Abstract

The frontier of the electron probe X-ray spectral method in the determination of trace metal quantities on a silicon substrate is studied. The experimental data are acquired for ultrathin chromium films on a silicon substrate. It is shown that the signal-to-noise ratio significantly increases at a noticeable sample inclination (80°), which allows one to determine an extremely low (available by this approach) chromium content. The calibration curve for the inclined sample position is plotted using the Monte Carlo method. The surface concentration of chromium atoms (2.2 ± 0.4) × 1014 cm–2 and the chromium detection limit (5 × 1013 cm–2) are measured under the given experimental conditions. For the electron probe X-ray microanalysis of bulk samples, it is a record value. The equivalent weight of chromium at the aforementioned surface concentration is approximately 4 × 10–18 g. The proposed technique requires no changes in the design of the device to be applied.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

The need for diagnostics of thin metal films on substrates is due to their application as structural elements in different nanotechnology devices. In particular, ultrathin chromium films serve as sublayers in the deposition of other metals. The film becomes an islet with decrease in its thickness. In this connection, it is expedient to use the surface concentration instead the effective thickness when chromium is deposited onto the surface at ultralow amounts for the further characterization of the coating.

The ultralow amounts of metals atop the bulk substrates are determined through various methods, such as angle-resolved X-ray photoelectron spectroscopy [1], electron Auger spectroscopy [2], secondary ion mass spectrometry [3], and Rutherford backscattering spectroscopy [4]. All the techniques possess limits of spatial resolution [1, 4] and detected concentration ranges [2, 3]. The latter most frequently deals with low intensity of the used informative signal.

In order to determine the trace amounts of chromium on the silicon substrates, the use of electron probe X-ray spectral analysis seems to be promising. The method aims at measuring the intensity of the electron-beam excited characteristic X-ray radiation (CXRR) of the material applied onto the substrate. The experimental implementation of the technique is quite simple, because most modern scanning electron microscopies are equipped with energy dispersion consoles for the recording of X-ray radiation. The abilities of the state-of-the-art energy dispersive X-ray spectrometers allow for the acquisition of the radiation intensity with high accuracy at achieving a counting error below 0.1% at high loading of the spectrometer. The low-intensity CXRR signals can therefore be collected against the background of the bremmstrahlung.

The X-ray spectral method was repeatedly used for studying the coatings with a surface concentration of metals above 1.6 × 1016–2 × 1017 cm–2 on bulk substrates [5–10]. The lower bound of range of thickness measurements is due to of the fact that the CXRR intensity of the coating material is insufficient for reliable signal recording in the conventional geometry of the experiment when the substrate with coating is oriented perpendicularly to the electron probe, and the direction to the detector makes an angle of 30°–40° with the plane of the sample. The change in the geometry of the experiment, e.g., the recording of the X-ray radiation at the sliding angle relative to the sample plane [11], leads to the effect caused by the fact that the CXRR signal comes only from the surface area. Nevertheless, the implementation of this configuration necessitates the device modernization, and it is also difficult to establish the calibration curve as the dependence of the recording CXRR intensity versus the coating material concentration.

A scheme with the angular incidence of the electron probe at the fixed angular position of the detector seems to be more preferable. As mentioned earlier [12–14], an increase in the incidence angle of the electron probe on a film–substrate system (measured from the normal to the sample surface at the incidence point of the electron probe) causes a substantial gain in CXRR intensity of the film because of an increase in the mean free path of the electrons in the substrate material.

The present work aims at studying the frontier of the X-ray spectral characteristics in the detection of trace amounts of metal on a substrate at the inclined incidence of the electron probe by the example of a chromium layer on a single-crystal silicon substrate.

The CXRR Kα1,2-line intensity of chromium (5.946 keV) as a function of its surface concentration was calculated using a specially developed static modeling code that allows one to describe the electron interaction in a film–substrate surface in the context of the Monte Carlo model [15] in the approximation of continuous energy losses. The chosen algorithm admitted the inclined position of a sample, where the inclination was toward the X-ray radiation detector. The angle between the direction to the detector and the horizontal plane was 35°. The Rutherford shielded section for elastic scattering [16] in the angularly differential form was used. In order to calculate the CXRR intensity, the ionization cross section was found from the Bethe formula [17].

The experimental studies were conducted using a JSM 6460 LV scanning electron microscope with an INCAx-sight energy dispersion console for the recording of X-ray spectra. The probe electron energy was 15 keV. Samples were silicon slabs with a size of 10 × 10 mm2 whose surface was covered with a chromium coating via the magnetron sputtering on a Sample Preparation System Q150T S/E/ES setup. The weight of the sputtered film was controlled by a sensor with a quartz resonator embedded inside the chamber. A sensor for a set sample position was aligned as follows. A 200-nm-thick chromium film (the thickness is estimated from the sensor data) was sprayed onto a 10-μm-thick aluminum foil through a mask with a diameter of 35 mm. In order to determine the weight of the sputtered chromium film, the foil was weighed on a Sartorius CPA 2P (Germany) balance before and after spraying. The film inhomogeneity within the spraying area was highlighted by the CXRR intensity of chromium. Taking into consideration the obtained chromium film spatial distribution, the sensor was realigned in the units of the surface chromium concentration. The subsequent experiments implied the linear dependence of the sensor data on the surface chromium concentration. The relative calibration error was less than 2%.

In order to verify the correctness of the Monte Carlo calculated data, a series of samples with different surface chromium concentrations on silicon substrates was prepared. During the experiments, the CXRR intensity of the Kα1,2 line I of chromium was recorded and compared with Iet of the bulk sample of chromium measured under the same conditions. The intensity ratio of both samples was then determined as k = I/Iet. The k parameters evaluated both experimentally and theoretically (using the Monte Carlo approach) are listed in Table 1. As is seen, the divergence between experiment and theory is less than 6%.

The CXRR intensity of the Kα1,2 line of chromium as a function of θ angle was determined by positioning a sample on exchangeable holders providing a suitable angular position. The experimental (for the surface chromium concentration of 9.1 × 1015 cm–2) and Monte Carlo calculated angular dependences are plotted in Fig. 1, where the intensities of the CXRR Kα1,2 lines of chromium are normalized with respect to the appropriate intensities at zero inclination. Figure 1 also displays the calculated angular dependence of the normalized intensity for the surface chromium concentration of 1.7 × 1017 cm–2.

Normalized CXRR intensity of Kα1,2 line of chromium as a function of inclination angle of sample: the solid line refers to the calculated surface chromium concentration of 9.1 × 1015 cm–2, the dotted line is the calculated surface chromium concentration of 1.7 × 1017 cm–2, and the points are the measured chromium concentration of 9.1 × 1015 cm–2.

The calibration plot, i.e., the dependence of the k ratio on the effective film thickness, is obtained using the developed calculation algorithm for the angle of sample inclination θ = 80° (Fig. 2). The calibration error is less than 10%.

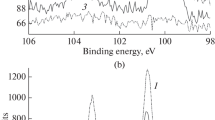

In order to show the ability to determine the trace amount of chromium on a silicon slab surface, the latter was covered with a chromium layer via the magnetron sputtering at the minimum rate and time of sputtering. No CXRR lines of chromium were observed for a sample horizontally oriented at the electron energy of 15 keV and the maximum loading of the spectrometer (the dead time was 20%). A CXRR peak of the Kα1,2 line of chromium arose for a sample inclined at 80° at the electron beam energy of 15 keV, the probe current of 10 nm corresponding to the minimum loading of the spectrometer, the acquisition (“life”) time of 2000 s, and the dead time of less than 20% (see Fig. 3). The CSRR intensity of the Kα1,2 line of chromium was evaluated through the processing of the X-ray spectrum in Fig. 3 by summing the number of pulses of a spectrum (IS) over the energy range of 5.355–5.465 keV, which is about 2/3 of the Kα1,2-line width at half-maximum. The energy range boundaries are shown in Fig. 3 with the dotted lines. The braking background intensity was found by summing the number of pulses in the energy range of the same width (110 eV) symmetrically to the left (Il) and right (Ir) of the Kα1,2 peak. The following values were obtained: Is = 50 614 pulses, Il = 51 661 pulses, Ir = 44 030 pulses, and the Kα-line intensity of chromium was ICr = Is – (Il + Ir)/2 = 2769 pulses.

The k ratio was determined by measuring the Kα1,2-peak intensity of chromium versus the bulk reference sample oriented vertically, as well as the background intensity over the same energy ranges. The main error components in the determination of the k ratio are the statistical error in measuring the Kα1,2-peak intensity of chromium for a sample and the calibration plotting error. For a sample represented by the spectrum in Fig. 3, k= (3.7 ± 0.7) × 10–4 at the confidence probability P = 0.95, which is equivalent to the surface concentration of chromium atoms Ns = (2.2 ± 0.5) × 1014 cm–2 in line with the calculated calibration curve (Fig. 2).

The correctness of the determination of the surface chromium concentration was verified by comparing the found value with that evaluated via the total external reflection X-ray fluorescence analysis on a TREX 610 S (Philips) spectrometer, which was (2.8 ± 0.4) × 1014 cm–2. The differences between data provided by various methods were insignificant.

The detection limit under the same experimental scheme was estimated in accordance with the 3σ criterion, where σ is the mean-square background deviation in the range of the Kα1,2 line of chromium. Assuming that the background obeys the Poisson statistics, one gets Nsmin ≈ 5 × 1013 cm–2. With consideration of the evaluated area of the analytical signal generation, this detection limit of the effective thickness measurement corresponds to the CXRR signal recorded from about 5 × 104 chromium atoms, and the equivalent chromium weight is around 4 × 10–18 g. This value is a record for the electron probe microanalysis of bulk samples.

REFERENCES

Opila, R.L. and Eng, J., Jr., Thin films and interfaces in microelectronics: composition and chemistry as function of depth, Prog. Surf. Sci., 2002, vol. 69, no. 4, pp. 125–163.

Podgornyi, D.A., Smetyukhova, T.N., and Irzhak, A.V., Determination of the thickness of ultrathin films by using Auger electron spectroscopy, Zavod. Lab., Diagn. Mater., 2012, vol. 78, no. 8, pp. 33–36.

Senoner, M. and Unger, W.E.S., SIMS imaging of the nanoworld: applications in science and technology, J. Anal. At. Spectrom., 2012, vol. 27, no. 7, pp. 1050–1068.

Chu, W.K. and Liu, J.R., Rutherford backscattering spectrometry: reminiscences and progresses, Mater. Chem. Phys., 1996, vol. 46, nos. 2–3, pp. 183–188.

Campos, C.S., et al., Thickness determination of ultra-thin films on Si substrates by EPMA, Microchim. Acta, 2004, vol. 145, no. 1–4, pp. 13–17.

Procop, M. et al., Electron probe microanalysis (EPMA) measurement of thin-film thickness in the nanometre range, Anal. Bioanal. Chem., 2002, vol. 374, no. 4, pp. 631–634.

Llovet, X. and Merlet, C. Electron probe microanalysis of thin films and multilayers using the computer program XFILM, Microsc. Microanal., 2010, vol. 16, no. 1, pp. 21–32.

Bakaleinikov, L.A. et al., Depth profiling of semiconductor structures by x-ray microanalysis using the electron probe energy variation technique, Semiconductors, 2009, vol. 43, no. 4, pp. 544–549.

Popova, T.B. et al., Electron probe microanalysis of heterostructures with nanolayers, Semiconductors, 2011, vol. 45, no. 2, pp. 260–264.

Gavrilenko, V.P. et al., Electron probe measurements of oxide film thickness on silicon surfaces, Meas. Tech., 2015, vol. 58, no. 9, pp. 953–957.

Tsuji, K., Grazing-exit electron probe x-ray microanalysis (GE-EPMA): fundamental and applications, Spectrochim. Acta, Part B, 2005, vol. 60, no. 11, pp. 1381–1391.

Wendt, M., Krajewski, T., and Bimberg, R., Detection of thin surface films by electron beam microanalysis. A comparison between wavelength-dispersive and energy-dispersive microprobes, Phys. Status Solidi A, 1976, vol. 36, no. 1, pp. 253–261.

Pouchou, J.L., Pichoir, F., and Boivin, D., Further improvements in quantitation procedures for X-ray microanalysis, Proc. XII Int. Symp. on X-Ray Optics and Microanalysis, Cracow: Acad. Min. Metall., 1990, pp. 52–59.

Wendt, M., Electron probe microanalysis of thin films at variable angle of incidence, Fresenius’ J. Anal. Chem., 1991, vol. 340, pp. 193–196.

Joy, D.C., Monte Carlo Modeling for Electron Microscopy and Microanalysis, New York: Oxford Univ. Press, 1995.

Reimer, L. and Krefting, E.R., The effect of scattering models on the result of Monte-Carlo calculations, Proc. Workshop “Use of Monte Carlo Calculations in Electron Probe Microanalysis and Scanning Electron Microscopy,” Gaithersburg, Maryland, October 1–3, 1975, Washington: US Govt. Print. Off., 1976, no. 460, pp. 45–60.

Llovet, X. et al., Cross sections for inner-shell ionization by electron impact, J. Phys. Chem. Ref. Data, 2014, vol. 43, no. 1, art. ID 013102.

ACKNOWLEDGMENTS

This work was supported by the Russian Science Foundation (agreement no. 14-19-01652 from June 27, 2014).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by O. Maslova

Rights and permissions

About this article

Cite this article

Darznek, S.A., Mityukhlyaev, V.B., Todua, P.A. et al. Electron Probe X-Ray Analysis of Nanofilms at Off-Normal Incidence of the Electron Beam. Inorg Mater 54, 1417–1420 (2018). https://doi.org/10.1134/S0020168518140066

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168518140066