the form of tetraethylammonium chloride are introduced into CuCl preliminarily oxidized by oxygen, then the reaction occurs rapidly and to 100% completion.

System Cu(OAc) 2 –PiPy–AcOH–Py (V)

This system is similar to the Eglinton system and to the system studied by Clifford and Waters [54] in the oxidation of propargyl alcohol. A more detailed study of this reaction in system V by Fedenok and colleagues [60, 62, 63] showed that the initial reaction rate R0 in the absence of CuOAc strongly depends on the water concentration, and in the absence of H2O, it is close to zero. The quasi-stationary rate of the decrease in [Cu(II)] with the appearance of CuOAc is virtually independent of [H2O] and increases with an increase in the concentration of piperidine and [BH+] (at a constant AcO– concentration). To explain this phenomenon, it was assumed that the acid shifts the equilibrium of the formation of Cu(I) alkoxide, which is inactive in the process.

where P are the reaction products.

The ionization of the π-complex (X1) to form an acetylide compound (X2) occurs, in Fedenok and colleagues’ opinion, irreversibly due to its rapid dimerization and further rapid oxidation of the dimer by Cu(II) acetate. The orders of the reaction in \(\left[ {{\text{A}'}} \right]\) and [CuOAc] under quasi-stationary conditions are less than 1, and the order in [PiPy] is equal to 1 at [B]/[BH+] = const. Zero order was obtained in the concentration of the oxidizing agent.

According to Fedenok and colleagues, in this case, too, the reaction occurs by the formation of the (RC≡CCuOAc)2 dimer from dimer X3 with Cu(I).

Kinetic equation (5) for the mechanism of the oxidation of propargyl alcohol (where \(X_{1}^{'}\) in the scheme of the mechanism is the alkoxide CuOCH2C≡CH) with the rate-determining step in the synthesis of copper(I) acetylide X2 was obtained taking into account the material balance of [Cu(I)]:

Although the existence of π-complexes of Cu(II) with olefins and alkynes has not yet been established, the appearance of RC≡CCuOAc at the initial stage of the reaction in the absence of Cu(I) can occur with the participation of even a very weak π-complex of alkyne with Cu(II) in the presence of amine bases. In connection with the above facts and hypotheses, it is interesting to compare the results of studying the kinetics of the catalytic syntheses of diynes with oxygen in basic media [59, 62] with the kinetics of the OD reaction in acidic Zal’kind systems in the oxidation of alkynes by Cu(II) chloride [66–68].

System CuCl 2 –CuCl–MCl–HCl–H 2 O (VI)

The kinetics of the reaction of OD of methylacetylene (MA) was studied in the CuCl2–CuCl–MCl–HCl–H2O system, where [MCl] = 5 M and M = Li, Na, K, under conditions of the simultaneous formation of chloromethylacetylene (CMA) [66–68]. Under these conditions, at [CuCl2]0 = 0.1–0.5 M and [CuCl]0 = 0.01–0.5 M, only mononuclear chloride complexes of Cu(I) and Cu(II) are present in the solution [7, 69, 70]. The [Cu(II)]/[Cu(I)] ratio was determined from the results of measurements of the platinum electrode potential, which was described by the Nernst equation due to the preservation of the constancy of all activity coefficients under conditions of a high cation background and a high concentration of chloride ions. The concentration of H3O+ ions was monitored by an empirical linear equation relating the pH values to log[H3O+] in the systems under study.

The kinetics was studied by measuring the initial reaction rates in a closed thermostated reactor (30–60°C) with an efficient precessional stirrer ensuring the kinetic control. The course of the reaction was monitored by analyzing gas samples taken from the reactor [65, 67]. Since chloroalkynes are obtained through the oxidation of ethynyl copper(I) compounds [69, 70], the study of the kinetics of two parallel routes (XXI) and (XXII) with an obvious species that couples them [70] allows answering a number of fundamental questions related to the mechanisms of oxidative transformations of organometallic copper compounds:

The experimental dependences of the rates of the formation of dimethyldiacetylene (RDMDA) and chloromethylacetylene (RCMA) on the concentrations of the reagents and components of the catalytic system are expressed by Eqs. (6) and (7) with the notation of the rate constants as in Hoan et al. [67]. The dependence on [Cl–]0 was determined by replacing LiCl by LiClO4 at [Li+]∑ = 5 M. It turned out that an increase in [Cl–]0 slows down the OD process and accelerates the process of oxidative chlorination of MA.

where PMA is the partial pressure of MA.

It follows from the form of the obtained equations that both processes occur with rate-determining steps, and that the material balances of [CuCl2]0 and [CuCl]0 do not include π- and σ-complexes of Cu(I) and Cu(II) with alkynes and products reactions. Thus, the degrees \({{F}_{{{\text{C}}{{{\text{u}}}^{{\text{ + }}}}}}}\) and \({{F}_{{{\text{C}}{{{\text{u}}}^{{{\text{2 + }}}}}}}}\) of complexation of Cu(I) and Cu(II), respectively, are independent of the concentrations of MA, DMDA, and CMA. An analysis of the states of Cu(I) and Cu(II) in solutions of NH4Cl and alkali metal chlorides [7, 67, 71] suggested that, in a solution with [LiCl] = 5 M, more than 80% Cu(I) is in the form of complexes \({\text{CuCl}}_{3}^{{2 - }}\) and \({\text{CuCl}}_{4}^{{3 - }},\) whereas the fraction of complexes \({\text{CuCl}}_{3}^{ - }\) and \({\text{CuCl}}_{4}^{{2 - }}\) is ≤30% of Cu(II). A complete analysis of kinetic models (6) and (7), taking into account the degrees of complexation \({{F}_{{{\text{C}}{{{\text{u}}}^{{\text{ + }}}}}}}\) and \({{F}_{{{\text{C}}{{{\text{u}}}^{{{\text{2 + }}}}}}}},\) and the activities of Cu+, Cu2+, and Cl– ions, was made by Hoan et al. [66, 67].

The first question that arises when analyzing the mechanisms corresponding to the kinetic model of DMDA synthesis is the sequence of participation of CuCl and CuCl2 molecules in the steps of the mechanism. To explain the second order in [CuCl]0, one can propose two hypotheses (A and B) with different sequences of participation of CuCl and CuCl2 molecules at different steps of the process:

A: (1) CuCl, (2) CuCl2, and (3) CuCl;

B: (1) CuCl, (2) CuCl, and (3) CuCl2.

Let the possible hypotheses about the mechanisms of the formation of dialkynes be considered using simple forms of chloride complexes \({\text{CuCl}}_{2}^{ - }\) and \({\text{CuCl}}_{3}^{ - }.\)

Variant A. The first two steps are quite obvious (in a simplified version) and are quasi-equilibrium:

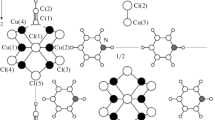

Ethynyl complex X1 is naturally formed through an intermediate π-complex [7, 70, 71]. Intermediate X2 is a mixed complex with possible fast electron transfer between the Cu(I) and Cu(II) forms. The second-order rate constant for the electron transfer between \({\text{CuCl}}_{2}^{ - }\) and \({\text{CuCl}}_{3}^{ - }\) is 5 · 108 L mol–1 s–1 [72, 73]. Therefore, complex X2 can be represented by electronic mesomers 2:

Intermediate X2 due to the fast intramolecular electron exchange cannot probably lead to the formation of RC≡CCuCl (X3) and dimer (RC≡CCuCl)2, which is necessary for oxidative transformation to dialkyne, but if intermediate X2 is a π-complex with structure 3, which is highly likely, its interaction with \({\text{CuCl}}_{2}^{ - }\) can lead to the disappearance of the π-complex in the rate-determining step (A3) and the appearance of a dimer capable of converting to dialkyne in the fast step.

Variant B. The participation of the second CuCl molecule in the OD process is also possible at an earlier step. Ethynyl Cu(I) compounds in the absence of strong ligands (R3N, Py, DiPy, PR3) are known to be poorly soluble in aqueous solutions. It is for this reason that most reactions of addition of HX molecules and oxidation involving alkynes (dimerization, hydrocyanation, diene synthesis, oxidative chlorination at the ≡С–Н bond) occur in more concentrated CuCl solutions than those used in the study of OD kinetics [66, 67]. In concentrated solutions, organometallic compounds of copper(I) are highly soluble due to the formation of polynuclear complexes [7, 70, 71]. In accordance with these considerations, this variant of the mechanism can contain the following sequence of steps with the first two quasi-equilibrium steps:

where intermediate \({\mathbf{X}}_{2}^{'}\) has the structure of π-com-plex 4:

The redox transformation of two molecules of the ethynyl complex RC≡CCuCl (X3) with the simultaneous formation of a C–C bond is considered, starting with Bohlmann [13], through the dimeric Cu(II) π‑complex with structure 5 (similar to complex 1), which is formed in the quasi-equilibrium step to steps (A4) and (B4):

Dimeric π-complexes of this type for metals that do not form stable π-complexes are extremely rare. For example, a dimeric π-complex consisting of two ethynyl Zn(II) complexes (Ph3P)ZnEt(C≡CPh) was isolated [74], and its structure 6 was determined by X‑ray powder diffraction analysis (XRD):

Bicyclic complexes of copper and other metals in the chemistry of alkynes. Since the transition state of the step of conversion of dimer 5 to dialkyne seems to be very complex (breaking of two C–Cu bonds and the simultaneous formation of a C–C bond), one can assume the existence of one more bicyclic intermediate, dicuprabicyclohexadiene (X5), with structure 7 [7, 70] (known for Ti(IV) complexes [75–80]), which is an organometallic compound of Cu(III).

The formation of two additional Cu–C bonds and a C–C bond compensates for the energy consumption for the breaking of two π-bonds in the dimer (RC≡CCuCl)2. Organometallic compounds of Cu(III) have now been synthesized, and their reactivity has been fairly well studied [81] (see below). In this regard, steps (A4) and (B4) can be detailed by the following sequence of fast elementary acts, where X4 is dimeric π-complex 5 and X5 is bicyclic complex 7:

The study of the transformations of ethynyl complexes Cp2Ti(C≡CR)2 and their reactions with dialkynes RC4R [75–80] determined that, depending on the nature of R in alkynes, dimeric ethynyl titanium(III) π-complexes of the type of complexes 1, 5, and 6 (R = SiMe3) or bicyclic titanium(IV) complexes of type 7 (R = Ph, Me, tBu). In this case, the reactions of π-complexes Cp2Ti(RC≡CR) (or \(''{\text{C}}{{{\text{p}}}_{{\text{2}}}}{\text{Ti}''}\)) with dialkynes also gives dimeric ethynyl titanium(III) π-complexes (R = SiMe3) or bicyclic titanium complexes (without breaking the C–C bond in dialkyne) in case R = Ph, Me, tBu (scheme 2)!

Scheme 2 . Mechanisms of the formation of bicyclic titanium(IV) complexes and dimeric ethynyl titanium(III).

Alkyne zirconium π-complexes Cp2Zr(RC≡CR) [82] in reactions with dialkynes are converted only into dimeric ethynyl zirconium(III) π-complexes of the type of complexes 1. Dimeric η1-η2-ethynyl π-complexes of type 1 can also contain different metals Cp2Ti (or Cp2Zr) with Ni(PPh3)2 [83]. The interaction of [Cp2Ti(C≡CR)]2 or the cumulene complex of Cp2Ti and 1,4-substituted butadiyne with NiL2 is a way to break the C–C bond in diyne [84]. Breakage of C–C bonds in diynes was also observed in the case of cumulene complexes of diynes with Cp2Ln and Cp2Ce [85]. The issues of mutual transformations of diethynyl π‑complexes into diynes and of diynes into diethynyl π-complexes were discussed in the reviews [86, 87], and the 2022 review [88] encompassed the synthesis, structure, and functions of titanium complexes, including dimeric ones, which are shown in Scheme 2. The review [87] noted that bicyclic dimetallahexadiene complexes can also contain different metals, e.g., Ti(IV) and Si(IV), or Zr(IV) and Si(IV) (7а), where X = SiR2 (see also [83]).

Two monoethynyl complexes of Sm(III), Ce(III), and Nd(III) easily form bimetallic complexes with the cumulene ligand \({\text{Cp}}_{2}^{*}\)M(Ph)C=C=C=C(Ph)M\({\text{Cp}}_{2}^{*}\) and cumulene products by the reactions of these complexes with alkynes [89]. Transformations of bicyclic Cu(III) complex 7 can also lead to Cu(II) cumulene intermediates and cumulene products.

Let us note another possible mechanism of the transformation of the intermediate RC≡CCuCl (X3) into products of the OD reaction, specifically, the reaction of dismutation of two X3 molecules to form diethynyl complex X6 with structure 8:

The redox decomposition of X6 with the transfer of two electrons to copper(II) atoms gives dialkyne.

The mechanism of the formation of CMA obviously includes the sequential oxidation of the ethynyl Cu(I) complex by two CuCl2 molecules:

C: (1) CuCl, (2) CuCl2, and (3) CuCl2.

Thus, the first two steps of this mechanism correspond to steps (A1) and (A2). The transformation of the RC≡CCu2Cl3– (X2) (A2) complex requires one more molecule of the oxidizing agent.

Intermediate X2 is a species that couples two routes (reactions (XXI) and (XXII)) with the following ratio of rates along the routes:

In the mechanism (С), the route-coupling species is intermediate X1 with the same ratio (8) of rates along the routes. The observed dependences of RDMDA and RCMA on [Cl–]0 do not follow from the considered steps of the mechanism, but are the result of approximating the complex dependences of the rates RDMDA and RCMA on the free concentration of Cl– by the following equations [67]:

where \({{F}_{{{\text{C}}{{{\text{u}}}^{{\text{ + }}}}}}}\) and \({{F}_{{{\text{C}}{{{\text{u}}}^{{{\text{2 + }}}}}}}}\) are the degrees of complexation of Cu(I) and Cu(II), respectively; and n and q are the numbers of chloride ligands in complexes \({\text{CuCl}}_{n}^{{\left( {n - 1} \right)}}\) and \({\text{CuCl}}_{q}^{{\left( {q - 2} \right)}}\), respectively.

The activation energy of DMDA synthesis in the range of 30–60°C according to Hoan et al. [67] is 67.7 ± 0.3 kJ/mol, i.e., below the Eact value 87.8 kJ/mol, which was obtained by Fedenok et al. [56]. The kinetics of the reaction of OD of acetylene under the same conditions obeys Eq. (6) for diacetylene (DA) and Eq. (7) for chloroacetylene (CA). The activation energy of DA synthesis is 53.9 ± 0.4 kJ/mol (25–50°C) [67].

Since the participation of two RC≡CCuCl molecules in the steps giving rise to a C–C bond after the rate-determining step is not confirmed by the kinetics in the studied chloride system (first orders in methylacetylene and acetylene and first orders in [CuCl2]0), it was necessary to study the cross coupling of methylacetylene and acetylene [68]. Cross coupling of two different alkynes makes it possible to have two route-coupling species (Scheme 3), specifically, intermediates X3 (CH3C≡CCuCl) and \(X_{3}^{'}\) (HC≡CCuCl), with the step of the formation of methyldiacetylene (MDA) and to test the hypothesis of the interaction of two ethynyl Cu(II) complexes at the step of C–C bond formation.

Scheme 3 . Route-coupling species in the three-route mechanism of the synthesis of DMDA, MDA, and DA.

Under the same conditions as in Hoan et al. [67], in the temperature range 25–45°C, we studied the kinetics of the formation of DMDA, MDA, and DA from a mixture of two alkynes, as well as MCA and chloroacetylene (CA) and a small amount of trans-1,2- dichloroethylene (DCE). The selectivity for the sum of diynes at 20°C is ~90%, and the maximum selectivity for MDA can reach 50%.

First, due to the coupling of three routes (Scheme 3), the reaction orders in C2H2 (PA) and MA (PMA) in the kinetic equations for the rates of the reactions of the formation of DA and DMDA, respectively, turned out to be lower than 1. This observation is explained by the routes presented in Scheme 3, which implies that the rates of the formation of the coupling and cross-coupling products are described by the following nonlinear equations:

The rates of the formation of X3 and \(X_{3}^{'}\) in the reactions of individual reagents are described by the following equations [66] at constant Cl– concentration:

Under the conditions of quasi-stationarity in [X3] and \([X_{3}^{'}]\), let us obtain, in accordance with Scheme 3, dependences of the first order in PMA and PA in the form of the equation

which satisfactorily describes all experimental results for j = DA, i = A and for j = DMDA, i = MA. At different pairs of indices, j = DA, i = A and j = DMDA, i = MA, different equations relating the reaction rates with \(~~{{k}_{i}}{{P}_{i}}.\)

Second, Eqs. (11)–(13) imply the equation

All experimental results at three temperatures (26, 30, and 45°C) in a solution with [LiCl] = 5 M are described by Eq. (17), and the β values are virtually constant within this temperature range at the initial and current rates (β = 1.92 ± 0.02).

Thus, there is no doubt that there are steps of coupling of ethynyl Cu(II) complexes in the mechanism of OD of alkynes in acidic solutions of chloride complexes of Cu(I) and Cu(II), even at the first orders of the reaction in the alkyne and CuCl2 concentrations. It follows from the kinetic results that the formation of the C–C bond and the transfer of two electrons occur simultaneously, whereas steps (XXIII)–(XXV) with single-electron transfer (SET) [81] in the case of OD of alkynes also contradict both the kinetic data, and the thermodynamic estimates [58]:

The variant of the OD mechanism with the step of alkyne insertion into the ≡C–Cu bond,

followed by the oxidation of the resulting enyne by the CuCl3– complex is not described by Eq. (16) and (17), whereas the oxidation of the enyne intermediate by Cu(II) chloride under the conditions of acetylene dimerization in the CuCl–NH4Cl–HCl–H2O system gives of 2-chlorovinylacetylene [1, 7] (see chapter 4):

It follows from the analysis of the kinetic models of the reactions of OD of alkynes that the dependences of the reaction rates on [CuCl2]n in various systems describe the experiment at n = 2, 1, and 0. What reasons lead to such a variety of reaction orders?

(1) The value n = 2 occurs in systems in which the rate-determining step is the interaction of two molecules of ethynyl complexes RC≡CCuX to form dimers that rapidly decompose to dialkynes.

(2) The value n = 1 arises if the rate-determining step is the formation of RC≡CCuХ by the oxidation of RC≡CCu or RC≡CCuL2 by Cu(II) chloride with possible subsequent dimerization (any form of dimeric ethynyl complexes of Cu(II) or even Cu(III)) .

(3) The value n = 0 occurs in the case of efficient catalysis by Cu(I) complexes with a slow step of the formation of copper acetylide RC≡CCu and its rapid oxidation.

Let us briefly consider some aspects of the technology of OD of alkynes.

The catalytic oxidation of lower alkynes (C2H2, C3H4) by oxygen (air) can be carried out in a two-reactor system with separate supply of gaseous alkynes (A) and air for the regeneration of CuCl2. If the Zal’kind catalytic system is used, it is easy to choose the conditions for the equality of the rates of diyne formation and Cu(I) oxidation by oxygen, since the kinetic equation

was derived for the CuCl oxidation rate at [LiCl] = 10 M [66], which does not depend on the Н3О+ ion concentration in the pH range 0.8–6.2.

The synthesis of DMDA in a synthesis reactor or an electrolyzer should be carried out in a two-phase system, e.g., with CCl4, to extract DMDA from the aqueous catalytic system [66]. The second version of the technology is the process in the anode chamber of a two-chamber electrolyzer with controlling the [CuCl2]/[CuCl] ratio. The high rate of C2H2 oxidation makes it possible to perform the process with a productivity of 30–50 g L–1 h–1 in a solution with 5 M LiCl at 0–5°C.

Since the OD mechanism of alkynes in the Zal’kind catalytic system involves two CuCl molecules, it was interesting to study the behavior of solid copper(I) methylacetylide in the same solution, i.e., to study the products and kinetics of the Glaser reaction with CuCl2 as an oxidizing agent [90].

Oxidative transformations of ethynyl compounds of copper and other metals. The kinetics of these reactions was studied in a closed reactor with intense stirring of three phases in an argon flow by measuring the initial rates of accumulation of reaction products at 20 and 30°C in a 5 M LiCl solution at [CuCl2] = 0.1 ± 0.5 M and a total amount of copper methylacetylide (MAM) of 0.3 M. The following facts were established:

(1) the only primary product is DMDA;

(2) chloromethylacetylene (CMA) is formed from MA released from MAM at pH ~ 4;

(3) in the oxidation of MAM by copper(II) bromide, that the amount of bromomethylacetylene (BMA) was twice as large as that of DMDA, the rate of formation of which is independent of MA (PMA) introduced into the reactor. The rate of BMA formation is described by the equation RBMA = kPMA;

(4) the activity of oxidizing agents decreases in their series (according to the values of the first-order rate constants in [Ox]): FeCl3 > CuCl2 > Li2Cr2O7 > KMnO4 > p-BQ;

(5) the absence of CMA and BMA among the primary products probably indicates that the OD reaction occurs on the surface of solid MAM;

(6) the redox decomposition of surface complexes of MAM with CuCl2 occurs without the participation of CuCl.

The participation of the CuCl molecule in MAM transformations under homogeneous conditions is probably due to not only the reasons considered above, but also the possible delocalization of the electron transferred from the Cu atom of methylacetylide to the Cu(II) atom of the oxidizing agent, which facilitates this transfer. On the surface of solid MAM, which is a coordination polymer, each copper atom is bonded to at least two ethynyl groups acting as η1- and η2-ligands [91–94]. In such a polymer, there is a high degree of conjugation, which is sufficient for electron delocalization. Therefore, the surface intermediate (MeC≡CCu∙CuCl2)s rapidly detaches a CuCl molecule and, interacting with the neighboring (MeC≡CCuCl)s, transforms into DMDA and does not give CMA.

To complete the picture, let us consider the redox reactions (RRs) of ethynyl complexes of other metals. Solid silver(I) methylacetylde [90] under the same conditions in the reaction with CuCl2 (and other oxidizing agents) turns into DMDA, apparently, also through the formation of complexes (MeC≡CAg∙CuCl2)s and (MeC≡CAgCl)s. However, it is possible that, in the case of silver complexes, a transmetalation process occurs on the surface with the formation of (MeC≡CCuCl)s and (AgCl)s.

When considering the mechanism of the oxidation of ethynyl compounds of Cu(I) and Ag(I), it should be kept in mind that, for ethynyl complexes of these metals, there are no thermodynamic constraints on single-electron electron transfer processes, and (MeC≡CCuCl)s and (MeC≡CAgCl)s can also be converted homolytically to form the MeC≡C• radical. This problem requires additional research.

Symmetrical solid Hg(II) methylacetylide Hg(C≡CMe)2 under the same conditions is not oxidized by such oxidizing agents as FeCl3, CuSO4, Na2Cr2O7, and KMnO4. At the same time, this compound easily interacts with CuCl2 to form CMA as the primary product. Obviously, it is the transmetalation to form MeC≡CCuCl in solution that leads to the synthesis of CMA by the reaction with the second CuCl2 molecule.

Interestingly, chloride complexes of Pd(II) and Rh(III) catalyze the oxidation of mercury methylacetylide by FeCl3 to DMDA, apparently via intermediate ethynyl compounds MeC≡CPdCl (or (MeC≡C)2Pd) and similar rhodium complexes. When studying the catalytic redox transformations of Hg(C≡CR)2 in solutions of hydride complexes of Ru and Os [95],

a new type of intermediates and an original mechanism for the transformation of ethynyl anions into OD products were discovered. For example, in the case of the initial complexes HRu(Cl)(CO)L3, stable complex ClRu{C(=CHR)(C≡CR)}(CO)L3 (9) was isolated, which is an intermediate in the synthesis of RC4R. In the case of a similar initial osmium complex, no intermediate with such a structure was isolated, but within 2 min a tenfold excess of Hg(C≡CR)2 in boiling toluene was converted into RC4R and Hg(0) to form the initial complex HOs(Cl)(CO)L3. The following mechanism of reaction (XXIX) was proposed:

Another variant of the mechanism of the formation of intermediate X8 with a carbene fragment can also be presented:

Obtained complex X7, just as in steps 4 and 5 in the previous mechanism, is converted into a dialkyne. Interestingly, complex X8 is also an intermediate in the nonoxidative dimerization of alkynes that is catalyzed by hydride complexes of Ru(II) and Os(II): HMX(CO)L2 [1]. An intriguing mechanism of the catalysis of Hg(C≡CR)2 demercuration by a rhodium(I) complex was proposed by Collman and Kang [96]. The possibility of oxidative addition of Rh(I) to the Hg–C bond was considered:

Intermediate of type X9 was synthesized and studied by Collman and Kang using Ir(I) complexes [96].

Reactions of stable di- and polyethynyl complexes are known for both Cu(I) and other metals, e.g., zirconium. Polyethynyl copper complexes have been obtained quite a long time ago: (RC≡C)2Cu–M+, (RC≡C)3CuM2, and even (RC≡C)3CuK3 with Cu(0) [94]. The [(PhC≡C)2Cu–]2 (NH3)x complex synthesized by Nast and Pfab [97] decomposes on heating to form RC≡C–C≡CR as a result of the oxidation of the [(PhC≡C)2Cu]– anion by the Cu(II) ammine complex to (PhC≡C)2Cu. Decomposition of the ethynyl complex (PhC≡C)2Cu thermally or under the action of the second Cu2+ ion gives dialkyne. This observation confirms to some extent the possibility of dismutation of two RC≡CCuCl molecules to form complex X6 and its participation in the OD reaction. Such an intermediate does not contradict the kinetic model obtained for a mixture of MA and A (Eq. (17)). The decomposition of the ethynyl Zr(IV) complex (the product of the oxidative addition of diyne to the Zr(II) complex) leads to a π-complex with diyne (or to a metallacyclopropene intermediate), which is oxidized by iodine to RC4R [98] (Scheme 4). In addition to the kinetic results indicating the participation of dimeric ethynyl Cu(II) complexes of types 1, X3, and 5 in the OD reaction, interesting data were obtained by Mizuno and colleagues [99, 100] by the catalysis of the OD reaction directly by dimeric Cu(II) complexes.

Scheme 4 . Mechanism of the formation of diynes with the participation of the ethynyl zirconium(IV) complex.

UV–Vis [99], and NMR and CSI-MS [100] spectroscopy studies convincingly showed that the monomeric complex [TBA]4[γ-H2SiW10O36Cu2(μ-1,1-N3)2] (a) in benzonitrile is an excellent catalyst for OD of alkynes in the reaction with oxygen. Complex a was obtained by the reaction of K4[γ-H2SiW10O36] with two equivalents of CuCl2 in excess of NaN3 in water at 25°С, followed by the addition of TBABr (TBA is tetrabutylammonium). The structure of the crystalline complex was determined by XRD [100]. Dimeric complexes of type a containing four Cu(II) atoms each were also synthesized earlier [101]. Figure 1 presents the structure of the azide fragment Cu2(μ-1,1-N3)2 of complex a.

The oxygen atoms belong to the silicotungstate anion. The azide ligand occurs as one of the electronic mesomers. Note that LCu(N3)2 complexes with macrocyclic ligands, e.g., 1,4,7-triazacyclononane, have long been studied in detail [102]. Complexes with trimethyl-substituted ligands [\({\text{L}}{\kern 1pt} '\)Cu(N3)2]2 and [\({\text{L}}{\kern 1pt} '\)Cu2(μ-N3)(N3)2]ClO4·H2O are also known [102]. It would be interesting to carry out the catalytic reaction of OD of alkynes with these complexes. The OD with complex a in an argon atmosphere occurs with an induction period, during which the azide anions are substituted by the reaction

Then, the stoichiometric (in Cu(II)) synthesis of dialkyne to form [Cu(I)]2 complex begins. It was shown that, under the same conditions, the use of CuCl2, CuCl, CuI, or Cu(AN)4PF6 leads to PhC4Ph with an (average) yield of <1%. In the catalytic variant with oxygen, the induction period is about 10 min, and the [Cu(I)]2 complex bound to silicotungstate is oxidized to form an ethynyl dimeric complex:

The amount of water formed over time was monitored by the change in the concentration of benzamide produced from benzonitrile. The catalytic process occurs very selectively in alkyne and in oxygen consumption. The yield of dialkynes for 31 substrates in benzonitrile at 100°C and 1 atm O2 is mainly 90 to 97% in 3 h at a catalyst turnover number of up to 470. A study of the kinetics of the reaction of OD with catalytic complex a showed [100] that the initial rate of diyne accumulation is described by the equation

The order in \({{P}_{{{{{\text{O}}}_{2}}}}}\) changes from 1 to 0. The observed activation energy is 68.9 kJ/mol. The kinetic isotope effect is kH/kD = 1, which indicates that the step of transformation of the dimeric ethynyl Cu(II) complex is rate-determining and that the main species of copper in the catalytic cycle is the dimeric ethynyl Cu(II) complex. The ethynyl ligand in this complex can be an η1, η2-ligand, as in complex 1, or a μ-ligand by analogy with the azide anion (see Fig. 1).

New ideas in the theory of the mechanisms of OD of alkynes involving two ethynyl complexes of Cu(II) and Cu(III) appeared as a result of a quantum chemical study of the mechanism of the OD reaction in the CuCl–TMEDA Hay system in acetone using oxygen by the Density Functional Theory (DFT) method [103]. The mechanism of CuCl oxidation by oxygen has long been known [64, 65] and was described above in the discussion of Fedenok et al.’s works [56–63]. Fomina et al. [103] considered the oxidation of ethynyl complexes Cu(C≡CH)L (L-TMEDA) by oxygen. The reaction sequence chosen for analysis in a simplified version (without the participation of protonated forms of the Me2NCH2CH2NMe2H+ ligand) is shown in Scheme 5, which includes a nonelementary step of oxidation of Cu(C≡CH)L to form ethynyl Cu(III) complexes.

Scheme 5 . Mechanism of the OD reaction involving Cu(III) complexes.

Dialkyne is formed at the step with transition state TS1.

Similar transition state TS2 is also accepted for the transformation of the ethynyl Cu(II) complex. A new idea in this work is the participation of Cu(III) complexes in the OD process, although the probable formation of intermediates containing Cu(III) (X5, 7) was also considered earlier [7]. At the same time, the structures of TS1 and TS2 are very doubtful: the convergence of ethynyl cationic (!) complexes in general, and even more so by the proposed method, is very unlikely. More likely, but not for cationic complexes, is the formation of intermediate dimeric ethynyl Cu(III) π-complexes of the type of Bohlmann complexes with structure 1. The use of cationic complexes for theoretical analysis in the presence of chloride anions in solution is not at all clear. Apparently, this theoretical study can only be considered in a conceptual aspect. Many questions arise regarding the quantitative results of the study involving cationic complexes (activation energies, etc.). It is hardly acceptable to use the Poisson–Boltzmann approach to take into account the solvation with LH+ cations and Cl– anions in this system containing cationic complexes of Cu(I), Cu(II), and Cu(III). It was necessary to consider additional intermediates, specifically, several molecules of acetone and water, as well as solvated Cl– ions, i.e., to use ion pairs separated by 3–6 solvent molecules in calculations, and to apply any other model of the polarization continuum. Our experience of theoretical analysis of the mechanism of ethylene oxidation in aqueous acetonitrile solutions of cationic Pd(II) complexes [104] showed the importance of taking into account the solvent in media with proton transfer in the presence of separated ion pairs.

Concluding the analysis of studies on the mechanisms of OD of alkynes in solutions of copper complexes, let us consider the 2013 article of Vilhelmsen et al. [105]. They improved the procedure for integrating the 13C NMR signals of alkynes and diynes to study the kinetics of OD of alkynes in the CuCl–TMEDA Hay system in dichloromethane and to optimize the composition of the catalytic system, including the choice of amines in OD of arylacetylenes. Unfortunately, all experiments were carried out under diffusion control, namely, under the conditions of the dependence of the conversion of alkyne on the speed of a magnetic stirrer. Meanwhile, in the case of very fast reactions, a magnetic stirrer is unsuitable for studying gas (O2)–liquid systems because it poorly mixes these two phases. Therefore, the found “optimal” conditions are such only for the chosen reactor design, the used mixer shape, and the given mixer speed. Nevertheless, Vilhelmsen et al. found a zero order in alkyne and a sharp jump in the reaction rate 50–80 min after the beginning of the reaction at a conversion of 50–80%, regardless of the concentrations of CuCl and TMEDA (1 : 3). The rate of the second slow step increases after the introduction of an additional portion of alkyne, and the inflection of the kinetic curve disappears after the addition of molecular sieves (4 nm) to the system. In Vilhelmsen et al.’s opinion, the decrease in the rate is due to the accumulation of water in the system during the OD reaction. In connection with these results, it would be useful to check the effect of the water concentration on the reaction rate in the CuCl–Py system (V) studied by Fedenok [62]. The zero order in alkyne, which was found by Vilhelmsen et al. [105], is most likely to be due to the fact that the rate-determining step under the studied conditions is the oxygen dissolution and, consequently, the oxidation of CuCl to Cu(II) complexes necessary for the synthesis of dialkyne. Although Vilhelmsen et al. [105] presented no results necessary to put forward hypotheses about the mechanism of the OD reaction, they, based on the literature data and their observations, proposed an original hypothesis of the formation of ethynyl Cu(III) complexes by the redox disproportionation of RC≡CCuCl complexes by the reaction

or

followed by the transformation of the RC≡CCuIII complex into diethynyl complex (RC≡C)2CuII, which decomposes to RC4R with simultaneous or subsequent oxidation of the formed Cu(0) to Cu(I).

1.2. Other Metal Catalysts for OD of Alkynes

Pd(II) complexes became the first copper-free catalysts for OD of alkynes. It is interesting to trace the history of the development of palladium catalysts in the OD reaction, which began with a series of fundamental works of Heck on the oxidative arylation, alkylation, and allylation of unsaturated compounds (olefins, dienes, CO) using organometallic compounds of non-transition metals as a source of aryl and alkyl groups: RHgX, R2Hg, R4Sn, R4Pb, etc. [106–113]. The oxidizing agents in stoichiometric processes were salts and complexes of Pd(II), Ru(III), and Rh(III) [106, 110, 112], which are converted by transmetalation processes into reactive intermediates RMXn; and the oxidizing agents in catalytic processes with Pd(II) were CuCl2, CuBr2 [106, 108–110, 112], and Pb(OAc)4 [111]. In some cases, the catalyst was a polyfunctional catalytic system (PFCS) Li2PdCl4–CuCl2, and the oxidizing agent was oxygen [106]. Below are a few examples:

Heck [113] discussed the mechanisms of the studied reactions and the problems of regio- and stereoselectivity at the steps of insertion of olefins into the R–PdX bond in the formed intermediates and at the step of β-elimination of HPdX.

Note that reactions of electrophilic substitution (or transmetalation) in the chemistry of organometallic compounds have long been known (see [114]). In our Laboratory at the Lomonosov Institute of Fine Chemical Technologies (LIFCF) simultaneously with and independently of Heck’s works [106–113] in 1969–1970 [114], we studied the reactions of PhH-gOAc with NaOAc and in the presence of Cu(II), Pd(II), and Pt(II) in AcOH. In the PhHgOAc–NaOAc system in boiling AcOH, PhOAc was obtained with a yield of 78–84%. In the PhHgOAc–PdCl2 system, diphenyl was synthesized; and in the PhHgOAc–Pd(ОАс)2 system, diphenyl and PhOAc were obtained at 25°C. Numerous examples from the chemistry of acetylene were used [114] to demonstrate the usefulness of using polyfunctional catalytic systems for the design of new catalytic reactions.

Subsequent Heck and colleagues’ works on the oxidative dicarboxylation of alkynes in PdCl2–HgCl2 solutions [115] and the use of Pd(II, 0) complexes in coupling reactions [116, 117], as well as Mizoroki et al.’s work [118] with a heterogeneous palladium catalyst, showed that it is possible to efficiently perform catalytic coupling reactions (XIII) or

which were later named the Heck reactions.

Our Laboratory at LIFCF also took a small part in developing the foundations of this reaction. Using experience in the synthesis of products of oxidative addition of alkyl halides (CHCl3) to PdL4 (L = Ph3P) [119] to catalyze the carbalkoxylation of acetylene to butyl acrylate [120], we carried out the arylation of ethylene to styrene without the use of PhHgX [121]. In a solution of PdL4 in PhBr (25°C), the PhPdBrL2 complex was formed, which was isolated and characterized. A solution of this complex in phenyl bromide was heated in an ethylene atmosphere to 100–120°C, and the formation of styrene (with a small amount of ethylbenzene) was found. Unfortunately, in 1970, we underestimated the importance of this reaction for synthetic chemistry and limited ourselves to a letter to the editors of the journal Kinetika i Kataliz [121]. The formation of ethylbenzene was related to the reduction of the produced olefin by palladium hydride. The Heck reduction reaction [9] was performed using the catalytic system [Pd(L)Cl]2 and CuH with R3SiH as a reducing agent.

The above studies finally led in 1975 to the publication of three articles on the oxidative transformations of alkynes. Cassar [122] proposed a PdL4 catalyst in DMF for arylation of alkynes (cross-coupling):

Heck [123] showed that a reaction similar to reaction (XXXVIII) can be catalyzed by the Pd(II)–Pd(OAc)2L2 complex in Et3N at 100°C. Since Et3N at 100°C does not reduce palladium to a Pd(0) complex, it was assumed that the initial palladium complex is reduced by alkyne to form dialkyne RC4R, followed by the oxidative addition of \({\text{R}' \text{X}}\) to PdL2 to form the intermediate RʹPd(C≡CR)L2 and the product of cross-coupling reaction (XXXVIII). Note that, as early as 1974, Dieck and Heck [117] observed an increase in the yield of dialkyne in the reaction of RC≡CH with \({\text{R}' \text{X}}\) with an increase in the [PhC≡CH]/[\({\text{R}' \text{X}}\)] ratio. Significantly milder conditions with excellent performance were proposed by Sonogashira, Tohda, and Hagihara [124], who used the PdCl2L2–CuI polyfunctional catalytic system in Et2NH (25°C, product yield in the case of PhC≡CH reaches 90–99%) during the formation of the active form of the PdL2 catalyst by the formation of PhC4Ph (!). The reactions of various I- and Br-substituted aromatic compounds and olefins with alkynes are called the Sonogashira reactions (method) and are discussed in chapter 3 of this review.

In further studies, it was found that stoichiometric (in palladium(II)) amounts of disubstituted 1,3-butadiynes are formed in the case of aromatic alkynes, most likely, by the decomposition of the Pd(C≡CR)2L2 intermediate [125]. It turned out that the use of the PdL4–CuI catalytic system in benzene with Et3N and an oxidizing agent (chloroacetone) at 25°C leads to ArC4Ar in the case of arylacetylenes and to RC4R (~50%) in the case of alkylacetylenes, as well as to the product of the addition of two ethynyl groups to diyne RC4R (10):