Abstract—

We have synthesized silica-based sorbents with MCM-41 and MCM-48 pore structures, modified with hydrazide groups based on tret-carboxylic acids of Versatic 10 and Versatic 1519 fractions, and investigated textural and structural properties of the silicas. Conditions for tungsten(VI) sorption from acid solutions by the silicas have been studied in relation to the pH of the medium and grafting density, and conditions have been found for tungsten(VI) and molybdenum(VI) separation from hydrochloric acid solutions using MCM-41 modified silica.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The ability to recover tungsten and molybdenum from poor process solutions is currently a topical issue because the production of most refractory metals in Russia is decreasing. Known methods of separating molybdenum and tungsten in aqueous solutions rely on the fact that compounds of these metals differ in behavior during precipitation, extraction, and ion exchange sorption [1]. One effective method of solution purification is sorption with the use of organic ion exchangers or inorganic sorbents [2]. Separation of tungsten from molybdenum is also a serious problem because in weakly acidic solutions (pH 2–3) containing these metals separation is hindered by the formation of mixed tungsten–molybdenum polyanions [3–5]. Effective separation is only possible via destruction of the polyanions using complexing agents, for example, N',N'-dialkylhydrazides [6, 7].

Chemically modified silicas [8–10] successfully combine advantageous properties of a chemically modified matrix and functional groups effective for isolating acid complexes of rare metals. It is worth noting that the modification of silicas with hydrazides synthesized using Versatic tert-carboxylic acids will allow for microcomponent preconcentration from large volumes of solutions on a relatively small mass of a sorbent in the absence of organic solvents, which is also a great advantage and makes this study topical.

The purpose of this work was to produce functionalized silica sorbents capable of selectively extracting tungsten and molybdenum ions from solutions.

EXPERIMENTAL

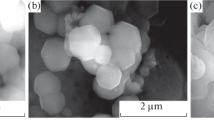

The silica (SiO2) basis of sorbents was prepared by template synthesis under hydrothermal conditions at a holding temperature of 100°C for MCM-41 (I) and 120°C for MCM-48 (II) over a period of two days. The silicon source used was tetraethyl orthosilicate (TEOS), and the structure-forming agent was cetyltrimethylammonium bromide (CTAB). In our syntheses, the starting reagents were used in the following ratios:

TEOS 1 : СTAB 0.2 : NH3 3.5 : H2O 100 for preparing SiO2 with a hexagonal pore structure (I) and

TEOS 1 : СTAB 0.4 : NaOH 0.4 : H2O 100 for preparing silicon dioxide with a cubic bicontinuous pore structure (II).

The surface of the mesoporous silicas was modified via impregnation to give two materials: I-DMH and II-DMH, where DMH stands for an N',N'-dimethylhydrazide based on Versatic CH3R1R2CC(O)ОH tert-carboxylic acids. Here R1 and R2 are alkyl radicals in which the number of carbon atoms is 10 and 1519, respectively [11, 12], as confirmed by IR spectroscopy in the range 150–4000 cm–1 on an IFS-66/S Fourier transform IR spectrometer (Bruker, Germany).

The sorption properties of the synthesized materials were studied as follows: The pH of a solution containing tungsten(VI) ions was adjusted by adding hydrochloric acid of appropriate concentration (in a 100-mL flask). Next, the resultant mixture was mixed with 0.2 g of the modified silica. After 1 h, the precipitate was filtered off and we measured the pH of the aqueous phase. The residual tungsten(VI) content was determined photometrically with a potassium thiocyanate solution [13].

To study conditions for separating tungsten(VI) and molybdenum(VI), standard solutions (1 mL) of these metals, appropriate amounts of hydrochloric acid and distilled water (to bring the volume to 100 mL), and 0.2 g of the modified silica were added to a flask. The mixture was left standing in the flask for 60 min. The precipitate was filtered off, and the residual tungsten(VI) and molybdenum(VI) contents of the filtrate were determined photometrically with potassium thiocyanate and ammonium thiocyanate, respectively.

To study desorption conditions, precipitates containing 1.1 g of tungsten(VI) were mixed with 10 mL of an aqueous solution containing different amounts of ammonia. After 20 min of holding, the percentage of tungsten(VI) in the liquid phase was determined photometrically.

The static sorption capacity for metals (EM, mol/g), the degree of extraction (E, %), distribution coefficients (D, L/g), and the separation factor β were evaluated with an accuracy within 5% using the following formulas:

where C0 (mol/L) is the initial metal concentration in solution, Ceq (mol/L) is the residual equilibrium concentration of the metal in solution, V (L) is the volume of the solution, and m (g) is the weight of the sorbent.

RESULTS AND DISCUSSION

The texture characteristics presented in Table 1 (ASAP 2020 (Micromeritics, USA)) demonstrate that the starting silica composites had the form of mesoporous materials with a rather large specific surface area, on the order of 950 m2/g for the MCM-41 sorbent and 1600 m2/g for MCM-48. The surface modification of the sorbents considerably reduced their specific surface area, but given the high content of functional groups (13–22 mmol/g) [12], capable of forming associates with tungsten ions (incorporation or attachment complexes), in the composition of the sorbents, it is reasonable to expect that the use of these materials as sorbents for the preconcentration, separation, and extraction of tungsten ions from complex mixtures will be effective.

Analysis of the effect of the phase contact time on sorption processes indicates that the maximum W(VI) sorption by the modified mesoporous silica sorbents based on MCM-41 and MCM-48 is reached in an hour.

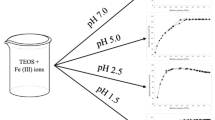

Assessment of the effect of solution pH on tungsten(VI) extraction with the starting silicas MCM-41 and MCM-48 (Fig. 1a) and silicas modified with different grafting densities (Fig. 1b) shows that high degrees of tungsten(VI) extraction (80–100%) can be reached in a wide acidity range: from hydrochloric acid concentrations in the range 3–5 mol/L to pH 3 (E M = 3.5–4.5 mmol/g). The pore shape has little effect on the adsorption capacity of the matrix: the dependences of the degree of extraction on pH for the MCM-41 and MCM-48 sorbents are essentially identical. Increasing the density of functional groups grafted onto the silica surface increases the sorption capacity of the MCM sorbents for tungsten(VI) ions. Given that the specific surface area decreases with increasing grafting density, this attests to chemisorption on the modified MCM surface.

Effects of the structure of the matrix, grafting density, and solution acidity on tungsten extraction with the MCM sorbents: (a) effect of the structure of the sorbent: (1) MCM-41, (2) MCM-48; (b) effect of DMH grafting density on MCM-41 at different SiO2/DMH ratios: (1) 1 : 0.2, (2) 1 : 0.4, (3) 1 : 0.8, (4) 1 : 1 (mI-DMH,II-DMH = 0.2 g; [W(VI)] = 0.01 mol/L; τ = 60 min; volume of the liquid phase, 100 mL).

For tungsten(VI) desorption, we used ammonia solutions. Complete tungsten(VI) desorption with aqueous ammonia solutions is possible for pH ≥ 5, which corresponds to NH3 concentrations of ≥0.1 mol/L.

Using the experimental data obtained while varying the initial tungsten(VI) concentration in the range 0.001–0.5 mol/L, we constructed tungsten(VI) sorption isotherms for MCM-41 in 0.001 M and 3 M hydrochloric acid (Fig. 2).

The isotherms have a Langmuir shape. In connection with this, the experimental data were fitted by a Langmuir isotherm. The characteristics of adsorption equilibria—limiting adsorption ( mol/g) and adsorption capacity equilibrium constant (KL)—were evaluated by linearizing a Langmuir isotherm [14] according to the following equation:

mol/g) and adsorption capacity equilibrium constant (KL)—were evaluated by linearizing a Langmuir isotherm [14] according to the following equation:

where E M (mol/g) is the magnitude of adsorption and Ceq (mol/L) is the equilibrium concentration of the substance in solution.

The constants of the equation for isotherm 1 (Fig. 2) and the correlation coefficient for this equation are presented in Table 2. The correlation coefficients obtained are inconsistent with linear behavior. Therefore, the surface of both the unmodified and modified MCM sorbents is energetically nonuniform.

In connection with this, we analyzed the results in terms of the Freundlich equation, linearizing the data in the form ln E M vs. ln Ceq (Table 2). The larger correlation coefficients obtained in this case attest to adsorption on an energetically nonuniform surface, where the first to be filled during the adsorption process are adsorption centers with the lowest energy, and the process is accompanied by a continuous variation in energy [15].

Both the  evaluated using the Langmuir equation and the KF in the Freundlich equation suggest that the sorbents under study have a high sorption capacity for tungsten ions. The inverse of the exponent in the Freundlich equation, 1/n = 0.142, obtained for adsorption from 0.001 M HCl solutions is much less than unity, which points to a chemical character of the sorption process.

evaluated using the Langmuir equation and the KF in the Freundlich equation suggest that the sorbents under study have a high sorption capacity for tungsten ions. The inverse of the exponent in the Freundlich equation, 1/n = 0.142, obtained for adsorption from 0.001 M HCl solutions is much less than unity, which points to a chemical character of the sorption process.

The results presented in Fig. 2 demonstrate that solution acidity has a significant effect on the adsorption process: the initial portions of the adsorption isotherm obtained in 0.001 M hydrochloric acid are distinguished by a considerable slope, with the limiting coverage rapidly reached, whereas in 3 M hydrochloric acid the surface becomes covered more gradually. This behavior leads us to assume that different adsorption mechanisms are involved: chemisorption in 0.001 M HCl and physisorption in 3 M HCl.

The same is evidenced by the average free energy of adsorption evaluated from Dubinin–Radushkevich plots: ln E M vs. ε2 (where ε = RT ln (1 + 1/Ceq)) (Fig. 3). The adsorption energy was found as

where KD is the slope of the plots of ln E M against ε2.

We obtained 8.32 kJ/mol in 0.001 M HCl and 4.672 kJ/mol in 3 M HCl, which attests to a physical nature of the interaction of tungsten ions with the modified MCM surface in 3 M HCl and chemical interaction in 0.001 M HCl [16].

IR spectroscopy results also suggest that the type of interaction of tungsten(VI) ions with the modified MCM sorbent depends on acidity during the extraction process.

IR spectra of DMH10 show absorption bands of amide groups: stretching mode of free NH groups (3282 cm–1), Amide I (1686 cm–1), and Amide II (1530 cm–1). The spectrum of the complexes of DMH10 with tungsten(VI), isolated at pH 1.2, contains absorption bands of tert-hydrazide salts (wing in the range 2400–2700 cm–1), indicating the formation of a protonated form of the ligand in the composition of the complex. The intensity of the absorption band of NH decreases and Amide I shifts to longer wavelengths. In addition, absorption bands emerge in the range 750–900 cm–1, due to tungsten(VI) oxide [17]. In more acidic media, at hydrochloric acid concentrations of 0.5 and 3 mol/L, the spectrum shows bands of the starting hydrazide, silicon oxide, and tungsten oxides, suggesting that, under such conditions, physisorption, rather than complexation, occurs in the system.

If both tungsten and molybdenum are present in solution, they have a strong mutual effect on sorption results as a consequence of the formation of \({\text{M}}{{{\text{o}}}_{{n - x}}}{{{\text{W}}}_{x}}{\text{O}}_{{3n + a}}^{{2a - }}\) heteropolyanions. Thus, the conclusions drawn from the data on sorption from individual solutions are supported by those on sorption from solutions containing a mixture of Mo(VI) and W(VI) ions. We examined the feasibility of separating Mo(VI) and W(VI) ions from hydrochloric acid solutions using MCM-41-based modified sorbents (Table 3). The results demonstrate that, in the case of acid solutions, W(VI) and Mo(VI) are extracted together. The best separation is possible at a hydrochloric acid concentration of 3 mol/L and to pH 1.5.

CONCLUSIONS

Tungsten(VI) can be extracted from hydrochloric acid solutions by silicas with MCM-41 and MCM-48 pore structures, modified with N',N'-dimethylhydrazide groups of branched higher carboxylic acids based on Versatic 10 and Versatic 1519 fractions. In the range from pH 0.5 to an HCl concentration of 3 mol/L, W(VI) extraction with I-DMH (at SiO2 : DMH ratios of 1 : 0.8 and 1 : 1) is quantitative. In the case of the modified sorbents, with increasing pH physisorption gives way to chemisorption, which is due to the ability of groups grafted onto silica to form complexes with tungsten(VI) ions and makes it possible to utilize the sorbents, even though they have a smaller specific surface area than does the parent matrix. Tungsten(VI) and molybdenum(VI) sorption at a hydrochloric acid concentration from 3 mol/L and to pH 1.5 suggests that these elements can be extracted together and separated using a I-DMH MCM-41-based sorbent.

REFERENCES

Fofanova, A.A., Troshkina, I.D., and Abdrakhmanov, T.G., RF Patent 2 505 612, 2014.

Blokhin, A.A., RF Patent 2 183 226, 2002.

Vol’dman, G.M. and Mironova, E.A., Composition of compounds resulting from the extraction of peroxomolybdates and peroxotungstates with salts of quaternary ammonium bases, Zh. Neorg. Khim., 1990, vol. 35, no. 4, pp. 888–892.

Vol’dman, G.M. and Zelikman, A.N., Extraction processes for tungsten recovery and molybdenum–tungsten separation, Zh. Neorg. Khim., 1993, vol. 38, no. 7, pp. 1234–1245.

Medkov, M.A., Smol’kov, A.A., Chernyshov, B.N., et al., Tungsten extraction with long-chain aliphatic amines from fluoride solutions, Zh. Neorg. Khim., 1990, vol. 35, no. 9, pp. 2421–2424.

Batueva, T.D., Tuktareva, T.A., Baigacheva, E.V., and Radushev, A.V., RF Patent 2 405 049, 2010.

Batueva, T.D., Pashkina, D.A., and Temerev, S.V., Tungsten (VI) and molybdenum(VI) extraction with hydrazides (N',N'-dimethylhydrazides) of Versatic tret-carboxylic acids from acid solutions and their separation, Izv. Altaisk. Gos. Univ., 2014, no. 3 (1), pp. 166–172. https://doi.org/10.14258/isvasu(2014)3.1-30

Perez-Quintanilla, D., Sanchez, A., Hierro, I., et al., Preparation, characterization, and Zn2+ adsorption behavior of chemically modified MCM-41 with 5-mercapto-1-methyltetrazole, J. Colloid Interface Sci., 2007, vol. 313, pp. 551–562. https://doi.org/10.1016/j.jcis.2007.04.063

Northcott, K.A., Miyakawa, K., Oshima, S., Komatsu, Y., Perera, J.M., and Stevens, G.W., The adsorption of divalent metal cations on mesoporous silicate MCM-41, Chem. Eng. J., 2010, vol. 157, pp. 25–28. https://doi.org/10.1016/j.cej.2009.10.038

Lam, K.F., Chen, X.Q., Yeung, K.L., and McKay, G., Anion effect on Cu2+ on NH2–MCM-41, Ind. Eng. Chem. Res., 2008, vol. 47, pp. 9376–9383. http://pubs.acs.org/doi/abs/10.1021/ie701748b

Radushev, A.V., Batueva, T.D., and Kataev, A.V., Versatic functional tert-carboxylic acids as metal extractive agents, Separation Sci. Technol., 2015, vol. 50, no. 4, pp. 512–519. https://doi.org/10.1080/01496395.2014.968258

Batueva, T.D., Kondrashova, N.B., Kuz’micheva, N.D., et al., Physicochemical properties of mesoporous silicas modified with hydrazide and amide functional groups, Russ. J. Appl. Chem., 2017, vol. 90, no. 11, pp. 1437–1443.

Busev, A.I., Tiptsova, V.G., and Ivanov, V.M., Prakticheskoe rukovodstvo po analiticheskoi khimii redkikh elementov (Practical Course in Analytical Chemistry of Rare Elements), Moscow: Khimiya, 1966, pp. 252–253.

Frolov, Yu.G., Kurs kolloidnoi khimii. Poverkhnostnye yavleniya i dispersnye sistemy (Course in Colloid Chemistry: Surface Phenomena and Dispersed Systems), Moscow: OOO TID Al’yans, 2004.

Adamczuk, A., Equilibrium, thermodynamic and kinetic studies on removal of chromium, copper, zinc and arsenic from aqueous solutions onto fly ash coated by chitosan, Chem. Eng. J., 2015, vol. 274, pp. 200–212. https://doi.org/10.1016/j.cej.2015.03.088

Nikiforova, T.E., Kozlov, V.A., Rodionova, M.V., and Modina, E.A., Sorption of zinc ions on materials containing cellulose and protein constituents, Izv. Vyssh. Uchebn. Zaved., Khim. Khim. Tekhnol., 2009, vol. 52, no. 3, pp. 27–31.

Busev, A.I., Ivanov, V.M., and Sokolova, T.A., Analiticheskaya khimiya vol’frama (Analytical Chemistry of Tungsten), Moscow: Nauka, 1976.

Funding

This work was supported by the Russian Federation Ministry of Science and Higher Education (state research target no. AAAA-18-118032790022-7).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Batueva, T.D., Shcherban’, M.G. & Kondrashova, N.B. Mesoporous Silica Materials and Their Sorption Capacity for Tungsten(VI) and Molybdenum(VI) Ions. Inorg Mater 55, 1146–1150 (2019). https://doi.org/10.1134/S0020168519110013

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168519110013