Abstract

Titanium-magnesium catalysts (TMCs) of propylene polymerization have been synthesized in the presence of ketones as internal donors. The molar ratio of titanium chloride to ketone in TMCs was found to depend on the structure of ketone. The composition and catalytic properties of the synthesized TMCs in propylene polymerization were significantly different from those of TMCs prepared without ketone. The TMCs were synthesized by replacing ketones with a stereoregulating donor dibutyl phthalate (DBP, DBP/Mg = 0.05 mol/mol). It was shown that ketones were substituted by phthalate; the crystallite size of MgCl2 (~6.5 nm in the 110 direction) did not change. The data on the molar ratio Ti/donor = 2 for different donors (ketone, phthalate) and the same MgCl2 crystallites are consistent with the predominance of 104 lateral cuts. The catalytic properties of the substituted catalysts are almost independent of the type of ketone used and are close to those of the standard TMC obtained with phthalate alone (DBP/Mg = 0.2 mol/mol) during the formation of MgCl2. Therefore, ketones, like esters, are involved in the formation of magnesium chloride. Their subsequent substitution by phthalate allows synthesis of TMCs with high activity and stereospecificity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Supported Ziegler–Natta titanium–magnesium catalysts (TMCs) are basically the only catalysts for the production of isotactic polypropylene (PP) [1]. They consist of titanium tetrachloride and a stereoregulating electron donor compound (internal donor, ID) on the surface of MgCl2 crystallites used as a support [2, 3]. In propylene polymerization, these TMCs are used in combination with an organoaluminum co-catalyst (usually AlEt3) and another stereoregulating donor (external donor, usually alkoxysilanes). The internal donor provides high isotacticity of PP and affects the stereoregularity of polymer chains and their molecular weight distribution (MWD) (see review [4] and references therein).

The internal donor ID is also involved in the formation of MgCl2 crystallites during the synthesis of the catalyst [5–11]. In modern catalysts, MgCl2 crystallites are formed by the interaction of magnesium-containing compounds with TiCl4 directly during the synthesis of TMC. For this purpose, various ethoxy-containing magnesium derivatives are often used, for example, Mg(OEt)2, MgClx(OEt)2 – x, and MgCl2 ⋅ nEtOH. Their interaction with titanium tetrachloride gives intermediate products, in particular, titanium ethoxychlorides TiCl3(OEt), which form molecular complexes with MgCl2, hindering the final formation of MgCl2 crystallites. The introduction of an internal donor makes it possible to remove the titanium alkoxy derivatives and finally form the MgCl2 crystallites [10, 11].

Thus, the donor controls the catalyst stereospecificity and the properties of PP, on the one hand, and participates in the synthesis of MgCl2 crystallites, providing high catalyst activity, on the other. The donors can occasionally provide the required properties of PP, but are ineffective in the synthesis of MgCl2 crystallites, leading to low catalyst activity. Therefore, two-stage synthesis of TMCs may be more reasonable. Earlier, we synthesized the catalysts in two stages [12]. At the first stage, the catalyst was obtained by the reaction of magnesium ethoxide with titanium tetrachloride in the presence of butyl acetate. This formed magnesium chloride with titanium chloride and butyl acetate adsorbed on the surface of its crystallites (on the lateral cuts). At the second stage, butyl acetate was replaced on the already formed magnesium chloride by the stereoregulating IDs: phthalate, 1,3-diether, diol dibenzoate. The resulting samples were compared with the standard catalysts when magnesium chloride was formed in the presence of IDs. The properties (melt index, MWD) of the polymers obtained on substituted or standard catalysts with the same stereoregulating donor were similar.

It is of interest to use simpler donors with one oxygen atom instead of two (ethyl benzoate, 1,3-diethers) or with more oxygen atoms (phthalate, diol dibenzoate, succinate) in commonly used stereoregulating donors for the formation of magnesium chloride. Here, we used ketones for the synthesis of magnesium chloride at the first stage of the synthesis of the catalyst. At the second stage, ketone was replaced by dibutyl phthalate on the already formed magnesium chloride (as in the case of previous replacements of butyl acetate by different IDs [12]) and the obtained substituted catalysts were compared with the standard TMC synthesized with dibutyl phthalate alone.

EXPERIMENTAL

Materials

Heptane, dibutyl phthalate (DBP), and chlorobenzene were kept over molecular sieves. The commercial TiCl4, propylene, and triethylaluminum, and the reagents (Aldrich) dipropyl ketone (DPK), butylisopropyl ketone (BiPK), butylphenyl ketone (BPhK), diisopropyl ketone (DiPK), isopropyl phenyl ketone (iPPhK), diphenyl ketone (DPhK), and magnesium ethoxychloride (MEC) were used without additional purification.

Synthesis of Catalysts with Ketones

Solid MEC of the composition Mg(OEt)nCl2–n with a particle size of 25 µm was used ready-made (prepared according to [13]). The catalysts with ketones were obtained by the interaction of MEC with TiCl4 in the presence of chlorobenzene (TiCl4/chlorobenzene = 1, v/v). The synthesis was performed in three stages in an argon atmosphere. At the first stage, TiCl4 was loaded in the reactor and heated to 100°C, then MEC was introduced; after 5 min, chlorobenzene was added (TiCl4/Mg = 13 mol/mol). Then the temperature was raised to 110°C, ketone (K, K/Mg = 0.3 mol/mol) was added, and the reaction mixture was kept at 110°C for 1 h. After the stirrer was stopped and the solid settled, the mother solution was decanted. At the second stage, a mixture of TiCl4 and chlorobenzene (TiCl4/chlorobenzene = 1, v/v, TiCl4/Mg = 13 mol/mol) was loaded in the reactor, the reaction mixture was stirred at 110°C for 30 min, and the mother solution decanted after precipitation of the solid product. The third stage repeated the second. The resulting catalysts were washed four times with heptane with a gradual decrease in temperature: 75–60–45°C–Troom for a total of 40 min.

Synthesis of Substituted Catalysts

Substituted TMCs were synthesized similarly to catalysts with ketones, with some differences at the first stage: a TiCl4/chlorobenzene mixture (1 : 1, v/v) was loaded in the reactor at room temperature, TMC (TiCl4/Mg = 13 mol/mol) with the corresponding ketone was introduced instead of MEC, and then DBP was added at 110°C (DBP/Mg = 0.05 mol/mol). The second and third stages were performed in the same way as in the synthesis of TMC with ketones.

Synthesis of TMCs without a Donor. Synthesis of Comparative and Standard Catalysts

TMCs without a donor were obtained similarly to TMCs with ketones, but without ketone addition. The comparative TMC was synthesized similarly to substituted TMCs, but TMC without a donor was introduced instead of TMC with ketone. The standard TMC was prepared in the same way as TMCs with ketones, but with a phthalate (DBP/Mg = 0.2 mol/mol) instead of ketone addition.

Chemical Analysis

The Ti and Mg contents were determined by inductively coupled plasma atomic emission spectroscopy on an Optima 4300 DV instrument (Perkin-Elmer, United States) from a catalyst solution in an aqueous 5% H2SO4 solution. The contents of ethoxy groups (in the form of ethanol) and nonaromatic donors were measured by gas chromatography on a Kristall-2000 instrument (Chromatec, Russia) with a flame ionization detector from a catalyst solution in methyl cellosolve on a Carbowax-20M capillary column (30 m × 0.32 mm) at 220°C using the NetChrom v2.0 program. Decyl alcohol was used as an internal standard. The content of aromatic donors was determined by liquid chromatography on an LC-20 Prominence instrument (Shimadzu, Japan) with a UV detector from an acetonitrile solution of the catalyst on a RESTEK Pinnacle II C18 5-μm column (250 × 4.6 mm) at 40°C. Dimethyl phthalate served as the internal standard.

XRD Analysis

The XRD study of TMC was performed on a NEW D8 ADVANCE diffractometer (Bruker, Germany) using CuKα radiation (λ = 1.54184 Å) in the range of 2θ = 5°–75°. The size of the coherent scattering region (CSR) in the 110 direction was calculated from the peak at 2θ = 50° using the Scherrer formula.

Propylene Polymerization

Propylene was polymerized in an autoclave in heptane (300 mL) at a temperature of 70°C and a total pressure of 7 bar for 1 h in the presence of hydrogen (1 vol % in the gas phase). Triethylaluminum (4 mmol AlEt3/L) was used as a cocatalyst, and cyclohexylmethyldimethoxysilane (CHMDMS, Al/Si = 20 mol/mol) was used as an external donor. The catalyst sample was ~10 mg. Before polymerization, prepolymerization was performed at 30°C and a propylene pressure of 1 bar for 2 min. The content of atactic PP (APP) was determined as the percent of the PP fraction soluble in polymerization heptane.

XS Measurements

The percent of the low-stereoregular PP fraction soluble in xylene (XS) was determined according to ASTM D5492.

RESULTS AND DISCUSSION

TMCs Synthesized with Various Ketones as Internal Donors

Table 1 lists the data on the composition of the catalysts synthesized with various ketones as internal donors. The catalysts contain 3.8–4.2% titanium, 16.6–17.6% magnesium, and 6.1–8.6% ketone. If titanium and magnesium are assumed to be present in the form of chlorides in the catalysts, the total content of MgCl2, TiCl4, and ID can be evaluated. It ranges from 87 to 93% for different TMCs, which is relatively close to 100%. The TMCs with different ketones are similar in composition, but differ significantly from TMC obtained without a donor. The TMC without a donor contains 7.8% titanium and 4.2% ethoxy groups as a by-product of titanation of TiCl3(OEt) [10]. The lower content of titanium (4%) and ethoxy groups (0.35–1.5%) in TMCs synthesized in the presence of ketones indicates that ketones remove the TiCl3(OEt) by-product, thus participating in the formation of MgCl2 crystallites similarly to esters.

Figure 1 demonstrates how the Ti/Mg, K/Mg, and (Ti + K)/Mg (K is ketone) molar ratios change in the obtained catalysts depending on the ketone used. The ketones are arranged in Fig. 1 (and in Table 1) in a series according to the increasing volume of substituents (branching at the carbon atom closest to oxygen): propyl (butyl) < phenyl < isopropyl. The K/Mg molar ratio tends to decrease slightly (from 0.078 in the case of DPC to 0.059 for DiPC) in the series, in which the Ti/Mg molar ratio increases simultaneously (from 0.105 to 0.126, respectively). As a consequence, the Ti/K molar ratio increases substantially (from 1.3 to 2.2) in this series.

Note that the total molar ratio (Ti + K)/Mg remains virtually unchanged and equals 0.182–0.186 for different catalysts. This may indicate that the number of chlorine vacancies on the lateral cuts of the formed MgCl2 crystallites on which TiCl4 and donor are adsorbed is approximately the same. The donors are presumably adsorbed first because of the higher affinity for MgCl2 compared to TiCl4. The remaining available chlorine vacancies are occupied by titanium chloride. Ketones with bulkier substituents are adsorbed less densely (with greater distances between adjacent ketones) for steric reasons, which increases the adsorption of titanium chloride. This can explain the observed tendencies in the changes in the Ti/Mg, K/Mg, and (Ti + K)/Mg molar ratios in Fig. 1.

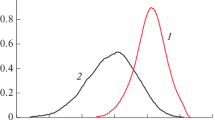

According to the XRD data for the catalyst prepared with DPhK (curve 1, Fig. 2), the size of the coherent scattering region (CSR or crystallite size) of MgCl2 in the 110 direction (along the Cl–Mg–Cl layer) is 6.4 nm.

Table 2 and Fig. 3 (time dependence of polymerization rate) shows the results of propylene polymerization on the obtained catalysts. TMCs with ketones have the high initial polymerization rate (activity) (16–22 kgPP \({\text{g}}_{{{\text{cat}}}}^{{ - 1}}\) h–1), which quickly decreases during polymerization. The average activity is 6.6–9.5 kgPP \({\text{g}}_{{{\text{cat}}}}^{{ - 1}}\) h–1. The isotacticity of the obtained PP is mainly 86–87% for different ketones. The content of the atactic PP fraction soluble in heptane during polymerization is 10–12%.

Note that the catalyst synthesized without a donor has low initial (7.5 kgPP gcat–1 h–1) and average (1.5 kgPP gcat–1 h–1) activities, as well as lower stereospecificity (the isotacticity of PP is 78.8%).

Thus, the data on the composition and catalytic properties of TMCs with ketones indicate that ketones are involved in the formation of the catalyst (MgCl2 crystallites) and provide high activity of TMCs.

TMCs Synthesized by Substitution of Ketones with Dibutyl Phthalate

Table 3 shows the compositions of the catalysts synthesized by replacing ketones with dibutyl phthalate at a molar ratio DBP/Mg = 0.05. They contain 2.9–3.2% titanium, 16.1–17.2% magnesium, and 6.9–8.6% DBP. It can be seen that phthalate almost completely replaces the aliphatic ketones. The content of aromatic ketones in the substituted TMCs is insignificant: 0.25, 0.4, and 1.2% for iPPhK, BPhK, and DPhK, respectively. The distinction of aromatic ketones from aliphatic ketones is apparently associated with increased donor properties of the oxygen atom in them because of the mesomeric effect of the benzene ring. If titanium and magnesium are assumed to be present in the form of chlorides in the catalysts, it is possible to calculate the total content of MgCl2, TiCl4, and ID, which is 85–89% for different TMCs.

According to the XRD data for the substituted catalyst (curve 2, Fig. 2), the CSR (crystallite) size of MgCl2 in the 110 direction is 6.6 nm, which is close to 6.4 nm for the catalyst before donor substitution (curve 1, Fig. 2). This indicates that MgCl2 crystallites formed in the presence of ketone are stable at the stage of donor substitution. Earlier, similar data were obtained for the replacement of butyl acetate by stereoregulating internal donors [12].

According to Table 4, the activity of substituted TMCs is high, mainly ranging from 11.6 to 13.8 kgPP \({\text{g}}_{{{\text{cat}}}}^{{ - 1}}\) h–1 (10.2 kgPP \({\text{g}}_{{{\text{cat}}}}^{{ - 1}}\) h–1 for BiPK). They are more stable than TMCs with ketones and demonstrate higher polymerization rate (Fig. 4 vs. Fig. 3) and stereospecificity (0.7–1.3 vs. 10–12% APP; polymer isotacticity is 93.6–96 vs. 86–87%).

Thus, the introduction of phthalate with a DBP/Mg molar ratio of 0.05 significantly changes the composition and catalytic properties of TMCs.

Comparison of Substituted TMCs with the Catalysts Obtained with DBP Alone

Table 4 shows for comparison the data for the catalysts obtained by the standard procedure with DBP alone (without ketone) at molar ratios of DBP/Mg = 0.05 (comparative TMC) and 0.2 (standard TMC).

The comparative TMC (DBP/Mg = 0.05) contains 3.9% titanium, 15.6% magnesium, and 7.6% DBP. It has low activity (3.3 kgPP \({\text{g}}_{{{\text{cat}}}}^{{ - 1}}\) h–1) and low stereospecificity (the isotacticity of PP is 91.8%).

The standard TMC (DBP/Mg = 0.2) contains less titanium (2.6%) and more phthalate (9.5% DBP), as well as 1.4% diethyl phthalate (DEP) and 0.5% ethylbutyl phthalate (EBP), which form during the exchange between the OBu and OEt groups because of the side interaction of DBP with TiCl3OEt during the synthesis of the catalyst. The activity of the standard TMC (12.9 kgPP \({\text{g}}_{{{\text{cat}}}}^{{ - 1}}\) h–1) and isotacticity of the obtained polymer (97.4%) are high.

Table 5 and Fig. 5 compare the data on the composition, activity, and stereospecificity for the comparative, standard, and substituted TMCs. The substituted TMCs are closer in composition to the standard catalyst than to the comparative one. They also have significantly higher activity and stereospecificity than the comparative TMC and are also close to the standard TMC in these properties. The introduction of phthalate alone in an amount of DBP/Mg = 0.05 is evidently insufficient for the formation of MgCl2 crystallites and stereospecific active sites. At the same time, addition of the same amount of phthalate (DBP/Mg = 0.05) to magnesium chloride already formed in the presence of ketones affords highly active and highly stereospecific catalysts. Consequently, ketones are involved in the formation of MgCl2 crystallites and are then replaced by phthalate, forming stereospecific active sites. It can be concluded that at the stage of formation of MgCl2 crystallites, ketones act similarly to esters, e.g., butyl acetate [12] or phthalate [10, 11].

Table 5 also shows the data on the CSR (crystallite) sizes of MgCl2 in the 110 direction obtained by XRD (Fig. 2) for the standard and substituted catalysts. They are 7.9 and 6.6 nm, respectively. Consequently, the use of ketones at the stage of formation of MgCl2 crystallites affords TMCs with smaller crystallites, which is important for the synthesis of highly active catalysts.

Distribution of Donor and TiCl4 on MgCl2

As is known, titanium chloride and the donor in TMC are adsorbed on the lateral cuts of MgCl2 crystallites as magnesium ions have chloride vacancies on these cuts. The proportion of these magnesium ions is higher when the size of MgCl2 crystallites in the 110 direction (along the magnesium chloride layer) is smaller. It can be evaluated from the catalyst composition as the (Ti + K)/Mg molar ratio. According to Table 1, this ratio has similar values (0.182–0.186) for different ketones. It can be assumed that the sizes of MgCl2 crystallites formed in the presence of different ketones are also close.

At the same time, the Ti/Mg and K/Mg molar ratios depend on the ketone used. When the volume (branching) of alkyl groups increases, the K/Mg molar ratio slightly decreases from 0.078 to 0.059, while the Ti/Mg molar ratio simultaneously increases from 0.105 to 0.126 (Fig. 1). As a result, the Ti/K molar ratio, which characterizes the distribution of the donor and titanium chloride along the lateral cut, increases more appreciably in this series of ketones (from 1.34 to 2.16).

It is logical to think that ketone with one oxygen atom forms a complex with one magnesium ion. If we assume that ketone cannot occupy adjacent magnesium ion sites on the 104 lateral cut (with a distance between magnesium ions of 0.36 nm) for steric reasons under the given conditions (otherwise, it would be impossible for TiCl4 to be adsorbed on MgCl2), then the magnesium ion sites adjacent to ketone will be occupied by TiCl4. It is believed that TiCl4 is adsorbed on magnesium ion sites in monomer or dimer form [14, 15 and references therein]. Then, in the former case, TiCl4 and ketone will alternate on the lateral cut of MgCl2 as …KTiKTiKTiKTi…, and the Ti/K molar ratio will be 1. In the latter case (formation of TiCl4 dimers among ketones), their distribution will be …KTiTiKTiTiKTiTi…, and Ti/K = 2. Apparently, with an increase in the volume of ketone alkyls, the stability of ketone complexes with magnesium ions decreases and becomes lower than that for dimeric TiCl4 complexes. As a result, the Ti/K molar ratio will increase from 1 to 2. Thus, the observed increase in the Ti/K molar ratio in the series of ketones under study is apparently associated with an increase in the fraction of TiCl4 dimers compared to that of the monomer form of TiCl4.

In the substituted catalysts, the Ti/Mg and donor/Mg molar ratios (Table 3) are lower than in the starting catalysts synthesized in the presence of ketones (Table 1). This can be explained by the fact that phthalate forms complexes with two magnesium ions, while ketone forms complexes with one magnesium ion. The fraction of magnesium ions with chlorine vacancies in the case of substituted catalysts can then be evaluated as (Ti + 2DBP)/Mg (or (Ti + 2DBP + K)/Mg in the case of aromatic ketones). According to Table 3, this ratio is 0.175–0.185 for the four substituted TMCs, which is close to (Ti + K)/Mg = 0.182–0.186 for the catalysts prepared with ketones (Table 1). For the same substituted TMCs, the Ti/DBP molar ratio is 2–2.2, which indicates that the distribution of TiCl4 dimeric complexes between phthalates is …DBPTiTiDBPTiTiDBPTiTi…. Note that in this case, the formation of complexes of the TiCl4 dimer and donor requires four magnesium ions, but not three as in the case of a similar distribution for ketones. Therefore, when ketone is replaced by phthalate, we can expect that the Ti/Mg and donor/Mg molar ratios will decrease in a ratio of 4 : 3, i.e., 1.33-fold. This corresponds to the afore-mentioned change in the titanium content in TMCs with ketones and in substituted TMCs (~4% vs. ~3%). Presumably, at the stage of the replacement of ketone by phthalate, complete rearrangement of surface complexes occurs, including the desorption of ketone and TiCl4 dimers among ketones followed by the adsorption of phthalate and new TiCl4 dimers among phthalates.

For two substituted catalysts, higher values of Ti/DBP = 2.4–2.5 are observed because of the lowered DBP/Mg = 0.35–0.37 (vs. 0.042–0.044 for other catalysts) (Table 3). Possibly, a slightly smaller amount of phthalate was introduced in the syntheses of these substituted catalysts, which just led to a decrease in DBP/Mg. The presence of a noticeable residue of ketone was not observed in this case, evidently because of the lower concentration of ketones in the mother solution: K/Mg = 0.073–0.078 (the amount of ketone in the TMC) at the stage of substitution compared to K/Mg = 0.3 in the synthesis of the catalyst with ketone. If small amounts of phthalate are used (DBP/Mg below 0.05), the magnesium ions between the titanium atoms will partially remain with an unoccupied chlorine vacancy because the amount of phthalate is insufficient and TiCl4 cannot occupy all the magnesium ion sites (on the 104 cut with an Mg–Mg distance of 0.36 nm). As a result, the Ti/donor molar ratio can be higher than two.

Note that the distribution of TiCl4 and donors is not discussed in relation to the 110 lateral cut of MgCl2 for the following reasons.

1. It is known that the 110 lateral cut, which contains four-coordinate magnesium ions with two chlorine vacancies, is thermodynamically less stable than the 104 lateral cut, which contains five-coordinate magnesium ions with one chlorine vacancy. It was shown [6] that MgCl2 · nEtOH · mID complexes formed crystallites with angles of 90° and 120° (110 and 104 lateral cuts) when ethyl benzoate or phthalate was used as ID and crystallites with angles of only 120° (110 lateral cut according to [6]) when 1,3-diether was used as ID. The authors assumed that, in the latter case, the 1,3-diether bidentate donor stabilized the preferable formation of the less stable 110 lateral cut relative to the 104 cut. In our case, the lateral cuts of MgCl2 crystallites form in the presence of ketone—a donor with one oxygen atom. Therefore, in contrast to the synthesis with 1,3-diether, there is no reason to expect the preferable formation of the unstable 110 lateral cut.

2. The molar ratio Ti/K = 2 for some TMCs obtained with ketones (Table 1) indicates that TiCl4 is distributed on the lateral cut of MgCl2 crystallites in the form of dimers among ketones. According to the data of many studies ([2–4] and references therein), isolated TiCl4 complexes with distances of 0.63 nm between magnesium ions form on the 110 lateral cut. If a TiCl4 complex can again form near the TiCl4 complex on this cut (in accordance with Ti/K = 2), then TiCl4 complexes can also appear in the form of trimers and longer chains. In this case, for TMCs with a large fraction of 110 lateral cuts, the Ti/K molar ratio should be significantly higher than 2. If, however, complexes with ketone preferably form on the 110 cut in these TMCs (instead of complexes with TiCl4), then Ti/K should be significantly lower than 2.

3. For some substituted TMCs, Ti/DBP = 2 (Table 3) also indicates that TiCl4 is distributed in the form of dimers among the DBP complexes. Because of the large distances between magnesium ions (0.63 nm), their complexes with DBP can be arranged one after another on the 110 lateral cut, preventing the formation of complexes with TiCl4. For TMCs with a large proportion of 110 lateral cuts, however, the Ti/DBP molar ratio should then be significantly lower than the resulting Ti/DBP = 2 (Table 3).

Thus, the data on the molar ratios Ti/K = 2 and Ti/DBP = 2 found for two very different donors and the same MgCl2 crystallites are quite consistent with the presence of MgCl2 crystallites with 104 lateral cuts and an insignificant fraction of 110 cuts in the synthesized TMCs.

CONCLUSIONS

TMCs with different ketones as an internal donor and without a donor have been synthesized. TMCs with ketones contain much less titanium and ethoxy groups than the catalyst prepared without a donor. Consequently, ketones remove the products of interaction of the magnesium-containing compound with TiCl4 (in particular, titanium ethoxychlorides) and are involved in the formation of magnesium chloride crystallites. The K/Mg molar ratio slightly decreased (from 0.078 to 0.059) in the synthesized catalysts, while the Ti/Mg molar ratio simultaneously increased (from 0.105 to 0.126) when the size of ketone substituents (branching at the carbon atom adjacent to oxygen) increased. As a consequence, the Ti/K molar ratio in this series of ketones noticeably increased (from 1.3 to 2.2); this may be associated with an increase in the proportion of the dimer TiCl4 complexes compared to that of the monomer TiCl4 complexes formed between ketones on the lateral cuts of MgCl2 crystallites.

In propylene polymerization, the TMCs with ketones have high initial (16–22 vs. 7.5 kgPP \({\text{g}}_{{{\text{cat}}}}^{{ - 1}}\) h–1) and average (6.6–9.5 vs. 1.5 kgPP \({\text{g}}_{{{\text{cat}}}}^{{ - 1}}\) h–1) activity and higher stereospecificity compared to TMC without ketone. Thus, the data on the composition and catalytic properties of TMCs with ketones indicate that ketones are involved in the formation of MgCl2 crystallites, providing high activity of TMCs.

The TMCs were synthesized by replacement of ketones by dibutyl phthalate (DBP/Mg = 0.05 mol/mol); comparative (DBP/Mg = 0.05 mol) and standard (DBP/Mg = 0.2 mol/mol) TMCs with phthalate alone were also prepared. Phthalate almost completely replaces the aliphatic and to a large extent, aromatic ketones. The substituted catalysts are closer in composition to the standard rather than comparative TMC. The change in the Ti/Mg and donor/Mg molar ratios at the stage of substitution of ketone by phthalate corresponds to the assumption that phthalate forms complexes with two magnesium ions on the 104 lateral cut, while ketone forms complexes with one magnesium ion. It is believed that this is accompanied by a complete rearrangement of the surface complexes with desorption of ketone and TiCl4 dimers followed by adsorption of phthalate and new TiCl4 dimers between phthalates. The data on the molar ratio Ti/donor = 2 for very different donors (ketone, phthalate) and the same MgCl2 crystallites are consistent with the presence of predominantly 104 lateral cuts and a small fraction of 110 cuts in them.

According to the XRD data, the size of MgCl2 crystallites in the 110 direction remains almost unchanged when ketone is replaced by phthalate (6.4 and 6.6 nm, respectively); the MgCl2 crystallites formed in the presence of ketone remain at the stage of donor substitution. These values are smaller than the size of MgCl2 crystallites for the standard catalyst (7.9 nm); i.e., in the presence of ketone, small MgCl2 crystallites can be obtained for the synthesis of TMCs with high activity.

The substituted TMCs have significantly higher activity and stereospecificity than the comparative catalyst and are close to the standard TMC in the composition and properties. Thus, ketones are involved in the formation of MgCl2 crystallites like esters. Their replacement by DBP makes it possible to preserve the structure of MgCl2 and obtain highly efficient TMCs.

REFERENCES

Ali, S., Catal. Rev., 2014, vol. 27, p. 7.

Barbe, P.C., Cecchin, G., and Noristi, L., Adv. Polym. Sci., 1987, vol. 81, p. 1.

Albizzati, E., Giannini, U., Collina, G., Noristi, L., and Resconi, L., Polypropylene Handbook, Moore E.P., Jr., Ed., Cincinnati: Hanser-Gardner, 1996, p. 11.

Taniike, T. and Terano, M., Adv. Polym. Sci., 2013, vol. 257, p. 81.

Chadwick, J.C., Morini, G., Balbontin, G., Camurati, I., Heere, J.J.R., Mingozzi, I., and Testoni, F., Macromol. Chem. Phys., 2001, vol. 202, p. 1995.

Andoni, A., Chadwick, J.C., Niemantsverdriet, H.J.W., and Thune, P.C., J. Catal., 2008, vol. 257, p. 81.

Makwana, U., Singala, K., Patankar, R.B., Singh, S., and Gupta, V.K., Macromol. Chem. Phys., 2009, vol. 210, p. 69.

Singh, G., Kaur, S., Makwana, U., Patankar, R.B., and Gupta, V.K., J. Appl. Polym. Sci., 2012, vol. 125, p. 896.

Song, B.G. and Ihm, S., Appl. Polym. Sci., 2014, vol. 131, p. 40536.

Chumachenko, N.N., Zakharov, V.A., Bukatov, G.D., and Sergeev, S.A., Appl. Catal., A, 2014, vol. 469, p. 512.

Chumachenko, N.N., Zakharov, V.A., Sergeev, S.A., and Cherepanova, S.V., Polyolefins, 2017, vol. 4, p. 111.

Bukatov, G.D., Maslov, D.K., Sergeev, S.A., and Matsko, M.A., Appl. Catal., A, 2019, vol. 577, p. 69.

RU Patent 2191196C1, 2002.

Potapov, A.G., Kriventsov, V.V., Kochubey, D.I., Bukatov, G.D., and Zakharov, V.A., Macromol. Chem. Phys. 1997, vol. 198, p. 3477.

Monaco, G., Toto, M., Guerra, G., Corradini, P., and Cavallo, L., Macromolecules, 2000, vol. 33, p. 8953.

ACKNOWLEDGMENTS

We are grateful to S.A. Sergeev for supplying us with a magnesium ethoxychloride sample and to L.V. Vorontsova for determining the donor contents in the catalysts. The studies were conducted using the equipment of the Center of Collective use “National Center of Catalyst Research.”

Funding

This study was supported by the Ministry of Science and Higher Education of the Russian Federation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by L. Smolina

Abbreviations and notation: TMC, titanium-magnesium catalyst; DBP, dibutyl phthalate; PP, polypropylene; APP, atactic polypropylene; MWD, molecular weight distribution; ID, internal donor; OEt, ethoxy group; DPK, dipropylketone; BiPK, butylisopropylketone; BPhK, butylphenylketone; DiPK, diisopropylketone; iPPhK, isopropylphenylketone; DPhK, diphenylketone; MEC, magnesium ethoxychloride; K, ketone; DEP, diethylphthalate; EBP, ethylbutylphthalate; CHMDMS, cyclohexylmethyldimethoxysilane; CSR, coherent scattering region; XRD, X-ray diffraction analysis; XS, the percent of low-stereoregular fraction of PP; XI, isotacticity of PP.

Rights and permissions

About this article

Cite this article

Maslov, D.K., Bukatov, G.D. Synthesis of Titanium–Magnesium Catalysts for Propylene Polymerization: Substitution of Ketones by Dibutyl Phthalate. Kinet Catal 62, 89–97 (2021). https://doi.org/10.1134/S0023158420060075

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0023158420060075