Abstract—

The description of detectors based on measuring the secondary-emission current and results of their tests are presented. Multichannel profilometers with a range of n × 103 to 109 ions/(cm2 s) have been created. This range is largely overlapped with the range from a few units to 106 ions/(cm2 s), which is characteristic of scintillation and semiconductor detectors. Current profilometers are used in the region of the overlap to monitor their degradation under exposure to the beam. The current profilometers are used in the transit of low-intensity beams, and their sensitivity is higher than the sensitivity of Al2O3 phosphors and Faraday cups by four orders of magnitude. A three-lamel probe has been created based on the secondary emission to measure the current of the internal accelerator beam with a lower-range value of 0.1 pA.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Beams of accelerated heavy ions with a low intensity ranging from a few units to 107 ions/(cm2 s) have found many applications, such as testing of electronic circuits or biological research. Diagnostics of such beams is usually carried out using scintillator or semiconductor detectors. Unfortunately, scintillators and semiconductors degrade under bombardment with an ion beam, possibly in different manners due to some differences in their individual properties or in the counting ability. Thus, a device is needed that can be used to monitor the degree of their degradation.

This problem can be solved using another detector, which is not subjected to degradation and is operable in this range of intensities. The ratio of readings of degrading and non-degrading detectors can be periodically measured. The non-degrading device should be easy to manufacture and have minimal maintenance requirements. A multiwire profilometer based on the principle of measuring the secondary-emission current could be used as the non-degrading device; e.g., see [1]. The disadvantage of this device is the ability to estimate the degradation only near the maximum limit of the counting ability of scintillation detectors, which is of the order of 106 ions/(cm2 s). In this case, the estimation accuracy is reduced by the contribution of noise pickup at the profilometer wires to the measured current. Due to the noise pickup, the indicated flux density is the lower limit of its applicability.

Shielding and proper grounding are the elementary methods for noise suppression [2]. The use of these methods has made it possible to create a multichannel device on the principle of measuring the secondary-emission current for monitoring the degradation of a profilometer based on scintillation detectors [3], which is used to measure the inhomogeneity of an ion beam in testing electronic circuits.

A PROFILOMETER BASED ON NINE SCINTILLATORS FOR USE IN A HEAVY-ION BEAM

In [3], the testing of electronic circuits was carried out using a technique based on international standards, e.g., in [4]. In accordance with these standards, a number of requirements are specified for the test procedure and, in particular, for ion beams. Testing should be carried out using a collection of ions with different values of their linear energy transfer in materials of tested samples. According to the requirements of these standards, the following parameters should be measured: the ion flux density ranging from a few units to 105 particles/(cm2 s), the fluence as high as 107 particles/cm2, and the beam homogeneity over the irradiated sample. Accelerated beams of ions ranging from oxygen to bismuth with energies of 14−60 MeV/nucleon were used in [3], and a profilometer that is part of the equipment was created to monitor the required beam parameters over an area 60 mm in diameter.

The profilometer consists of nine organic scintillators, whose light signals are fed to nine photomultiplier tubes (PMTs) over optical fibers. The scintillators are arranged in three lines, each with three scintillators located in at distances of 2.2 cm between their centers. The area of the scintillators is 1 cm2. The profilometer is placed into the ion guide during beam alignment and during periodic verification of the distribution uniformity before each new exposure. The required inhomogeneity of the beam should not exceed 20%.

The similarity of the counting characteristics of all nine scintillation detectors is monitored by track detectors [5] upon each change in the type of accelerated ions. If dissimilarities are detected, the counting characteristics are corrected and a new test is carried out using the track detectors. The entire process takes 3−4 h. Therefore, a device is needed with which degradation could be monitored promptly.

This process can be significantly by using the created non-degrading multichannel profilometer that is based on the principle of measuring the secondary-emission current. Its characteristics change upon a change of the type of ions, but remain constant for each specific ion type, regardless of the exposure time.

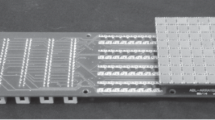

DESCRIPTION OF A NON-DEGRADING 25-CHANNEL PROFILOMETER

The created profilometer based on measuring the secondary-emission current consists of 25 measuring metal plates with an area of 1 cm2, which are arranged in five lines with five plates in each. Each line of plates is surrounded by a trough-shaped shield, which in turn is surrounded by another trough-shaped shield. The second shield is grounded, while the first is kept at a voltage of +9 V supplied from a Krona battery, due to which almost all secondary-emission electrons from the measuring plates are collected onto the shield. The other pole of the cell is connected to the grounded second shield. The entire structure is placed on a substrate measuring 8 × 8 cm, which can be remotely introduced into the ion beam. The insulation between the measuring plates and the shields is made of Al2O3 ceramic. The structure withstands heating to 300°C. The temperature is limited by the presence of Teflon insulation of the connecting wires. The current from each of the 25 plates is measured using two 16-channel current amplifiers [6]. The II16-03 amplifier that is used has been designed to measure currents in the range of ±1 nA. The total measurement time of all 16 channels is 267 ms. The polling frequency is 1 s–1.

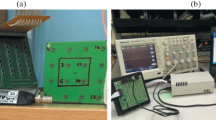

The amplifiers are placed in a standard Eurocard rack. The main micromodule of the system is SMARTBOX-6 [6]. This provides the functioning of the system and its communication with an external computer of the control system via the TCP/IP and USB interfaces. Information is transmitted to the computer.

The trough shields are open towards the beam and do not prevent accelerated ions from hitting the plates. The double shielding of the measuring plates is used in the described construction. It has been experimentally established that the shielding coefficient remains high when the measuring plate is located at the bottom of the trough shield and the wall height is not less than the width of its bottom.

Figure 1 shows a fragment of the profilometer drawing, which demonstrates the mutual positions of one of the measuring plates and the shields.

Figure 2 shows the images from the screen of an external control computer during measurements using the current multichannel profilometer in the absence of a beam (Fig. 2a) and in the presence of an 84Kr ion beam with an energy of 22.9 MeV/nucleon and a flux density of 5 × 104 ions/(cm2 s) (Fig. 2b), and during measurement of this beam using a 9-channel scintillation profilometer (Fig. 2c).

Images from the screen of an external control computer during measurements using the multichannel current profilometer (a) in the absence of the beam, (b) with an 84Kr ion beam with an energy of 22.9 MeV/nucleon and a flux density of 5 × 104 ions/cm2, and (c) during measurements of this beam using the 9-channel scintillation profilometer.

A comparison of the readings of a multichannel current profilometer and the 9-channel scintillation profilometer was carried out at beam flux densities ranging from 0 to 106 ions/(cm2 s). Complete linear correspondence was observed. Based on this correspondence and the mean dark current in the absence of a beam, we established the minimum beam density Nmin above which the multichannel current profilometer is applicable. This value depends on the ion type and energy. The quantity numerically equal to 1/Nmin is taken as the detector efficiency. Figure 3 shows the dependence of the efficiency of the current profilometer on the differential energy loss of ions in stainless steel, i.e., the material of the measuring plates. This graph was constructed based on the measurements with Ar, Kr, Xe, and Bi ions. As expected, this dependence is almost linear.

As follows from the results of their measurements, the developed profilometer with the II16-03 current amplifier can be used to monitor the degradation at ion flux densities ranging from n × 103 to n × 107 ions/cm2 s. This range is largely overlapped with the operating range of scintillation and semiconductor detectors; degradation in the region of the overlap can be monitored with a high accuracy. It can be noted that the upper limit of measurements with the developed profilometer can be expanded to 109 ions/(cm2 s) if the II16-02 current amplifier capable of measuring the current in the range of ±100 nA is used. At the same time, operation without external cooling is still possible.

The created non-degrading profilometer is also used for preliminary tuning of the ion beam to obtain a uniform distribution before it is used to test electronic circuits. This prolongs the life of the scintillation profilometer, without which it is impossible to monitor the beam homogeneity in the counting mode in accordance with the requirements of the methodology [3].

DESCRIPTION OF A NON-DEGRADING 13-CHANNEL PROFILOMETER

In view of the fact that the developed profilometer successfully operates in the range of low-intensity beams, we decided to manufacture a detector of this type for diagnostics during transit of the beams through the ion guide from the accelerator to the end user. In normal practice, beams with a current as high as 10 µA are used in physical experiments at the accelerators of the Laboratory of Nuclear Reactions, while water-cooled unshielded Faraday cups and phosphors made of quartz or Al2O3 are used for beam transit. As indicated in [2], the luminescence intensity of phosphors is also subject to degradation under exposure to the beam.

The profilometer for diagnostics in transit of low-intensity beams was produced according to the above principle, but has only 13 measuring plates, whose current is measured using a single II16-03 16-channel amplifier. The profilometer was located at the intermediate focus of two dipole bam-deflecting magnets of the ion beam transit system.

Figure 4 shows the image from the screen of an external control computer when measuring the current (in picoamperes) of the accelerated beam of 132Xe ions with an energy of 23.5 MeV/nucleon using the 13-channel profilometer.

COMPARISON ACCORDING TO THE SECONDARY EMISSION OF THE PROFILOMETERS WITH A PHOSPHOR AND A FARADEY CUP

The 25-channel profilometers with the phosphor and the Faraday cup were compared in order to evaluate the efficiency of the secondary-emission profilometers on accelerated low-intensity heavy-ion beams. At first, for comparison with the phosphor according to its glow, a beam was formed in the form of a vertical line. The beam intensity decreased until a faint glow was achieved. After this, a 25-channel profilometer was introduced into the beam. The results of this measurement are shown in Fig. 5.

Thus, using the current profilometer, it is possible to roughly (using only 25 points) measure the shape of a low-intensity beam and make a conclusion about the performance of the beam-forming elements (lenses, magnetic correctors, etc.).

Next, a Faraday cup was introduced into the beam, and, based on its readings, the beam intensity was decreased to the minimum measurable value, i.e., to 2 nA. Upon a further decrease in the beam current, the range in which the 25-channel profilometer was operable was determined. According to the estimates, the lower limit on the sensitivity of the 25-channel profilometer is lower by four orders of magnitude relative to the phosphor and the Faraday cup.

A THREE-LAMEL PROBE FOR MEASURING THE BEAM CURRENT INSIDE THE ACCELERATOR

The principle of secondary emission and double shielding was also used to create a three-lamel probe for measuring the beam current inside the accelerator. The necessity to create a high-sensitivity probe resulted from the need for beams with the highest possible energy; this could be achieved only by accelerating ions with the highest possible ion charge from the entire set that could be obtained using a source based on the electron cyclotron resonance (ECR). Unfortunately, the fraction of such ions is very small; therefore, the current of the accelerated beam is low.

In the design of the created probe, the central lamel is located in the median accelerator plane, and the other two are located above and below it. The lamel height is 8 mm. For making measurements, the probe is remotely placed to the final orbit of the internal accelerator beam. The current from the lamels is measured using an II-01 4-channel current amplifier designed to measure currents in the range of ±1 nA. The amplifier is placed in a Eurocard rack. Information is transmitted to a computer. Figure 6 shows the screen images of an external control computer during measurements using the three-lamel current probe of the internal beam of 32S ions with an energy of 51 MeV/nucleon.

The current of the 32S ion beam with an energy of 51 MeV/nucleon, which was measured using the three-lamel probe mounted on the final orbit of the MTs-400 cyclotron. The indications of the ADC_1 – ADC_3 currents correspond to the measurements of the currents from (1) the upper (ADC_1), (2) central (ADC_2) and (3) lower (ADC_3) lamels.

Before starting the measurement, the internal beam was intercepted by a standard probe available at the accelerator, with which the beam current is usually measured. The beam current was reduced to the lower limit of measurements using a standard 1-nA probe. After this, the three-lamel probe was introduced into the beam. The results are presented in Fig. 6, where the time trend of the current measurements is shown. The current that exceeded the measurement limits of the used amplifier (this is the first peak in Fig. 6) was detected at all three lamels. We then began to reduce the current blindly until we reached the range in which the probe stopped going off the scale (the second and third peaks). It can be noted that the current on the central lamel is higher than on the others, and the level of pickups from extraneous sources is negligible. The valley between the second and third peaks corresponds to the moment of the ion-beam interception ECR source. The current amplifier did not have a very wide range during the experiment, which did not allow us to relate the readings of the standard and three-lamel probes. However, we can state with confidence that the three-lamel probe provides an way to measure the currents of the internal ion beam at a level of 0.1 pA.

CONCLUSIONS

Multichannel profilometers based on the principle of measuring the secondary-emission current have been created. The operating range of the profilometers varies from n × 103 to n × 109 ions/(cm2 s). This range is largely overlapped with the operating range of scintillation and semiconductor detectors from a few units to 106 ions/cm2 s, and the current profilometer is used in the region of the overlap to monitor their degradation under exposure the beam.

A comparison of a 25-channel profilometer with a profilometer based on an Al2O3 phosphor and with a Faraday cup was performed. According to the estimates, the lower limit on the sensitivity of the 25-channel profilometer is lower by four orders of magnitude compared to the Faraday cup.

Based on the measurement of the secondary emission, a three-lamel probe was created for measuring the current of the internal accelerator beam with a lower measurement limit of 0.1 pA.

REFERENCES

Revenko, R.V., Vin’e, Zh.-L., Isataev, T., Luk’yanov, S.M., Mendibaev, K., Pansin, L., and Penionzhkevich, Yu.E., Preprint of Joint Institute for Nuclear Research, Dubna, 2017, no. R7-2017-58.

Harasimowicz, J., Welsch, C.P., Cosentino, L., Pappalardo, A., and Finocchiaro, P., Phys. Rev. Spec. Top.–Accel. Beams, 2012, vol. 15, p. 122801. https://doi.org/10.1103/PhysRevSTAB.15.122801

Skuratov, V.A., Anashin, V.S., Chlenov, A.M., Emeliyanov, V.V., Gikal, B.N., Gulbekyan, G.G., Kalagin, I.V., Milovanov, Y.A., Teterev, Yu.G., and Kazacha, V.I., Proc. 12th European Conference on Radiation and Its Effects on Components and Systems (RADECS), Sevilla, 2011, p. 756. https://doi.org/10.1109/RADECS.2011.6131461.

Test Procedures for the Measurement of Single-Event Effects in Semiconductor Devices from Heavy Ion Irradiation, EIA/JEDEC STANDARD, EIA/JESD57, Electronic Industries Association, 1996.

Mitrofanov, A.V., Apel, P.Yu., Blonskaya, I.V., and Orelovich, O.L., Tech. Phys., 2006, vol. 51, no. 9, p. 1229.

http://smartbox.jinr.ru/smartbox6.php?select=2103#ii162.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Goryacheva

Rights and permissions

About this article

Cite this article

Teterev, Y.G., Krylov, A.I., Issatov, A.T. et al. A Multichannel Detector for Monitoring the Degradation of Scintillation and Semiconductor Detectors in Low-Intensity Heavy-Ion Beams. Instrum Exp Tech 63, 334–338 (2020). https://doi.org/10.1134/S0020441220030057

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020441220030057