Abstract

History of the development and use of homogeneous metal complex catalysts in the chemistry of acetylene and its derivatives is considered. Achievements of the catalytic chemistry of alkynes in the creation of affective catalytic systems (based on Groups 3—11 and 13 of the Periodic Table) for alkyne dimerization, capable of producing desired dimeric isomers possessing high chemo-, stereo- and regioselectivity are analyzed. The nature of elementary stages in four mechanisms of dimerization and the relations of the nature of organometallic intermediates to the nature of catalyst (metal and ligand), substrate, and type of mechanism, and, hence, to the selectivity of dimerization process are discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

CONTENTS

1. INTRODUCTION

2. BRIEF HISTORY OF DEVELOPMENT OF THE CATALYTIC CHEMISTRY OF ACETYLENE AND ITS DERIVARTIVES IN SOLUTIONS OF METAL COMPLEX CATALYSTS

3. DIMERIZATION OF ALKYNES IN SOLUTIONS OF METAL COMPLEX CATALYSTS

3.1. Complexes of Metals of Group 11 of the Periodic Table

3.2. Complexes of Ru, Os and Fe

3.3. Complexes of Rh, Ir and Co

3.4. Complexes of Ni, Pd and Pt

3.5. Complexes of Metals of Groups 4—7 of the Periodic Table

3.6. Complexes of Metals of Groups 3 and 13 of the Periodic Table.

4. CONCLUSION

1. INTRODUCTION

In 1991, monograph [1] summarized outcomes of the development of catalytic chemistry of acetylene and its derivatives with participation of homogeneous metal complex based catalysts and heterogeneous catalysts. Achievements of the acid-base and nucleophilic catalysis were generalized in monographs of Tedesсhi [2] and Trofimov [3] (see also some more recent reviews [4—6]), while some problems of “organocatalysis” were recently addressed in [7]. The kinetic aspects and mechanisms of old classical processes and new alkyne reactions discovered in the past quarter century were considered in monograph [8].

During the past 25—30 years, new catalysts, new reactions, new types of intermediates, and new mechanisms of alkyne reaction catalysis have appeared. This development of modern alkyne chemistry was described in numerous monographs [8—21] and reviews [22—45]. The most popular catalysts in modern homogeneous catalysis are based on complexes of copper, nickel, gold, ruthenium, palladium, rhodium, platinum, titanium and zirconium. In particular, the scale of research works in the field of gold complex catalysis of fine chemical synthesis of carbocycles, heterocycles, and various biologically active compounds is very impressive [9, 11, 13, 15, 18, 19, 22, 36, 44].

Increasing interest in the chemistry of alkynes, related to the appearance of more active catalysis of chemo- and stereo-selective reactions proceeding under softer compounds, is clear evidence for the revival and “golden age” of the development of acetylene chemistry. At the same time, one can hardly agree with the statement of B.M. Trost and Ch.-J. Li, editors of monograph [18], that modern chemistry of alkynes as formed in the past several decades “provides an alternative to classical stoichiometric alkyne chemistry,” Indeed, it should be recalled, first, that the classical chemistry of acetylene and its derivatives as established by works of M.G. Kucherov (1881), A.E. Favorsky, J. Nieuwland, and W. Reppe was to a considerable degree catalytic rather than purely stoichiometric and involved w the use of metal complexes in solution and on surfaces, metals, metal oxides, acid-base and nucleophilic catalysts [1–3, 9, 46–52]. Until the end of 1950s, homogeneous catalysis with metal complexes was developing mostly on the basis of acetylene chemistry. Second, note that even monographs devoted mainly to thermal stoichiometric reactions of acetylene compounds and their organometallic derivatives also considered many reactions catalyzed by Brønsted and Lewis acids and bases and metal salts [48–50, 53–55].

For the past three decades, the chemistry of acetylene transformed into the chemistry of complex acetylene compounds such as enynes, dialkynes, alkynols, aryl- and heterylacetylenes, and other derivatives, but quite impressive results were also obtained for acetylene as such—even in the form of СаС2 [45]. Considerable development took place in the chemistry of pharmaceutical chiral preparations and materials possessing special optical, electrical, thermochemical, and mechanochemical properties based on acetylene substrates. New reactions, hypotheses, and paradigms found due to progress in the chemistry of acetylenes are undoubtedly worth of consideration and generalization, together with the results of successful development and verification of “old” hypotheses concerning the mechanisms of catalytic reactions. The present review deals with issues related to the use of metal complex catalysts in the chemistry of acetylene compounds, including necessary supplementary information concerning surface-supported metal complexes and “microheterogeneous” catalytic systems.

2. BRIEF HISTORY OF DEVELOPMENT OF THE CATALYTIC CHEMISTRY OF ACETYLENE AND ITS DERIVARTIVES IN SOLUTIONS OF METAL COMPLEX CATALYSTS

It is interesting to follow the history of using various metals as metal complex catalysts in the chemistry of acetylene and its derivatives and their role in the discovery of new alkyne reactions. It is convenient to subdivide this analysis into four stages:

First stage: until beginning of 1950s.

Second stage: 1950–1970.

Third stage: 1970–1990.

Fourth stage: 1991–2018.

In 1968, monograph [52] attempted to follow the appearance of various metals in the catalytic chemistry of acetylene compounds at the first stage (20th century until 1950s) beginning with the first Kucherov’s work on the acetylene hydration (1881) and then up to about 1967. The works of M.G. Kucherov, A.E. Favorsky, J. Nieuwland, W. Reppe, W. Carothers, A.L. Klebansky, Yu.S. Zalkind and many other researchers in the first half of 20th century laid foundations of the catalytic chemistry of acetylene.

In 1925—1945, a group of chemists headed by W. Reppe in the main laboratory of IG Farben (Ludwigshafen) developed the chemistry of and technology of the four types of catalytic reactions of acetylene and its derivatives with participation of base and metal complex catalysts. These processes included ethynylation, vinylation, carbonylation, and cyclization of acetylene to benzene and cyclooctatetraene. Results of investgations in this laboratory only became widely known after the World War II due to reports of the US Technical Mission [56], Reppe’s report [47], and monograph [57] generalizing the results on acetylene carbonylation. Review [56] expressed the general opinion of participants of the 110th Meeting of ACS the outstanding results obtained by Reppe’s research group would be exceptionally important for the development of organic chemistry in the United States (see also [39]).

In a lecture made at the Moscow State Institute of Fine Chemical Technology (MIFCT) in the beginning of 1960s, academician I.L. Knunyants recalled his work with a commission for reparations in post-war Germany. Once he saw a tank marked as “Cyclooctatetraen” on railways of a chemical plant and decided that it was some hidden secret product, although he knew about this compound that was synthesized in 1911 by the Nobel Laureate R.M. Willstätter via a highly complicated 9-stage synthesis from alkaloid pseudopelletierin (isolated from pomegranate bark). What a surprise it was on finding that the tank it fact contained cyclooctatetraene produced via single-stage industrial catalytic synthesis. The history of cyclooctatetraene synthesis discovery and captive Reppe’s report [47] about his research results was also described in the lectures on organic chemistry by Yu.I. Ustynyuk [58].

In the first half of 20th century, various homogeneous conversions of acetylene were mostly catalyzed, besides acids and bases, by compounds of non-transition and post-transition metals including Hg(II), Zn(II), Cd(II), Bi(III), Sb(V), Cu(I), Ag(I), Fe(III, II), and Cr(III). Gold compounds were used to catalyze the ethynylation of carbonyl compounds (with Au2C2/SiO2 [59]) and the stoichiometric oxidation of acetylene to glyoxal (with AuCl3 [60]), while Pt(II) complexes were used only once for the catalysis of acetylene oxidation by nitric acid to oxalic acid [52].

The conversions of acetylene compounds in heterogeneous catalysis were performed using a more diverse set of catalysts including metals and alloys (Pt, Pd, Ni, Co, Fe, Cu), metal oxides (Zn, Cd, Sn, Ni, Co, Mo, Ag, V, Ti, Th) and sulfides (Zn, Cd, Mo, Th), аs well as supported salts of Co, Ni, and Ce.

Organometallic compounds of Hg(II), Cu(I), and Sb(V) formed from acetylene were the first products considered as intermediates of catalytic reactions. For example, acetylene chlorination to tetrachloroethane in SbCl5 solutions via intermediate compound SbCl4(CH=CHCl) (Nesmeyanov’s “quasi-complex“ compound) was treated as a rare case of a catalytic reaction with “clear mechanism” [61]. Complexes of Ni(0) and Ni(II) were introduced by Reppe into practical homogeneous catalysis for the synthesis of acrylic acid and its derivatives in reactions of acetylene cyclotrimerization and cyclotetramerization. In 1952, Reppe [52] reported on the synthesis of 5-ethylpyridine from acetylene and ammonia in solutions of Ni(II) and Co(II) complexes.

At the second stage (1950–1970) extensive development of the catalysis with metal complexes in general and particularly in the acetylene chemistry was accompanied by the development of coordination and organometallic chemistry. Complexes of all metals of Groups 8—10 and some metals of Groups 4—7 of the Periodic Table were introduced into practical catalysis (see Table 1) [52].

New catalysts appeared in many of the well-known reactions (hydration, hydrochlorination, isomerization, carbonylation, cyclization, etc.). First active non-mercury catalytic systems have been discovered in 1950s—1960s for the hydration of acetylene and alkynes, including CuCl–ZnCl2–H2O system (comparable with mercury catalyst in efficiency for the synthesis of acetaldehyde, but much more stable) [52, 62, 63] and RuCl3 catalyst [64]. Metal comlex catalyst compositions were modified to include new ligands such as PR3, AsR3, SbR3, \({\text{SnCl}}_{3}^{ - }\), and Py. The discovery of the oxidation of olefins in solutions of palladium complexes [65] (so-called Wacker process [66]) drawn much attention to various conversions of acetylene catalyzed by palladium complexes [52]. It was found that acetylene carbonylation in alcohol solutions of Pd(II) complexes yielded a mixture of products of the oxidative, reductive, and additive dicarbonylation (see, e.g., [67]), while the Pd(PPh3)4–CHCl3–n-BuOH system under conditions of ClPd(CHCl2)(PPh3)2 complex formation led to the selective synthesis of butyl acrylate [68—70]. Analogous processes were found to occur in solutions of Co(0) and Rh(III) complexes [52]. After the discovery of Zigler—Natta catalysts of olefin polymerization, they were successfully used not only for the polymerization of acetylene and alkynes, but also in the reactions of hydration, dimerization, and cyclization of alkynes [52]. New catalytic reactions of alkynes included the co-cyclization of acetylene with nitriles, Cadio–Chodkiewicz cross-coupling, acetylene allylation (Kurts condensation), some oxidative chlorination reactions [52] and metathesis of alkynes [71], catalytic diene synthesis of norbornadiene with participation of intermediate [Cu](C≡CH) ethynyl complex [72], and hydrosilylation of alkynes [1].

Beginning with 1950s, extensive investigations were devoted to studying the mechanisms of homogeneous catalytic conversions of alkynes, including both the well-known and new reactions (see, e.g., works by F. Bohlmann, A.N. Nesmeyanov, E.A. Shilov, R.M. Flid, R. Vestin, В.V. Sokolsky, A.A. Petrov, O.A. Chaltykian, I.L. Kotlyarevsky, S.A. Vartanyan [8, 52, 73]). Numerous studied were devoted to the organometallic and coordination chemistry of acetylene-based compounds, which provided deeper insight into the mechanisms of catalytic reactions. Important achievements at the second stage (1950–1970) included the synthesis of ethynyl (alkynide) complexes of various metals (Cu, Ag, Au, Zn, Cd, Hg, Cr, Mn, Fe, Co, Ni, Pd, Pt, and Ir), elucidation of the structures of mononuclear and cluster π-complexes of 16 metals, synthesis of linear β-substituted vinyl complexes of some metals, synthesis of μ2-derivatives М‒СН=СН–М of nickel, cobalt, and chromium, as well as metallacyclopentadienes and other σ-organometallic compounds [52]. It is also worth of mentioning numerous studies of the kinetics and mechanisms of dimerization and oxidative dimerization of alkynes and mechanisms of various cyclization and co-cyclization reactions [52].

Investigations carried out by M. Dewar in 1946—1949 made it possible to establish a relation between the hypothesis concerning participation of π-complexes of metals with acetylenes in the mechanism of their catalytic reactions and the laws of addition reaction of various molecules at the triple bond (see, e.g., works by E.A. Shilov, R.M. Flid, R. Vestin, I.I. Moiseev). At the end of the second stage (1950–1970) first attempts were made to solve the problem of acetylene activation by metal complexes (see [74]) and to develop scientific principles of catalyst selection, which led eventually (at the third stage [1]) to understanding a simple idea: a justified choice of catalysts for any reaction can only be made using a procedure of formulating hypotheses about the reaction mechanisms (and, hence, the nature of intermediates) followed by analysis of these hypotheses. A metal complex adopted to be the possible catalyst must ensure the formation and proper conversion of intermediates in the proposed mechanism. Problems related to the formulation of hypothetical reaction mechanisms and the creation of computer software for generating hypotheses have been considered in [75—78].

At the third stage (1970—1990), the class of well-known metal complex catalysts of alkyne conversion expanded to include the complexes of Sc, Y, Zr, Nb, and Ta [1]. Chloride complexes of Au(III) in solutions proved to be effective catalysts of alkyne hydration [79] and amination [80] reactions, while Au(I) and Au(III) complexes both in solutions and on carriers effectively catalyzed acetylene hydrochlorination [15, 81]. New metal complex catalysts were also found for many other well-known reactions including the hydration, hydroiodination, hydrocyanation, arylation, hydrogenation, cyclization, dimerization, polymerization, carbonylation, and hydrosilylation of alkynes [1].

At the same time, new reactions were discovered including the vynylation of olefins [82] and methane [83, 84], anti-Markovnikov (anti-M) hydration of alkynes in a polyfunctional system of three catalysts CuCl–RSH–HCl with “hard” nucleophile (Н2О) replaced by the “soft” one (RSH) [85, 86], and anti-M addition of carbamate anions to terminal alkynes in ruthenium complexes with participation of vinylidene intermediates [87]. New catalysis were also proposed for the arylation of acetylene in solutions of Co(II), Ni(II), and Pd(II) complexes with the formation of 1,2-diarylethanes [88], Sonogashira cross-coupling in solutions of palladium and Cu(I) complexes [89], and homogeneous variants of acetylene hydrodimerization to butenes and acetylene–ethylene hydro-codimerization to butenes in Pd[P(OPh)3]4 complex solutions [90]. Catalytic systems were created for the oxidative carbonylation of alkynes at С–Н bonds [91, 92] and various reactions of carbonylation [93], including the oscillatory oxidative carbonylation of acetylene [94], oxidative chlorocarbonylation of acetylene to trans-1-chloroacrylates and trans-1-chloroacrylic acid [95, 96]. It was established that the synthesis of mixed esters of saturated and unsaturated mono- and diacids could be catalyzed by Pd(I) complexes and proceeded as a result of conjugated processes [97—99]. New metal complex catalysts were found for the metathesis of alkynes under homogeneous conditions [100].

Numerous organometallic complexes were synthesized or isolated from the reaction media, including π‑complexes of 25 metals with МmAn composition (where M is a metal and A is an alkyne) and potential intermediates of catalytic reactions formed from π‑complexes (Scheme 1) and small М2–alkyne clusters (Scheme 2) [1].

Scheme 1. Organometallic compounds obtained from π-complexes of alkynes.

Scheme 2. Products of reactions of metal clusters and alkynes.

Based on the results of systematic investigations of the kinetics and mechanisms of catalytic conversions of acetylene and its derivatives in metal complex solutions, kinetic models of reactions in concentrated solutions of copper chloride complexes were established for the hydrochlorination and hydration of acetylene, methylacetylene, and vinylacetylene, anti-M-hydration of methylacetylene in a system of polyfunctional catalysts, synthesis of norbornodiene from acetylene and cyclopentadiene, hydrocyanation of acetylene, and trimerization of acetylene [1, 8]. Extensive investigations were also devoted to the mechanisms of catalytic reactions of carbonylation [101], hydrogenation, cyclization, and polymerization of alkynes, and oxidative chlorination of alkynes in aqueous systems of polyfunctional catalysts CuCl–CuCl2, CuCl2–HgCl2, and PdCl2–HgCl2 [8].

At the fourth stage (1990s to present) in development of the catalytic chemistry of acetylene compounds to which the present review is devoted, most significant progress has been achieved in conducting catalytic reactions using Ni(II), Pt(II, IV), Ru(0, II, III, IV), Pd(0, I, II), and Au(I, III) complexes, as well as clusters and nanoparticles of these metals, and numerous new ligands involving these metals have appeared. A characteristic feature of this stage is the use of extremely large variety of acetylene substrates in the synthesis of complex biologically active compounds [9, 12–19, 22, 24, 27, 34, 35, 44].

New processes were found for the dicarbomylation of acetylene and alkynes to anhydrides of saturated diacids [93, 102—104], new oscillatory reactions were discovered in the catalytic systems of oxidative carbonylation of alkynes [8, 104–106] and new reactions were found for the catalytic oxidation of acetylene by nitric acid to glyoxal in solutions of Hg, Pd, Pt, Rh, Ir, and Au in the presence of sodium nitrite catalyst [107, 108], and new variants were discovered for the reactions of cycle formation, isomerization, cycloisomerization [11–15, 17–19, 24] and, in particular, very important reaction of cycloisomerization of unconjugated enynes [11, Ch. 3]. Considerable progress was achieved in the creation of new catalysts for the reactions of alkyne addition to compounds with Е–Н, Е–Е, and E–E' bonds (Е = S, Se, Te, P, B) and methods of controlling the selectivity of these processes [23, 28, 29, 33, 109–111]. Catalytic systems based on palladium complexes were found for extremely active and regioselective process of methylacetylene methoxycarbonylation to methyl methacrylate 112, 113] and systems based on ruthenium complexes were proposed for regioselective anti-M-carboxylation of alkynes [114, 115]. Reaction of the oxidative iodination of acetylene (and terminal alkynes) with the formation of (Е,Е)-1,4-di-iodobutadienes [116] and some other catalytic reactions of alkynes were discovered in solutions of platinum(IV) complexes. Remarkable success was achieved in regioselective synthesis of the products of classical dimerization of alkynes [18]. Specific reactivity of gold complexes was established in the catalytic synthesis of very complicated molecular structures [117].

Some commercially important directions of С2Н2 application reported in 2013–2018 and the prospects of its use in synthetic organic chemistry were considered in review [45].

At the present (fourth) stage of metal complex catalysis development, extensive investigations have been devoted to studying the mechanisms of both traditional and new catalytic reactions. It was established that an important role in some processes is played by the catalytic cycles involving metal nanoclusters, “giant” clusters, and nanoparticles and the multiplicity of catalytic centers in “homogeneous” processes [8, 118—120]. It was found that the stages of formation and deactivation of active centers play an important role in the mechanisms of catalytic reactions, i.e., in the possible realization of chain mechanisms in homogeneous catalysis with metal complexes [8, 118].

The conceived series of reviews will consider catalytic reactions of alkynes in which achievements of the catalysis with metal complexes in acetylene chemistry are most clearly pronounced as manifested by the development of high-selectivity processes with a variety of catalysts and mechanisms. The first review is devoted to one of the oldest catalytic reactions—dimerization and linear oligomerization of terminal alkynes. Alkyne dimers (enynes) are important substrates in the synthetic chemistry of biologically active compounds and in the chemistry of materials. Synthetic aspects of the dimerization reaction were described in detail by S. E. Garcıa-Garrido in monograph [18, p. 301]. The kinetic and mechanistic aspects of this reaction and the influence of the nature of intermediates on the regioselectivity of reaction will be considered in Section 3 below (including recent results reported in 2014–2018). Oxidative conversions of alkynes will be considered in the second review of this series.

3. DIMERIZATION OF ALKYNES IN SOLUTIONS OF METAL COMPLEX CATALYSTS

The formation of enyne hydrocarbons via dimerization of terminal alkynes can be classified into reactions of various types, including oligomerization (first member in the series), ethynylation, and vinylation (addition of HZ molecules to triple bonds). In the reaction of catalytic homodimerization of terminal alkynes, three enynes I–III (E-, Z-, and heme-isomer, respectively) and two cumulene 1,4-substituted butatrienes IV and V can be formed (Scheme 3). In the case of cross-dimerization, the number of chemo-, regio-, and stereo-isomers increases to 18. For this reason, the creation of catalytic systems (metal, ligand, solvent) ensuring selectivity of the dimerization process is a topical task, the solution of which for some systems is among remarkable achievements of the chemistry of catalysis with metal complexes [18].

Scheme 3. Products of alkyne homodimerization.

3.1. Complexes of Metals of Group 11 of the Periodic Table

This review of catalysts and reactions of alkyne dimerization naturally begins with metals (Cu and Au) of Group 11 of the Periodic Table, which have been historically the first catalysts of this process (for acetylene dimerization) [46, 121, 122]. The corresponding coordination and catalytic chemistry was studied in much detail, especially in the chemistry of alkynes [1, 8, 12, 14, 34, 51, 123]. In recent 20—25 years, gold complexes replenished arsenal of the catalytic chemistry of alkynes. Specific features of the coordination chemistry of Au(I) and Au(III) complexes are now quite sufficiently studied, including the nature and reactivity of gold-containing intermediates of catalytic reactions [10, 11, 13, 15, 18, 33, 124–127].

Fundamental differences of the physical and chemical properties of Cu(I) and Au(I) are related to peculiarities of the electron structures of copper and gold atoms. Filling of the 4f shell (lanthanide contraction) and the 4d and 5d shells of Au atom and, accordingly, the large numbers of electrons on atomic orbitals (AOs) at a high positive charge (79) of the nucleus lead to specific relativistic effects (REs) that determine to a considerable degree the reactivity of gold atoms in oxidation states 0, I, and III (see [124, 125] and references therein).

Briefly, the REs lead to the need for taking into account increase in the effective electron mass on s-AO due to high rotation speeds of remote electrons. This increase in the electron mass is accompanied by a decrease in the Bohr radius and, accordingly, the atomic and ionic radii. The RE refers to all s- and (to a lower degree) р-electrons. The lanthanide contraction and RE-induced contraction of AOs lead to the following consequences [124, 125]:

(i) The contraction of 6s-AO stabilizes vacant AOs and enhances the electron-acceptor properties of Au(I) and Au(III), thus increasing the Lewis acidity of Au(I) and Au(III).

(ii) The REs strongly increase the redox potentials of gold: Au+/Au0 (~1.68 V), Au3+/Au0 (1.5 V), Au3+/Au1+ (~1.4 V), Au2+/Au1+ (>1.3 V), particularly in comparison to copper ions (0.15 V for Cu2+/Cu1+). Note that analogous patterns are observed in Ni–Pt and Zn–Hg series, since the RE is also significant for Pt and Hg.

(iii) The Au+ ion is very unstable and, in the absence of ligands containing nitrogen, sulfur, and phosphorus atoms, readily exhibits disproportionation (dismutation) via reaction 3Au+ ⇄ Au3+ + \(2{\text{Au}}_{{{\text{met}}}}^{0}\) with an equilibrium constant close to to1010.

(iv) The first ionization potential of Au atom ((.22 eV) is significantly increased as compared to that of silver (7.57 eV) and copper (7.72 eV).

(v) The electronegativity of Au(I) reaches a level of 2.4 (vs. 1.8 for Cu(I) and 1.9 for Ag(I)).

(vi) The 5d-AOs of Au become more diffuse, but the repulsion of electrons and their energies decrease, which is accompanied by increasing electron—nucleus binding energies and decreasing donor properties of Au atom and ion. Therefore, the ability of forming dative bonds and participating in oxidative addition reactions significantly decreases.

(vii) Decreased repulsion of 5d-electrons on diffuse AOs in Au(I) complexes makes s-, p-, and d-AOs closer to each other, which facilitates their hybridization and increases stability of the linear geometry of LAuX and L2Au+X– complexes.

(viii) There is more clearly pronounced aurophilicity manifested by the formation of Au(I)–Au(I) bonds as compared to the case of cuprophilicity.

(ix) High electrophilicity of Au(I) increases the strength of Au(I)–L and Au(I)–X bonds, including those in numerous π-complexes of alkynes [125, 126], which makes π-complexes of alkynes capable of adding various nucleophiles (Nu) including olefins and even alkynes. For example, π-complex Au(С2Н2)+ is about 10 kcal/mol stronger than the analogous complex of Au(С2Н4)+.

(x) Dative Au+ → L contacts in π-complexes are less pronounced as compared to the case of copper ions, but are more significant in σ-complexes such as Au=СНR+ and Au≡СR+, which leads to the appearance of stable cationic carbene intermediates, e.g.,

(xi) The ability of Au(I) to form π-complexes, ethynyl compounds (alkinides), and Au(I)–Au(I) bonds (aurophilicity) allowed obtaining a large number of various clusters and supramolecular associates [11, 15, 125] and conducting unique syntheses of complex organic molecules [117]. Naturally, all the aforementioned properties of Au(I) led to its wide use in catalysis of alkyne dimerization processes.

Let us first consider the process of cuprocatalytic dimerization. The discovery of terminal alkyne dimerization reaction had a long and cautionary history that began in 1905 with the work of F. Strauss [121]. On studying the Glaser reaction [1, 8, 51, 52] of oxidative condensation of Cu(I) ethynyl compounds with various oxidants, it was established that boiling of PhC≡CCu ion acetic acid in the absence of oxygen led to the precipitation of PhC≡CCu ∙ Cu(OAc) and formation of С16Н12 hydrocarbon (1,4-diphenylbutenin) according to the following stoichiometric equation:

Here, the formation of phenylacetylene dimers results from the acidolysis of PhC≡CCu and dimerization of phenylacetylene catalyzed by Cu(I) acetate. In 1959, the Strauss’ observation was confirmed [122] and alkyne dimerization product was obtained from initial RC≡CCu in hot acetic acid solution (aerated for the oxidation of metallic copper appearing due to Cu(I) acetate dismutation) with the formation of 1% diacetylene derivative.

Upon return to the RC≡CCu–АсОН system in 1997 [128], it was established that the dissolution of Cu2О in boiling acetic acid with addition of terminal alkyl alkynes led to the formation of Z- and E-1,4-dialkylbutenins (II and I, respectively). This process terminated with the appearance of RC≡CCu and Cu(OAc)2, but alkyne did not exhibit dimerization in case of using a stronger dichloroacetic acid. By analogy with the structure of tetrameric complex [PhC≡CCuPMe3]4 [129], it was suggested that the product of phenylacetylene insertion at ≡С–Cu bond formed via dimeric complex [Cu(PhC≡CH)2]+[Cu(C≡CPh)2 ∙ AcOH]–, but the proposed mechanism was not confirmed by any evidence.

At the second and fourth stages of the development of metal complex catalysis of acetylene and its derivatives, detailed investigations were devoted to acetylene dimerization in the catalytic system discovered in 1931 by Nieuwland [46] in concentrated aqueous solutions of CuCl–NH4Cl(KCl)–HCl [1, 8, 52, 123]. For this system (Nieuwland catalyst), a correct kinetic model was proposed with a quite well substantiated mechanism of acetylene dimerization. Now let us briefly consider the main stages of studying Nieuwland catalysts.

1. Studies of the solubility of CuCl in aqueous NH4Cl and KCl solutions in a temperature interval of in the range 25–100°С showed that the [CuCl]/[NH4Cl] ratio at 80–100°С reached a maximum of 1.1–1.5 [8, 73, 123], which unambiguously pointed to the formation of polynuclear anions \({\text{C}}{{{\text{u}}}_{m}}{\text{Cl}}_{n}^{{(n - m) - }}.\) Chaltykian [73] noticed that, at CuCl concentrations below 4–5 m and NH4Cl concentrations below 6–7 m (where m is molality), the catalytic system ceases to be homogeneous and various acetylenide compounds precipitate from the solution.

2. Investigations of the equilibrium reactions of complex formation between CuCl and Cl– ion using the Hedström potentiometric method (see [130—134]) with the aid of electronic spectroscopy [134] showed that concentrated solutions contained about twenty anionic complexes \({\text{C}}{{{\text{u}}}_{m}}{\text{Cl}}_{n}^{{(n - m) - }}\) with m = 1–5 and n – m = 1–4. For example, at 25°С, [CuCl] = 4 m, [NH4Cl] = 6.5 m, and cationic background (CB) [NH4Cl + NH4NО3] = 14 m, the total molar fraction of mononuclear complexes is ~0.4 and the molar fraction of six complexes with m = 2–5 accounts for ~0.35 [132].

It is the large molar fraction of mononuclear complexes in the CuCl–KCl–Н2О system [135] that probably leads to the crystallization of KCuCl2 and KCuCl3 complexes from solutions on cooling. Note that systems used for the dimerization of acetylene to vinyl acetylene at 75°С contained 6.7 М CuCl and 6.4 М KCl or 8 М CuCl and 7.6 М KCl. In these solutions, the content of chloride ions is insufficient for the formation of even \({\text{CuCl}}_{2}^{ - }\) complexes, not speaking of \({\text{CuCl}}_{3}^{{2 - }},\)which is evidence for the existence of significant amounts of polynuclear anions in solution. The formation of binuclear complexes was established even at low CuCl concentrations (e.g., for [NaCl] \( \leqslant \) 5 M and [CuCl] \( \leqslant \) 1.6 M [136]) by the solubility method. Numerous crystalline polynuclear complexes were isolated from the Nieuwland catalytic system (see, e.g., [123, 137]), including (NH4)2Cu3Cl5 · 1/3(H2O) · 1/5(CuCl).

3. For studying the reaction kinetics and mechanisms of acetylene dimerization in multicomponent media such as Nieuwland catalysts with very complicated complexity function, a special method [8] was developed based on potentiometric measurements in situ, which allowed determining the activities of Cu+ (\({{a}_{{{\text{C}}{{{\text{u}}}^{ + }}}}}\)) and Cl– (\({{a}_{{{\text{C}}{{{\text{l}}}^{ - }}}}}\)) ions (proportional to the concentrations of these ions at CB = const) and, which is more important, maintaining their constant levels during variation of \({{P}_{{{{{\text{C}}}_{2}}{{{\text{H}}}_{2}}}}}\) and concentration of H3O+ ions [8, 138–141]. The concentration of H3O+ ions was determined by measuring (also in situ) the Hammett acidity h0 in samples of solution (taken from reactor) by the indicator method in a hermetic temperature-controlled cell [138, 140].

Investigations of the process kinetics [138, 141–145] in a gradient-free flow reactor [146] with determining \({{a}_{{{\text{C}}{{{\text{u}}}^{ + }}}}}\), \({{a}_{{{\text{C}}{{{\text{l}}}^{ - }}}}}\), h0, and \({{a}_{{{{{\text{H}}}_{2}}{\text{O}}}}}\) values [130] at constant CB gave correct dependences of the reaction rate W on \({{P}_{{{{{\text{C}}}_{2}}{{{\text{H}}}_{2}}}}}\) and h0\( \propto \) [H3O+] at \({{a}_{{{\text{C}}{{{\text{u}}}^{ + }}}}}\) = const, \({{a}_{{{\text{C}}{{{\text{l}}}^{ - }}}}}\) = сonst and led to the following formula [138, 141]:

Since the value of constant \(K_{\text{a}}^{/}\) was independent of \({{a}_{{{\text{C}}{{{\text{u}}}^{ + }}}}}\)and \({{a}_{{{\text{C}}{{{\text{l}}}^{ - }}}}}\) ([CuCl]), it was possible to analyze the behavior of kH = f(\({{a}_{{{\text{C}}{{{\text{u}}}^{ + }}}}}\), \({{a}_{{{\text{C}}{{{\text{l}}}^{ - }}}}}\)) depending on [CuCl] by approximately assuming that catalysis involves a single active complex \({\text{C}}{{{\text{u}}}_{m}}{\text{Cl}}_{n}^{{(n - m) - }}\) [142]. This analysis showed that the catalytic activity was inherent in polynuclear complexes with m = 3 and 4, and dominating contribution of \({\text{C}}{{{\text{u}}}_{4}}{\text{Cl}}_{5}^{ - }\) [142]. A more strict analysis [145] led to a conclusion that m values were within 4.3–4.7 and the active complexes included anions \({\text{C}}{{{\text{u}}}_{4}}{\text{Cl}}_{5}^{ - },\)\({\text{C}}{{{\text{u}}}_{4}}{\text{Cl}}_{6}^{{2 - }},\)\({\text{C}}{{{\text{u}}}_{5}}{\text{Cl}}_{6}^{ - }\), and \({\text{C}}{{{\text{u}}}_{5}}{\text{Cl}}_{7}^{{2 - }}.\) The mechanism of acetylene dimerization can be described by the following set of reactions (I)–(VI):

Here, the initial copper chloride complex is represented by only one molecule of water coordinated by copper atoms. Substitution of acetylene for this molecule leads to the formation of π-complex (π1) that is converted into ethynyl complex (σ1).

The ethynyl complex (σ1) is converted via π-complex (π2) into σ-organometallic compound (σ2) as a result of the π-coordinated acetylene insertion at Cu–С≡ bond (reaction (IV)). Compound σ2 is subject to fast protolysis with the formation of monovinyl acetylene (MVA).

It is also possible that the formation of σ2 via reaction (IV) involves a water molecule leading to an aqua-complex at stage (V), while the protolysis of σ2 and attachment of Cl– (reaction (VI)) proceed via two fast stages. Using the condition of quasi-stationary reactions in this mechanistic scheme with a single route, we obtain a kinetic equation for the rate of MVA synthesis. Estimation of the model parameters and their statistical analysis [142] showed that a minimum dispersion of reaction rates was achieved under assumptions that k–1\( \gg \)\({{k}_{2}}{{a}_{{{{{\text{H}}}_{2}}{\text{O}}}}}\) and \({{k}_{{ - 3}}}{{a}_{{{{{\text{H}}}_{2}}{\text{O}}}}}\)\( \gg \)k4, which yielded the following relation:

where keff = k4K1K2K3(\(K_{1}^{/}\))2Kpb; Kа = k4K3\(K_{1}^{/}\)/bk–2; \(K_{1}^{/}\) is the equilibrium constant of acetylene dissolution; Kp is the equilibrium constant of \({\text{C}}{{{\text{u}}}_{m}}{\text{Cl}}_{n}^{{(n - m) - }}\)anion formation from Cu+ and Cl–; \({{a}_{{{{{\text{H}}}_{3}}{{{\text{O}}}^{ + }}}}}~\) = bh0\({{a}_{{{{{\text{H}}}_{2}}{\text{O}}}}}\); and b is the coefficient of proportionality.

It follows from Eqs. (1) and (2) that the process of acetylene dimerization at temperatures within 50–100°С [143] proceeds without a rate-limiting stage (see discussion of the limiting stage notion in [147]). Under the reaction conditions studied, the rates of [Cu]C≡CH complex protodemetalation (W–1) and the rate of [Cu]C4H3 formation are comparable. For \({{h}_{0}}a_{{{{{\text{H}}}_{2}}{\text{O}}}}^{2}{{a}_{{{\text{C}}{{{\text{l}}}^{ - }}}}}\)\( \gg \)\({{K}_{{\text{a}}}}{{P}_{{{{{\text{C}}}_{2}}{{{\text{H}}}_{2}}}}}\) (k–2\({{a}_{{{{{\text{H}}}_{3}}{{{\text{O}}}^{ + }}}}}{{a}_{{{\text{C}}{{{\text{l}}}^{ - }}}}}\)\( \gg \)k4), the rate-limiting stage is reaction (IV), while for \({{h}_{0}}a_{{{{{\text{H}}}_{2}}{\text{O}}}}^{2}{{a}_{{{\text{C}}{{{\text{l}}}^{ - }}}}}\)\( \ll \)\({{K}_{{\text{a}}}}{{P}_{{{{{\text{C}}}_{2}}{{{\text{H}}}_{2}}}}}\), the process rate is controlled by the formation of compound σ1 via reaction (II).

The composition of ethynyl complex CumCln– 1-(С2H)(n –m)– was established with the aid of spectrophotometric and potentiometric techniques [148]. Under assumption that dominating contribution to the catalytic process is determined by a single “yellow” complex of this type, a minimum dispersion of function F related to the total optical absorption of these complexes in the wavelength interval of 350—420 nm would be observed for m = 4.3 and n = 5.0. These investigations also showed that copper acetylenide Cu2C2 is well-soluble in concentrated CuCl solutions, but only provided weak acidity (рН > 5 and h0 < 0.2). For this reason, the synthesis under adopted conditions (h0 = 0.2–0.5 in solution of CuCl (6.6 m) and NH4Cl (8.84 m) at an optimum temperature of 80°С [143]) yields MVA at a much lower concentration as compared to that of ethynyl complexes.

Valuable information on the nature of second organometallic intermediate [Cu]C4H3 (σ2) considered as a product of acetylene insertion at [Cu]–C≡ bond in the π-complex was obtained from investigations of the influence of the concentration of various metal chlorides on the process rate in the CuCl–NH4Cl–HCl–Н2О system [144]. It was found that metal chlorides can be subdivided into three groups with respect to their influence on the reaction rate:

– ZnCl2, CdCl2, and BiCl3 increase the reaction rate by increasing \({{a}_{{{\text{C}}{{{\text{u}}}^{{\text{ + }}}}}}}\) and, hence, the concentration of active chloride anions and σ1 complexes;

– BеCl2, MgCl2, CaCl2, SrCl2, BaCl2, FeCl2, CoCl2, MnCl2, and CrCl3 decrease the reaction rate by increasing \({{a}_{{{\text{C}}{{{\text{l}}}^{ - }}}}}\) and decreasing \({{a}_{{{\text{C}}{{{\text{u}}}^{{\text{ + }}}}}}}\) (similar to the effect of NH4Cl and KCl);

– HgCl2, SnCl2, and CuCl2 sharply decrease the rate of dimerization reaction. The effect of SnCl2 and HgCl2 is related to the growth in solution acidity as a result of SnCl2 hydrolysis and the formation of organomercuric compounds stable with respect to protolysis, which appear due to the transfer of organic groups via reaction

with R = C≡CH, CH=CHC≡CH, or C≡CCН=CH2.

It was established that the main factor increasing the Hammett acidity to h0 = 2 upon mercury chloride addition is the formation of ClHgCH=CHC≡CH compound on solution, which decomposes udder the action of concentrated HCl with the formation of MVA. The introduction of CuCl2 leads to conversion of the proposed intermediate compound [Cu]C4H3 (σ2) to 2-chlorovinyl acetylene (CVA) CH2=C(Cl)C≡CH. Measurements of the kinetics of competitive reactions of MVA and CVA formation [149, 150] provided information on the reaction mechanism after irreversible formation of [Cu]C4H3. In addition, it was found that, in the presence of CuCl2 under stationary conditions ([CuCl] = 12 m, [NH4Cl] = 12 m, [CuCl2] = 10–3–10–2 М, and continuous regeneration of CuCl2 via anodic oxidation of CuCl with established linear dependence of \({{a}_{{{\text{C}}{{{\text{u}}}^{{\text{ + }}}}}}}\) = const[Cu(II)]Σ), the rates of MVA and CVA formation at \({{a}_{{{\text{C}}{{{\text{u}}}^{{\text{ + }}}}}}}\) = const and \({{a}_{{{\text{C}}{{{\text{l}}}^{ - }}}}}\) = const under conditions corresponding to the mechanism of MVA synthesis according to Eqs. (I)–(VII) and their common intermediate [Cu]C4H3 (σ2) conversion according to Scheme 4 are given by the following formulas:

Scheme4. Mechanism of intermediate [Cu]C4H3 (σ2) conversion in the system with [CuCl] = 12 m, [NH4Cl] = 12 m, and [CuCl2] = 10–3–10–2 М.

Equations (3) and (4) show that the ratio of reaction rates is WCVА/WМVА = kIII[Cu((II)Σ]/h0 and their sum WCVА + WМVА equals the rate of MVA formation in the absence of CuCl2. The mechanism of [Cu]C4H3 conversion into CVA is considered in monograph [7].

4. Solid π-complexes of CuCl and Cu2SO4 with acetylene, complexes of CuCl with с MVA, as well as CuC≡CH and solid “yellow” acetylenide complexes that were described during the first two stages of acetylene chemistry development in works of M. Berthelot, R. Chavastelon, В. Manchot, J. Osterlof, O.A.Chaltykian, R. Westin, A. L. Klebanskii, I. M. Dolgopolskii, L.G. Zurich, A.A. Ginzburg, I.K. Khristich, and R. Nasta are considered in monograph [52].

It should be also noted that various important issues of organometallic and coordination chemistry related to the Nieuwland catalytic system were developed in 1990–1999 by the Lviv group of crystal chemists (M.G. Mys’kiv at al.) [137, 151—160] and by other researchers [123, 129, 161–165]. These investigations elucidated the structures of polynuclear π-complexes of acetylene, MVA, divinyl acetylene (DVA), and ethynyl complexes with CuC≡CH, CuC≡CR, and Cu2C2 fragments, which help representing the structural (crystallochemical) aspects of acetylene dimerization mechanism as considered in [8, 123].

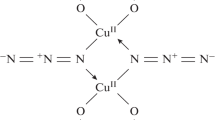

5. Scheme 5 presents the structures of four-nuclear copper complexes as probable intermediates of the dimerization process, which were constructed based on the fragments of structures of the corresponding crystalline Cu(I) complexes (i.e., crystallochemical reconstruction of the reaction mechanism). According to the kinetics of dimerization reaction, formation of the acetylene π-complex B from A at stage (I) proceeds as a result of the chloride bridge fracture or the replacement of coordinated water molecule (cross-hatched) with transferred bridging Cl– ion (without displacement of chloride ion). The coordination note in complex B is structurally analogous to one of the possible π-complexes [123], e.g., NH4Cu3Cl4(C2H2) [152] or NH4Cu8Cl9(C2H2)4 [154]. During the formation of ethynyl intermediate C (σ1), Cl– ions can either go to solution simultaneously with Н3О+ (stage (II)) or escape at the next quasi-equilibrium stage (without changing the kinetic equation).

Scheme5. Crystallochemical) aspects of acetylene dimerization mechanism [123].

Among a huge variety of ethynyl complex structures [123], intermediate C may be compared to (PyH)4Cu9Cl12(C≡CH) presented in Fig. 1 [123, 160]. A very rich coordination chemistry has been found among ethynyl derivatives of propargyl alcohol, (NH4)2Cu4Cl5(C≡CCH2OH) ∙ H2O, which are presented in Fig. 2 [123, 156].

It should be noted that Nieuwland catalyst solutions contain pH-dependent ethynyl and symmetric “yellow” acetylenide complexes \(({\text{C}}{{{\text{u}}}_{2}}{{{\text{C}}}_{2}}){\text{C}}{{{\text{u}}}_{p}}{\text{Cl}}_{q}^{{(q-p)-}}.\) Increasing acidity (рН < 1.5) leads to the breakage of acetylenide complexes and increase (to within certain limits) in the concentration of intermediate C.

The insertion of acetylene from a π-complex via Cu–C≡ bond into intermediate D (Scheme 5) leads to the formation of fragment [Cu](CH=CHC≡CH) in Х1 (stage (IV)), probably via intermediate D*. The mechanism of this stage that is responsible for the stereochemistry of dimerization products of terminal alkynes is discussed in review [123]. The stage of protolysis of intermediate Х1 (stage (VI)) with the formation of E poses no questions and is well-known in the chemistry of σ-organometallic Cu(I) compounds [166].

Kinetic models of acetylene trimerization (synthesis of 1,3-hexadien-5-yne) and codimerization of acetylene and MVA (synthesis of 1,5-hexadien-3-yne, DVA) were also constructed using the method described above [167, 168].

6. In addition to the well-known types of coordination of alkynide ligands RC≡C– with copper atoms (VI, VII, VIII, IX), copper chloride complexes revealed another two structures (X and XI) [123]:

Rather interesting variants of coordination were also found upon the interaction of Сu2C2 with copper chloride anions [158]:

π,6-Coordination nodes in (NH4)8Cu29Cl29(C≡C)4 · 7H2O complex structure.

Quite recently, additional results important for understanding the mechanism of MVA synthesis were obtained [169, 170] by analysis of the 1Н and 13С NMR spectra of copper chloride solutions purged with acetylene. It was found that passing acetylene through a solution of 7.0 М CuCl and 6.66 М KCl at 50°С led to the appearance of signals corresponding to acetylene π-complexes, MVA, and DVA (Table 2) and the concentration of π-complexes varied with the reaction time. In addition, acetylene exhibited rapid H/D exchange in D2O solutions with the formation of HC≡CD, DC≡CD, and deuterated MVA exhibiting significant kinetic isotope effect (KIE) in which the rate of С2Н2 π-complex consumption and acetylene (in the gas phase) was ~3 times lower in the case of D2O. These observations are quite natural in the framework of the kinetically and spectrophotometrically studied mechanism of acetylene dimerization (see above) involving the kinetically reversible stage

Kinetic data [169, 170] determining the first order of reaction (VIII) with respect to the concentration of С2Н2 π-complex and acetylene concentration in the gas phase caused major doubts because they were obtained from the values of chemical shifts under nonstationary conditions and in the absence of control over the acidity of solution. In particular, reversible reaction (VIII) cannot have the first order (in (C0/C)–t) coordinates) with respect to the concentration of π‑complex even at an almost constant concentration of Н3О+, while the kinetically irreversible stage would not be accompanied by rapid H/D exchange (even if this exchange actually proceeded via the formation of σ-ethynyl Cu(C2H)complex and its protolysis). For example, data obtained previously [171] on the kinetics of isotope exchange in AcOH showed that the rate of RC≡CCu formation was ~100 times lower than the rate of H/D isotope exchange. The possible mechanisms of isotope exchange are discussed in [1]. Another questionable issue was the role of diffusion constraints in determining the reaction order with respect to gaseous acetylene.

Increase in the stability of Nieuwland catalysts in aqueous [172] and nonaqueous [173] solutions using controlled variation of their acidity (by adding HCl during the process) has been used in practice for a long time. In aqueous systems, the concentrations of “yellow” acetylenide complexes and [Cu](C2H)–, as well as their solubilities, depend on the concentration of acid (HCl) that is consumed for the side processes of hydrochlorination pf acetylene, MVA, and acetylene trimers and for the oxidative chlorination of all alkynes due to the presence of oxygen traces and, hence, CuCl2.

Now let us consider the process of aurocatalytic dimerization. Based on investigations of the activity of Au(I) complexes in reactions of alkyne dimerization under variable conditions in various solvents [174], it was established that the dimerization of n‑BuO(CH2)3C≡CH ester in boiling toluene led to the formation of isomers II and III in a (4.5–20) : 1 ratio. This ratio depends on both the nature of ligands and the nature of a base added to the catalytic system, so that the yield of a heme-isomer can reach 91–96%. The function of catalysts was performed by gold complexes LAuNTf2, where \({\text{NTf}}_{2}^{ - }\) is a non-coordinated anion and L is a carbene (NНС) or phosphine ligand:

Ligands in Au(I) complexes.

The best results were obtained using ligand XIV with additions of solid NaOAc.

Investigation of the dimerization of nine aliphatic alkynes containing various substituents in the alkyl groups led to a proposed reaction mechanism analogous to that for Cu(I) complex solutions, which is referred to below as the ethynyl mechanism. The cis-insertion of π-complex-bound alkyne at [Au]–C≡ bond (according to Markovnikov) or the interaction of [Au]–C≡CR with π-complex [Au](RC≡CH)+ (due to aurophilicity) lead to predominant formation of RC≡C–C(R)=CHAuL intermediate. Then, replacement of AuL+ with proton (probably from acetic acid) leads to isomer III. The formation of isomer II as a side product via anti-M insertion can be evidence of the possible anti-M addition of RC≡C– anion to alkyne. Taking into account the ability of Au+ to stabilize carbene and vinylidene ligands, it is also possible to suggest the participation of vinylidene ligand in a mechanism of dimerization with the formation of dimer II. The conversion of RC≡CAu(L)(=C=CHR)– can probably also lead to isomer II. However, this mechanism would require the appearance of tri-coordinated gold atom that is not characteristic of Au+.

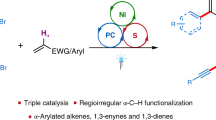

Thus, already at the third stage of development of the modern alkyne chemistry, effective catalysts for highly selective processes of alkyne dimerization were developed based on Ni(II), Rh(I), Cr(IV), Sc(III), Y(III), and Ti(IV) complexes [1]. In 1990—2018 (fourth stage), new metal complex catalysis of alkyne dimerization were proposed and new intermediates and reaction mechanisms were found (see also review [18]).

3.2. Complexes of Ru, Os and Fe

Let us begin with the most thoroughly studied processes of alkyne dimerization catalyzed by metal complexes of Group 8 of the Periodic Table, firstly, by ruthenium (Ru) complexes.

Investigations of the selectivity of alkyne homodimerization and catalytic activity of Ru complexes with various mono- and polydentate ligands (including cyclopentadienyl and carbene complexes, see Table 3) showed that Ru(II) and Ru(0) complex solutions contained precursors of active catalysts representing selectively (≥95%) formed isomers I and II (Scheme 6) with Е/Z ratios determined by the sterical and electronic properties of ligands and alkyne substituents.

Scheme 6. Products of alkyne dimerization in catalytic systems based on ruthenium complexes.

Heme-isomer III is a product rarelyencountered in selective homodimerization, which is formed in solutions ofcomplexes 15 (Table 3, R = PhCH2) and 17 (Table 3, R = n-hexyl).Other rare isomers are cumulenes IV and V (Table 3, Scheme 6). The reactionselectivity is especially significantly influenced by geometry of thecoordination sphere of Ru atom, that is, by the degree of its screening.

The contributions of sterical effects and the nature of ligands to the regio- and stereoselectivity of dimerization were most thoroughly traced in the case of rather “closed” complex 15 (Table 3, η5-С5M5)RuLH(H2) [182, 183]. For L = PPh3 (15a) and large R (tBu and SiMe3), isomer I is formed at 95–98% selectivity. In case of L = PMe3 (15c) and the same substituents R, a mixture of isomers I–III is formed, and only the reaction with R = Ph gives isomer II at 90% yield.

Isomer V (>95%) is obtained in solutions of complex 15b for L = PCy3 and R = PhCH2. The reactions of alkyne cross-dimerization will be considered below, after analysis of the mechanisms of reactions catalyzed by ruthenium complexes.

General notions of the mechanisms of alkyne dimerization were formulated based on the results of investigations of the dimerization of acetylene and alkynes in solutions of Cu(I) complexes (Section 3.1), Ni(II) and Ni(0) complexes [1], and so-called vinylidene hypothesis proposed by Yamazaki [175] in his first work devoted to the catalysis of alkyne dimerization by Ru(II) complexes.

A. Ethynyl mechanism:

B. Vinyl mechanism:

The order of formation of intermediates can be different—whereby the ethynyl group is formed first, followed by vinyl (alkenyl) group—but the key intermediate must contain both groups.

C. Vinylidene mechanism:

Vinylidene group can form via different pathways:

(a) H[M](C≡CR) \( \to \) [M](=C=CHR).

(b) [M](η2-HC≡CR) \(\xrightarrow[{ - {\text{BH}^{ + }}}]{{{\text{BH}^{ + }}}}\) [M](=C=CHR).

(c) [M](η2-HC≡CR) \( \to \) [M](=C=CHR).

In the framework of this mechanism, different variants of decomposition of intermediate [M]-C4 can lead to regio- and stereoselective formation of isomers I, II, IV and V.

An analysis of works devoted to the synthesis of enynes in solutions of Ru(II, IV) complexes [175–191], which frequently reported the results of studying particular aspects of the dimerization mechanisms, and works devoted directly to these mechanisms in reactions catalyzed by ruthenium complexes [192–200] reveals the main problems and paradigms existing in this field of the chemistry of dimerization processes. The most profoundly substantiated and developed mechanism of catalysis with Ru complexes is the vinylidene mechanism C [176–178, 181, 192, 195, 197, 200], which are briefly illustrated below by several examples.

Dobson et al. [192] studied the reactions between HRu(O2CCF3)(CO)(PPh3)2 complex and terminal alkynes and diarylacetylenes with the formation of vinyl derivatives and, in addition, synthesized a hypothetical model intermediate for the dimerization of alkynes with 1,4-diphenylbut-1-en-3-in-2-yl ligand from HRu(O2CCF3)(CO)(PPh3)2 hydride complex and 1,4-diphenylbutadyine (i.e. [M]-C4 or σ-С4). The structure of this Ru(С4НPh2)(O2CCF3)(CO)(PPh3)2 complex contains [Ru]–C(=CHPh)–C≡CPh fragment (XII, σ-С4):

It was pointed out that this intermediate could not form via alkyne insertion at [Ru]–C≡CPh bond, that is, in the framework of mechanism A. Based on the previously (1968—1972) described vinylidene complexes of Fe and Pt (see review [200]), it was suggested that intermediate XII could appear as a result of the formation of vinylidene complex of alkyne with subsequent coupling between vinylidene group and ethynyl ligand (nucleophilic attack of RC≡C– group at α‑atom of the vinylidene group). In the case of formation of isomer III, vinylidene mechanism C can be excluded.

The complex with fragment XII was found [176, 178, 194] among the intermediates formed directly from alkyne and ruthenium complex during the dimerization of alkynes. In addition, [177, 193] complexes with [M]-C4 fragment were also synthesized, but their structure XIII was different from that of complex XII:

The transition from complex XII to XIII can be explained by taking into consideration two mesomers of asymmetric η3-allyl complex XIII:

Thus, complexes of types XII and XIII can be considered as key intermediates in the vinylidene mechanisms leading to dimers I, II, IV and V [179, 180, 190, 194, 197, 198].

Vinylidene complexes of ruthenium were probably first obtained from alkynes in 1979 by Bruce and Wallis [201] and then studied in detail (including structures) [176–178, 195] and described in reviews [115, 180, 200–203] and monograph [204]. These reviews considered the possible mechanisms of vinylidene ligand formation and, in addition, it was established that mono- and diethynyl complexes can form from alkynes and vinylidene complexes [177, 178, 181, 184] via the following reaction:

Bullock [195] studied the kinetics of π-methylacetylene complex isomerization to vinylidene complex via the following reaction:

Reaction (X) turned out to be monomolecular (first order with respect to π-complex) with ∆Н0 = 23.4 kcal/mol and \(\Delta {{S}^{ \ne }}\) = 3.9 ± 0.9 cal mol–1 K–1. At 80–110°С, the vinylidene complex converted into CpRuL2(MeCN)+\({\text{PF}}_{6}^{ - }\) complex with methylacetylene evolution. It is interesting to note that the conversion of π-complex into vinylidene complex takes place only at 60–90°С.

Wakatsuki et al. [197] performed quantum-mechanical modeling of the monomolecular transformation of acetylene π-complex with Ru(II) to vinylidene complex with the analysis of various conformations of RuCl2(PH3)2(η2-C2H2) π-complex (XIV) and RuCl2(PH3)2(=C=CH2) complex (XV). A comparison of the results of MP2/6–31G* calculations obtained for the thermal isomerization process

(∆Н0 = –48.7 kcal/mol and ∆Ea =1.07 kcal/mol) to experimental data (∆Н0 = –47.4 ± 4 kcal/mol and ∆Ea = 2 kcal/mol) showed good coincidence [197]. Calculations performed by the same method for various basis sets gave the values about ∆Н0 = – 51.7 kcal/mol and ∆Ea = 0.1 kcal/mol. For the transformation of complex XIV into XV

it was found that ∆Н0\( \cong \) 0 and the barrier of transient state TS2 of reaction XIV → XV was 34.5 kcal/mol. The transient state TS2 (a) forms via intermediate (b) as

with agostic bond

Estimates obtained for the transformation of π‑complex RuCl2(PH3)2(η2-C2H2) (XIV) into a product of oxidative addition of С2Н2 to Ru(II) with the formation of octahedral ethynyl complex Н[Ru](C≡CH) showed that the energy of this complex is much higher than the energy of transient state TS2 so that this transition in the given system is even thermodynamically hardly probable.

Now it is expedient to consider the issue of metal (ruthenium) degree of oxidation (DO) in vinylidene complexes, since carbene ligand is frequently treated as neutral ligand (singlet carbene) donating σ-electron pair to the metal atom. This approach is valid for Fischer carbene complexes. In the case of Schrock carbene complexes (М=СН2 and М=С=СНR), carbene (according to all formal rules) is a ligand with charge –2 that forms σ- and π-bonds with the metal—that is, increases the metal DO by 2 (for commonly accepted approaches to DO definition see [205]). Therefore, the ruthenium DO in a vinylidene complex becomes IV (i.e., increases by 2 as compared to that in the initial π-complex, where it was II) as in [197]. Analogous situation takes place in imides [M2+](=NR2–), nitrides [M3+](≡N3–), and phosphides [M3+](≡P3–) of transition metals. Note also that Ru=С= bonds (1.76 and 1.84 Å [202] and 1.8 Å [181]) are significantly shorter than Ru–С≡ bonds (2.08 and 2.05 Ǻ). The Ru–С bond length in [Ru]–С4 is within 2.07–2.48 Å [177, 192, 193], while the Ru=С= bond length determined via optimization of geometry [197] amounts to 1.63–1.66 Å (depending on the conformation) and the Ru–С≡ bond length in ethynyl complex is 1.95 Å.

The cumulene products of alkyne dimerization are formed as a result of the chain of transformations of intermediates XII and XIII with the shift of Ru atom from position 2 (XII) to 4 (via XIII) as shown in Scheme 7 (where A = alkyne):

Scheme7. Mechanism of synthesis of cumulene isomers IV and V.

It was established as long ago as in 1991 [179] that cumulene Z–H3SiCH=C=C=CHSiH3 has an energy higher by 17–19 kcal/mol than that of the corresponding enynes (I and II), so that the isomerization of cumulenes IV and V to isomers I and II is thermodynamically possible. This possibility was confirmed in experiments with HRuCl(PiPr3)2 complex [190]. Therefore, some stages in Scheme 7 can be kinetically reversible.

In view of the possible realization of the ethynyl mechanism of dimerization (A), it is interesting to note that the process can begin with the formation of a vinylidene complex, which subsequently converts into the ethynyl complex via reaction (IX) [181]. The corresponding mechanism of dimerization is presented in Scheme 8.

Scheme8. Dimerization mechanism А in catalysis with ruthenium complexes.

Note that the last stage–demetalation of intermediate [Ru](σ-C4) with the formation of product I in this mechanism takes place as a result of the metathesis of σ-bonds [Ru]–C and Н–С≡, but the source of H atom in some Ru-based catalytic systems still remains unclear. Bassetti et al. [187] solved the problem of demetalation in the framework of mechanism C at the stage of [Ru](σ-C4) intermediate protolysis in a system containing AcOH.

There are only few examples of the cross-dimerization of alkynes catalyzed by Ru complexes. Yi and Liu [185] used a reaction of RC≡CH addition to internal alkynes R1C≡CR catalyzed by Cp*Ru(C≡CPh)(PPh3) complex (16, Table 3) to obtain PhC≡C–C(R1)C=CHR2 product with 44–90% yield from a vinylidene precursor. A high chemoselectivity was only achieved with R1 = tBu, iBu, SiMe3 and R2 = CO2Et, COMe and amounted to 100% in reaction with tBuC≡CH and MeС≡СMe. This investigation revealed an interesting intermediate (XVI) in mechanism A with agnostic bond [Ru](Н–СН2–):

Katayama et al. [188] described the cross-dimerization of alkynes ArC≡CH with Me3SiC≡CH catalyzed by vinylidene complex RuCl2L2(=C=CHPh). In the case of p-TolC≡CH and L = PiPr3, this reaction in the presence of amines gave predominantly Me3SiC≡CCH=CH(p-Tol) (isomer II) with a yield of 82–93% (depending in the nature of amine) while the content of heme-isomer III varied within 7–14%. The formation of isomer II was considered as a result of the operation of mechanism C, while isomers I and III were formed by mechanism A.

Investigation of alkyne reactions with osmium(II) complexes by Dobson et al. [192] showed that Os(O2CCF3)2(CO)L2, OsH(O2CCF3)(CO)L2 and Os{C(C≡CPh)=CHPh)}(O2CCF3)(CO)L2 complexes catalyzed phenylacetylene oligomerization with the formation of С64Н48 and С90Н80 oligomers and osmium hydride complex catalyzed the formation of isomeric vinyl products of phenylacetylene addition to tolane and methylphenylacetylene.

Various osmium hydride complexes (H[Os], H2[Os], H3[Os] and H4[Os]) react with alkynes to form diverse organometallic compounds (see [206] and references therein) containing alkenyl, alkylcarbyne (alkylidyne), vinylidene, and alkynide ligands, respectively. Complex HOs(=C=CHPh)(η2-O2CCH3)L2 catalyzes PhC2H dimerization to a mixture of isomers I and II. Barbaro et al. [207] thoroughly studied the mechanism of dimerization with the participation of HOs(PP3)(N2)BPh4 complex (PP3 = P(CH2CH2PPh3)3, XVII). It was established that, similar to ruthenium complexes (see above), osmium complex XVII in reaction with Me3SiC≡CH forms (via vinylidene complex H[Os](=C=CHSiMe3)) an intermediate of type ХIII (Os[η3–Me3SiC3=CHSiMe3][BPh4], XVIII) and 1 eq. styrene. In excess of PhC2H, the catalytic reaction proceeds with the formation of isomer II at ~90% yield. Measurements of 1H and 31P (1H) NMR spectra in situ and modeling intermediates and their reactions established the following sequence of phenylacetylene conversions in the presence osmium hydride complexes:

It was found that the catalytic cycle begins and ends with the formation of [Os](C≡CR)+ and involves the formation of active centers

and the catalytic cycle proper

It is interesting to note that, as long ago as in 1985, Gotzig et al. [208] established that the oxidation of complex Os(C≡CPh)L2 (L = PMe3) by silver ion (AgPF6) also yields Os(σ-C4)L4PF6 product as a result of the oxidative coupling of ethynyl groups with detachment of H from solvent and reduction of Ag+ to Ag0.

Reactions of simple hydride complexes HOsCl(CO)(PiPr3)2 with alkynes in the presence of Et2NH led to the formation of butatrienes IV and V, which were stable in the case of R = tBu and Cy [209]. In the case of R = Ph, the obtained butatrienes exhibited polymerization with the formation of oligomers [–CH(Ph)C≡CC(H)Ph)–]n. In the case of R = Me3Si, the butatriene exhibited isomerization to enyne II. It was shown that the role of amine consists in the formation of active intermediates:

Investigations of various osmium pincer complexes showed (see [210] and references therein) that Os complexes were a promising alternative to other metal complex catalysts. For example, a pincer complex with POP ligand, H4Os[POP] (XIX), where РОР = [Xant(PiPr3)2] (XX)

is an active catalyst of alkyne dimerization to isomers II with a yield of 94% (R = Ph, TOF = 100 h–1) and 90% (R = tBu, TOF = 30 h–1). The formation of active catalyst starts from complex XIX and proceeds via the formation of two olefin molecules and liberation of Н2 molecule:

The catalytic cycle is presented in Scheme 9 [210]:

Scheme9. Catalytic cycle with H4Os[POP] (XIX) precursor (reproduced with permission from Inorg. Chem. 52, 6199 (2013) [210]. Copyright (2013) Am. Chem. Soc.).

Catalysts based on iron complexes were rarely used in investigations of alkyne dimerization, but yet gave some interesting results [211–216]. Complexes FeCl2L and HFeClL, HFe(H2)L+ with L = PP3 and [P(CH2CH2PMe2)3] showed generally low activity in alkyne dimerization [211], where Z-isomer (II) was formed from PhC2H selectively but slowly, at a catalyst TOF about 1 turn per day.

However, there were found and studied four isomers of intermediate complexes (PP3)Fe(η3-PhC3C=CHPh)+\({\text{BPh}}_{4}^{ - }\) leading to predominant formation of isomer XXI:

Midya et al. [212, 213] studied simple systems based on FeCl3L complexes (L = dimethylethylenediamide, DMEDA) in the presence of KOtBu and other bases. Reactions with 17 arylacetylenes revealed the formation of a mixture of isomers I and II, with predominant synthesis of isomer I (78–89%). Investigation of the influence of various amines as ligands and radical inhibitors (ТЕМРО) [213] led to the creation of an original mechanism of dimerization with the participation of arylvinyl radicals and a change in the degree of iron atom oxidation (Fe(II) → Fe(III) → Fe(IV) → Fe(II)). The role of KOtBu reduces to the formation of radical anions from ArC2H and subsequent formation of arylvinyl radicals from these anions:

The obtained intermediates interact, e.g., with Fe(III) to form [Fe(IV)](C≡CAr)(CН=CHAr) complex decaying into Fe(II) and isomer I.

Investigation of the reactions of iron pincer complex HFe(BH4)(iPr-PNP) showed selective formation of isomer II (94%) in homodimerization of phenylacetylene and 13 other arylalkynes [214]. In addition, highly selective cross-coupling between ArC2H and Me3SiC2H (Z–isomer II) at 79–99% yield) without any additions. The active catalyst [Fe](BH4)(C≡CAr) formed from the initial complex with Н2 evolution and BH4 ligand retention in the coordination sphere of Fe atom during the catalytic process.

An interesting aminocarbene ligand (XXII) was used by Bhunia et al. [215] in the presence of KOtBu:

Complex Fe(CО)4L with this ligand catalyzed phenylacetylene dimerization at high selectivity with respect to isomer I (82–84%) and large turnover number (6500). The work included discussion of the mechanism of II → I isomerization via metal carbene intermediate and quantum-chemical analysis of the mechanism. However, for unclear reasons, the consideration referred to trans-addition of the ethynyl fragment to alkyne π-complex.

Recently, Liang et al. [216] studied the catalysis of alkyne dimerization by pentamethyl cyclopentadienyl complexes Fe–Ср*Fe(HL)Cl and Ср*Fe(L), where HL = XXIII,

and established extremely high selectivity of reaction with respect to heme-isomer III (>99%) in the case of Ср*Fe(L) complex, which was also highly selective in the cross-dimerization of propargyl alcohol with arylalkynes in which isomer III (ArC≡CC(CH2OH)=CH2) was formed at 90–94% yield. Similar to the case of other metals, the nature of ligands was a significant factor determining selectivity of the process.

In concluding this section, it should be noted that the interest in catalysis with iron complexes in various reactions of organic synthesis has incredibly increased: recent (2015) updated review [217] contains 1651 references.

3.3. Complexes of Rh, Ir, and Co

Catalysts based on Rh(I) complexes have been used in alkyne dimerization (and oligomerization) reactions already at the second and third stages of development of the chemistry of acetylene and its derivatives. Probably, Singer and Wilkinson [218] carried out the first reaction of alkyne dimerization with Rh(I) complex (Wilkinson’s complex RhCl(PPh3)3). It turned out that phenylacetylene was rapidly polymerized and substituted α-hydroxypropargyl amines rapidly dimerized with the formation of isomer I (73%) and π‑complex with RhCl(PPh3)2. Based on these results, the so-called ethynyl dimerization mechanism A was proposed with the formation of an intermediate product of oxidative addition of RC≡CH to Rh(I).

Albano and Aresta [219] studied activity of the cationic complex of cis-Rh(diphos)(CO)2BPh4 in the nonselective oligomerization of МеС2Н into СН2Cl2 and obtained 50% dimers (I/III = 3), 8% linear trimers, 42% isomeric trimethylbenzenes at 60оС. Analogous dimers are formed from α- and β-hydroxy substituted terminal alkynes. At 80°С, the reaction with β-hydroxy derivatives yielded same isomers in III/I ratio from 55/45 to 75/25 [220]. Kinetic measurements showed second order with respect to the alkyne concentration for these substrates. It was also found that additions of AsPh3 and PPh3 ligands to Rh(C8H14)2Cl complex influence the ratio of trimers and dimers: for [L]/[Rh] = 6 and variable [AsPh3]/[PPh3], the ratio of trimers and dimers changes from 1/19 до 6.7/1 [220].

In 1990, it was established [221] that reaction with rhodium complex RhCl(PМе3)3 in acetone yielded a sum of isomers I and III (95–98%) but (in contrast to alkyl alkynes) phenylacetylene did not exhibit dimerization. The analysis of 1Н and 31Р (1Н) NMR spectra measured during 1-pentyne reaction (–65°С) showed evidence of the formation of a π-complex. At –10оС, this complex converted into π-complex isomers Rh(PМе3)3(RC≡CH\()_{2}^{ + }\)Cl– and a mixture of ethynyl complexes НRh(PМе3)3(C≡CR)(RC≡CH)+Cl– (а, b) with the isomer ratio (а)/(b) ≈ 1.5, which is close to the ratio of concentrations of isomeric dimers I/III. An increase in the temperature to 25°С leads to the formation of ethinylvinyl intermediates (c, d),

the first of which, complex (с), leads to product III, while complex (d) leads to product I. The obtained results confirmed realization of the vinyl dimerization mechanism B. Boese and Goldman [222] also confirmed cis-addition of alkyne at Rh–Н bond (in both Markovnikov and anti-Markovnikov mode) and showed that reaction with dimeric complex (RhClL2)2 at 25–50°С yields isomers I and III. The complex with R = Ph yields 100% isomer III, complex with R = tBu yields 100% isomer I, and R = n–Pr leads to 37% isomer I and 63% isomer III.

Investigation of the reaction with π-allyl rhodium complex Rh(η3-C3H5)(PiPr3)2 [223] showed evidence of the operation of dimerization mechanism C via the formation of ethinylvinylidene intermediates. In 2005, same researchers [224] continued studying the intermediates and laws of alkyne dimerization and showed that the ethinylvinylidene intermediate converts via reaction with CO into a type XII complex (σ-C4):

The obtained E-isomer under the action of acids forms isomeric dimers (R = Ph):

Isomerization of the E-isomer of type XII under the action of a strong acid leads to a cumulene product [Rh](RC=C=C=CHR) subsequently converting into dimer IV. Same work thoroughly studied conversions of the ethinylvinylidene intermediate into product XII (E, Z) and then into dimers I, II and butatrienes during thermal and photochemical processes. Interesting conversions were also observes in the case of unsubstituted acetylene:

Here, the oxidative addition of MeI to complex RhCl(CO)L2 stimulates the reaction of dimerization with active complexes of Rh(III) [225]. Besides a small amount of alkyne RC≡CMe (acetone, tetrahydrofuran, СН2Cl2) formed in quantitative amounts in excess MeI, the process of dimerization by mechanism A in the presence of sodium methylate leads to products I and III (80/20, %). The nature of products and selectivity of dimerization significantly depend on the nature of solvent. In acetonitrile, phenylacetylene and methyl iodide yield only methylphenylacetylene, while the reaction of alkynes in methanol with К2СО3 addition in the presence of methyl iodide yields product II (80–99%). Formation of this product was considered as evidence of the operation of mechanism C.

Investigation of the reaction of alkyne addition to diesters of acetylenedicarboxylic acid [226] in solutions of pincer complexes Rh(III)(NCN)(OAc)2(H2O), where NCN is bis-(oxasolinyl)phenyl, allowed Z-isomer of the dimerization product to be obtained with 98–100% yield. There are two pathways of ethynyl intermediate formation in the framework of mechanism A:

In the presence of H2, the ethynyl ligand is formed as a result of the metathesis of σ-bonds H–[Rh] and Н–С≡ according to equation

The rather seldom dimerization product III is formed selectively (90%) in the case of N-substituted propargylamines RNHCH2C≡CH in solutions of RhClL3 and [RhCl(COD)]2 complexes in the presence of 1,1-bis-(diphenylphosphino)ferrocene (dppf) [227]. Isomers III and I in a percentage ratio of 56/8 form from arylalkynes in the case of 8-oxyquinolinate complexes of Rh(I) with COD and in the presence of PPh3 [228]. Catalysis of alkyne dimerization was also observed in solutions of Rh(I) carbene complexes [Rh(NHC)(Cl)(COE)]2 and Rh(NHC)(Cl)(COE)(Py) (XXIV), where COE is cyclooctene and NHC is 1,3-bis-(2,6-diisopropylphenyl)-2-imidasole [229]. For example, complex XXIV catalyzes the formation of 82% III, 4% trimers, and 10% 1,2,4-Ph3С6Н3 from phenylacetylene in С6D6 at 40°С. In excess Py, the same complex leads to 92% III and 6% trimers. In the case of R = tBu, Me3Si, the reaction at alkyne conversion 90–100% leads to product III at 84–98% yield. Intermediates of this process were synthesized and the NMR spectra of π-complexes with PhCH2C≡CH and product I (tBu) and of ethynyl complex Rh[NHC](Cl)(H)(C≡CSiMe3)Py2 were obtained. It has been concluded that complex XXIV is an active universal catalyst operating in the framework of mechanism A for 3—6 h at 100% conversion with 92–95% selectivity.

Catalysts based on Ir and Co complexes were only used in several investigations of the catalysis of dimerization reactions. For example, complex Ir(η2-SNC5H4)(PPh3)2 [230] catalyzed alkyne dimerization by mechanism B with the formation of isomer I (94–100% for R = Ph, tBu, and n-Bu) via intermediate НIr(η2-SNC5H4)(С≡СR)L2.

Detailed experimental and quantum-chemical investigation [231] of the activity of pincer iridium hydride complexes Ir(РСР)(Н)2 (РСР = (2,6-СН2РtBu2)2С6Н3) gave interesting results. Reaction of this metal hydride complex with norbornene (NBE) yields norbornane and π-complex Ir(РСР)(NВЕ), which acts as the active catalyst of PhC2H dimerization with the formation of product I in the framework of mechanism B:

This investigation led to some important observations and conclusions:

(i) The ethynyl hydride complex was more stable (by 29 kcal/mol) than its phenyl analog H[Ir]Ph.

(ii) The reaction of alkyne addition at H–[Ir] bond is fast and yields 1,2-addition product [Ir]–С(Ph)=CH2, but this process is reversible.

(iii) As a result of β-elimination H–[Ir], the 1,2-addition product converts into a π-complex and then slower transforms into the 2,1-addition product [Ir](C≡CPh)(CH=CHPh), which exhibits fast reductive elimination to yield product I.

(iv) Constraints in the formation of С–С bonds is a general feature of the intermediates of type [Ir](C≡CR)(С(R)=CH2) which are related to the screening of Ir atom with substituents of PCP ligands.

(v) Computer simulations showed that the vinyl group in transient state of stage (3) must rotate by 90о for attaining the necessary orientation. This rotation is hindered by significant screening with substituents in the case of α-substituent in the vinyl group. Although the reductive elimination with the formation of С–С bonds reduces stress in the coordination sphere of the metal, the sterical hindrances inhibit the process of dimer elimination.

It should be noted that the observed effects do not require reversibility of the stage of alkyne addition at the М–Н bond. The products of 2,1- and 1,2-addition can also be formed in parallel. In this case, the product of 2,1-addition forms slowly but rapidly converts into a dimer, while the product of 1,2-addition appears rapidly but then slowly transforms into a dimerization product. Naturally, reversibility of the stage of addition would be useful, since it hinders the accumulation of waste intermediates (see kinetics of the asymmetric hydrogenation of olefins [8]).

Investigation of the hydrosilylation of alkynes in solutions of Co(I) complexes [232] established that СоСl(РМе3)3 complex catalyzed phenylacetylene dimerization with the formation of isomer I (78%) and alkyne cyclomerization to 1,3,5-Ph3С6Н3 (19%), while СоСl(РМе3)2(СО)2 complex predominantly catalyzed the formation of isomers I ((76%) and II (13%). The reactions of alkyne dimerization and cycle formation were also catalyzed by CoBr2(dppe) complexes in the presence of Zn0 and Mg0 reducers [233]. The yield of dimer I from phenylacetylene amounted to 47% and the yield of cyclic trimer was 41%.

In concluding this section, it should be noted that the tryad of metals under consideration participates in the catalysis of alkyne dimerization with predominant formation of isomers I, III, IV and linear trimers in complexes with various ligand environments and metals in oxidation states I and III.

3.4. Complexes of Ni, Pd, and Pt

Catalysts based on Ni(0, II) complexes were already studied in reactions of alkyne dimerization and oligomerization [1, 52] at the second and third stages of development of the chemistry of acetylene compounds [234—237] beginning with W. Reppe’s works on carbonylation and cyclization of acetylene and alkynes (see [1, 47, 56]).

A comparison of the reactivity of metals in Group 10 of the Periodic Table (see review [43]) shows that the activation energy of the stage of reductive elimination in reaction

increases in the following order (kcal/mol): Ni (16.5) < Pd (24.9) < Pt (45.8). The same sequence describes growth in the activation energy of the reverse reaction of oxidative addition (kcal/mol): Ni (20.9) < Pd (43.9) < Pt (49.3). The strongest π-complexes with alkynes (and alkenes) are also formed by Ni(0) [43]. The most frequently encountered nickel complexes can be ordered as Ni(II) > Ni(I) > Ni(III) [43]. As for palladium complexes with various metal oxidation states, their accessibility and occurrence can be presently ordered (by data of the author of this review) as Pd(II) > Pd(0) > Pd(I) > Pd(IV) > Pd(III).

The aforementioned properties of nickel complexes also account for the high activity of Ni(CO)2(PPh3)2 complexes in the reactions of linear and cyclic oligomerization of terminal alkynes [234, 235] and polymerization of unconjugated terminal alkynes [236]. In the case of alkyl substituents С2–С5, dimeric products were found to contain isomers I and III [235], while linear trimers contained three branched isomers with structures determined using spectroscopic and chemical methods.